Ceramic tile structure with concave-convex textures and manufacturing process thereof

A technology of concave-convex texture and ceramic tile, applied in the field of ceramic tile structure and its production process, can solve the problems of mismatched design texture, long R&D and manufacturing cycle, shortened life of rubber roller, etc., so as to reduce production cost, reduce use limitation, and improve production The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

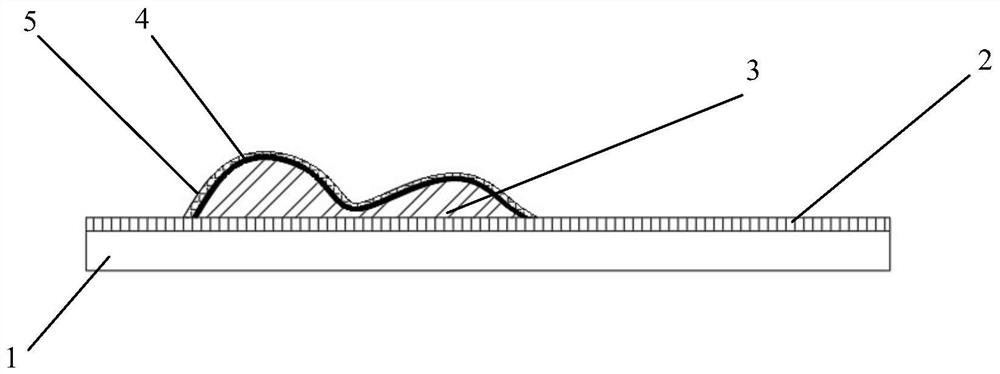

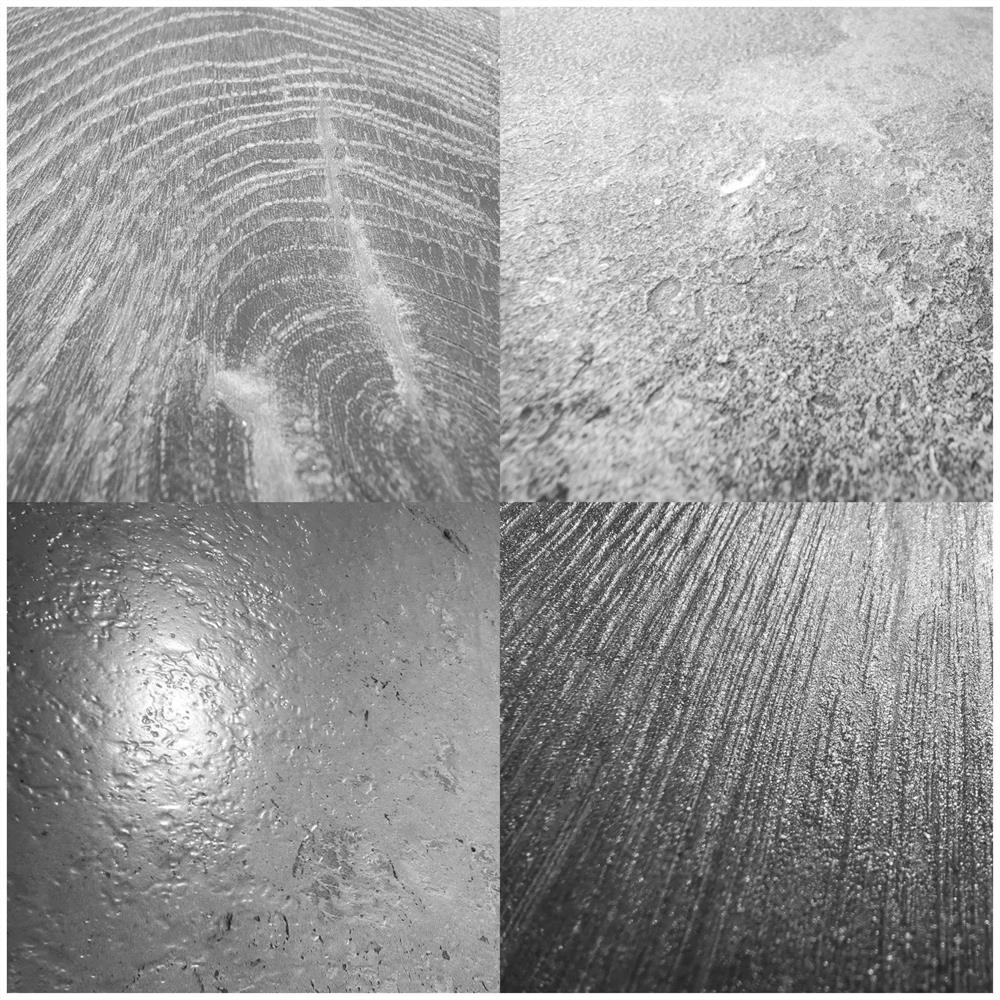

[0039] Embodiment one: see Figure 1~3 As shown, a ceramic tile structure with a concave-convex texture includes a ceramic tile body 1, on which a first glaze layer 2, a mold ink layer 3, and a second glaze layer are arranged sequentially from bottom to top. Layer 4 and colored ink layer 5, the distribution path of the mold ink layer 3 matches the designed pattern, the distribution position of the second glaze layer 4 and the colored ink layer 5 is adapted to the position of the mold ink layer 3 , forming a relief pattern on the surface of the ceramic tile body 1, the height of the relief pattern is between 1.5 mm and 2.0 mm.

[0040] In order to form some decorative surfaces with special effects, a surface effect layer may also be provided on the second glaze layer.

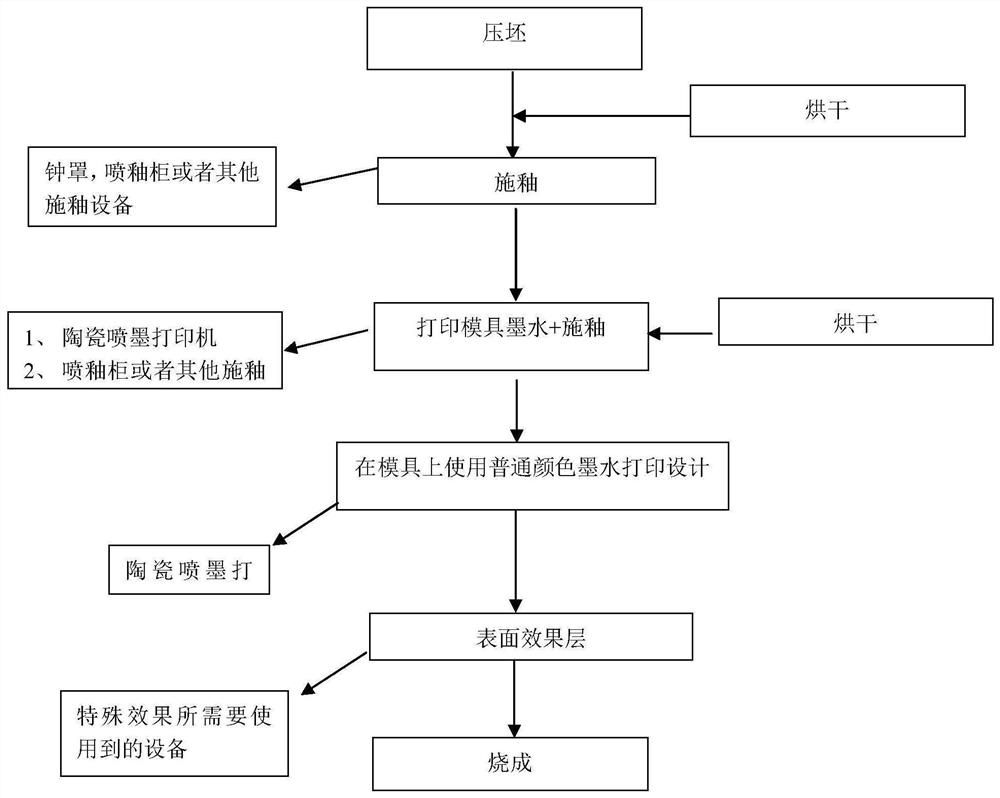

[0041] The specific manufacturing process includes the following steps:

[0042] ⑴ Make the ceramic tile body, cool to room temperature after drying;

[0043] (2) Glazing the ceramic tile body through glazing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com