Patents

Literature

41results about How to "Reduce production burden" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

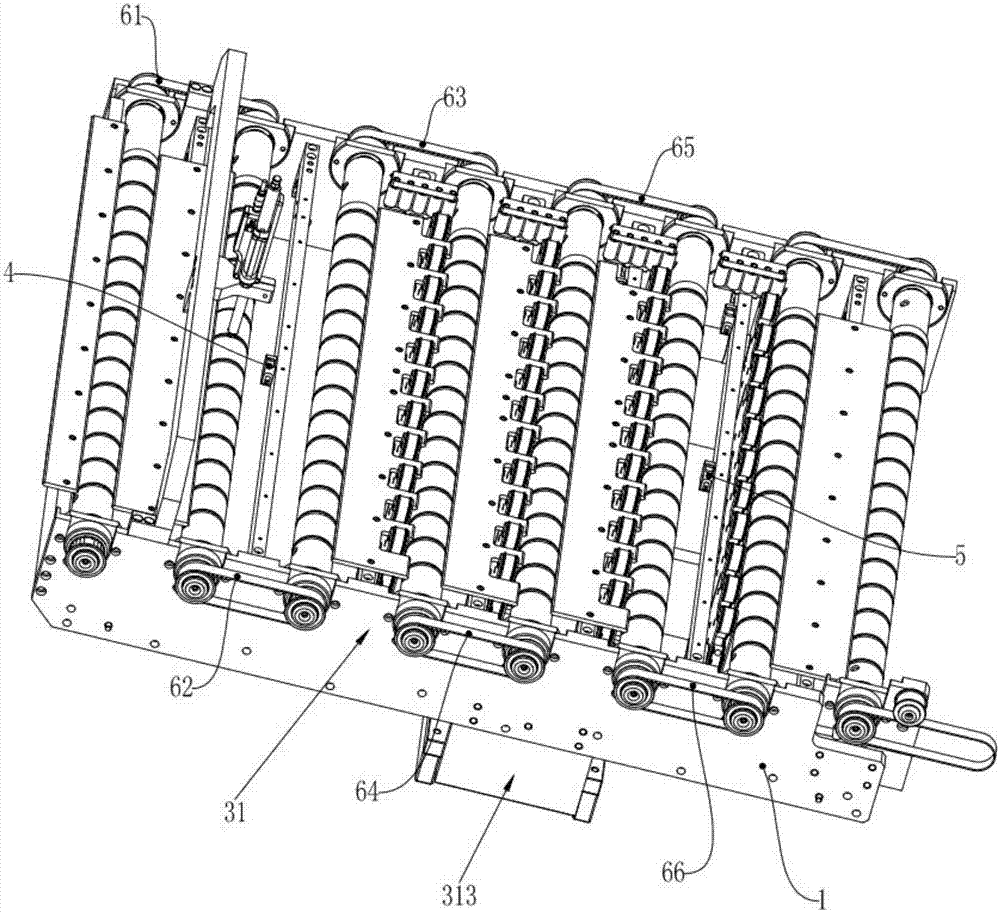

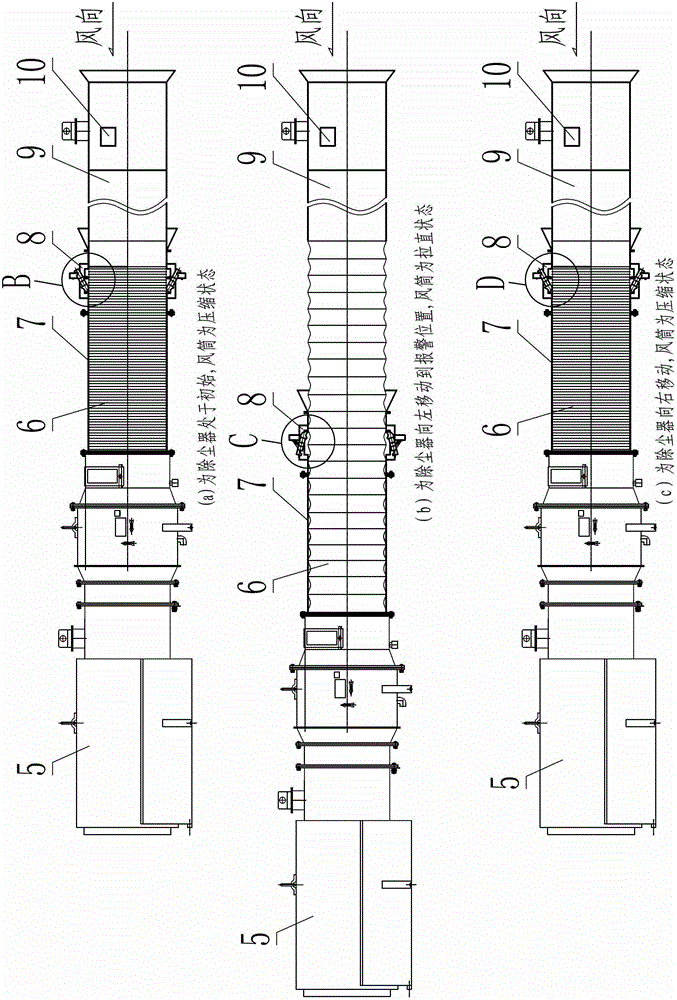

Highly automatic plate-overturning and plate-picking production line for producing large-size decorative plates

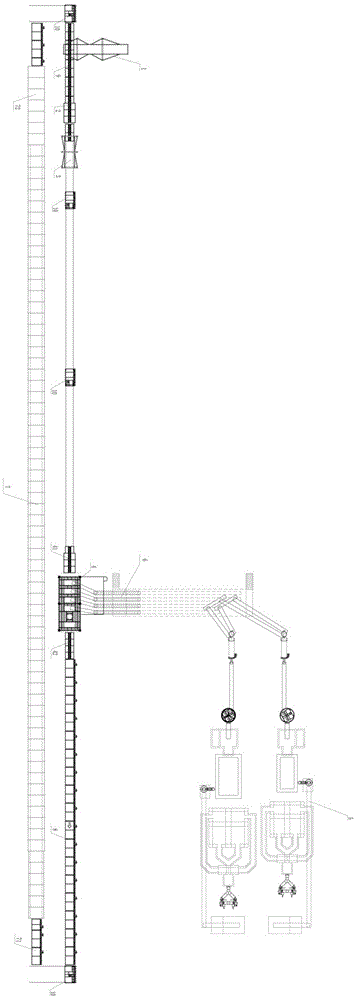

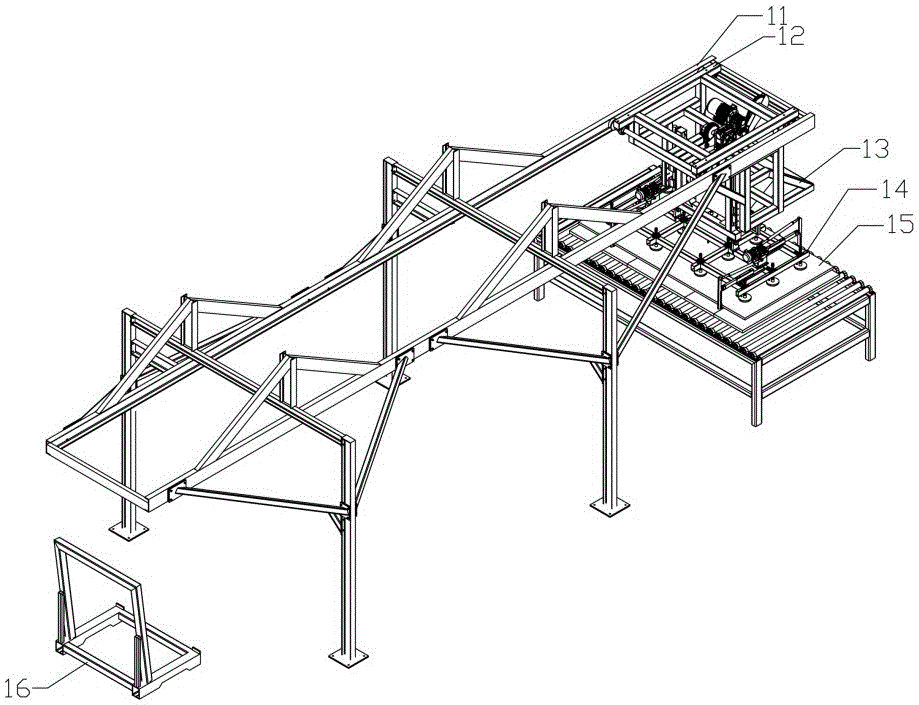

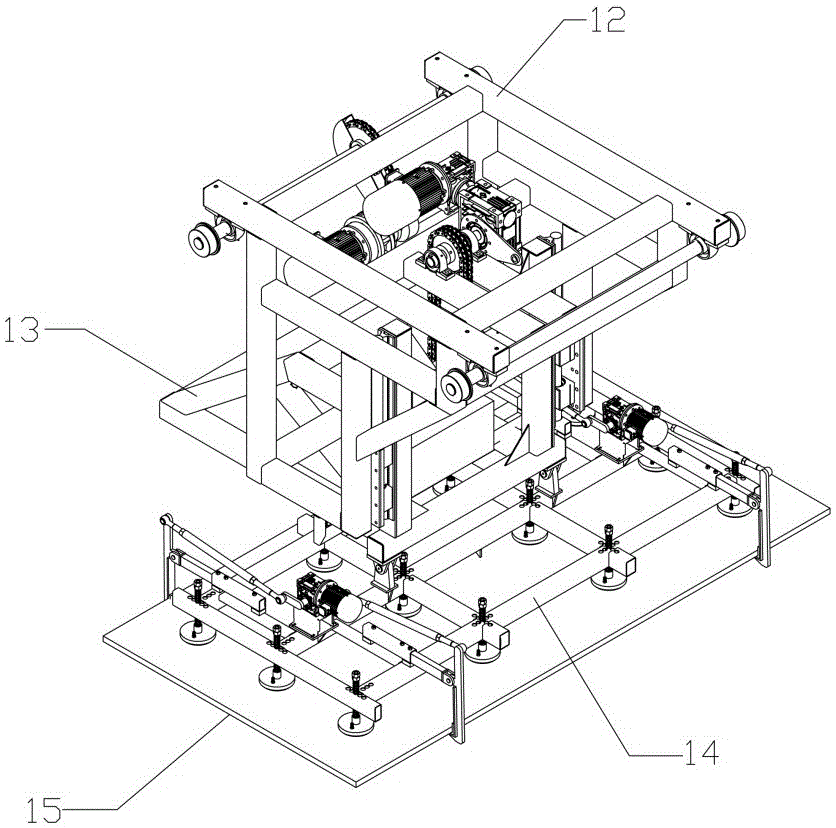

The invention discloses a highly automatic plate-overturning and plate-picking production line for producing large-size decorative plates. The highly automatic plate-overturning and plate-picking production line comprises a material mixing machine set, a material distribution mechanism, a kiln, a kiln tail fixed roller table, a kiln furniture, a plate-picking mechanism, a deviation-correcting mechanism and an overturning mechanism, wherein a belt conveyor is disposed between the material mixing unit and the material distribution mechanism; an inlet and an outlet of a material distribution machine position of the material distribution mechanism are respectively equipped with a deviation-correcting roller table and a receiving roller table; the other end of the receiving roller table is connected with a conveying roller table in a matching manner; a kiln inlet and a kiln outlet are respectively equipped with a kiln-incoming roller table and a kiln-outgoing roller table; shuttling roller tables are disposed between the kiln-incoming roller table and the conveying roller table and are used for conveying in a matching manner; the kiln-outgoing roller table is equipped with the shuttling roller tables and the kiln tail fixed roller table which are used for conveying in a matching manner; the kiln tail fixed roller table is sequentially matched with the plate-picking mechanism and the deviation-correcting mechanism for conveying along the movement direction of rollers; and the overturning mechanism and the shuttling roller tables are also disposed between the kiln tail fixed roller table and the deviation-correcting roller table.

Owner:佛山市创瓷窑炉有限公司

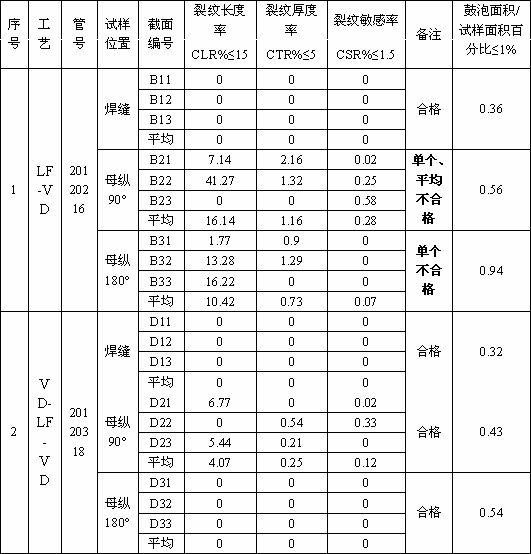

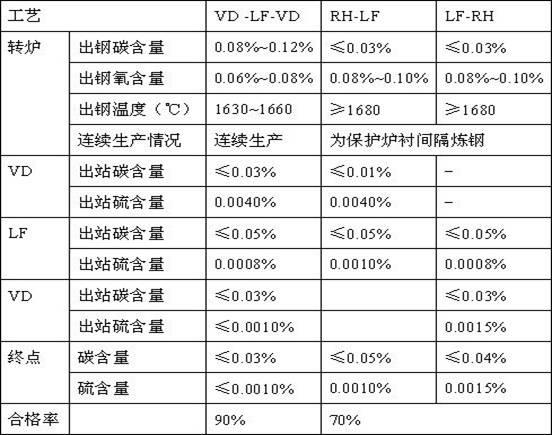

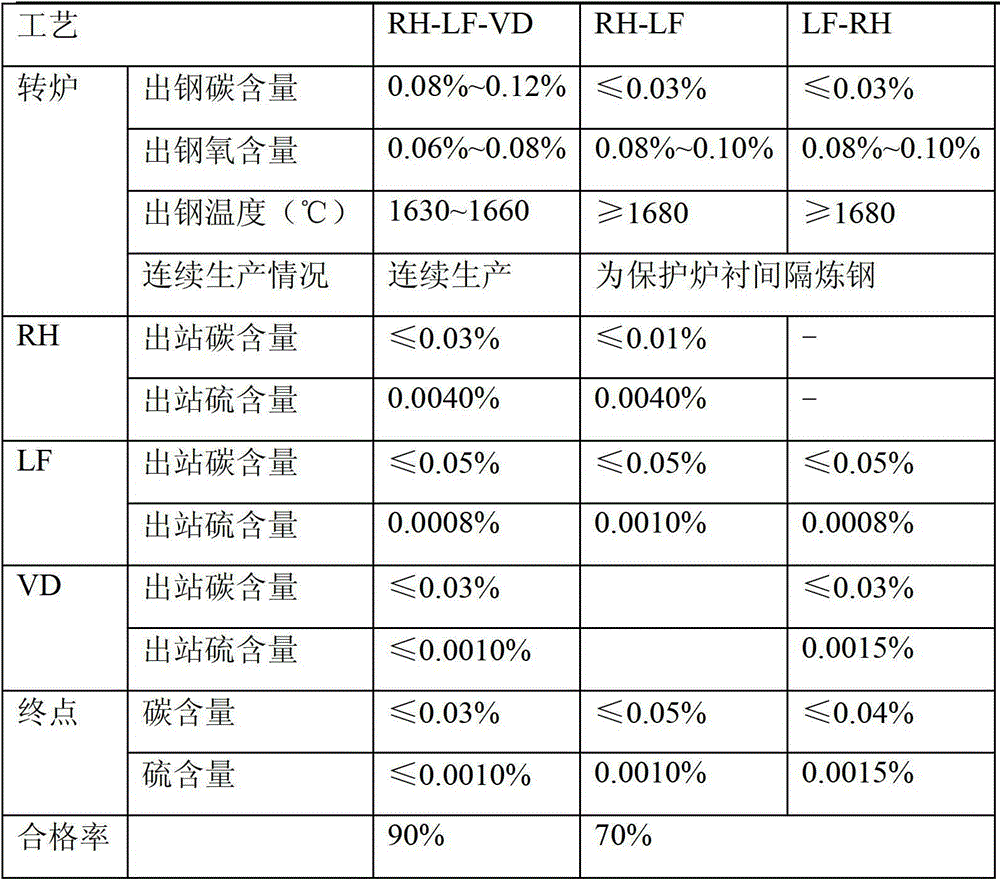

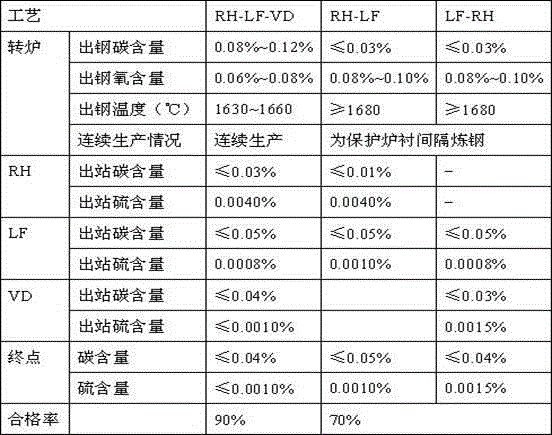

Technique for refined production of antiacid pipeline steel through VD-LF-VD

InactiveCN102676744AReduce production burdenReduce oxidationManufacturing convertersProcess efficiency improvementDecarburizationSmelting

The invention relates to a technique for refined production of antiacid pipeline steel through VD-LF-VD. According to the technique, elements of molten steel are controlled by utilizing a converter crude refining and RH-LF-RH refining technique to produce low-carbon low-sulfur antiacid (HIC-resisting and SCC-resisting) pipeline steel. The technique comprises the following specific flow of: molten steel pre-desulfurization, converter smelting, first VD vacuum refining, LF refining desulfurization, second VD vacuum refining and continuous casting. By utilizing the second VD vacuum refining technique, the technique for the refined production of the antiacid pipeline steel through the VD-LF-VD, disclosed by the invention, has the advantages of reducing decarburization load of the converter and oxidability of the molten steel, eliminating negative influence of carbon increase in an LF refining process, reducing the use of a strong deoxidizer, stabilizing production, ensuring that the elements of the molten steel are stably controlled within production targets, and meeting requirements of the antiacid pipeline steel on low carbon, low sulfur and high-purity element control. Through finished-product steel produced by the technique disclosed by the invention, the content of carbon can be stably controlled to 0.03-0.04%, and the content of sulfur can be stably controlled to be smaller than or equal to 0.0010%.

Owner:UNIV OF SCI & TECH BEIJING

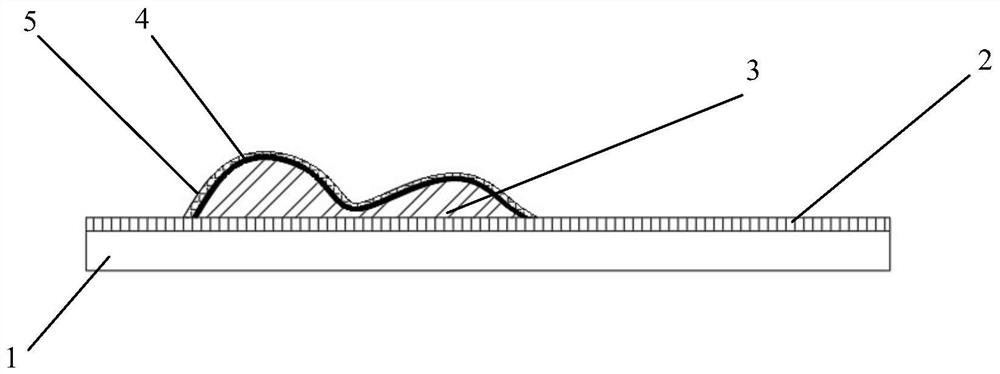

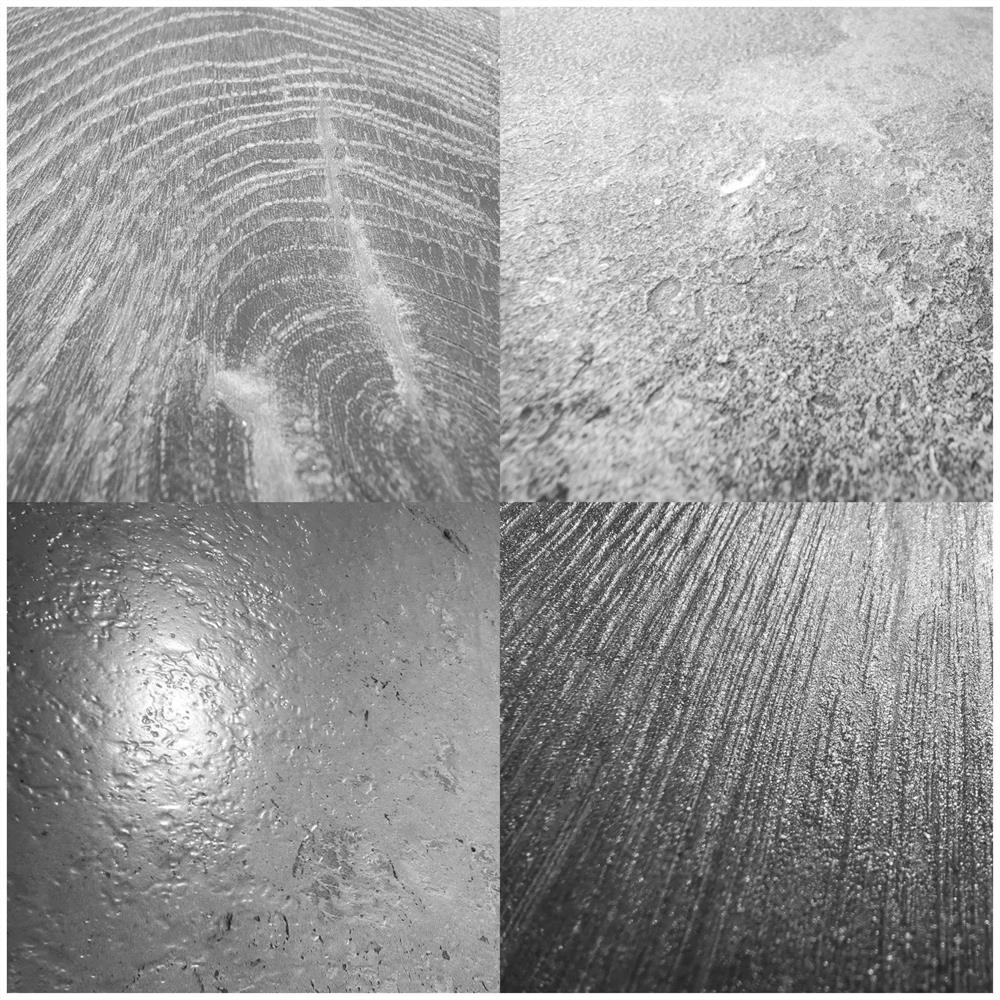

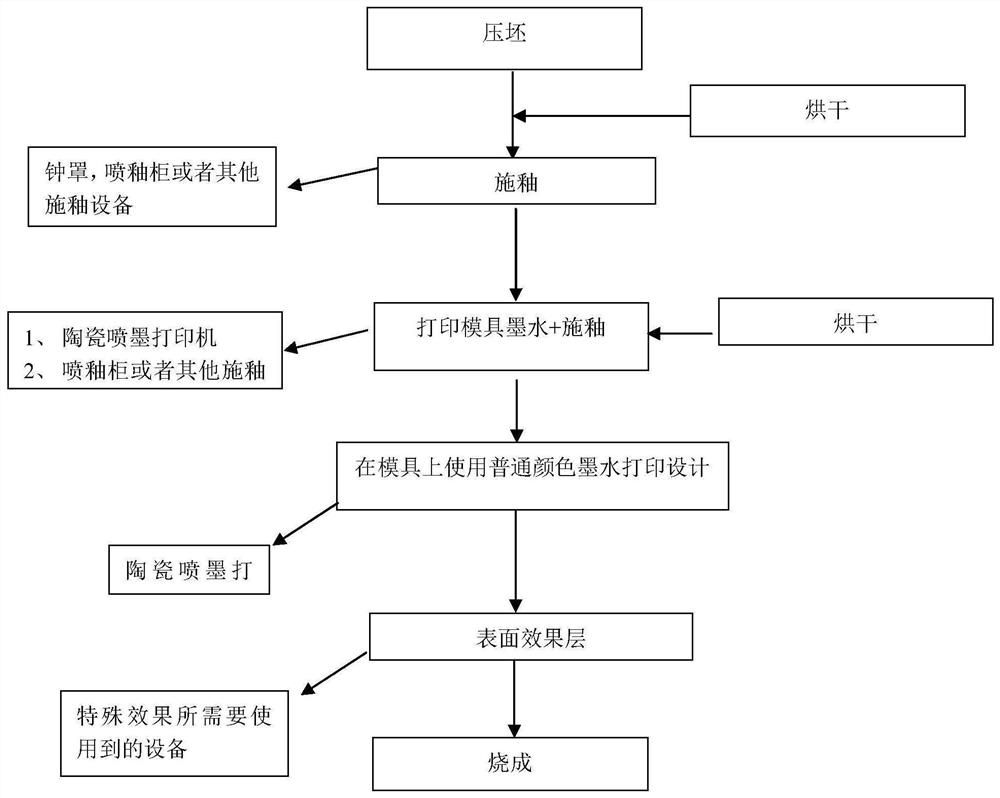

Ceramic tile structure with concave-convex textures and manufacturing process thereof

ActiveCN112374914AImprove clarityImprove realismInksCeramic materials productionGlazeComputer printing

The invention discloses a ceramic tile structure with concave-convex textures and a manufacturing process thereof. The manufacturing process is characterized by comprising the following steps: (1) manufacturing a ceramic tile green body, drying, and cooling to the room temperature; (2) glazing the ceramic tile green body through glazing equipment; (3) spraying mold ink on the surface of the ceramic tile green body obtained in the step (2) through a ceramic ink-jet printer, matching the path of the mold ink with a pre-designed pattern, glazing again along the position of the mold ink, baking, and cooling; (4) coloring the surface of the brick body obtained in the step (3) by using the ceramic ink-jet printer, wherein the coloring ink layer covers the second glaze layer; and (5) firing in akiln; wherein the mold ink in the step (3) comprises the following components: an ester solvent, fatty acid methyl ester, a ceramic mixture, a hydroprocessing medium fraction, a polymer dispersant andaluminosilicate. Convex lines are formed by spraying the mold ink, the concave-convex stereoscopic impression of the surface of the ceramic tile is achieved, the sense of reality is better, the construction is convenient, the efficiency is high, and the cost is low.

Owner:陶丽西(苏州)陶瓷釉色料有限公司

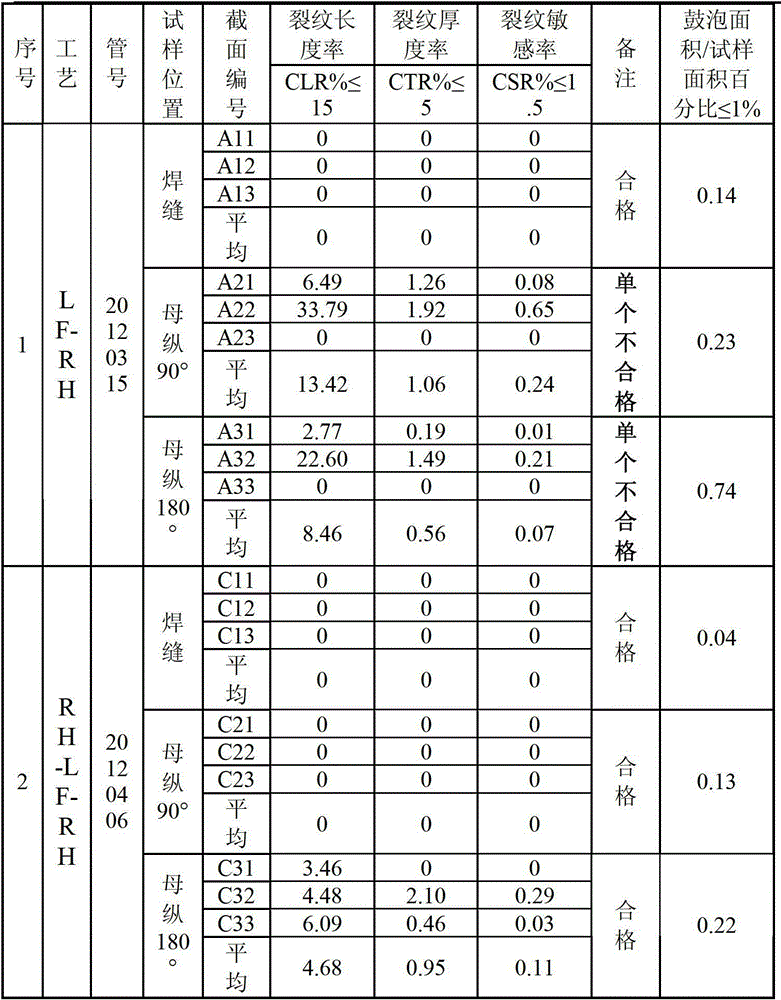

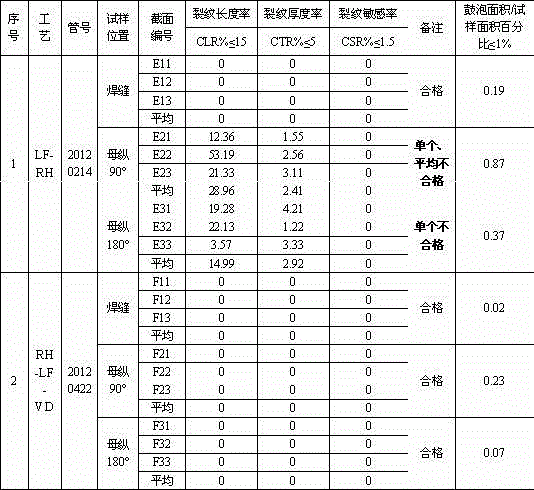

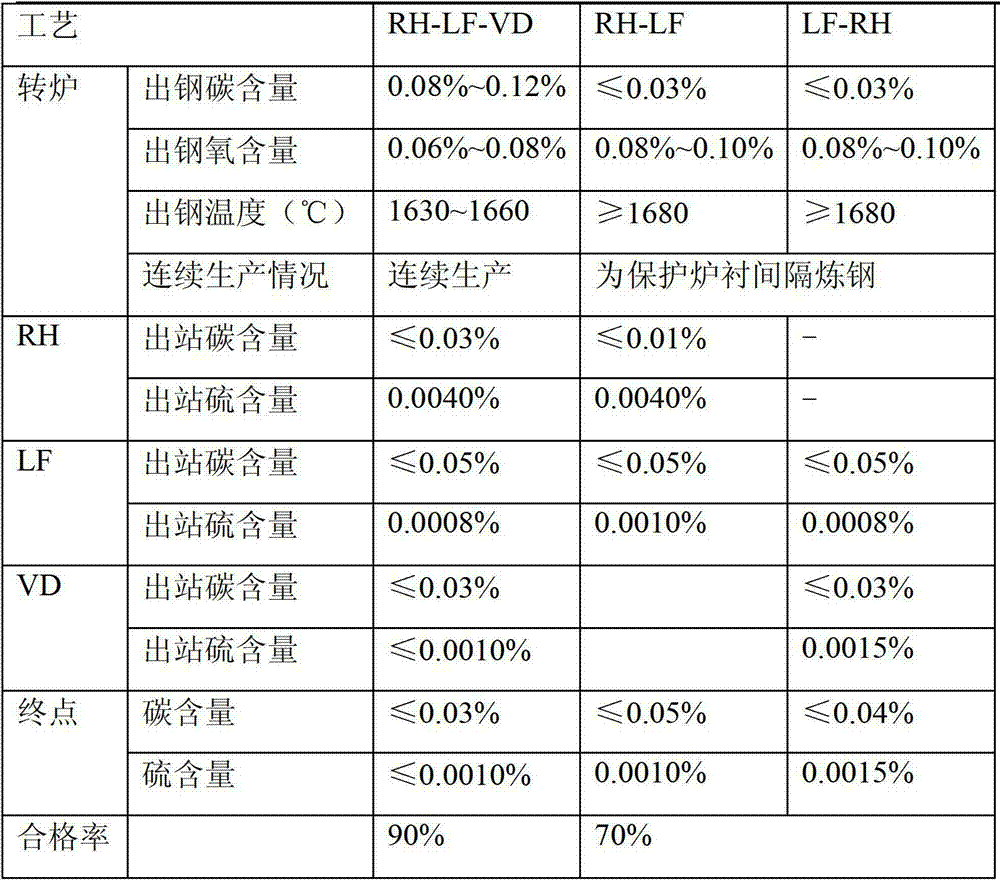

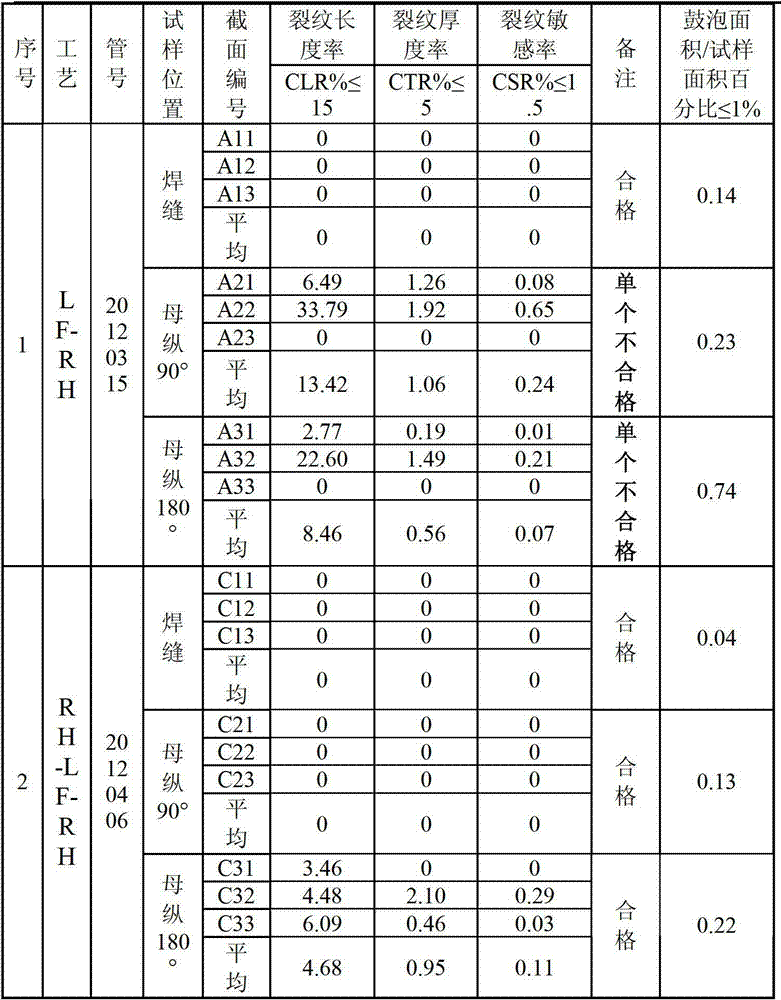

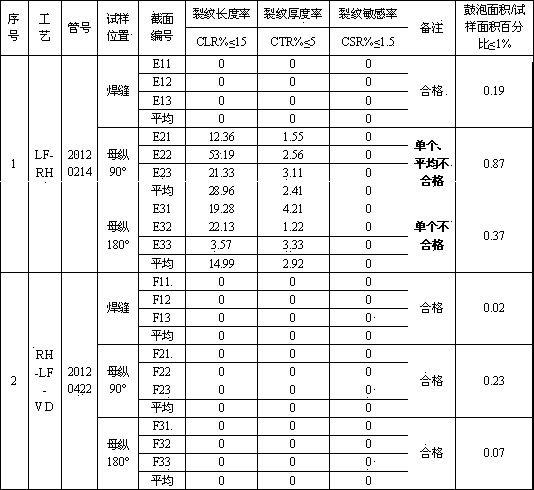

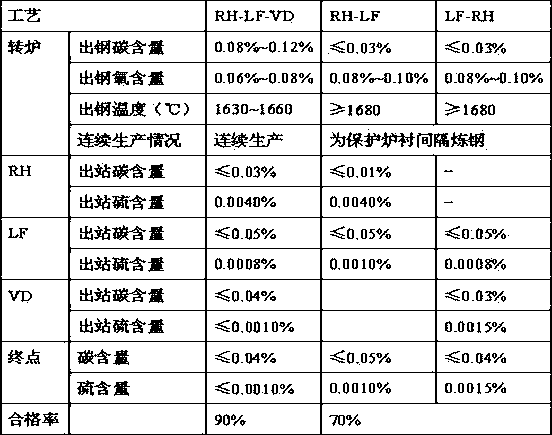

Process for producing anti-acid pipeline steel by Ruhrstahl Heraecus (RH)-ladle furnace (LF)-RH refining

InactiveCN102719614AReduce production burdenReduce non-metallic inclusion contentManufacturing convertersHydrogenStress corrosion cracking

The invention discloses a process for producing an anti-acid pipeline steel by Ruhrstahl Heraecus (RH)-ladle furnace (LF)-RH refining. In the process, the composition of molten steel is controlled by converter smelting and RH-LF-RH refining process, so as to produce a low-carbon low-sulfur anti-acid (hydrogen-induced cracking HIC and stress corrosion cracking SCC resistant) pipeline steel. The specific flow is as follows: pre-desulphuzation of molten steel - converter smelting-primary RH vacuum refining - LF refining desulphuzation - secondary RH vacuum refining - continuous casting. By the secondary RH vacuum refining process, the decarburization burden of the converter and the oxidability of the molten steel can be reduced, and the adverse effect caused by recarburization in the LF refining process can be eliminated; furthermore, the use of a strong deoxidizer is reduced, the production is stabilized, and the composition of the molten steel is ensured to be controlled within a production target stably to meet the control requirements of the anti-acid pipeline steel on the low-carbon low-sulfur and high-purity composition. The carbon content of the finished steel produced by the process of the invention can be stably controlled to be 0.03% to 0.04%, and the sulfur content is stably controlled to be less than or equal to 0.0010%.

Owner:UNIV OF SCI & TECH BEIJING

Technique for producing anti-acid pipeline steel by RH-LF-VD refining

InactiveCN102719728AReduce production burdenReduce oxidationManufacturing convertersProcess efficiency improvementMolten steelDecarburization

The invention relates to a technique for producing anti-acid pipeline steel by RH-LF-VD refining. According to the technique, convertor steel making and RH-LF-VD refining techniques are utilized to control the components of molten steel, thereby producing the low-carbon low-sulfur anti-acid (anti-HIC and anti-SCC) pipeline steel. The technique comprises the following steps: predesulfurizing molten iron, smelting in a convertor, carrying out RH vacuum decarburization, carrying out LF heating for desulfurization, carrying out VD vacuum decarburization, carrying out calcium treatment, carrying out soft blowing, continuously casting, and carrying out hot rolling. By using the secondary vacuum refining processes (RH vacuum refining and VD vacuum refining), the invention can reduce the decarburization load of the convertor, lower the oxidizability of the molten steel, eliminate the adverse effect of carburization in the LF furnace refining process, reduce the consumption of a strong deoxidizer, stabilize the production, ensure that the molten steel components are stably controlled within the production target, and satisfy the component control requirements of low carbon, low sulfur and high purity for anti-acid pipeline steel. The carbon content of the finished steel produced by the technical process provided by the invention can be controlled to 0.03%, and the sulfur content can be stably controlled to at most 0.0010%.

Owner:UNIV OF SCI & TECH BEIJING

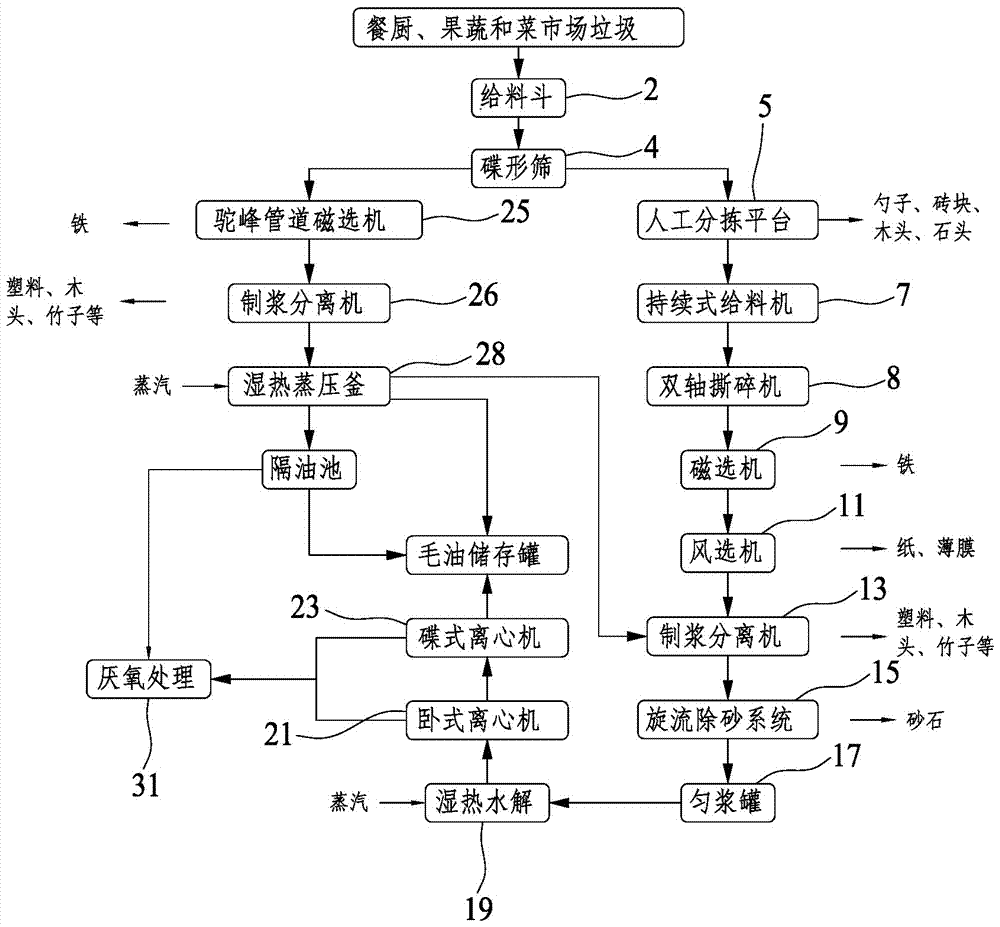

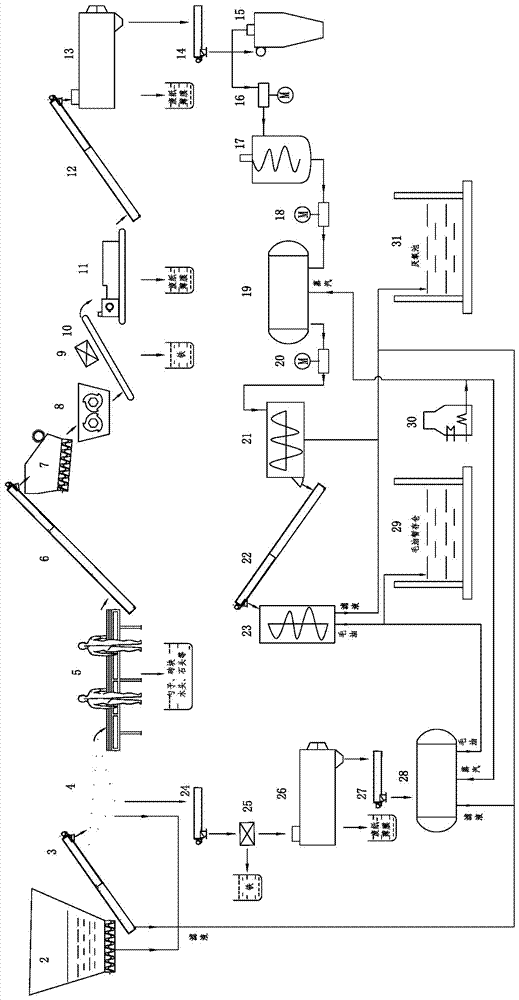

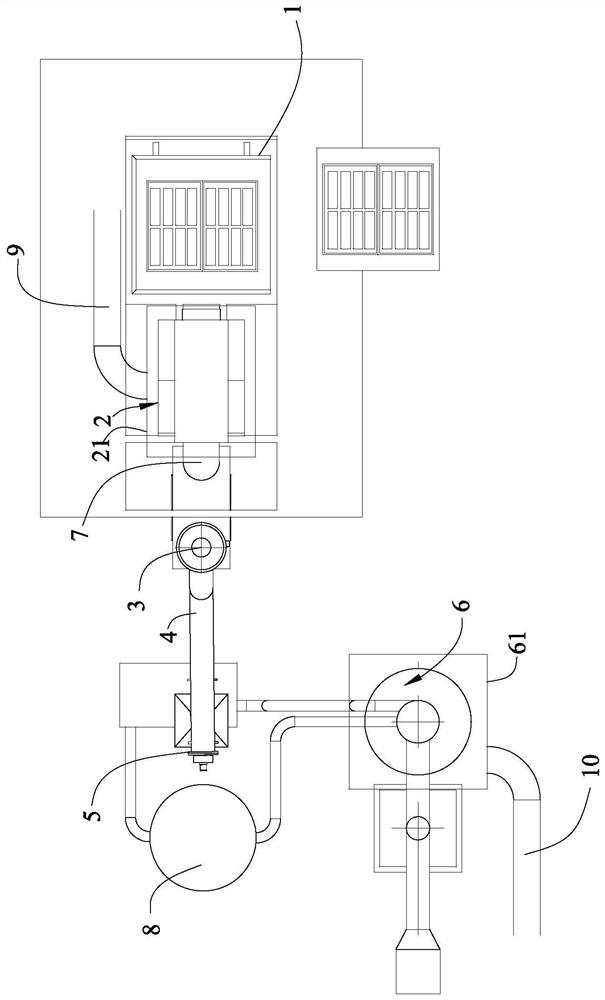

Harmless treatment process and equipment for kitchen wastes, fruit and vegetable wastes and vegetable market wastes

ActiveCN106903137AEfficient sortingReduce work intensitySolid waste disposalTransportation and packagingBiodieselMaterials processing

The invention discloses a harmless treatment process and equipment for kitchen wastes, fruit and vegetable wastes and vegetable market wastes. The harmless treatment process comprises the steps of material pretreatment, oil-water separation, product prouduction and the like. Crude oil produced after materials are subjected to oil-water separation can be used as a raw material to be processed into biodiesel, and a filtrate produced by oil-water separation is subjected to anaerobic treatment to produce methane used as a heat source during oil-water separation, so that the harmless treatment process has the advantages of simple process steps, high automation degree and the like and can be used for effectively sorting inorganic matter impurities and grease in organic matters, relieving the production burden of the final anaerobic treatment, reducing the work strength of a worker and achieving a certain economic benefit.

Owner:HUANCHUANG XIAMEN TECH

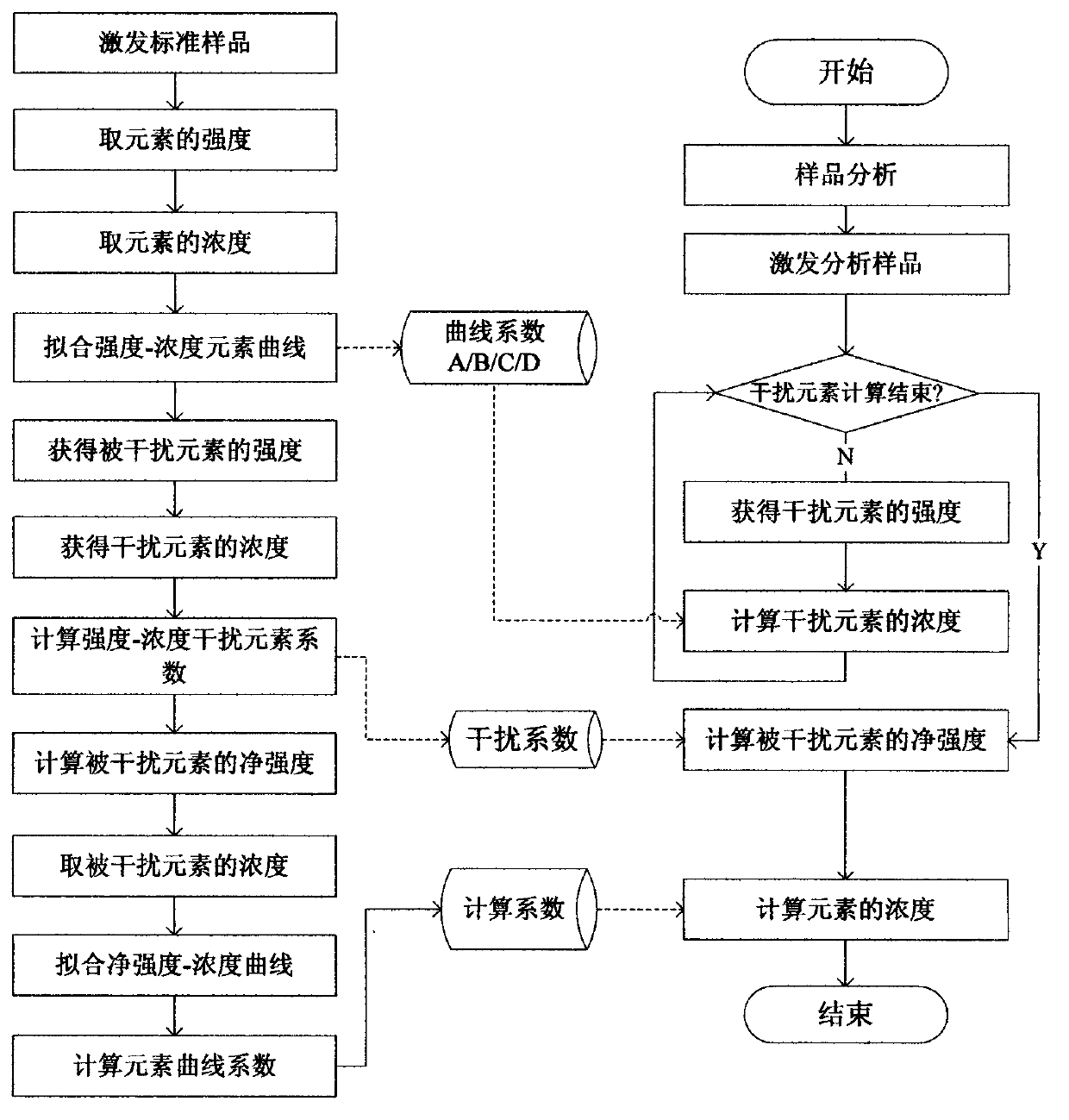

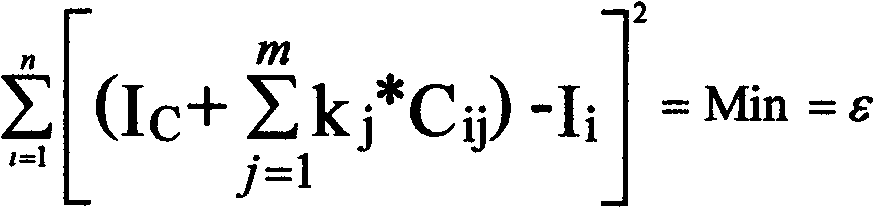

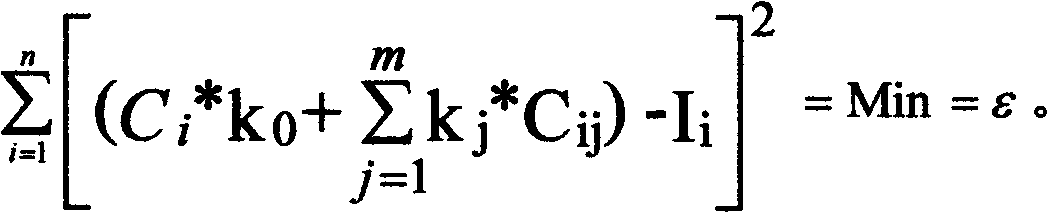

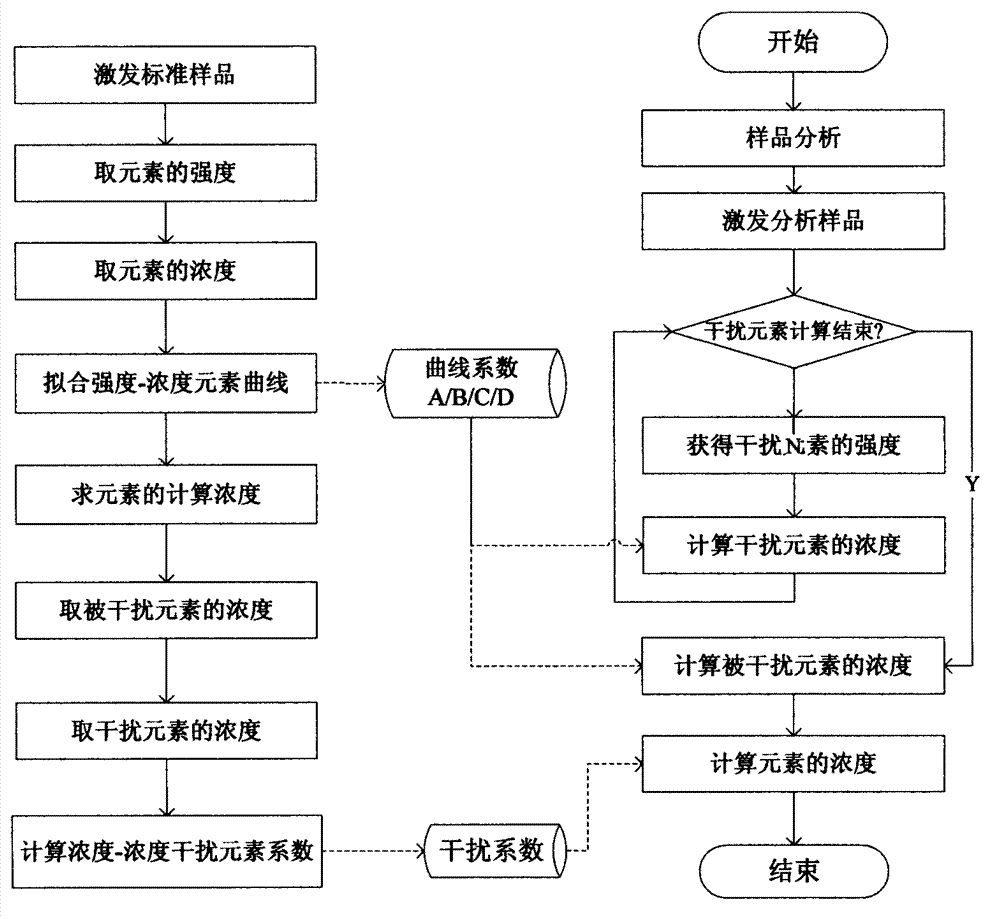

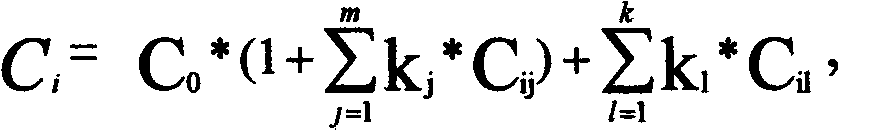

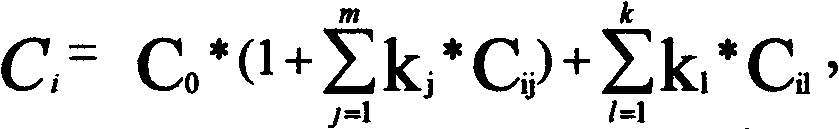

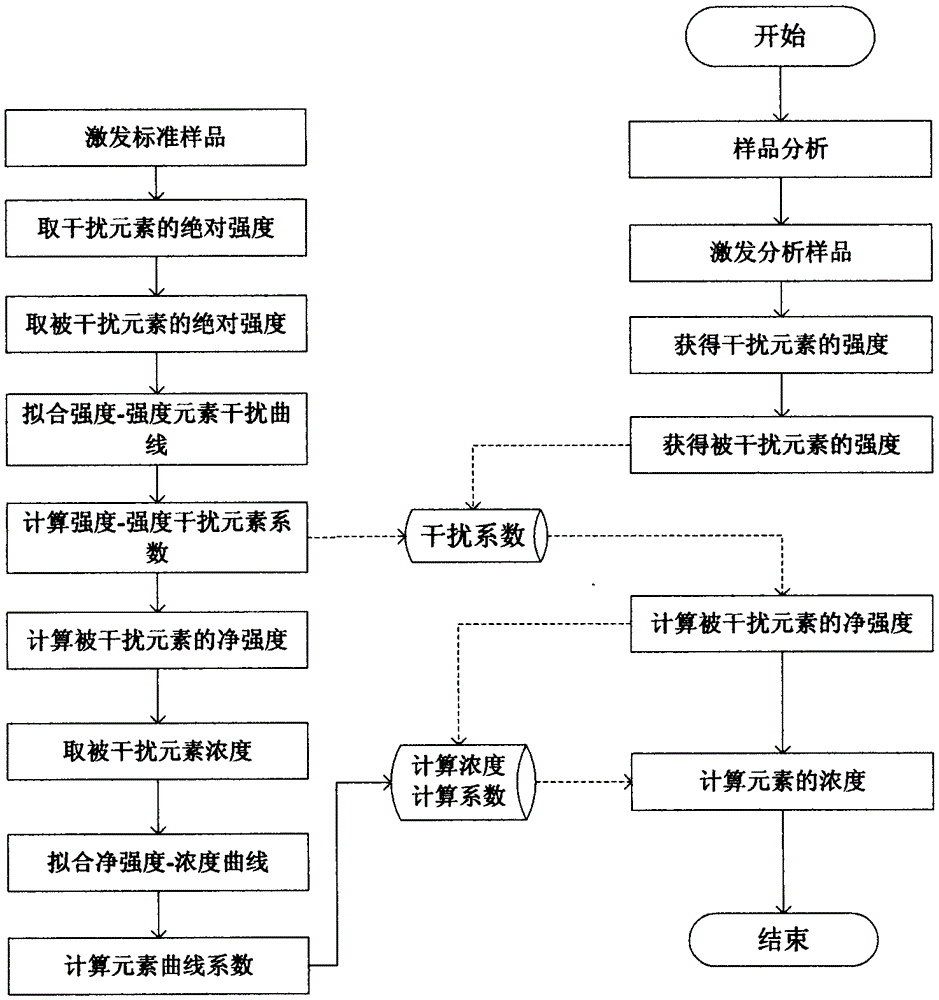

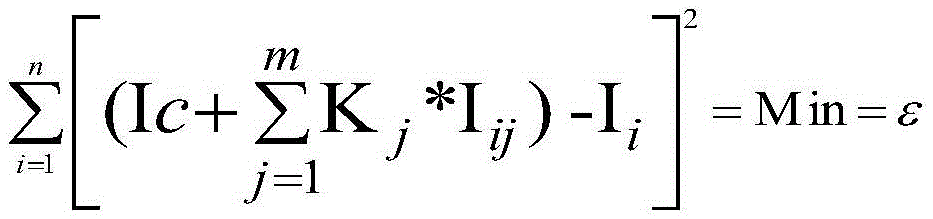

Method for calculating concentration of interfered element through measurement intensity and concentration of element

ActiveCN103592287AImprove accuracyImprove analysis accuracyAnalysis by electrical excitationSelf-absorptionUltimate tensile strength

Owner:TIANJIN JINGLIWEI SCI & TECH

Weather-resistant matt polycarbonate regenerated material and preparation method thereof

The invention provides a weather-resistant matt polycarbonate regenerated material and a preparation method thereof. The weather-resistant matt polycarbonate regenerated material is prepared from thefollowing raw materials in percentage by mass: 3 to 15 percent of first polycarbonate recycled crushed materials, 60 to 83 percent of polycarbonate recycled crushed materials, 3 to 10 percent of thirdpolycarbonate recycled crushed materials, 10 to 25 percent of matte surface agents, 0.2 to 1.0 percent of antioxidants, 0 to 0.6 percent of light stabilizing agents and 0.1 to 1.0 percent of ultraviolet absorbents. Through the addition of the matte surface agents, the antioxidants, the light stabilizing agents and the ultraviolet absorbents, the weather resistant performance of polycarbonate is improved; the processing performance is improved; the modified material with stable melt index is obtained; the performance is similar to that of a new material.

Owner:SHANGHAI AUSELL CHEM TECH

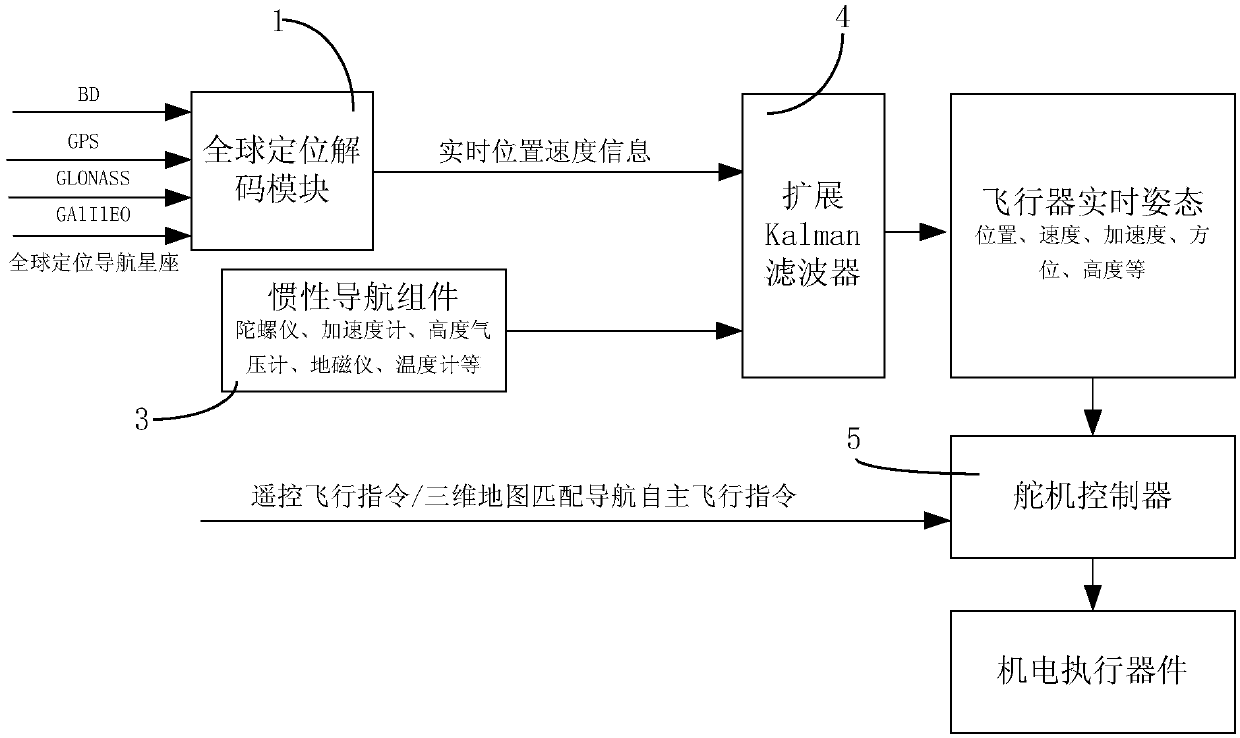

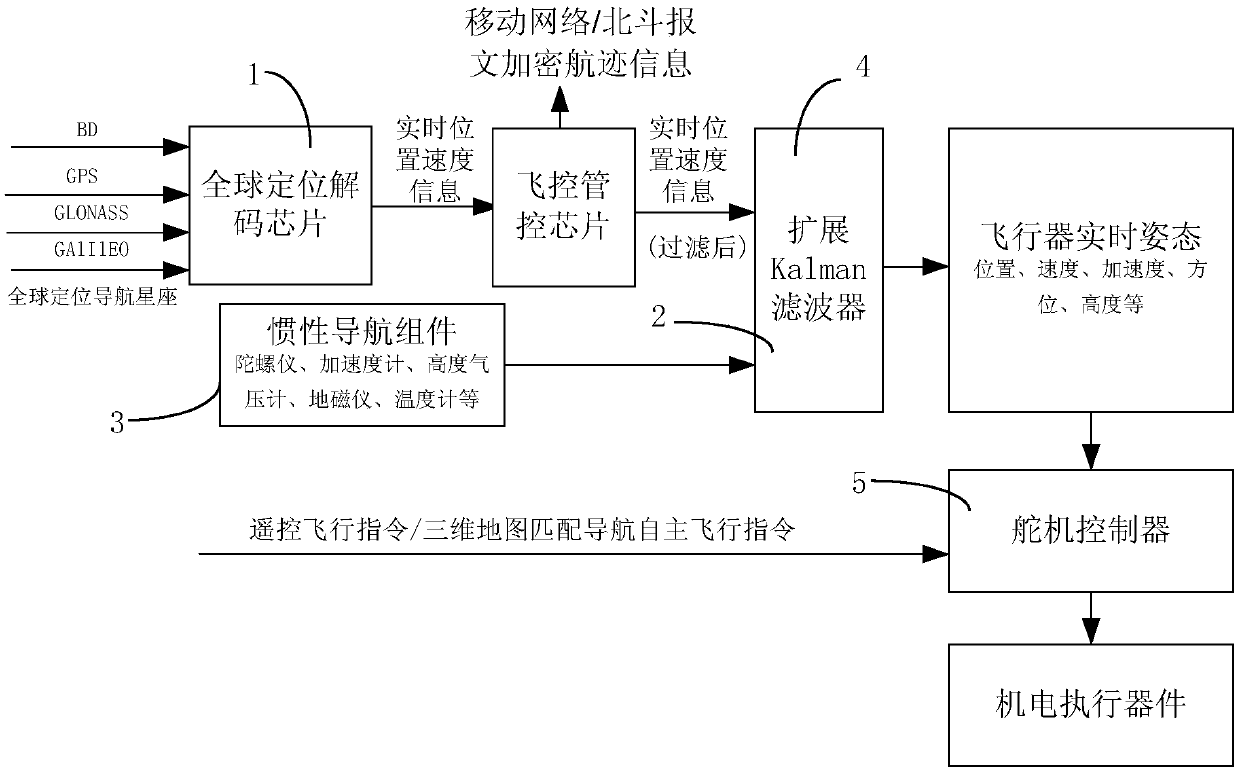

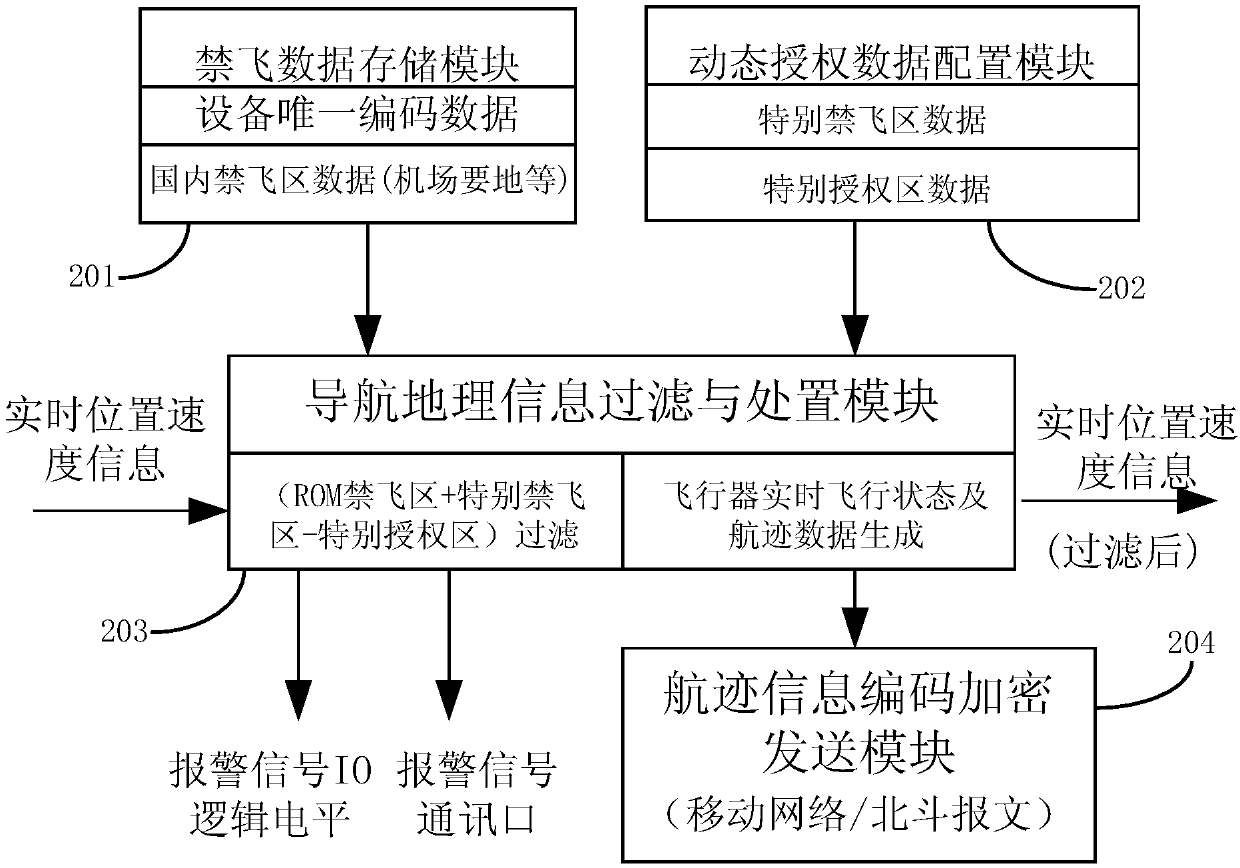

Low-altitude aircraft safety management system and method

PendingCN109523837ASafety will not be compromisedEnsure flight control effectivenessAircraft navigation/guiding aidsTime informationKaiman filter

The invention discloses a low-altitude aircraft safety management system. The system includes a global positioning decoding module, a flight control unit, an inertial navigation assembly, an extendedKalman filter and a steering gear controller, wherein the inertial navigation assembly is connected with the extended Kalman filter, the steering gear controller is connected with the extended Kalmanfilter, and the flight control unit is connected with the global positioning decoding module and the extended Kalman filter respectively and is used for receiving the real-time position information and the real-time speed information of an aircraft to determine whether the aircraft is located within the preset authorized airspace and starting a control plan if the aircraft is not located within the preset authorized airspace. The invention further discloses a method. The method comprises steps that S01, the real-time location information and the real-time speed information of the aircraft areobtained; and S02, the real-time location information and the real-time speed information are compared with preset authorized airspace data, if the aircraft is not located within the preset authorizedairspace, the control plan is initiated. The system and method have advantages of low cost, high reliability, and the like.

Owner:湖南智晶电子科技有限公司

Method for calculating concentration of interfered element through calculated concentration of element

InactiveCN103592286AImprove accuracyImprove analysis accuracyAnalysis by electrical excitationSelf-absorptionComputer science

Owner:TIANJIN JINGLIWEI SCI & TECH

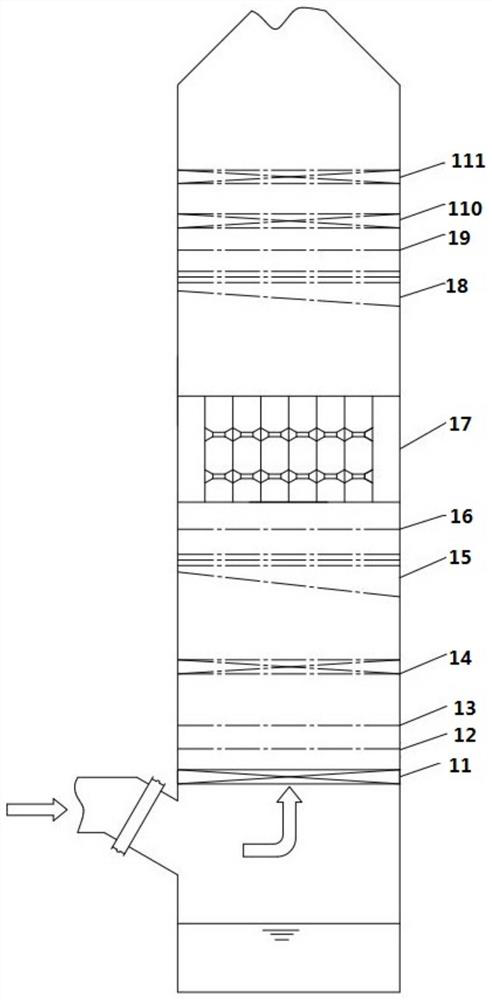

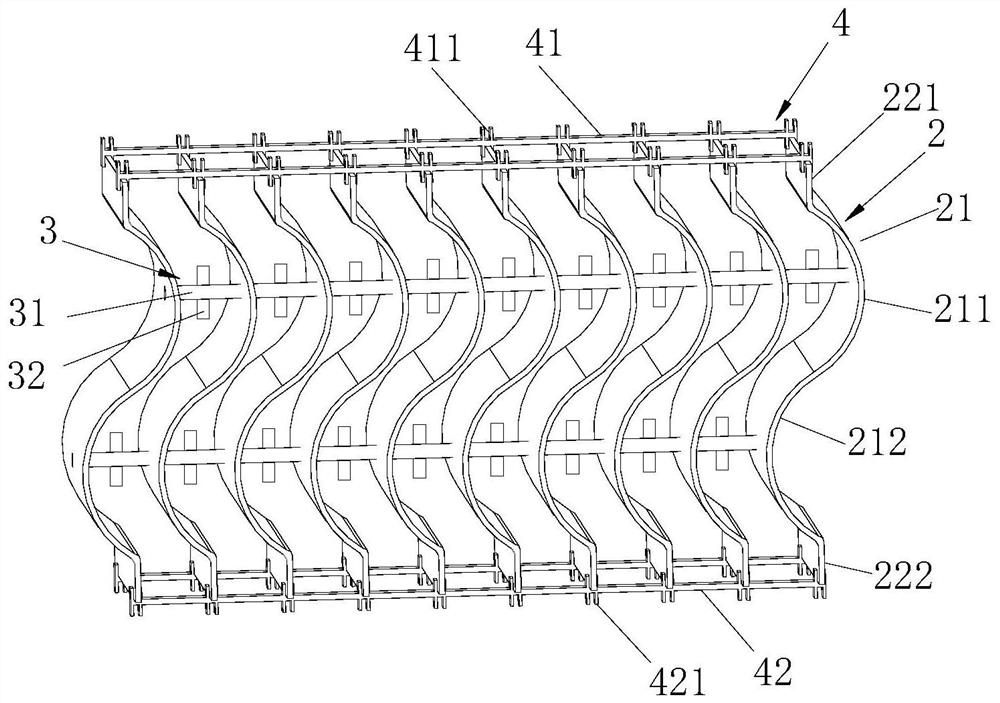

Demister for wet desulphurization tower and wet desulphurization tower

PendingCN112090260AIncrease surface areaSlowing down drastic changes in speedDispersed particle separationDemisterMechanical engineering

The invention discloses a demister for a wet desulphurization tower, which comprises a plurality of demisting blades arranged side by side, each demisting blade is vertically arranged, and each demisting blade is divided into a plurality of demisting sections with the same length from bottom to top; the vertical cross section of each demisting section is of an arc structure, and the circle centersof the arc structures on the adjacent demisting sections are located on the two sides of the corresponding demisting blade in a staggered mode. A traditional baffle plate is improved to be of a novelarc structure, the demisting effect can be greatly improved, the liquid drop trapping efficiency reaches 96.5% and is far higher than 85% of that of the traditional baffle plate, and therefore the demisting efficiency is improved. The overall investment cost is low, and the production burden is not increased. The invention discloses the wet desulphurization tower.

Owner:ZHEJIANG SCI-TECH UNIV

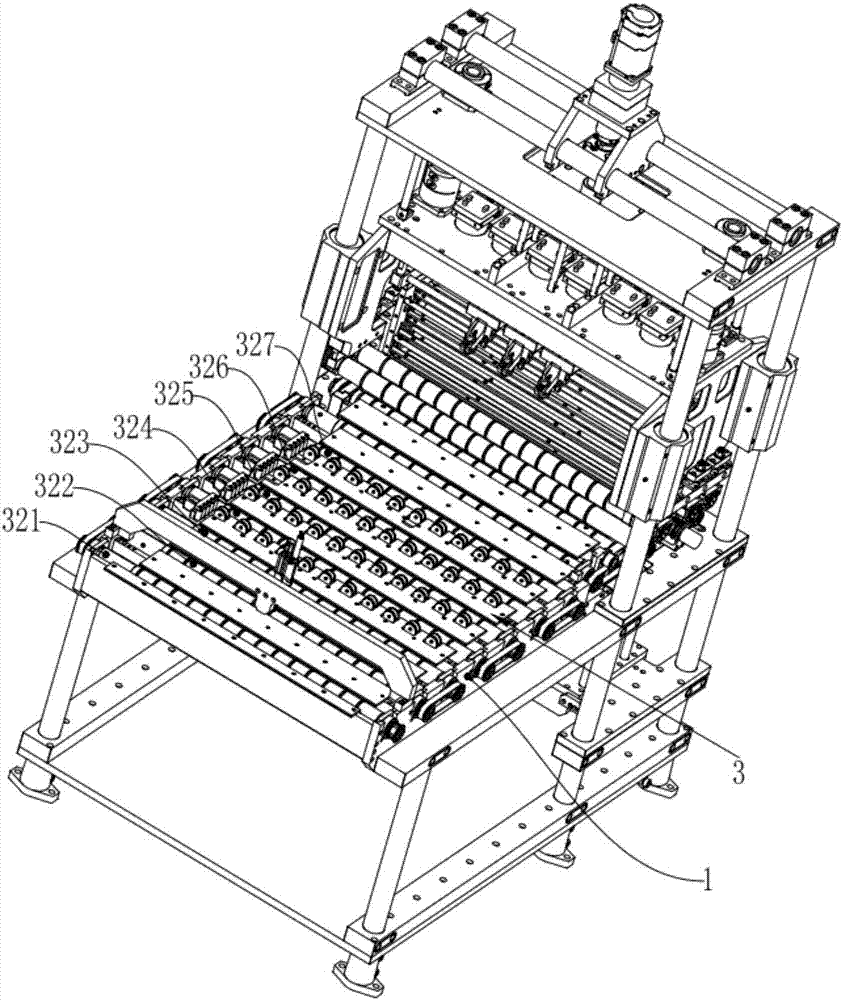

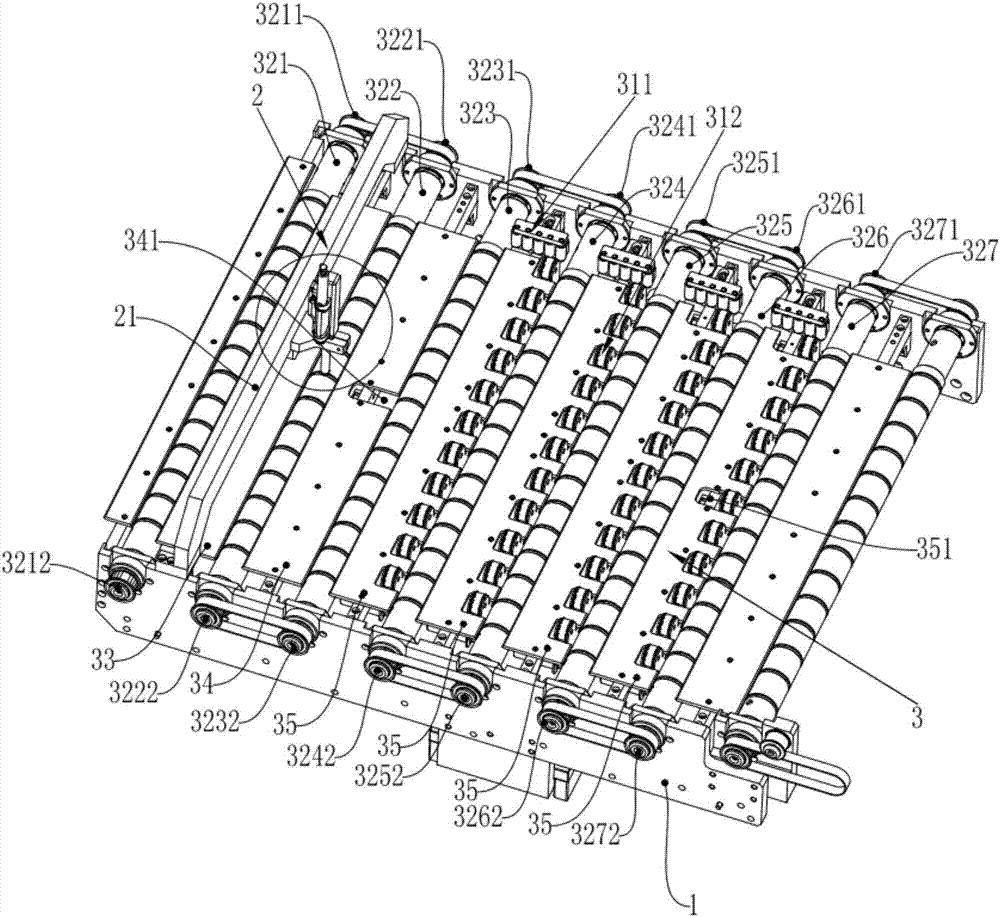

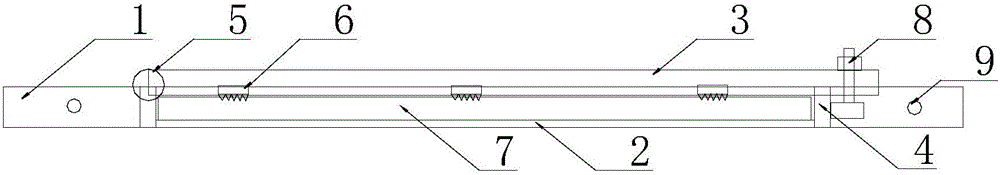

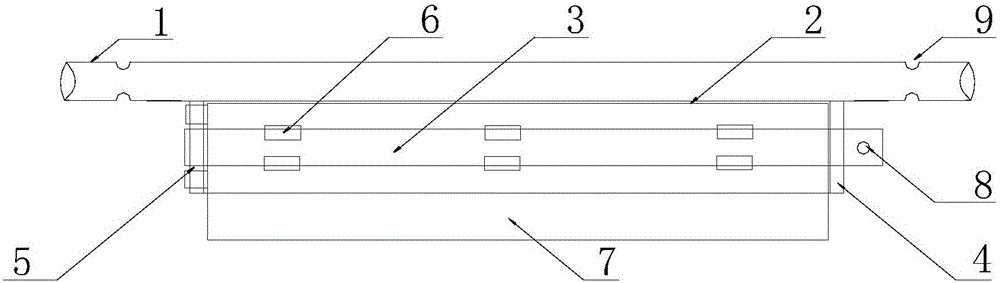

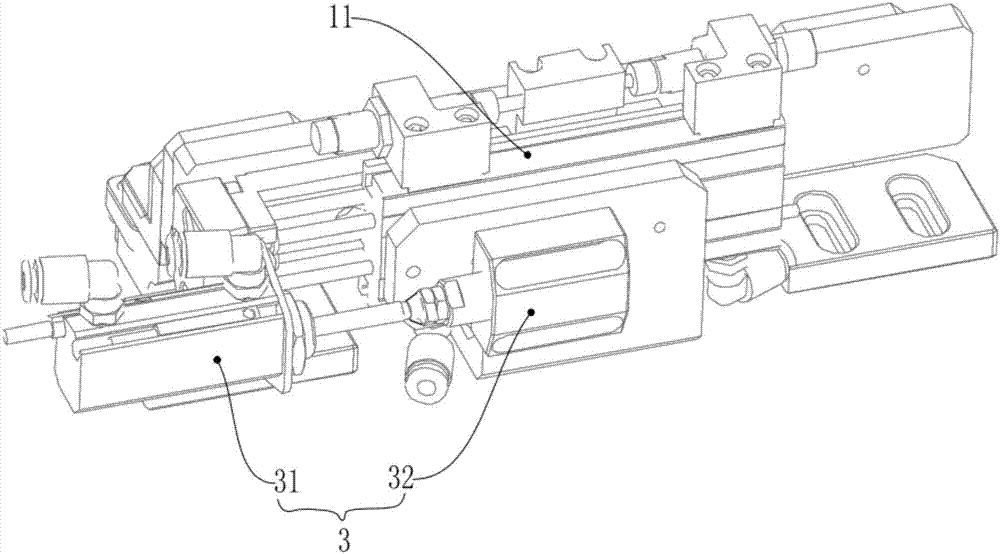

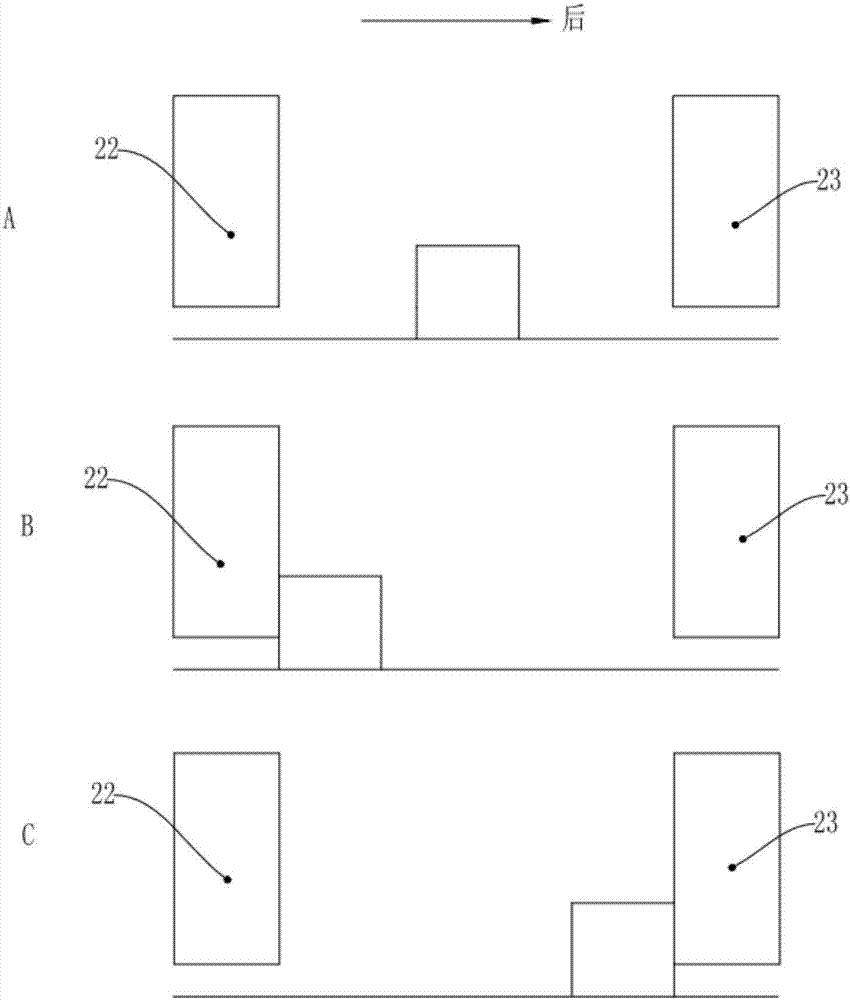

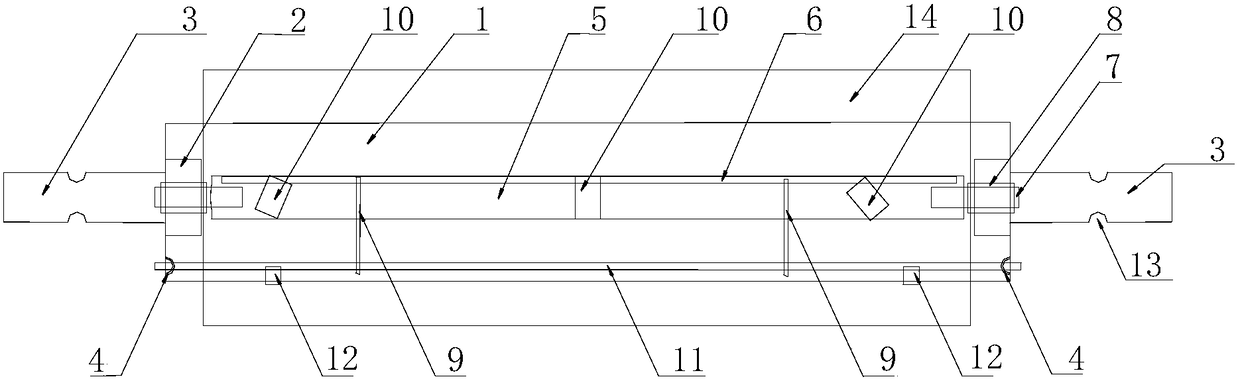

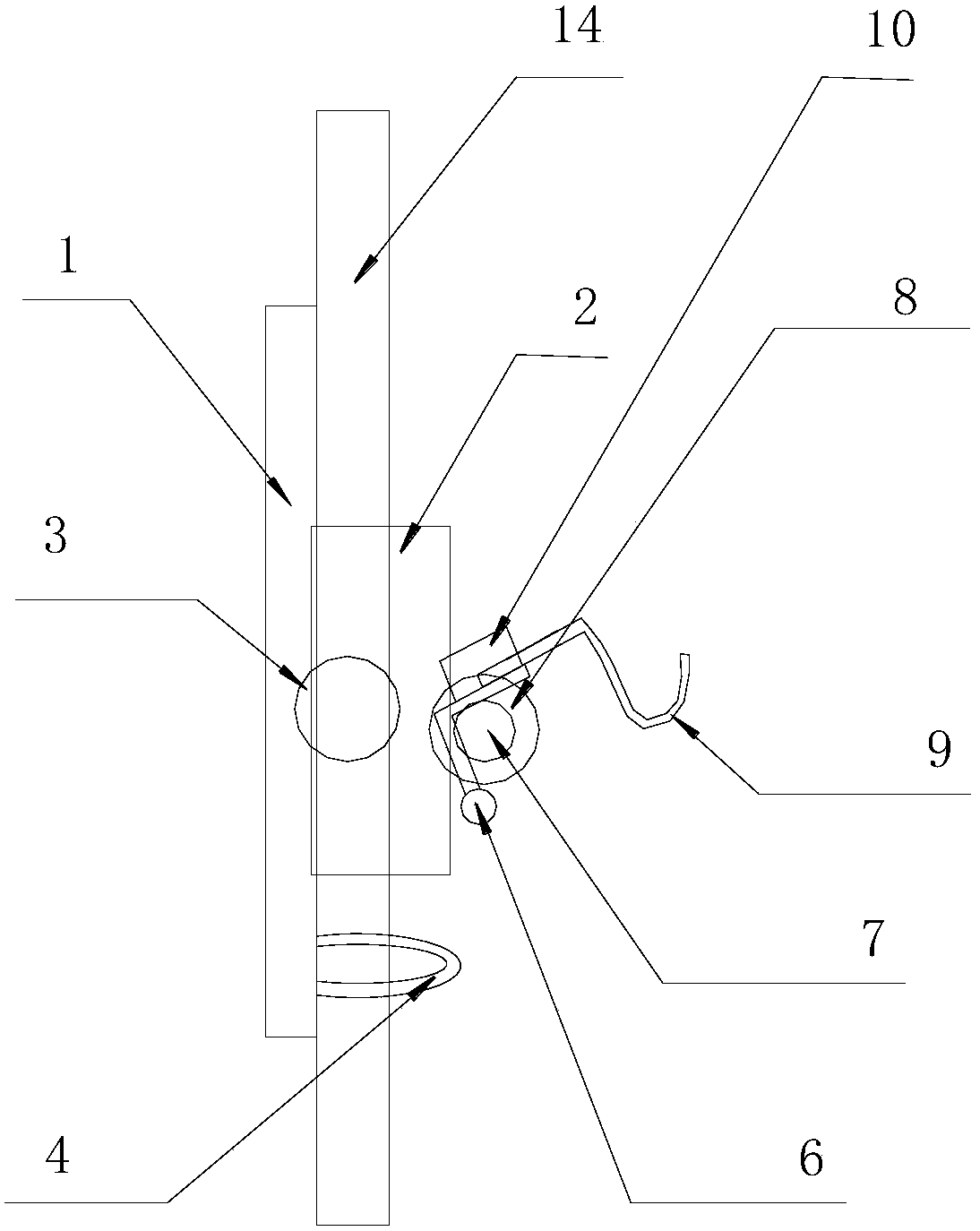

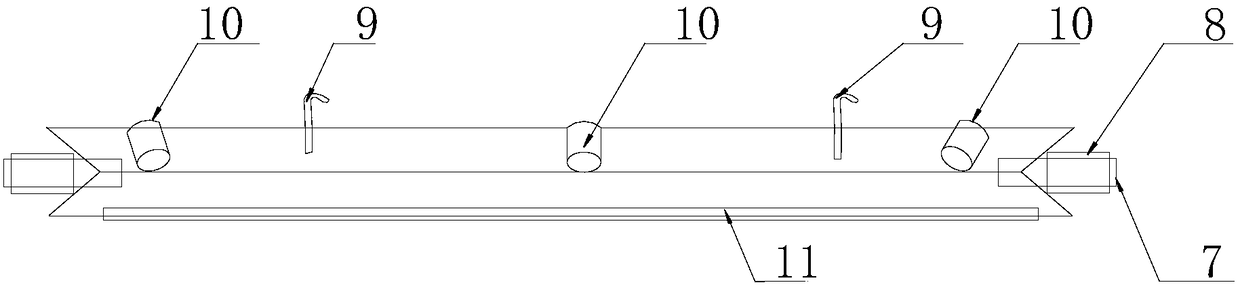

Automatic ranging, straightening and transmitting mechanism applied to circuit board detection machine

PendingCN107044982AWon't hurtWill not cause uneven placementMaterial analysis by optical meansElectrical connectionInfrared detector

The invention relates to the technical field of circuit board detection and discloses an automatic ranging, straightening and transmitting mechanism applied to a circuit board detection machine. The automatic ranging, straightening and transmitting mechanism is arranged at the front end of a rack detection end and comprises a rotating roller installation platform, an automatic ranging device and a straightening and transmitting device; the straightening and transmitting device is used for straightening and transmitting a circuit board to the direction of the detection end; the automatic ranging device comprises a hanging beam and a dimension measurement instrument; the dimension measurement instrument comprises a detection shaft and a measurement instrument installation seat; the detection shaft is arranged on the measurement instrument installation seat; the measurement instrument installation seat is arranged on the hanging beam; a feeding infrared detector is also arranged at the rear end of the lower part of the detection shaft; an output end of the feeding infrared detector is electrically connected with an input end of the dimension measurement instrument; and the feeding infrared detector is arranged at the lower part of the rotating roller installation platform.

Owner:SHENZHEN YANCHUANG PRECISION EQUIP MACHINERY

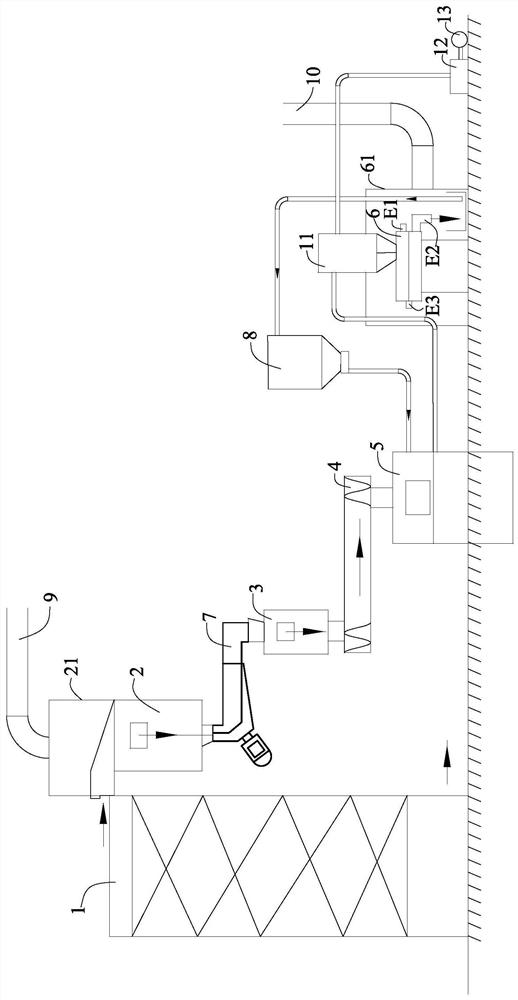

Production equipment and method for dissipated metal fine powder

The invention provides production equipment for dissipated metal fine powder. The production equipment comprises a lifter, a crusher, a rough grinding machine, a material conveyor, a fine grinding machine and a screening machine, wherein the lifter ascends and descends in the up-down direction; the crusher is arranged on one side of the lifter so as to crush blocky dissipated metal raw materials;the rough grinding machine is connected to the crusher so as to carry out rough grinding on blocky dissipated metal; the material conveyor is connected between the rough grinding machine and the finegrinding machine and is used for automatically conveying dissipated metal particles to the fine grinding machine; the fine grinding machine is connected to the rough grinding machine and is used for carrying out fine grinding on the dissipated metal particles, and the dissipated metal fine powder with different particle sizes and different proportions is obtained through fine grinding in the finegrinding machine; and the screening machine is connected to the fine grinding machine so as to screen out the dissipated metal fine powder meeting the production requirements from the dissipated metalfine powder obtained through fine grinding. The production equipment for the dissipated metal fine powder is integrally and automatically operated, the production burden of single equipment is reduced, the production efficiency of the dissipated metal fine powder is improved, and the dissipated metal fine powder which meets requirements and has different particle sizes and different proportions can be obtained in the fine grinding machine.

Owner:江苏先导微电子科技有限公司

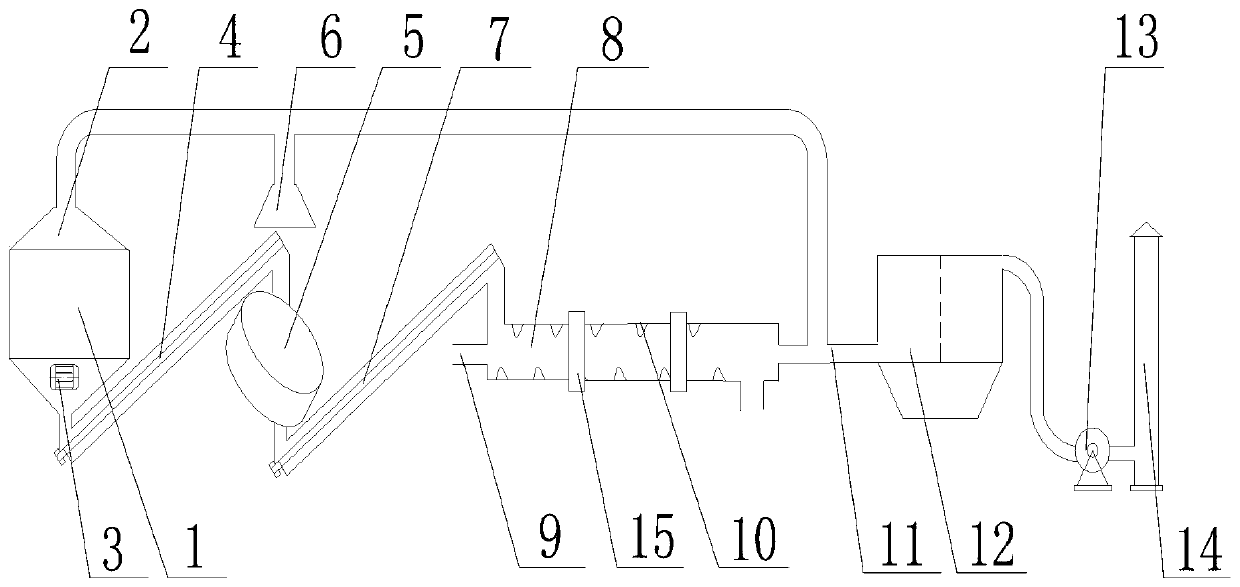

Production method and device of efficient circulating bio-organic fertilizer

InactiveCN111348948AQuality improvementWell mixedBio-organic fraction processingOrganic fertiliser preparationAgricultural scienceFlue gas

The invention discloses a production device of an efficient circulating bio-organic fertilizer. The device comprises a raw material mixing bin, a disc mixer and a dust remover; a feed opening of the raw material mixing bin is connected with the top of the disc mixer through a lifting belt; a feed opening of the disc mixer is connected with a feed opening of a rotary granulation drying cylinder through a conveying belt; a flue gas outlet in the rear part of the rotary granulation drying cylinder is connected with the dust remover through a pipeline; the dust remover is connected with a dust removal fan, the dust removal fan is connected with a dust removing chimney arranged at the rear part, a bin top dust collection cover is arranged at the top of the raw material mixing bin, a dust collection cover is arranged at the upper part of the disc mixer, and the bin top dust collection cover and the dust collection cover are communicated with a dust collection pipeline and are connected withthe dust remover. The organic fertilizer produced by the scheme not only can provide various required nutrients for the growth of crops, but also conforms to the production concept of environmental protection, reduces the burden of related departments for treating burning straws, reduces the production cost of the efficient bio-organic fertilizer, and reduces the production burden of farmers.

Owner:宁夏谷农农业科技有限责任公司

Belt sweeping device and belt conveyor

The invention provides a belt sweeping device and a belt conveyor. The belt conveyor comprises the belt sweeping device. The belt sweeping device comprises a scraper (7), a tray and a pressure plate (3). One end of the pressure plate (3) is rotatably connected with the tray, the other end of the pressure plate (3) is fixedly connected with the tray, and the scraper (7) is fixedly compressed between the pressure plate (3) and the tray. The belt sweeping device and the belt conveyor have the advantages that the scraper of the belt sweeping device is convenient to mount and detach; the utilization rate of the scraper can be increased, material and spare part costs can be effectively reduced for enterprises, and accordingly production burden can be relieved.

Owner:SHANDONG IRON & STEEL CO LTD

Process for producing anti-acid pipeline steel by Ruhrstahl Heraecus (RH)-ladle furnace (LF)-RH refining

InactiveCN102719614BReduce production burdenReduce non-metallic inclusion contentManufacturing convertersHydrogenStress corrosion cracking

The invention discloses a process for producing an anti-acid pipeline steel by Ruhrstahl Heraecus (RH)-ladle furnace (LF)-RH refining. In the process, the composition of molten steel is controlled by converter smelting and RH-LF-RH refining process, so as to produce a low-carbon low-sulfur anti-acid (hydrogen-induced cracking HIC and stress corrosion cracking SCC resistant) pipeline steel. The specific flow is as follows: pre-desulphuzation of molten steel - converter smelting-primary RH vacuum refining - LF refining desulphuzation - secondary RH vacuum refining - continuous casting. By the secondary RH vacuum refining process, the decarburization burden of the converter and the oxidability of the molten steel can be reduced, and the adverse effect caused by recarburization in the LF refining process can be eliminated; furthermore, the use of a strong deoxidizer is reduced, the production is stabilized, and the composition of the molten steel is ensured to be controlled within a production target stably to meet the control requirements of the anti-acid pipeline steel on the low-carbon low-sulfur and high-purity composition. The carbon content of the finished steel produced by the process of the invention can be stably controlled to be 0.03% to 0.04%, and the sulfur content is stably controlled to be less than or equal to 0.0010%.

Owner:UNIV OF SCI & TECH BEIJING

Formula and production process of multifunctional bio-organic fertilizer

InactiveCN113429226AIn line with the production concept of green environmental protectionSolving Recycling ProblemsBio-organic fraction processingExcrement fertilisersAgricultural scienceSucrose

The invention discloses a formula and a production process of a multifunctional bio-organic fertilizer. The organic fertilizer is prepared from the following raw materials in parts by weight: 20 to 30 parts of straw, 15 to 20 parts of dry animal waste, 5 to 10 parts of duckweed, 5 to 10 parts of water, 3 to 5 parts of plant ash, 0.5 to 1.5 parts of EM bacterial liquid, 0.5 to 1.5 parts of cane sugar, 15 to 20 parts of sawdust, 15 to 20 parts of vinasse residue and 25 to 30 parts of pond sludge. The production process includes the following steps: 1, weighing the raw materials in parts by weight; 2, crushing the straws until the length is less than 0.8 cm; 3, uniformly mixing the crushed and sieved raw materials to obtain a mixture; 4, pouring cane sugar into water, adding the EM bacterial liquid after the cane sugar is dissolved, spraying the mixture onto the mixture after being evenly stirred and uniformly stirring the components; 5, drying and crushing the fertilizer obtained by fermentation. According to the invention, the problems of recycling of crop straws and treatment of poultry manure are solved, and the burden of related departments for governing straw combustion is reduced; meanwhile, the production cost of the multifunctional bio-organic fertilizer is reduced, and the production burden of farmers is relieved.

Owner:遵义君宇生物工程有限公司

A non-invasive delivery assistance guidance device and guidance method thereof

ActiveCN109106433AImprove the quality of lifeWith anti-interference compensation functionSensorsMeasuring/recording heart/pulse rateNon destructiveObstetrics

The invention discloses a non-invasive delivery assistance guiding device, which comprises a fetal heart rate monitoring unit and a sensor connected with the fetal heart rate monitoring unit. The prompting unit is used for prompting when the parturient starts to exert force; the microprocessor is respectively connected with the prompting unit and the sensor. An air pump and a suction cup connectedwith the air pump through a pipe. The invention also provides a non-invasive delivery type delivery guidance method, which can intelligently cooperate with the uterine contraction of the parturient to adjust the force size and the force application time, meanwhile, the suction cup realizes the non-destructive labor induction to the fetus, lightens the production burden of the parturient, and ensures the smooth delivery even if the parturient is in the uterine contraction inertia state or other extreme cases. The provided non-invasive delivery assistance guidance device and guidance method thereof have the functions of real-time monitoring, real-time adjustment and real-time intelligent voice prompting, and can basically cancel the conventional perineotomy, greatly reduce the perineotomy rate, and can reach the goal of improving the quality of life of parturients.

Owner:惠州卫生职业技术学院

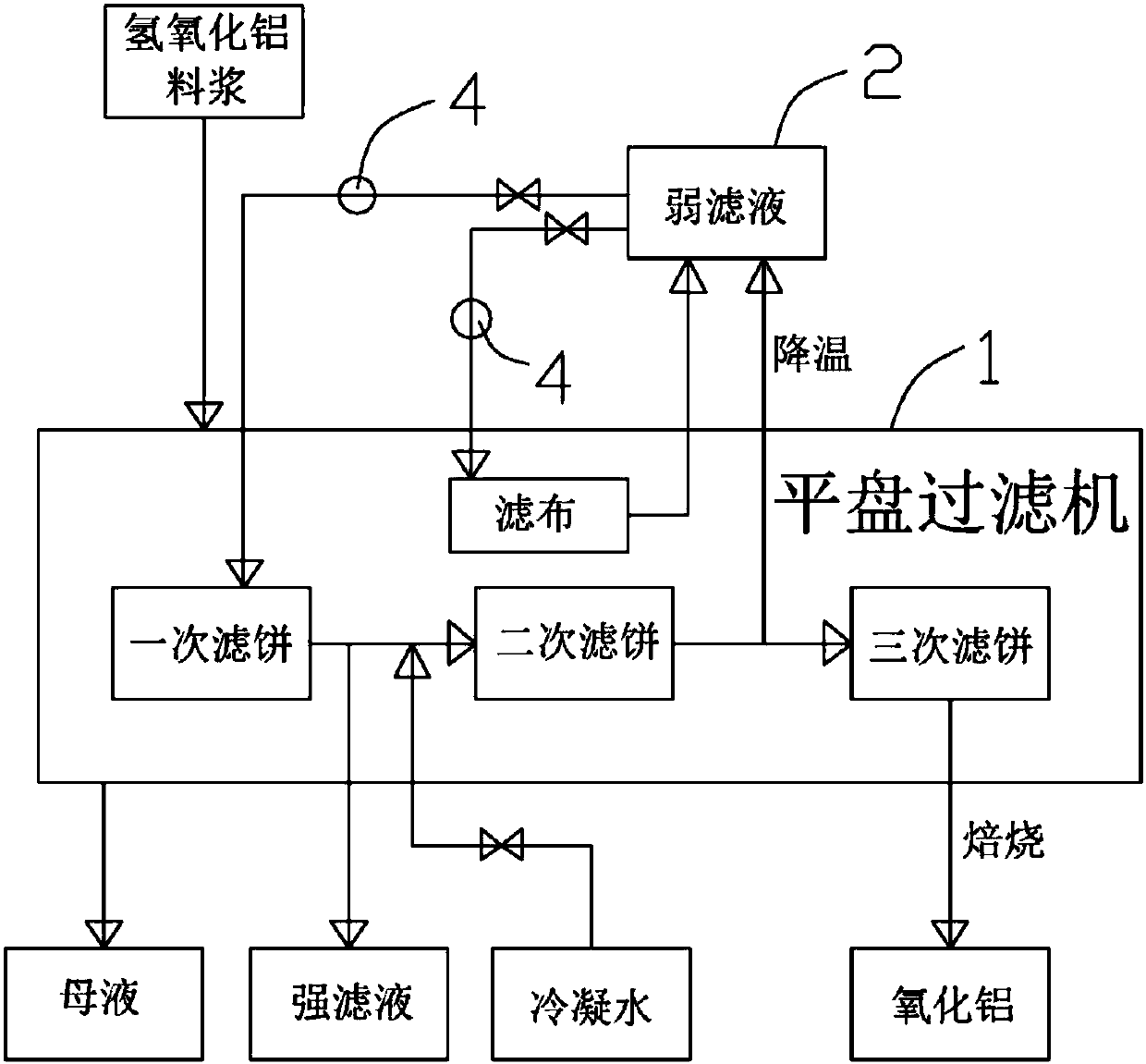

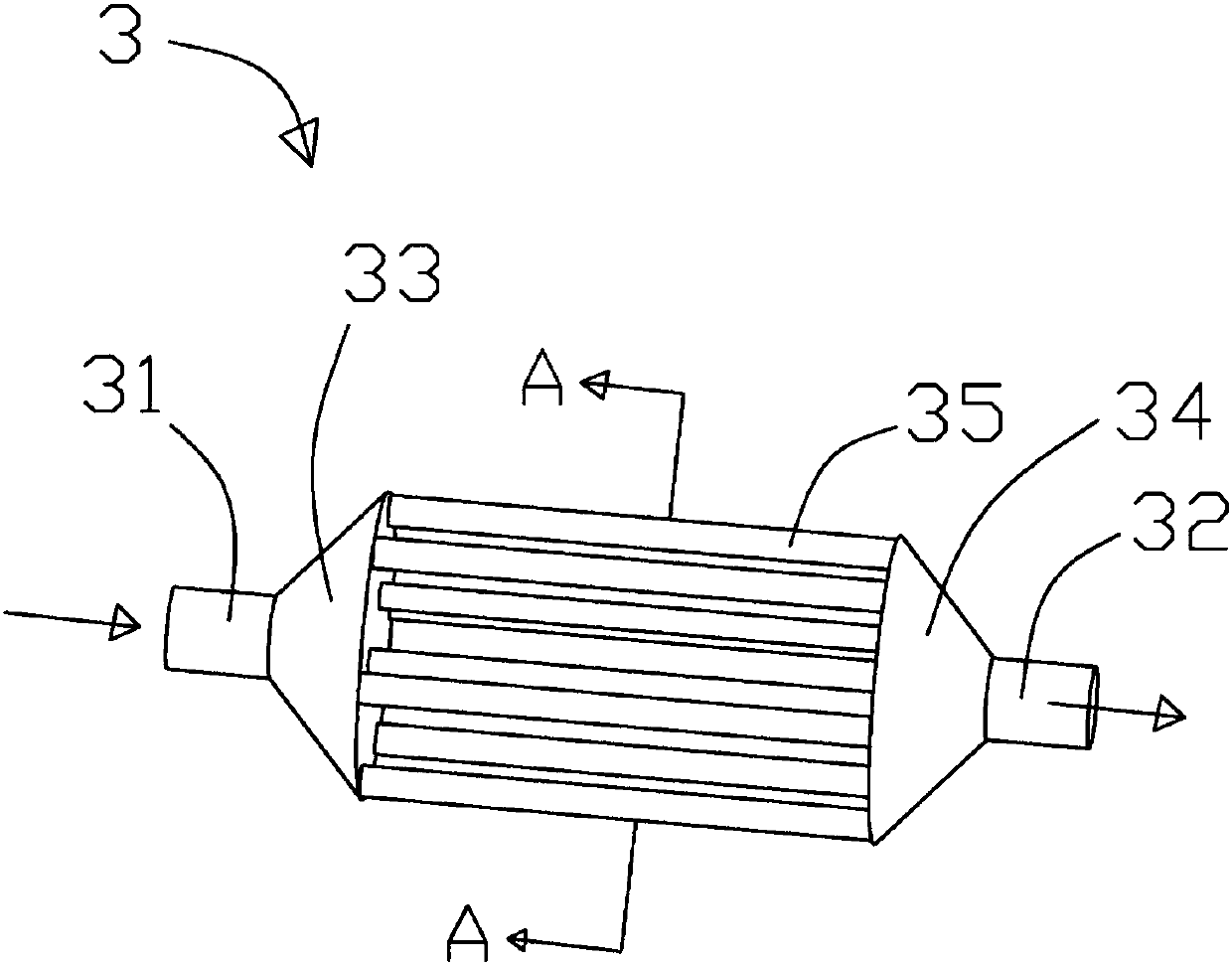

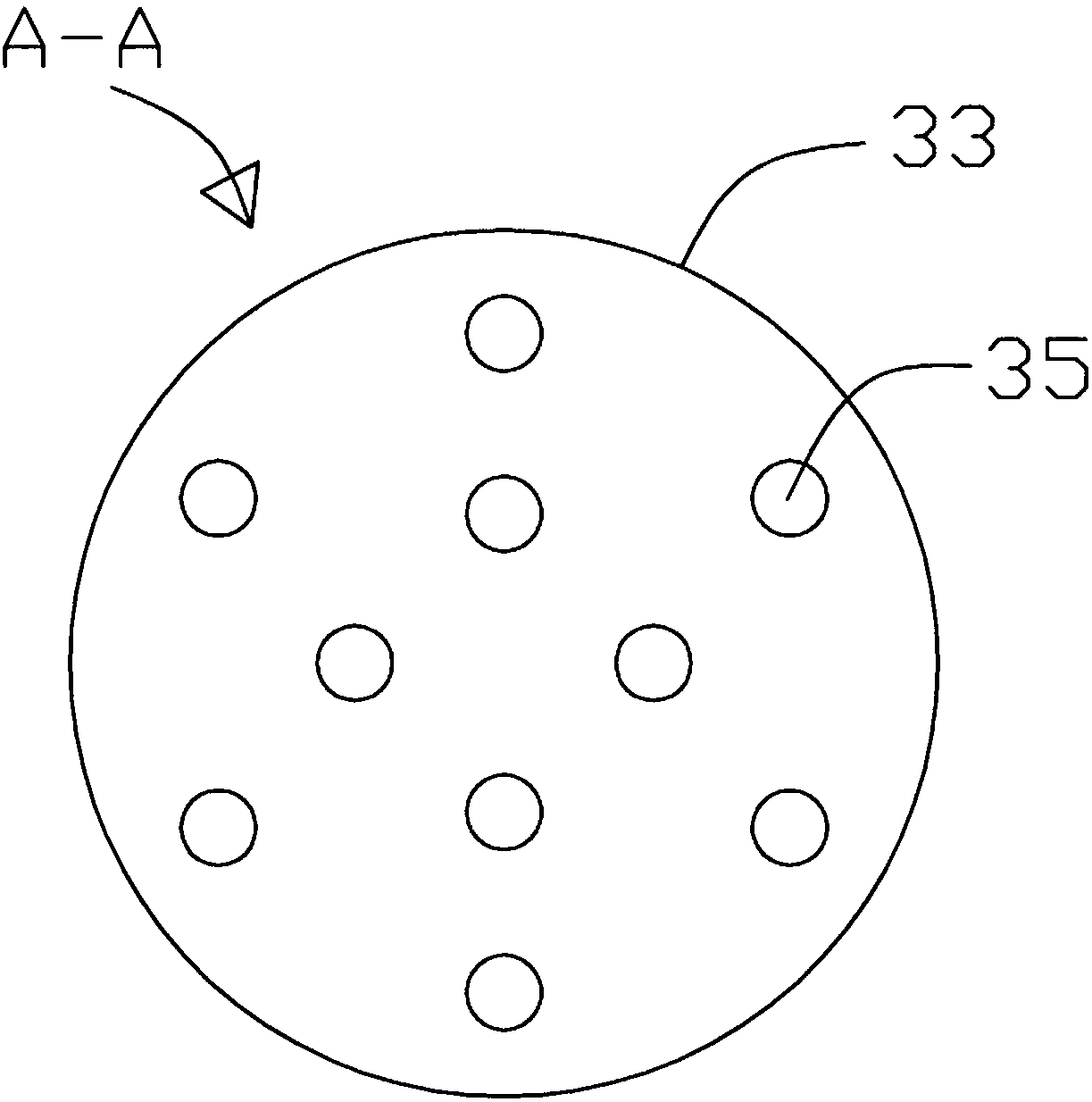

Flat plate filtration lotion circulating system for aluminum oxide

PendingCN107555457ASave condensate consumptionReduce production burdenAluminates/aluminium-oxide/aluminium-hydroxide purificationStationary filtering element filtersPhysicsChemistry

The invention provides a flat plate filtration lotion circulating system for aluminum oxide, belonging to the field of production equipment of aluminum oxide. The flat plate filtration lotion circulating system comprises a flat plate filtering machine, a cooling device, a weak filtrate storage slot and a plurality of pipelines, wherein a weak filtrate flowing from the flat plate filtering machineis cooled by the cooling device and is used for washing aluminum hydroxide crystals, and a pipeline is guided from the weak filtrate storage slot and is used for flushing flat plate filtering cloth. According to the flat plate filtration lotion circulating system, the weak filtrate is utilized for replacing condensate water for flushing the filtering cloth, so that the condensate water is saved, the production burden of procedures is reduced, the production energy consumption is reduced, and the operation cost is lowered; and after being cooled by the cooling device, the weak filtrate is conveyed to the flat plate filtering machine and is used for washing the aluminum hydroxide crystals, so that the volatilization of water vapor is reduced, and the volatilization of a large amount of thermal strong base water vapor is avoided, and furthermore, the wasting of resources and the pollution to an atmospheric environment are avoided.

Owner:广西信发铝电有限公司

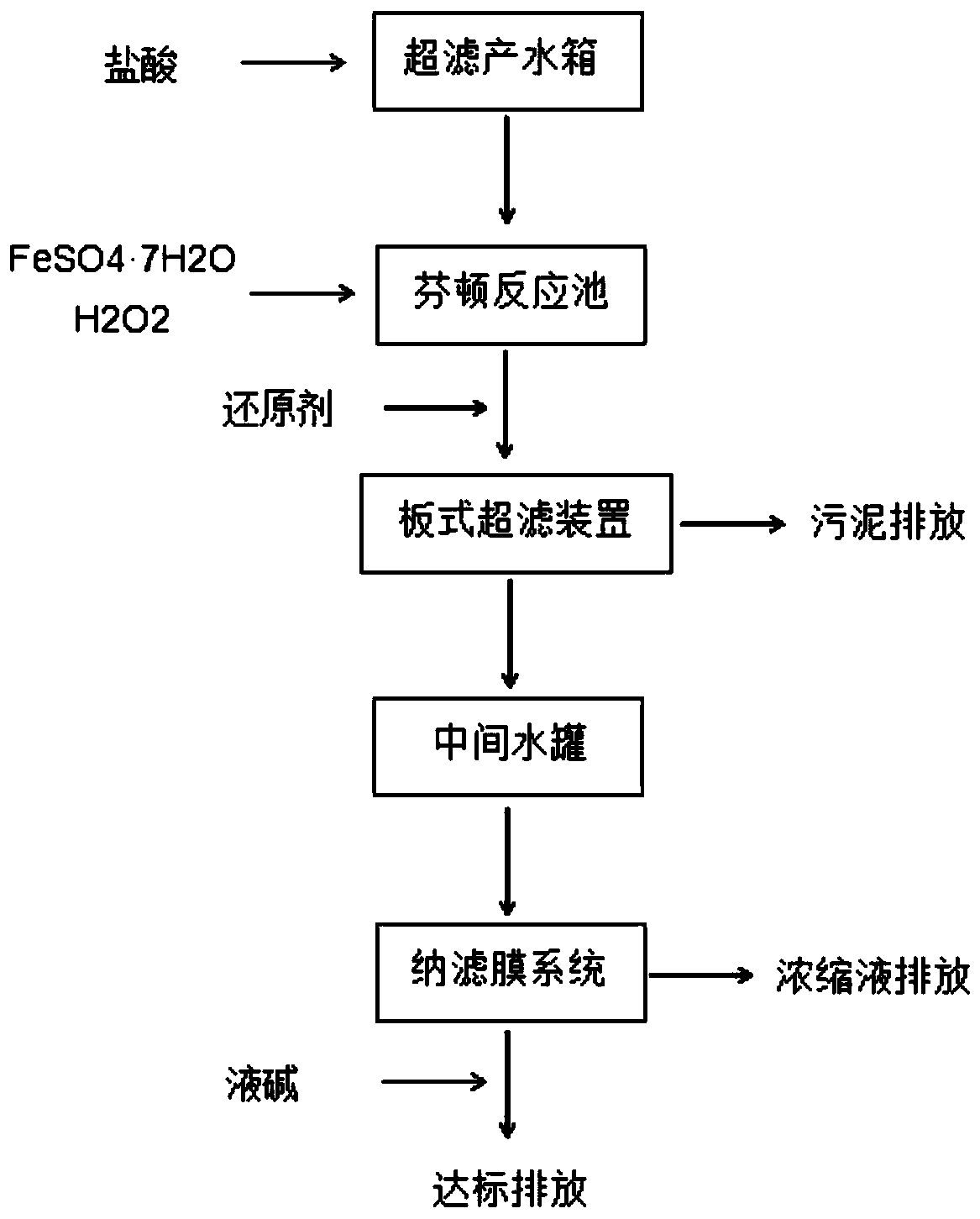

Leachate membrane treatment method capable of reducing yield of concentrated solution

InactiveCN110104845ASave reverse osmosis membrane advanced treatment processReduce production burdenWater treatment compoundsMultistage water/sewage treatmentUltrafiltrationChemistry

The invention relates to a leachate membrane treatment method capable of reducing the yield of a concentrated solution. The leachate membrane treatment method comprises the following steps: S1, addinghydrochloric acid into ultra-filtered produced water collected by an ultra-filtered produced water tank to adjust a pH value to meet the Fenton reaction requirement; S2, adding hydrogen peroxide andferrous sulfate into the ultra-filtered produced water after the pH is regulated in a Fenton reaction tank, executing Fenton reaction to reduce the COD of the ultra-filtered produced water to be belowa set value; S3, adding a reducing agent to remove the strong oxidizing substances left after the reaction, then feeding the water into a plate-type ultrafiltration device for filtering treatment, enabling the produced water to enter an intermediate water tank for storage, starting the nanofiltration system for nanofiltration treatment after the starting liquid level of the nanofiltration systemis reached, enabling the pH of the ultra-filtered produced water to be regulated back to be medium, and then executing up-to-standard discharging. The method has the advantages that the produced waterafter the Fenton reaction and the plate type ultrafiltration device can reach the discharge standard after passing through the nanofiltration system, so that a next reverse osmosis membrane treatmentprocess is omitted, the yield of the concentrated solution is greatly reduced, and the investment cost is greatly reduced.

Owner:XINGOU GARBAGE POWER GENERATION CO LTD (WUHAN) SHENZHEN ENERGY ENVIRONMENT CO LTD

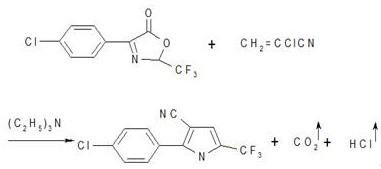

Method for producing chlorfenapyr intermediate pyrrole by replacing acetonitrile with solvent DMF

PendingCN112608268ASolve technical problemsImprove production efficiencyOrganic chemistryPyrroleEnvironmental chemistry

The invention provides a method for producing chlorfenapyr intermediate pyrrole by replacing acetonitrile with a solvent DMF. The solvent DMF is used for replacing acetonitrile. The method for producing the chlorfenapyr intermediate pyrrole by replacing acetonitrile with the solvent DMF comprises the following steps: extraction replacement, heat preservation reaction and condensation desolvation. The method has the beneficial effects that the reaction temperature of the pyrrolation cyclization reaction for preparing the intermediate is increased to 80 DEG C, the yield is increased to 90% or above in a breakthrough manner, the consumed solvent amount is reduced by more than 30%, the production cost is reduced by about 86%, the production cost is greatly reduced, and the production burden of enterprises is reduced.

Owner:李通

Monovalent copper electroless copper plating solution

InactiveCN104141120BGuaranteed to workReduce usageLiquid/solution decomposition chemical coatingSal ammoniacCopper plating

Monovalent copper electroless copper plating solution, the invention relates to the preparation and use method of monovalent copper electroless copper plating solution. The invention aims to solve the technical problems of low electroless copper plating speed and high consumption of formaldehyde at present. The monovalent copper electroless copper plating solution contains components such as cuprous chloride, potassium chloride, ammonia water, auxiliary complexing agent, formaldehyde, stabilizer, and antioxidant. It needs to be heated to 40~70°C and the loading capacity is 0.2 ~4.0dm2 / L. The electroless copper plating solution for monovalent copper of the present invention can deposit more metal copper under the condition of consuming equivalent formaldehyde, not only can improve the plating speed of electroless copper plating, but also can save the amount of formaldehyde used, which is beneficial to the improvement of production efficiency Improve and control production costs.

Owner:UNIV OF JINAN

Set-top box production verification method and system

ActiveCN108200474BAvoid affecting subsequent processesUndiscoverable problems will not occurCo-operative working arrangementsProgram loading/initiatingProcess engineeringIndustrial engineering

The invention relates to a set top box production check method and system. According to the method, through preset check configuration, after working processes are finished, working process finishingsituations are checked timely, so the working processes and products in which problems exist are discovered timely, follow-up working processes are prevented from being influenced and undiscoverable problems are avoided. Not all products need to be rechecked and reprocessed, the production load is greatly reduced, and the labor and time cost is reduced.

Owner:SHENZHEN JIUZHOU ELECTRIC

Back silver paste for low-silver-content crystalline silicon solar battery and preparation method thereof

InactiveCN103000250BReduce manufacturing costReduce production burdenNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteAdhesive

The invention discloses back silver paste for a low-silver-content crystalline silicon solar battery. The back silver paste is prepared by components including, by weight percentage, 50-64% of spherical silver coated copper powder, 25-40% of modified organic adhesive and 1-10% of inorganic adhesive. The invention further discloses a preparation method of the back silver paste for the low-silver-content crystalline silicon solar battery. The back silver paste is prepared by spherical silver coated copper powder for the low-silver-content crystalline silicon solar battery has the advantages that production cost of the paste is reduced, production burden of photovoltaic enterprises is alleviated, and requirements for weldability and adhesion force of the battery can be met.

Owner:NINGBO GUANGBO NEW NANOMATERIALS STOCK

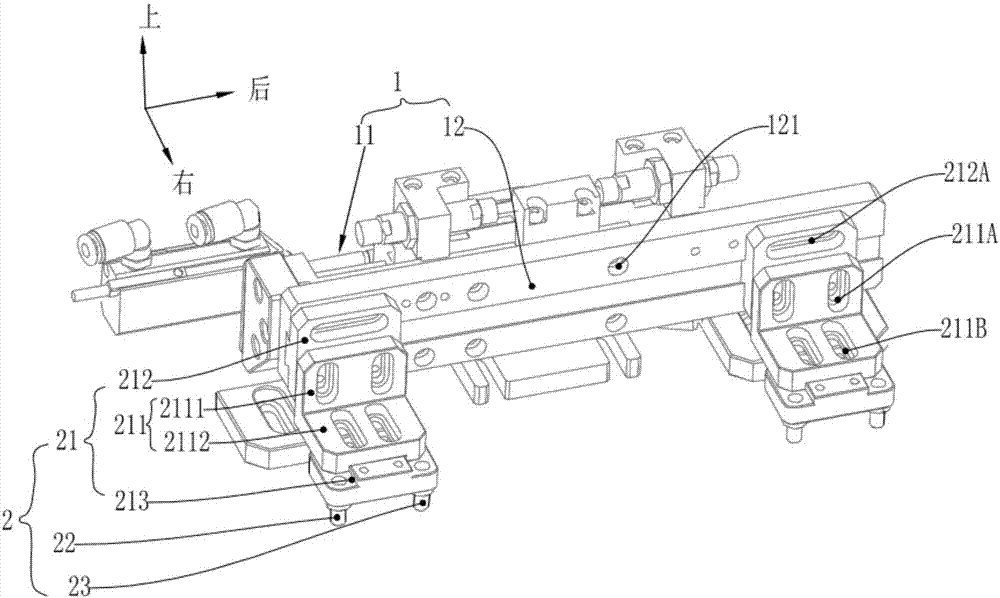

Clip pushing device of tool board and clip pushing system employing same

ActiveCN107454751AReduce production burdenReduce manufacturing costCircuit board tools positioningPCB positioning during processingEngineeringMechanical engineering

The invention relates to the technical field of electric component and part assembling and processing. The clip pushing device of a tool board includes an action assembly and a toggle assembly. The toggle assembly includes a mounting base, a first pin and a second pin. The first pin and the second pin are arranged on the front side and the rear side of the bottom part of the mounting base and are both arranged vertically downward. The distance between the first pin and the second pin is greater than the width of an action end of the toggle on the tool board. The action assembly is connected to the mounting base and is used for driving the toggle assembly to move back and forth. A clip pushing system employing the above clip pushing devices includes two clip pushing devices arranged opposite to each other in a spaced manner.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Method for Calculating the Concentration of Interfering Elements from the Measured Intensities of Elements

ActiveCN103592226BImprove accuracyImprove analysis accuracyColor/spectral properties measurementsUltimate tensile strengthPhysics

Owner:TIANJIN JINGLIWEI SCI & TECH

Technique for producing anti-acid pipeline steel by RH-LF-VD refining

InactiveCN102719728BReduce production burdenReduce oxidationManufacturing convertersProcess efficiency improvementMolten steelDecarburization

Owner:UNIV OF SCI & TECH BEIJING

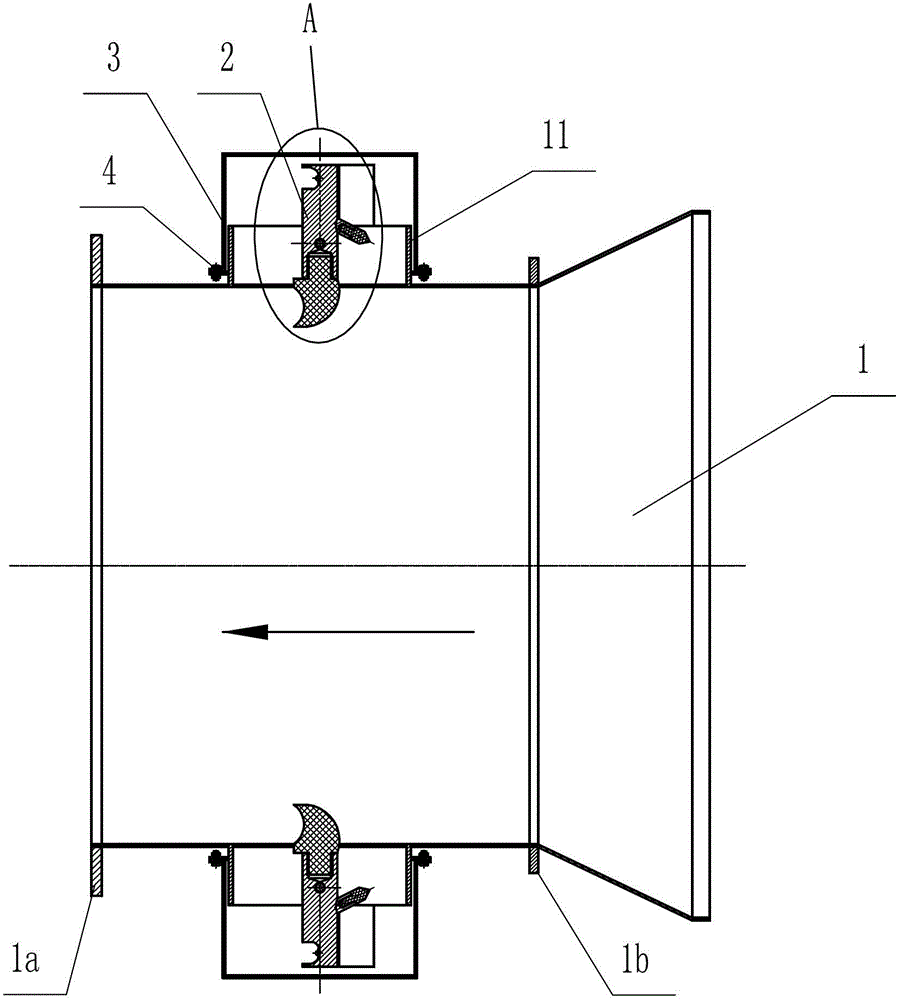

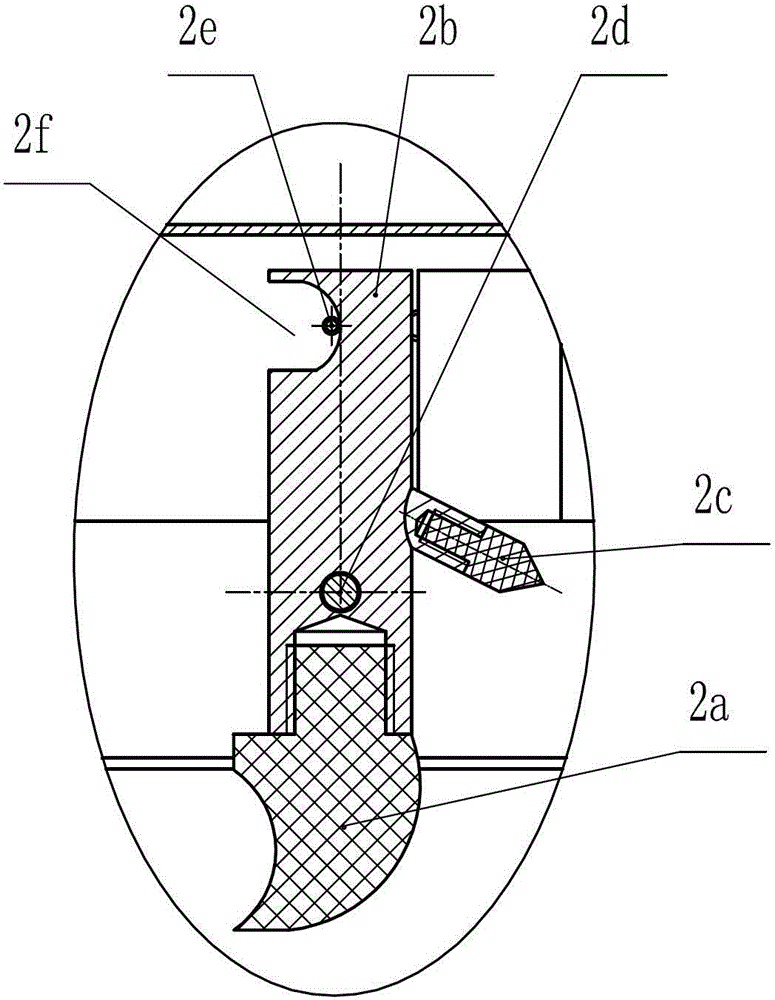

Automatic control device for extending and retracting framework air cylinder

ActiveCN103321668BAchieve recoveryReduce production burdenDust removalFire preventionAutomatic controlUltimate tensile strength

The invention discloses an automatic control device for extending and retracting a framework air cylinder. The automatic control device comprises a cylindrical guide device (1) with a horn mouth. A flange plate (1a) is disposed at the left end of the guide device (1). A control lock support part (11) and a detachable control lock protecting shell (3) are welded outside the side wall of the guide device (1). The detachable control lock protecting shell (3) covering a control lock component (2) is connected with the control lock support part (11) through bolts. By the automatic control device, traditional manual framework air cylinder extending and retracting is replaced by automatic framework air cylinder extending and retracting, work intensity of workers is relieved greatly, and work efficiency is increased.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Modifying method of vanadium catalyst for preparing sulfuric acid through sulfur dioxide

ActiveCN110052262ALow costReduce production burdenSulfur compoundsMetal/metal-oxides/metal-hydroxide catalystsSulfur dioxideSulfuric acid

The invention discloses a modifying method of a vanadium catalyst for preparing sulfuric acid through sulfur dioxide. The method includes: combining Pr doping with a hydrothermal process to modify thevanadium catalyst. The method has the advantages that the method is low in modifying cost, nontoxic and harmless in modifying process and conducive to large-scale production, and the vanadium catalyst after being modified is high in catalytic activity.

Owner:GUIZHOU UNIV

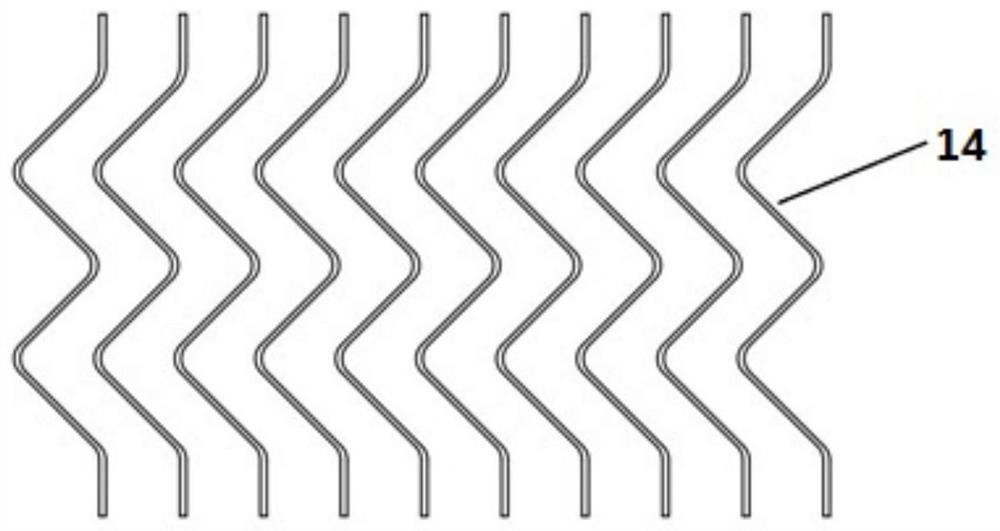

Belt cleaning device, belt conveyor

The invention provides a belt cleaning device and a belt conveyor. The belt conveyor comprises a the belt cleaning device; the belt cleaning device comprises a scraper (14), a supporting plate (1) and a pressing plate; the scraper (14) is placed on the supporting plate (1); support plates (2) are separately arranged at two ends of the supporting plate (1); two ends of the pressing plate (5) are rotationally connected with the corresponding support plates (2); one side of the pressing plate (5) is used for propping against a propping side of the scraper (14); and the scraper (14) is pressed and fixed between the pressing plate and the supporting plate (1). The scraper of the belt cleaning device provided by the invention is more convenient to mount and dismount. In addition, according to the belt conveyor provided by the invention, the utilization rate of the scraper can be improved, and material spare expenses of enterprises are effectively reduced, thereby reducing the production burden.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com