Clip pushing device of tool board and clip pushing system employing same

A technology for pushing devices and fixture boards, which is applied to the positioning of circuit board tools, PCB positioning during processing, and electrical components. It can solve the problems of increasing labor force, slowing down production efficiency, and low production efficiency, so as to speed up production efficiency. , Reduce production burden, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

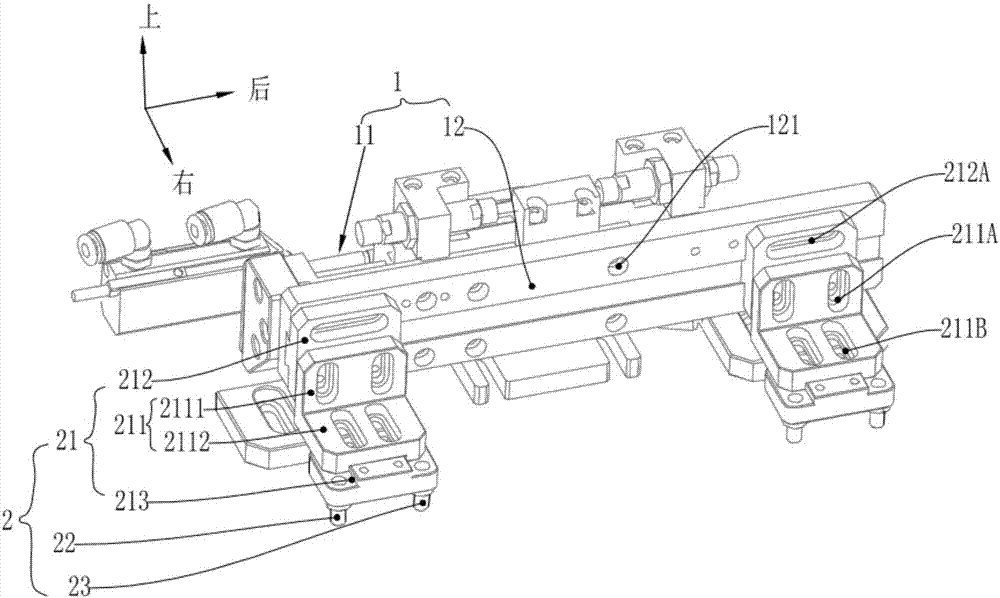

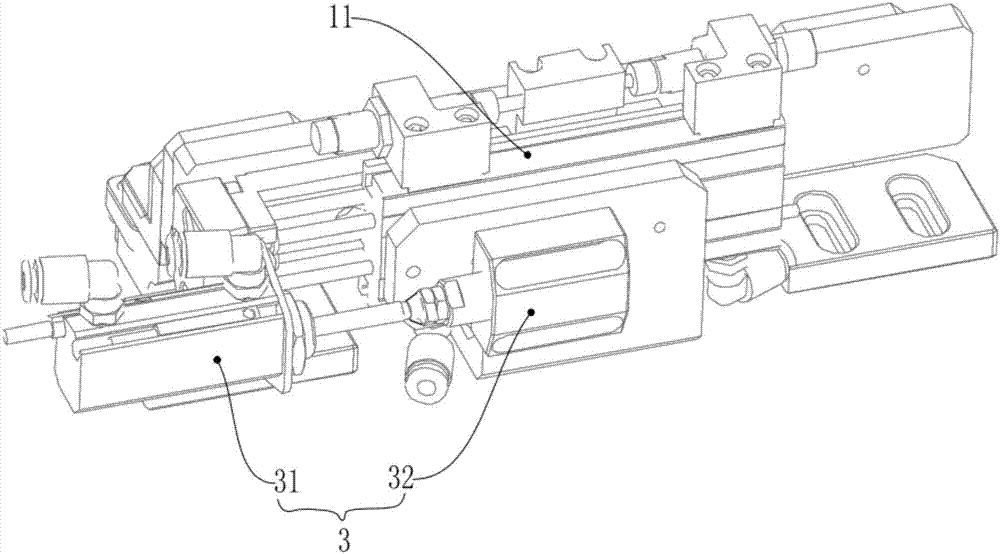

[0032] A buckle pushing device for a jig plate, comprising an action component 1 and a toggle component 2;

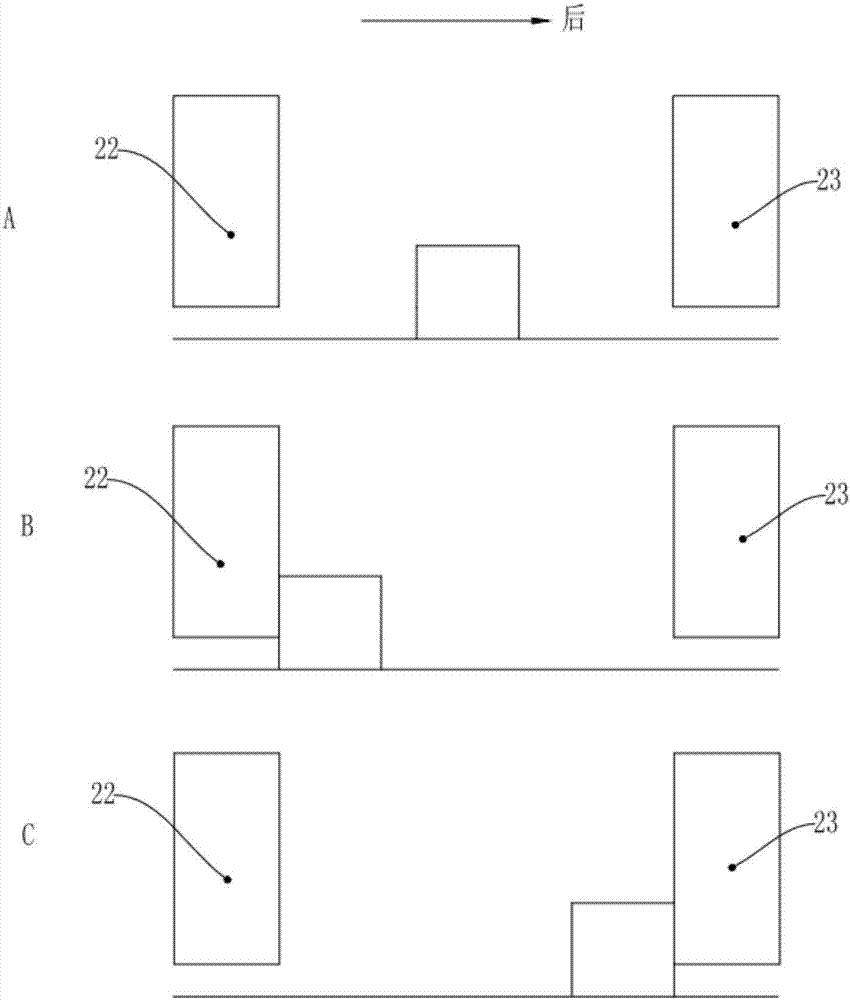

[0033] The buckle assembly 2 includes a mounting base 21, a first pin 22 and a second pin 23; the first pin 22 and the second pin 23 are respectively arranged on the front and rear sides of the bottom of the mounting base 21, and are vertically Straight down; the distance between the first pin 22 and the second pin 23 is greater than the width of the action end of the button on the jig plate;

[0034] The action component 1 is connected to the mounting base 21 for driving the button component 2 to move back and forth.

[0035] The width of the action end of the toggle on the jig board is the end that is in contact with the toggle assembly 2, and the other end is the end that limits the PCB c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com