Leachate membrane treatment method capable of reducing yield of concentrated solution

A technology of leachate and membrane treatment, applied in the direction of contaminated groundwater/leachate treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of large concentrate output, inability to fully consume economic benefits, and reduce membrane concentration Liquid production and other issues, to achieve the effect of reducing production burden, saving reverse osmosis membrane advanced treatment process, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

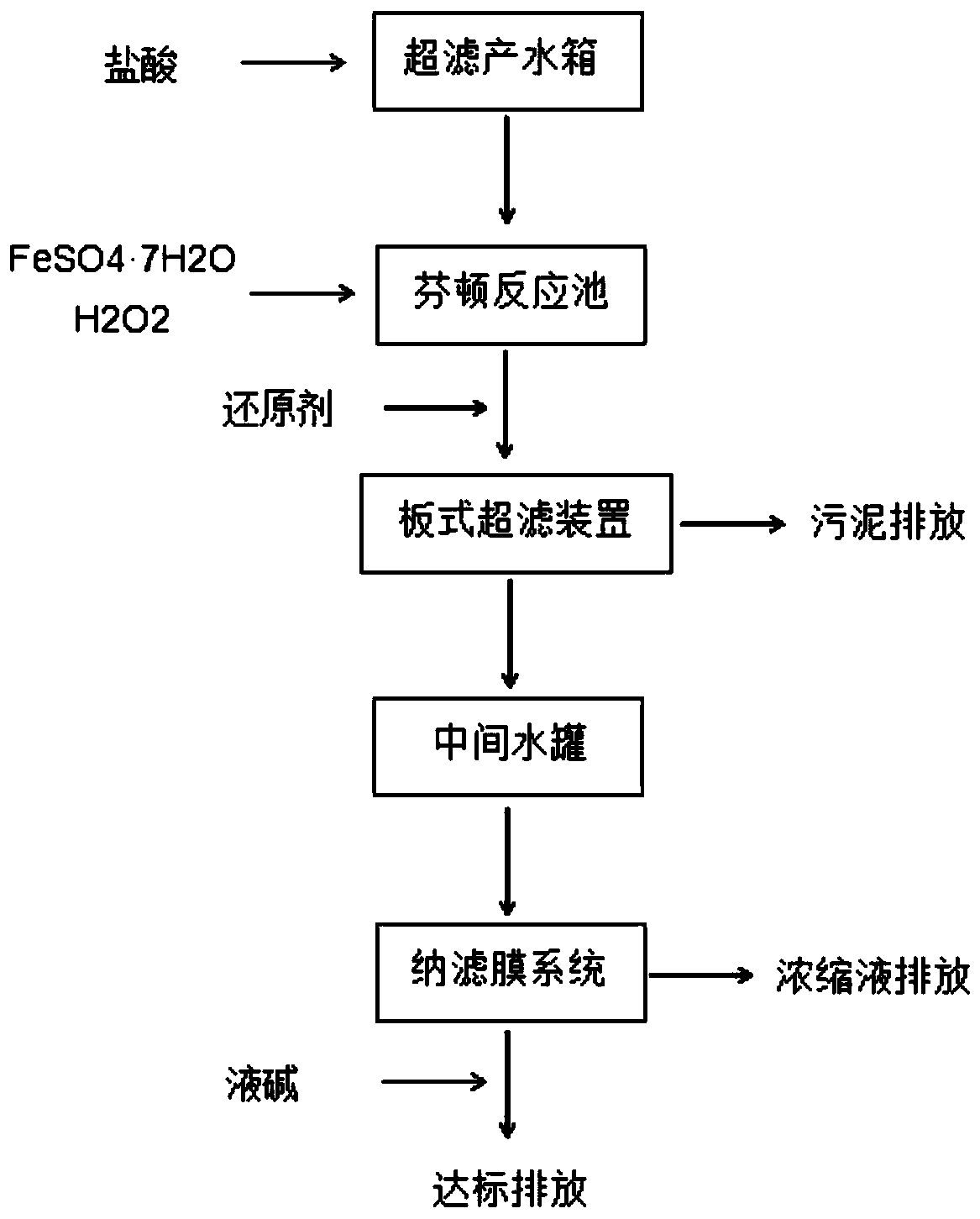

[0026] A leachate membrane treatment method that can reduce the concentrate output, it comprises the steps:

[0027] 1) After the ultrafiltration product water tank collects the ultrafiltration product water, according to the ultrafiltration product water volume and pH situation, add hydrochloric acid to adjust the pH value to between 4.5-5, and enter the next process after reaching the reaction conditions of the Fenton reaction;

[0028] 2) After receiving the ultrafiltration product water in the Fenton reaction tank, add ferrous sulfate and hydrogen peroxide to stir, wherein, the mass ratio of hydrogen peroxide dosage to ultrafiltration COD content is 1.2:1, and the dosage of ferrous sulfate is hydrogen peroxide The molar ratio of the dosage is 1:10, and the COD in the ultrafiltration product water is degraded from 500-600mg / L to below 200mg / L;

[0029] 3) It will have a greater oxidation effect on the subsequent plate ultrafiltration membrane and nanofiltration system. Ther...

Embodiment 2

[0031] A leachate membrane treatment method that can reduce the concentrate output, it comprises the steps:

[0032] 1) After the ultrafiltration product water tank collects the ultrafiltration product water, according to the ultrafiltration product water volume and pH situation, add hydrochloric acid to adjust the pH value to 3.5-4.5, and enter the next process after reaching the reaction conditions of the Fenton reaction;

[0033] 2) After receiving the ultrafiltration product water in the Fenton reaction tank, add ferrous sulfate and hydrogen peroxide to stir, wherein, the mass ratio of hydrogen peroxide dosage to ultrafiltration COD content is 1.3:1, and the dosage of ferrous sulfate is hydrogen peroxide The molar ratio of the dosage is 1:10, and the COD in the ultrafiltration product water is degraded from 500-600mg / L to below 200mg / L;

[0034] 3) It will have a greater oxidation effect on the subsequent plate ultrafiltration membrane and nanofiltration system. Therefore,...

Embodiment 3

[0036] A leachate membrane treatment method that can reduce the concentrate output, it comprises the steps:

[0037] 1) After the ultrafiltration product water tank collects the ultrafiltration product water, according to the ultrafiltration product water volume and pH situation, add hydrochloric acid to adjust the pH value to 2.5-3.5, and enter the next process after reaching the reaction conditions of the Fenton reaction;

[0038]2) After receiving the ultrafiltration product water in the Fenton reaction tank, add ferrous sulfate and hydrogen peroxide to stir, wherein, the mass ratio of hydrogen peroxide dosage to ultrafiltration COD content is 1.2:1, and the dosage of ferrous sulfate is hydrogen peroxide The molar ratio of the dosage is 1:10, and the COD in the ultrafiltration product water is degraded from 500-600mg / L to below 200mg / L;

[0039] 3) It will have a greater oxidation effect on the subsequent plate ultrafiltration membrane and nanofiltration system. Therefore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com