Patents

Literature

45results about How to "Avoid affecting subsequent processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing photoresist residues and semiconductor device manufacturing method

ActiveCN110391135AAvoid affecting subsequent processesAvoid problems affecting subsequent processesSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solventPhotoresist

The invention provides a method for removing photoresist residues and a semiconductor device manufacturing method. The method for removing photoresist residues comprises the steps that a wafer which comprises an intermediate region and an edge region surrounding the intermediate region is provided; a photoresist layer is formed on the intermediate region and the edge region of the wafer; at leasta hydrophilic organic solvent is coated on the photoresist layer in the edge region; and a de-edge process is used to remove the photoresist layer and the organic solvent in the edge region. Accordingto the technical scheme of the invention, the photoresist layer in the edge region of the wafer is completely removed, thereby preventing photoresist residues from affecting a subsequent process.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

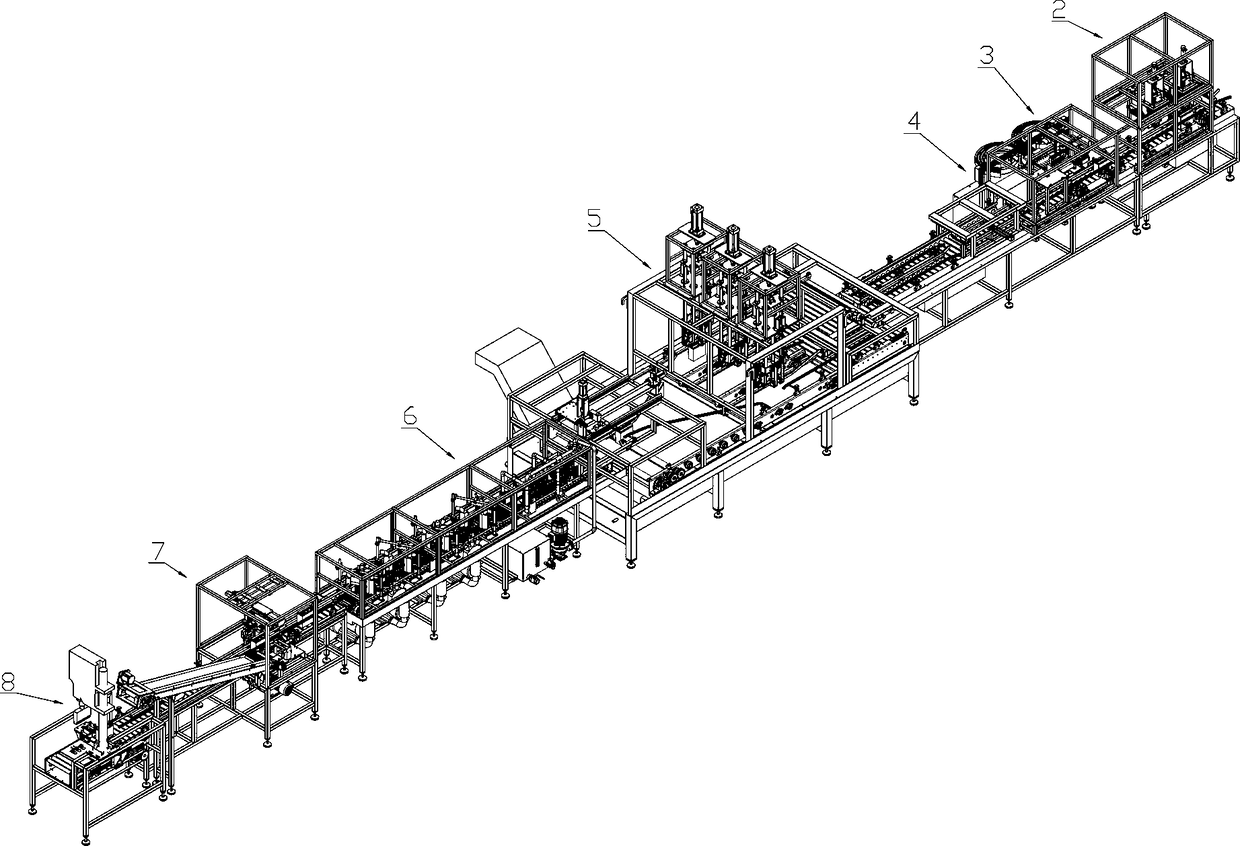

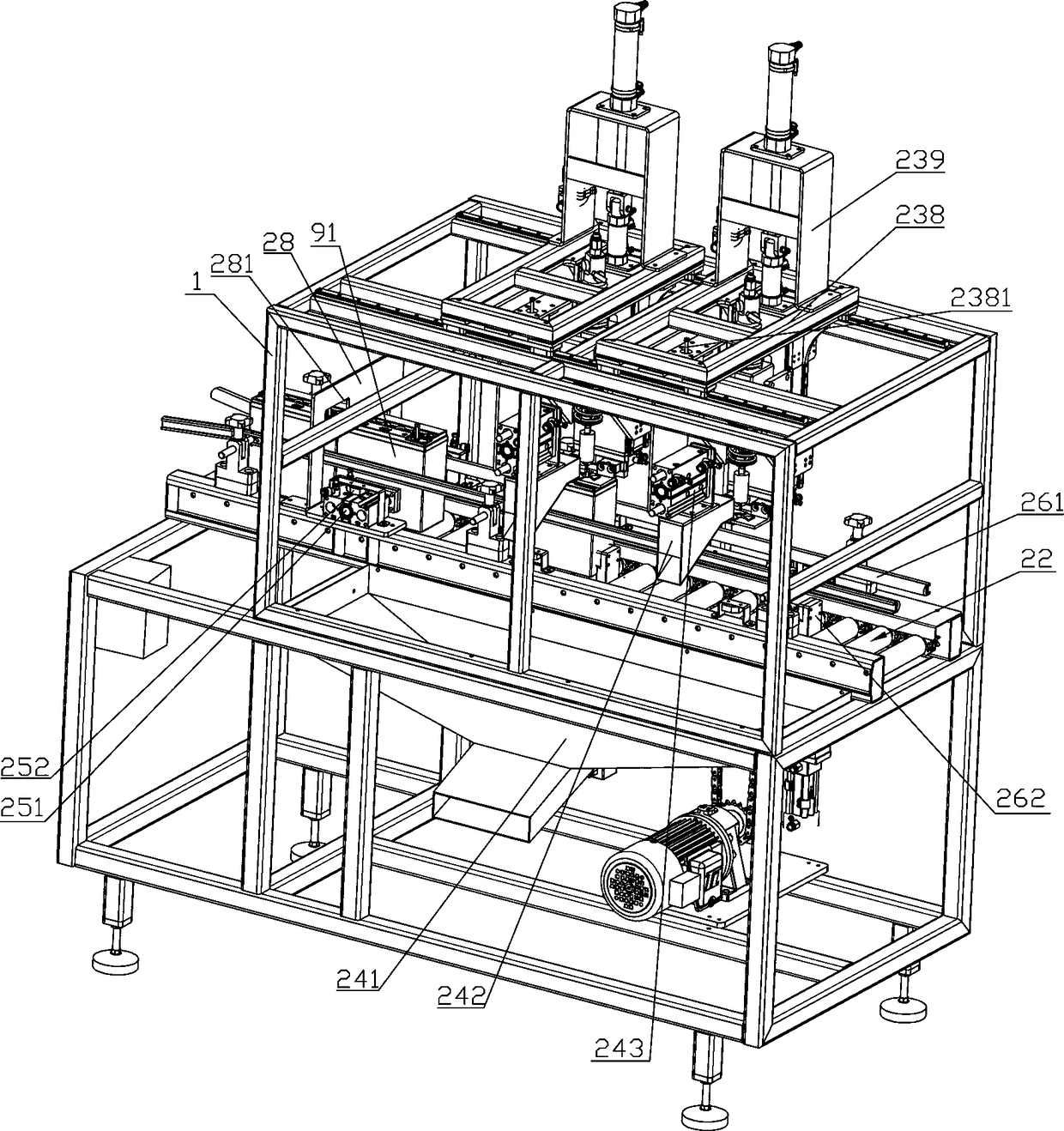

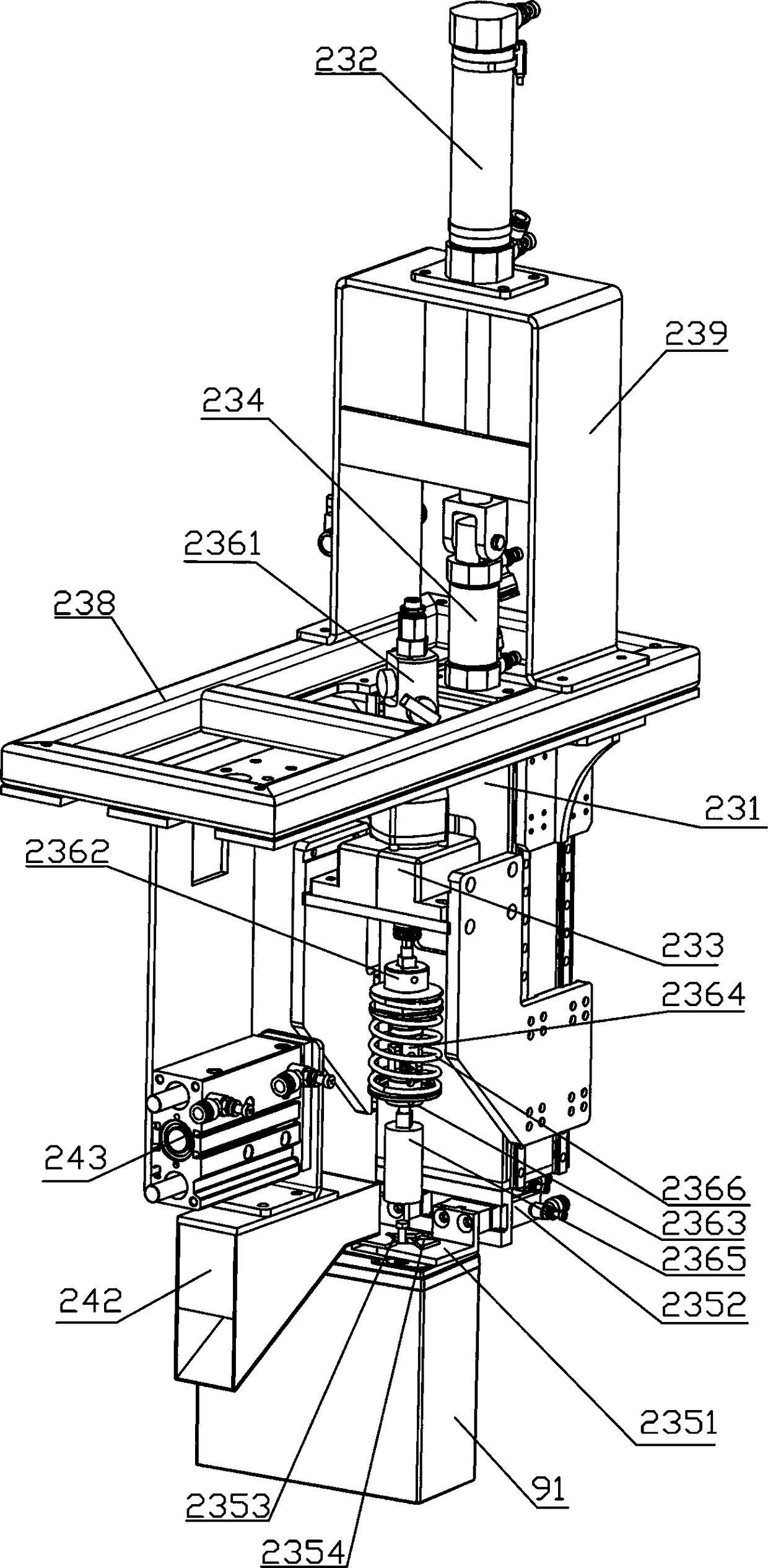

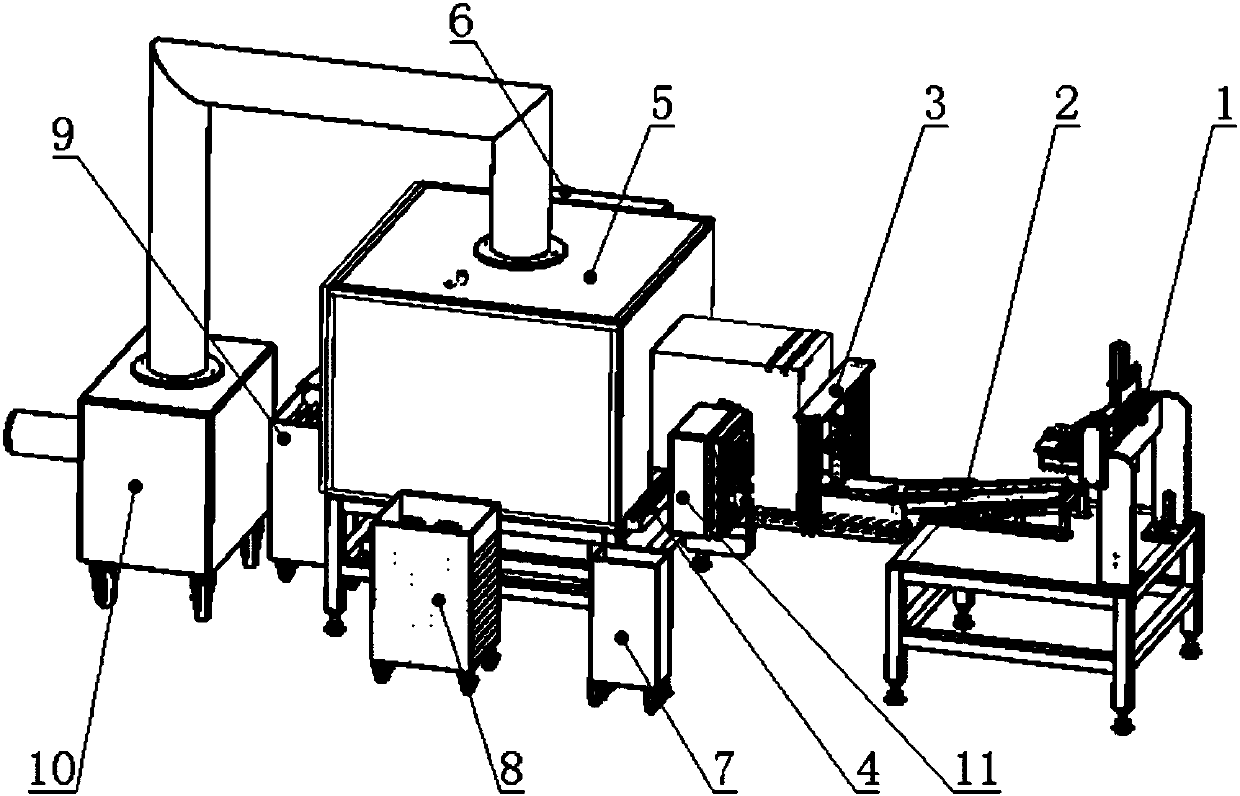

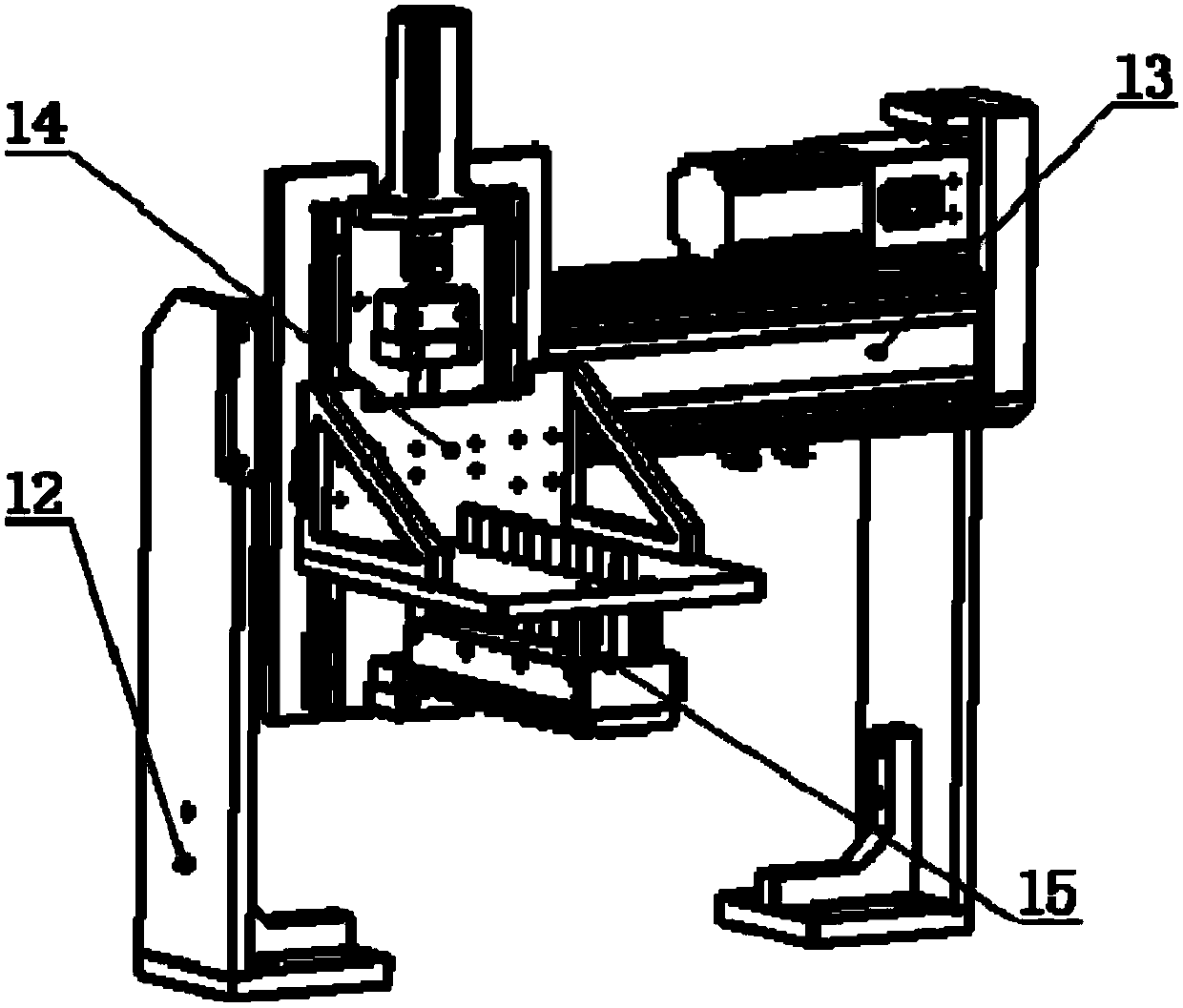

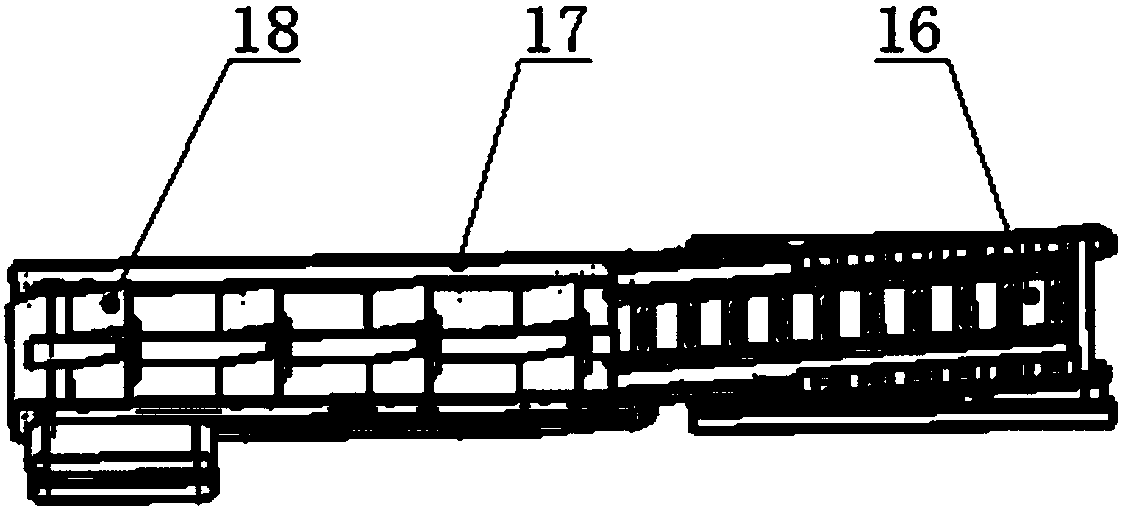

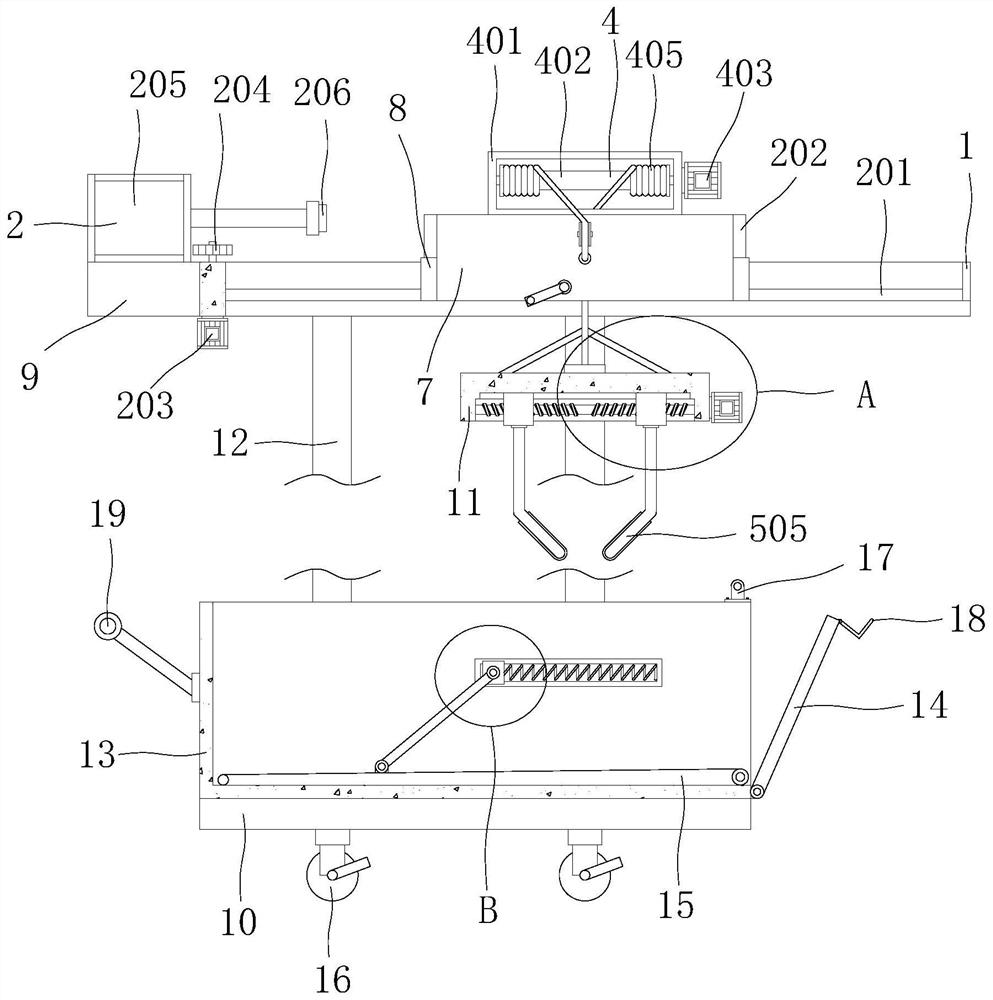

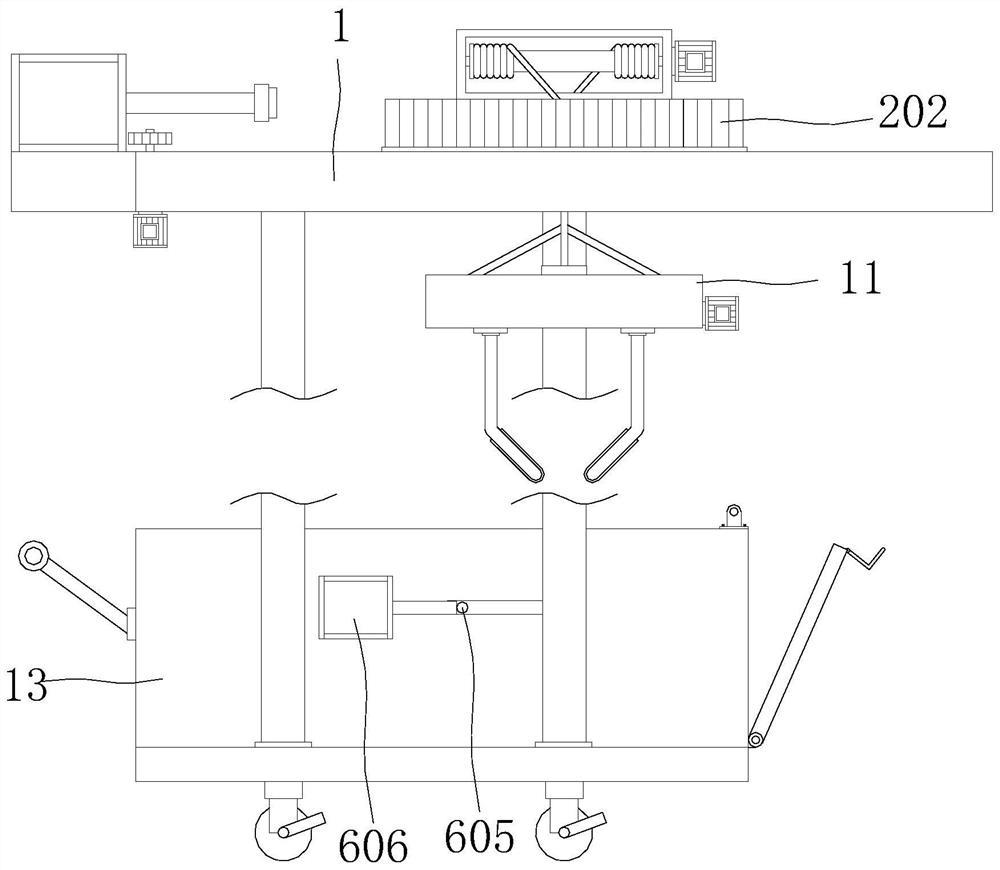

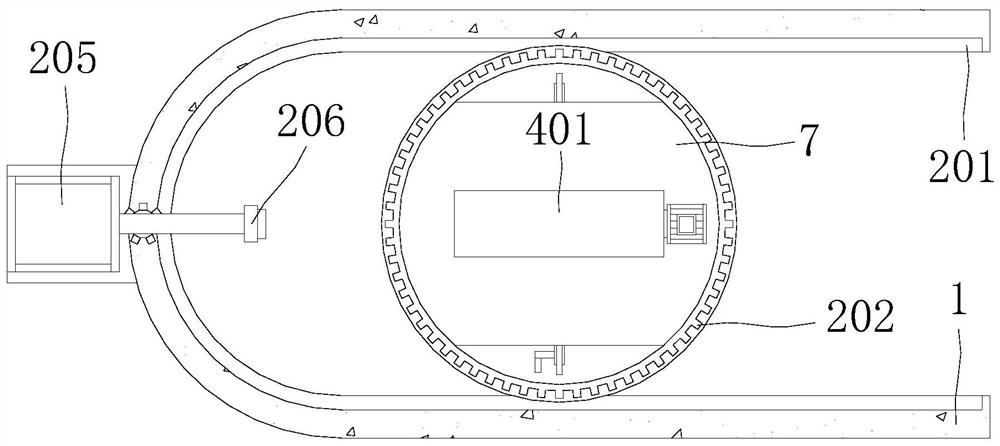

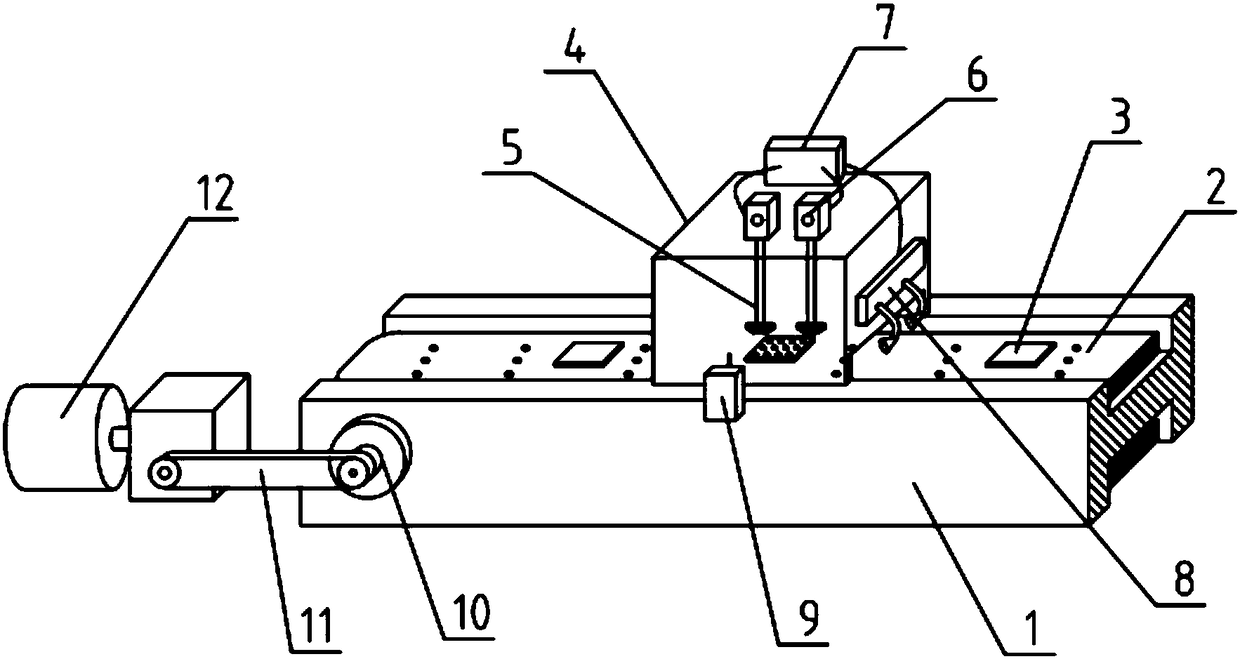

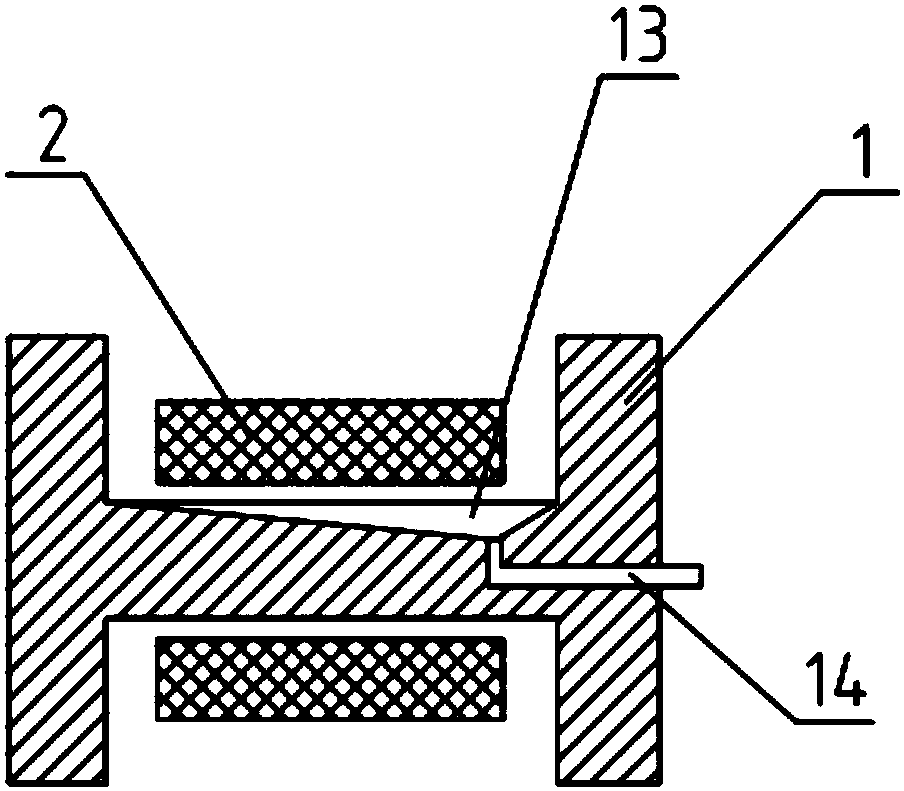

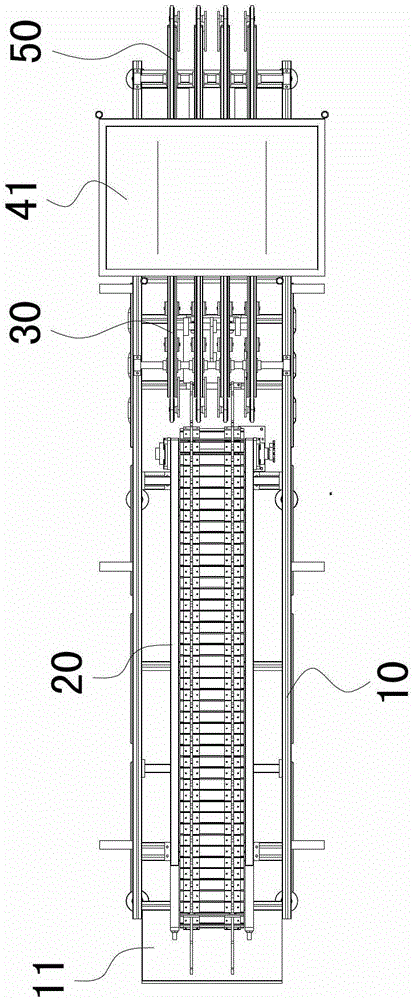

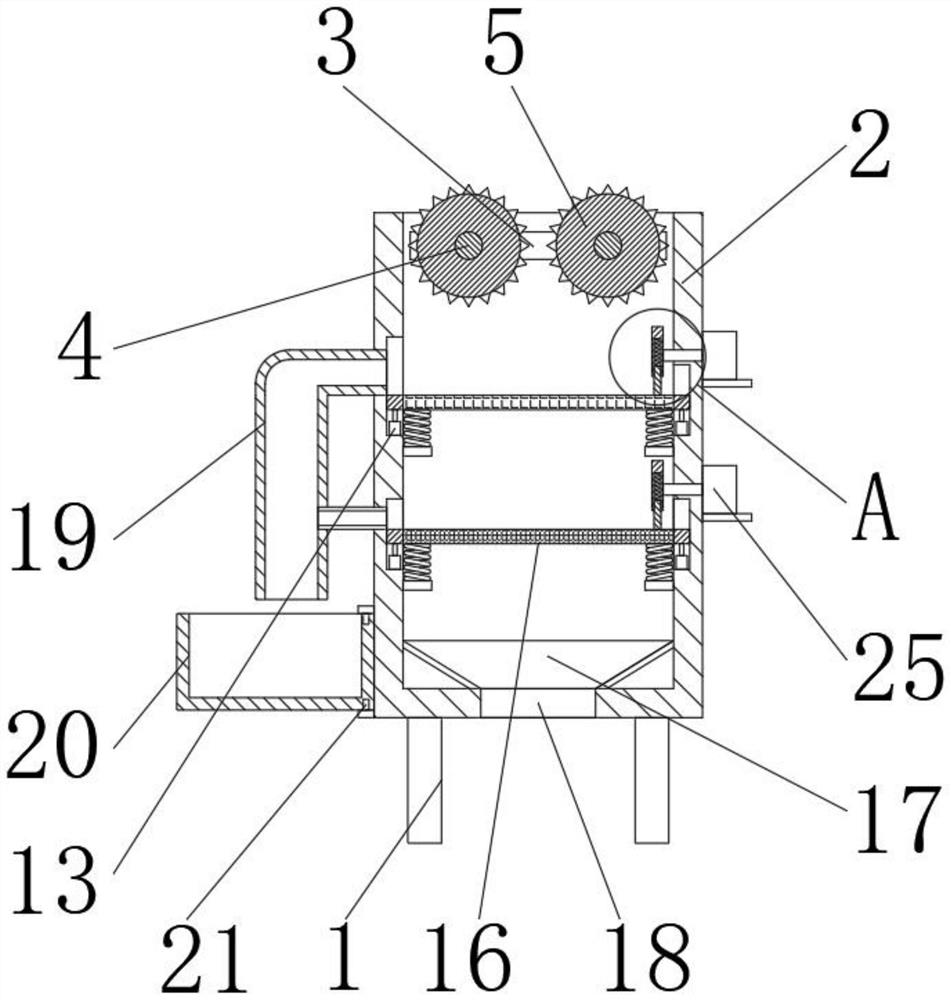

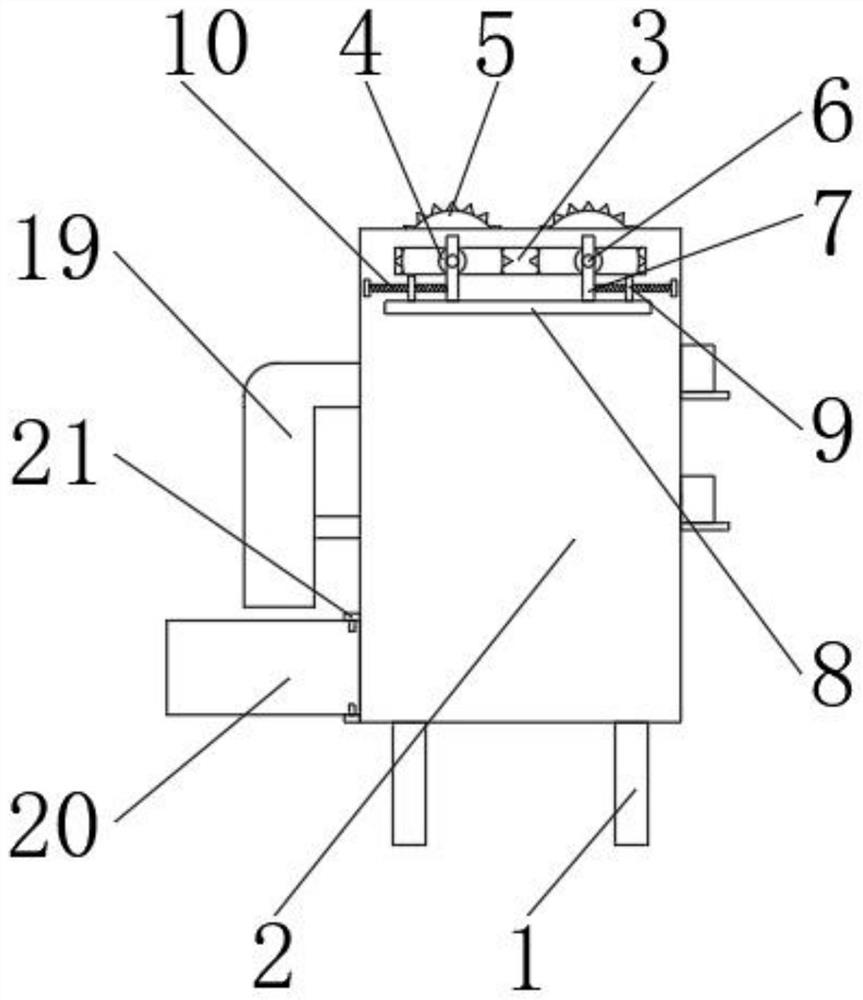

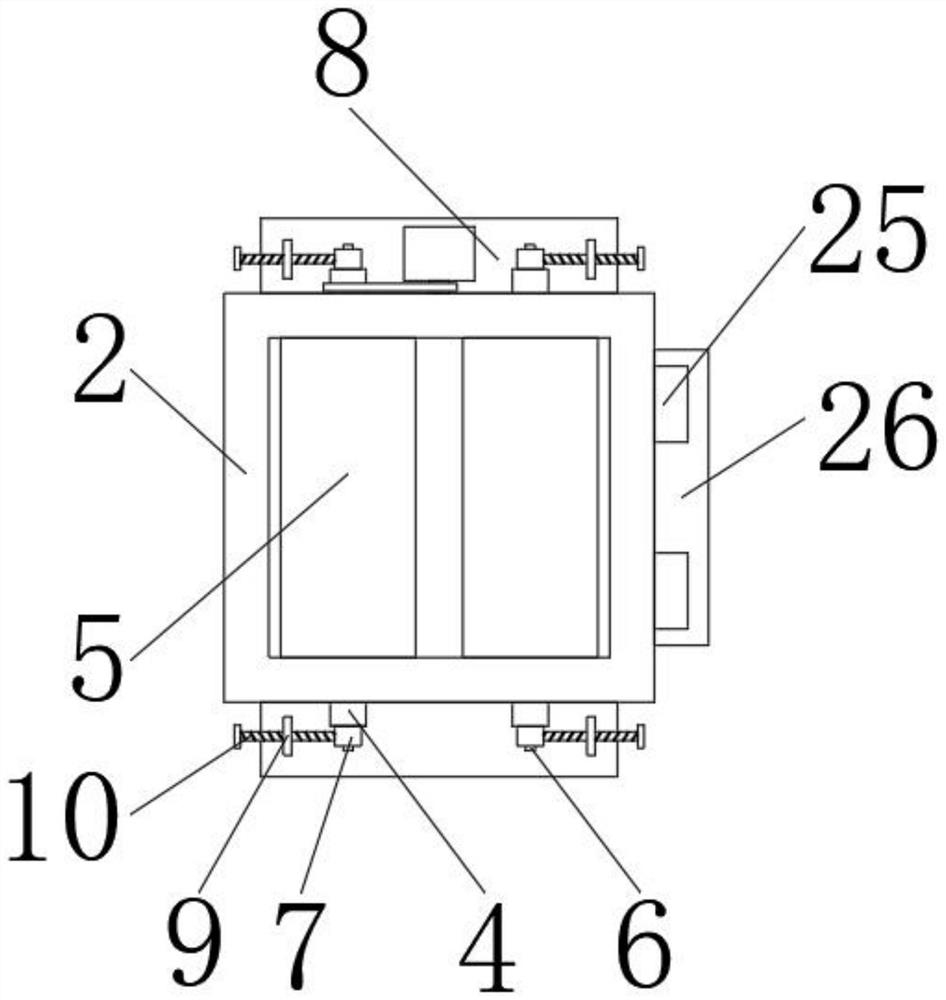

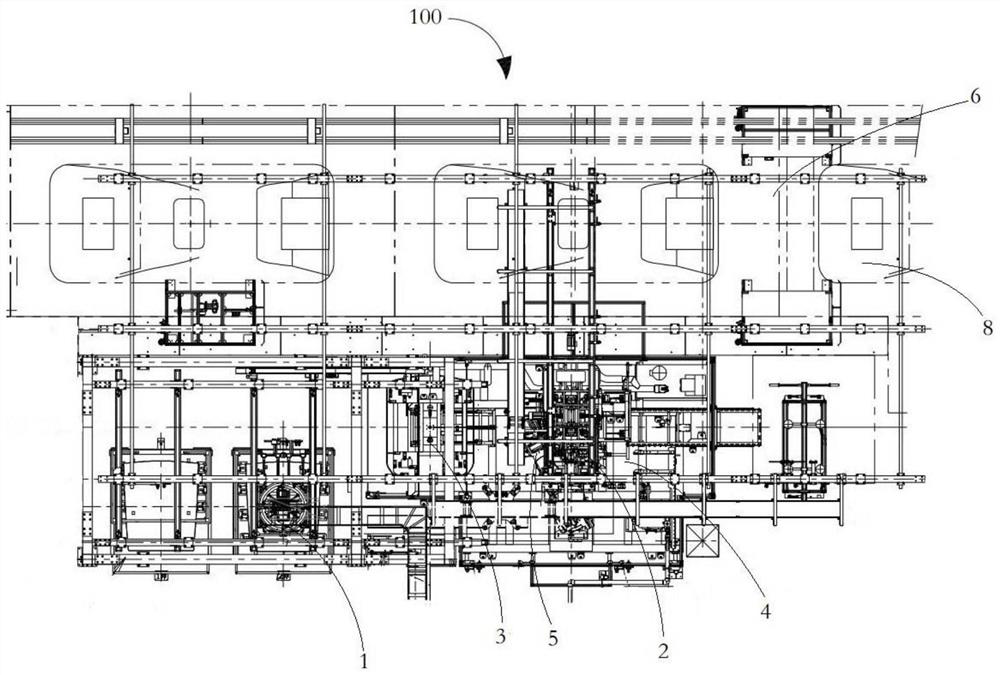

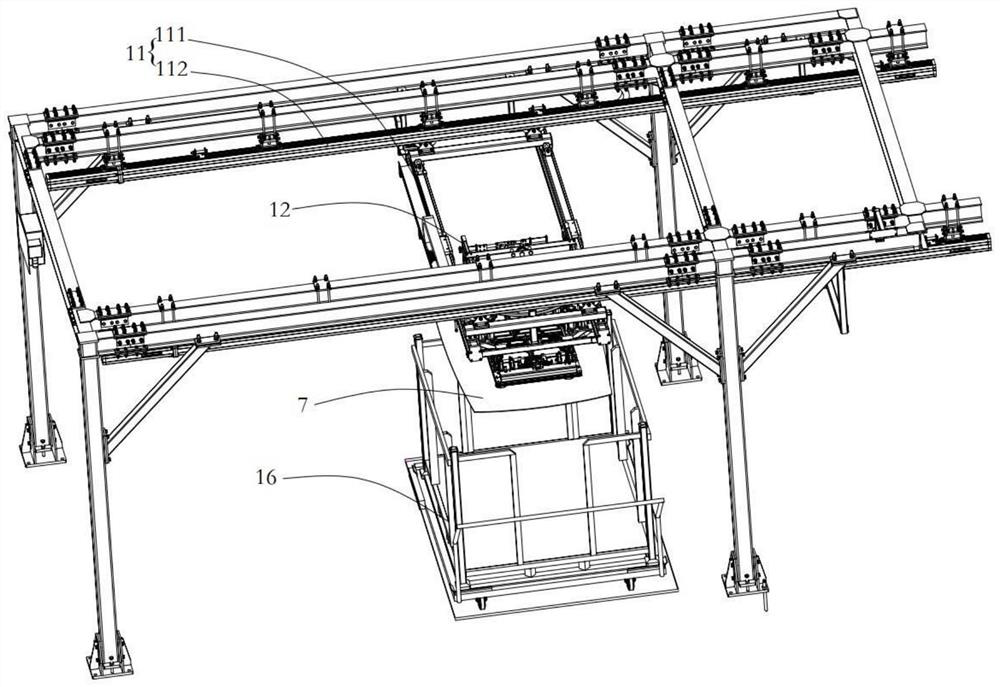

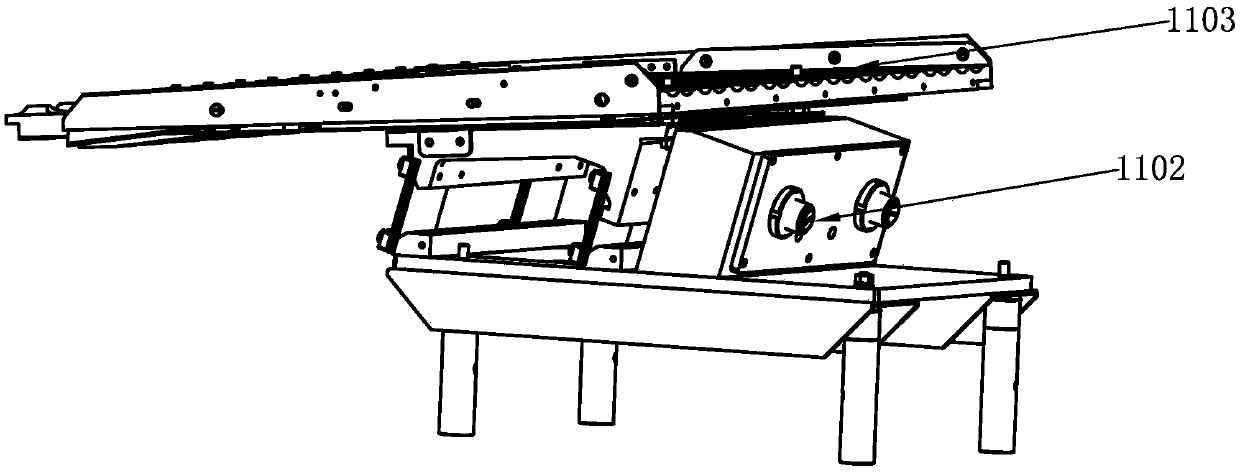

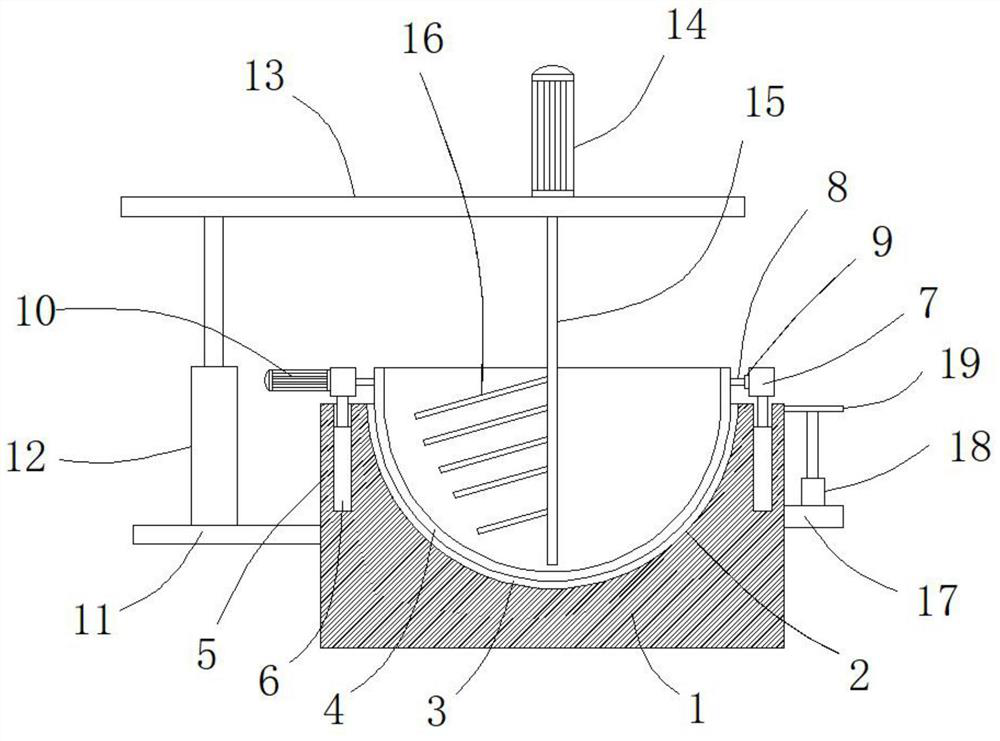

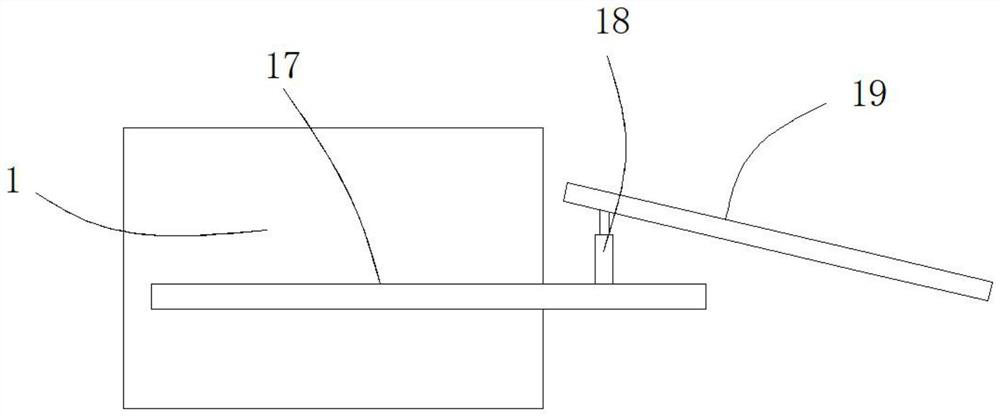

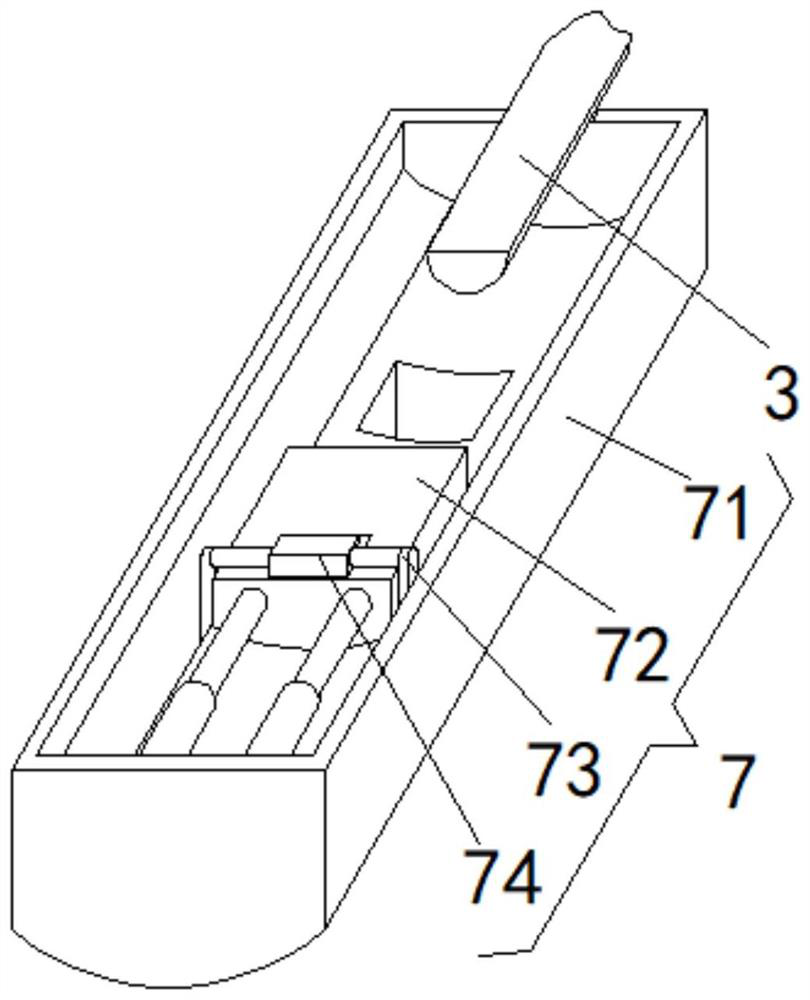

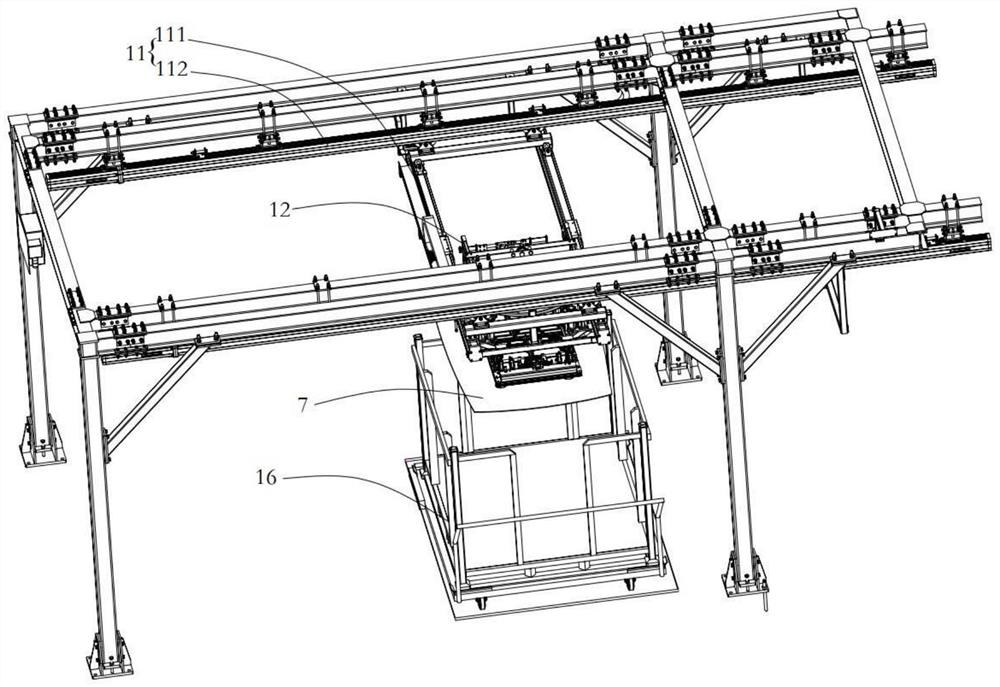

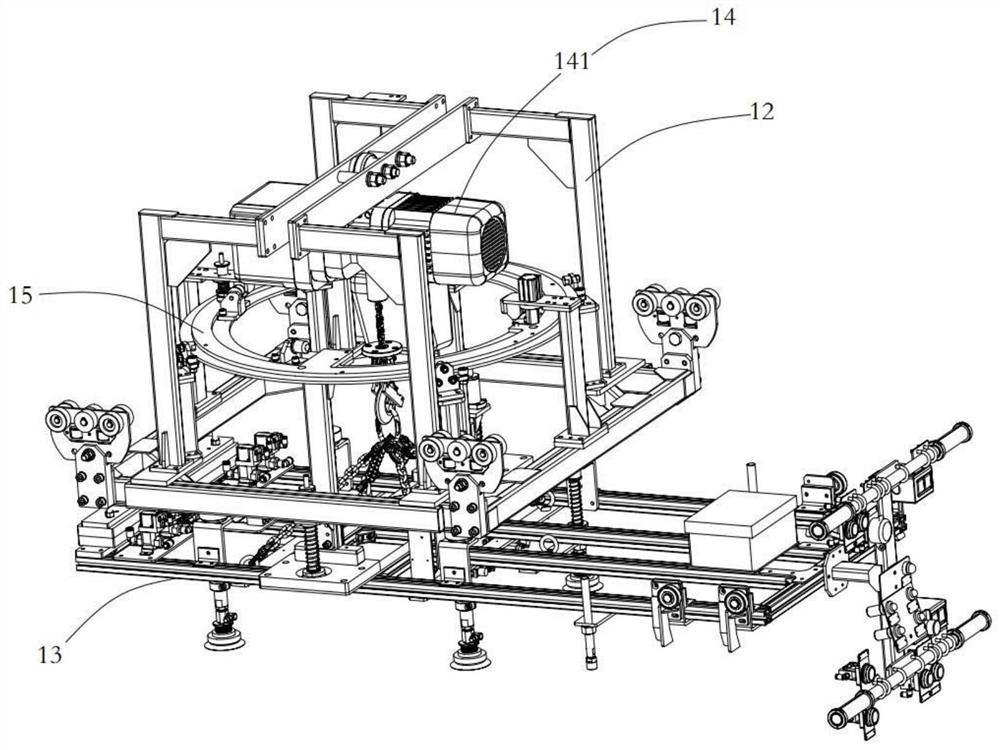

Storage battery pre-packaging treatment production line

PendingCN108736075AQuick washEasy to dryFinal product manufactureLead-acid accumulators constructionProduction lineCap device

The invention discloses a storage battery pre-packaging treatment production line which comprises a rack. A charging screw disassembling device, a cap device, a film tearing device, a cover plate covering device and a cover welding device are sequentially arranged on the rack from back to front. According to the storage battery pre-packaging treatment production line, two charging screws on a storage battery can be efficiently disassembled, each acid adding hole on the storage battery can be effectively covered with a sealing cap, whether the charging screws on the storage battery are disassembled and whether the sealing cap on each acid adding hole is covered well can be detected, after detection, an unqualified storage battery can also be sorted out to avoid influence of the unqualifiedstorage battery on the back-end processing, a protection film on the storage battery can be efficiently torn, the storage battery can also be rapidly cleaned and air-dried, a cover plate groove on thestorage battery can be efficiently covered with a cover plate, and the covered cover plate can also be welded in the cover plate groove, so that labor cost of storage battery pre-packaging treatmentis greatly reduced, and working efficiency is also greatly improved.

Owner:江苏云天高胜机器人科技有限公司

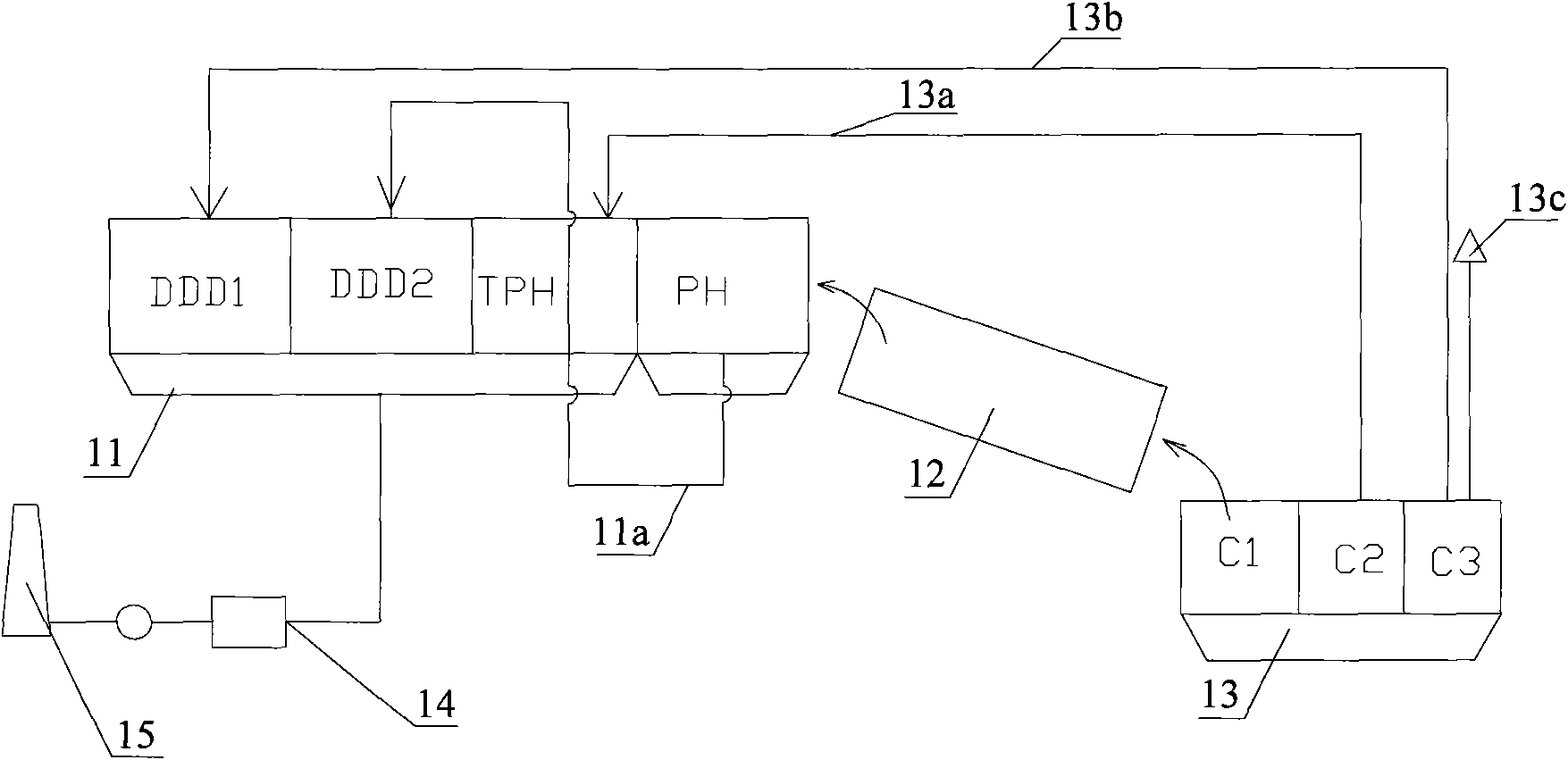

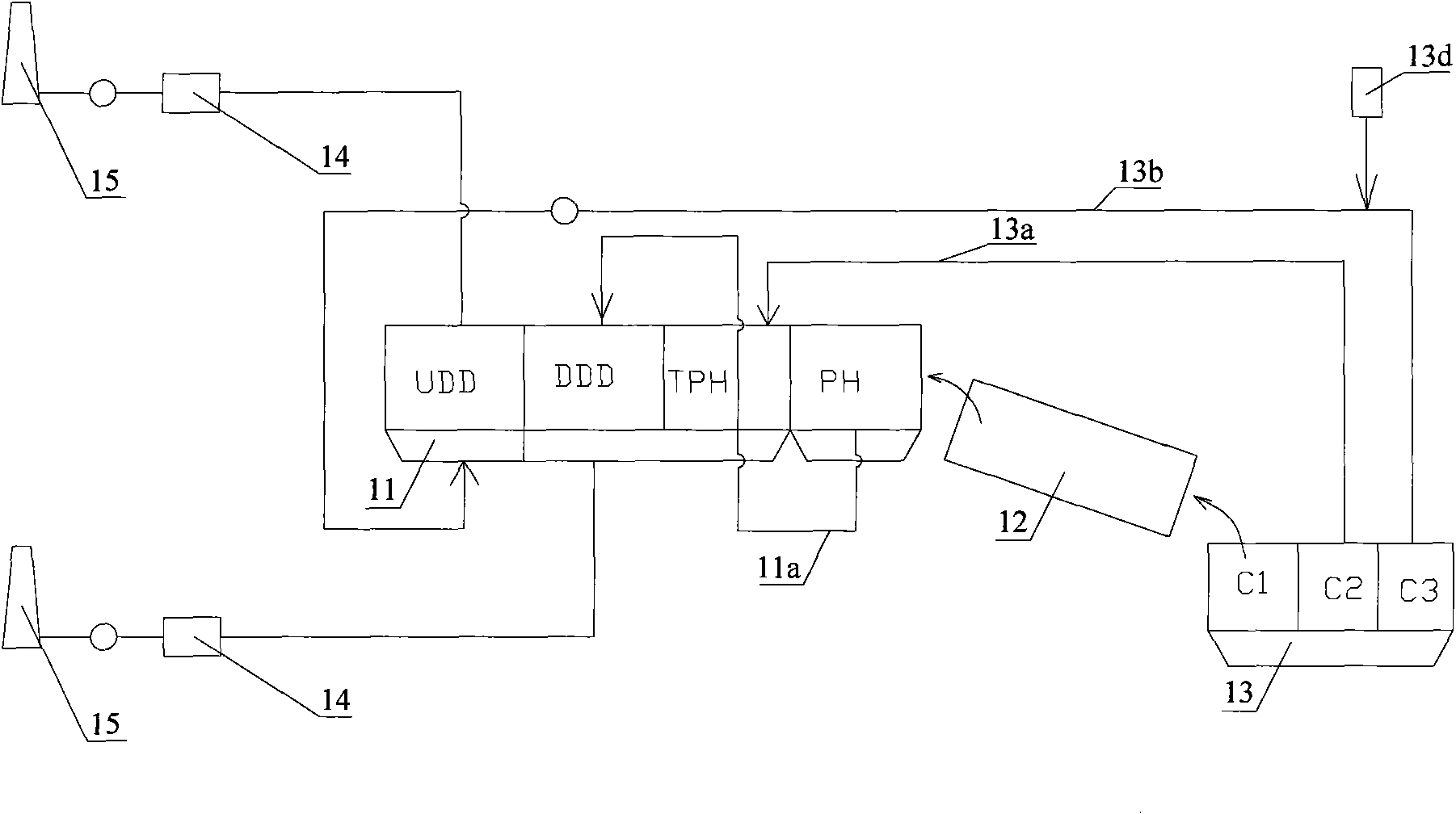

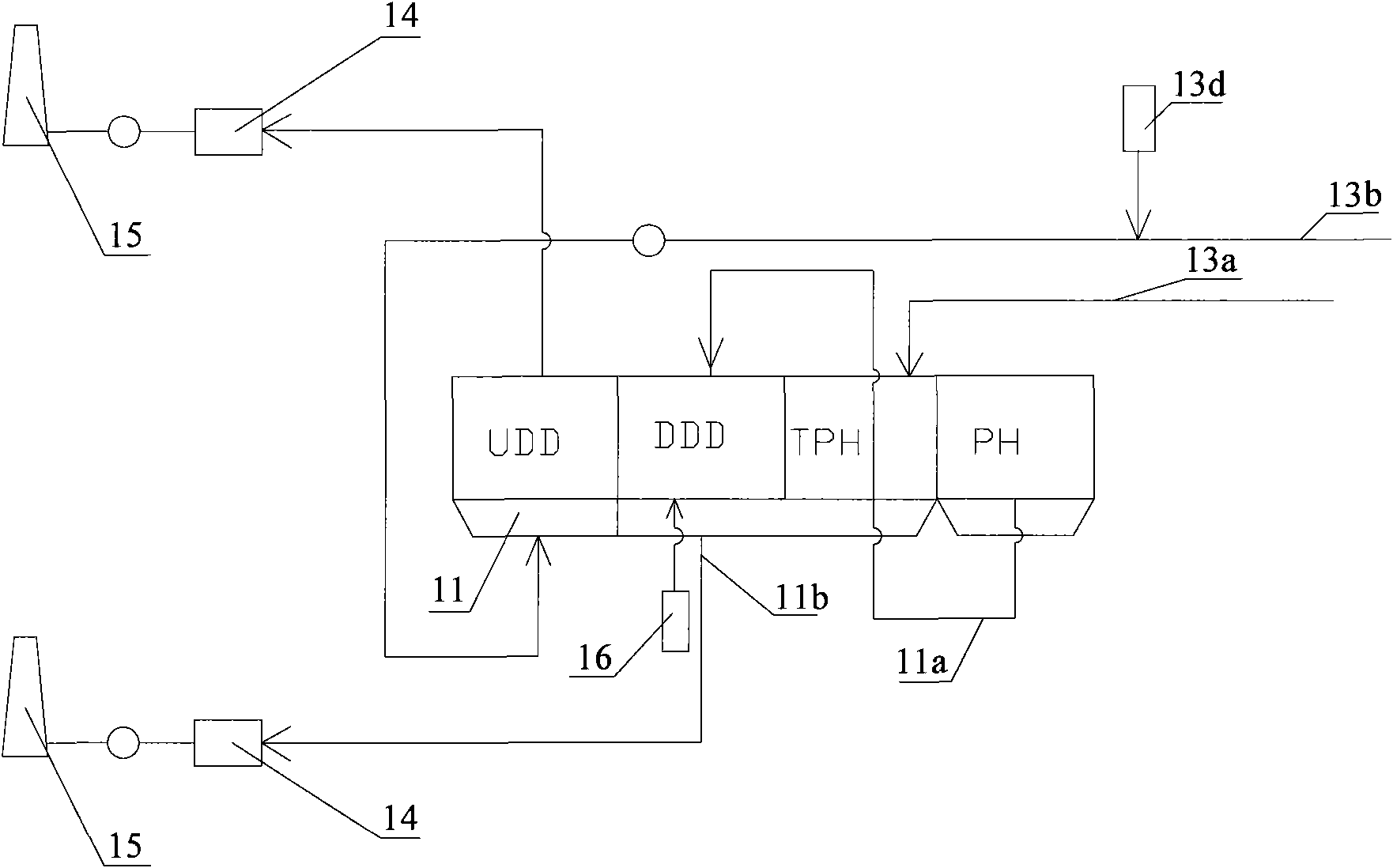

Pre-heating method of sulfate slag pellet ore

The invention provides a pre-heating method of sulfate slag pellet ore. The method comprises the steps of: sending sulfate slag green pellets into a chain grate for to be subject to forced air drying,draft air drying, primary pre-heating and secondary pre-heating in sequence; taking the fume discharged by a rotary kiln as the hot air source during the secondary pre-heating; taking the fume discharged by secondary cooling of a cooler as the hot air source during the primary pre-heating; taking the fume discharged after secondary pre-heating as the hot air source during the draft air drying; and taking the fume discharged by tertiary cooling of the cooler as the hot air source during the forced air drying. The invention firstly carrying out forced air drying on the sulfate slag pellets, when the moisture of the green pellets move upwards from the bottom of the material layer, thus preventing an overdamp layer from being formed on the bottom layer of the material layer, avoiding the appearance of flattened or cracked green pellets on the bottom of the material layer and ensuring the following procedures to be carried out smoothly.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

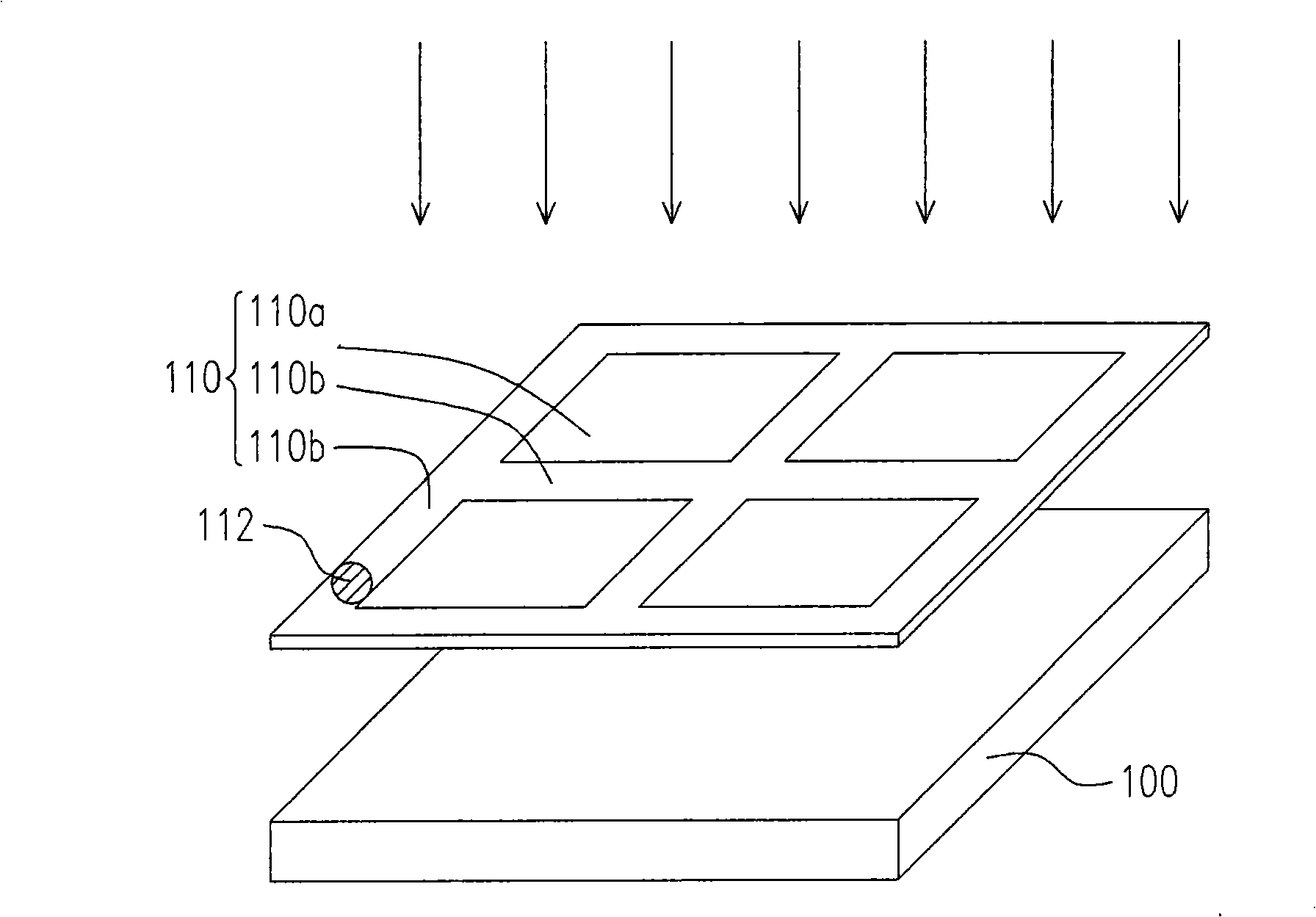

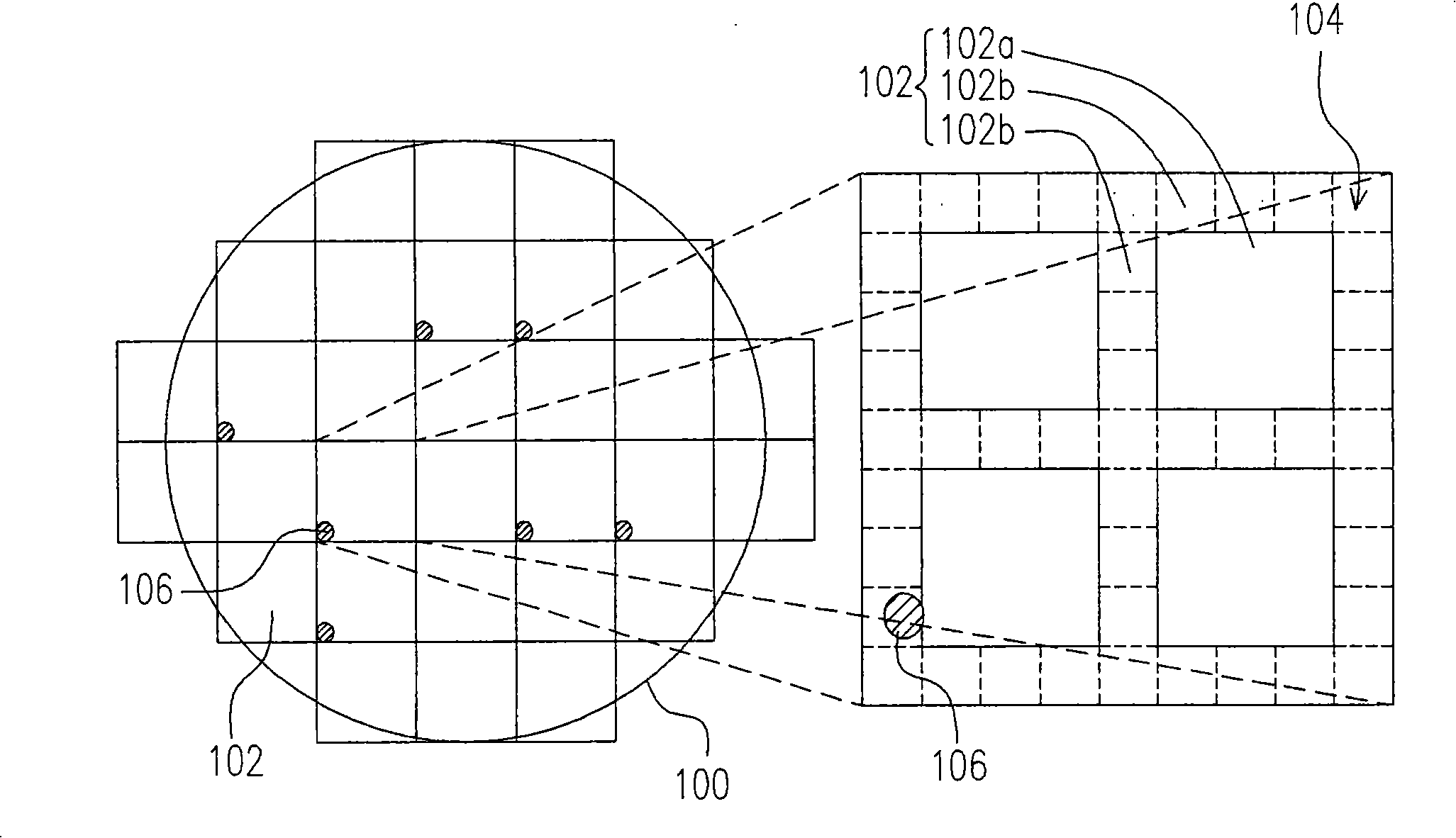

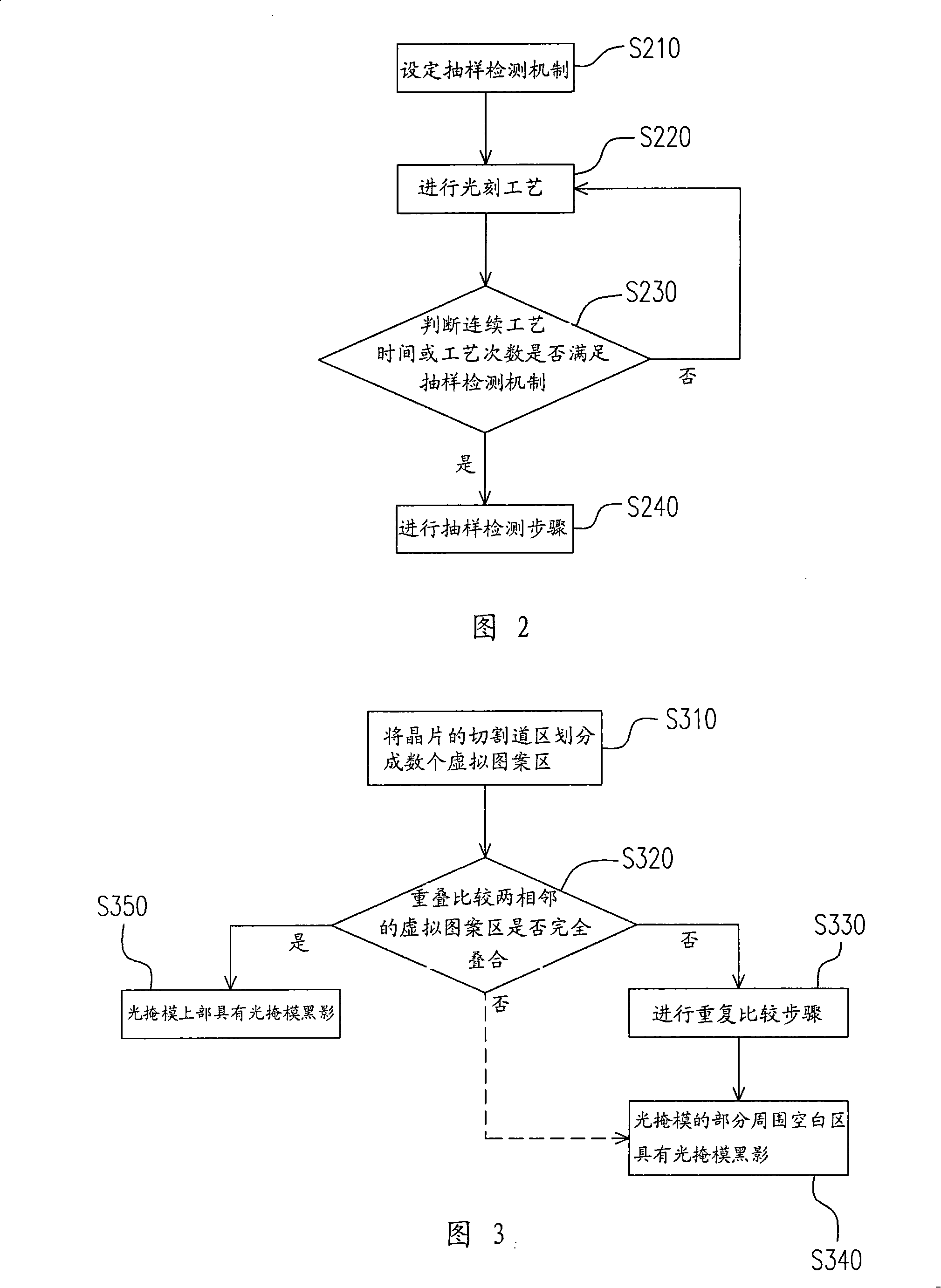

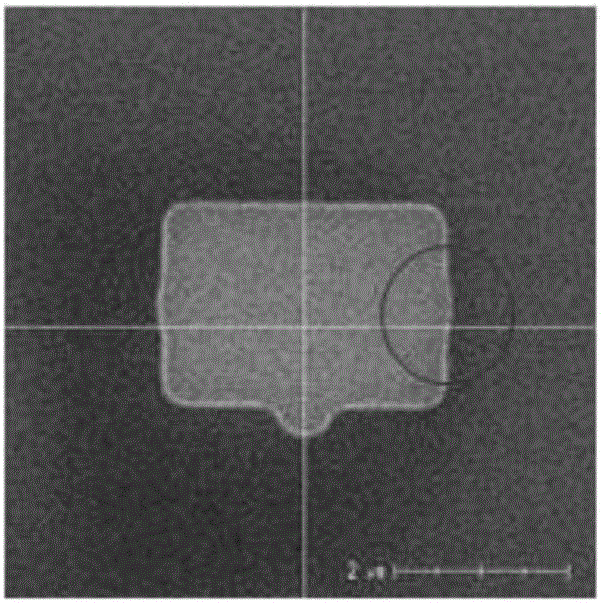

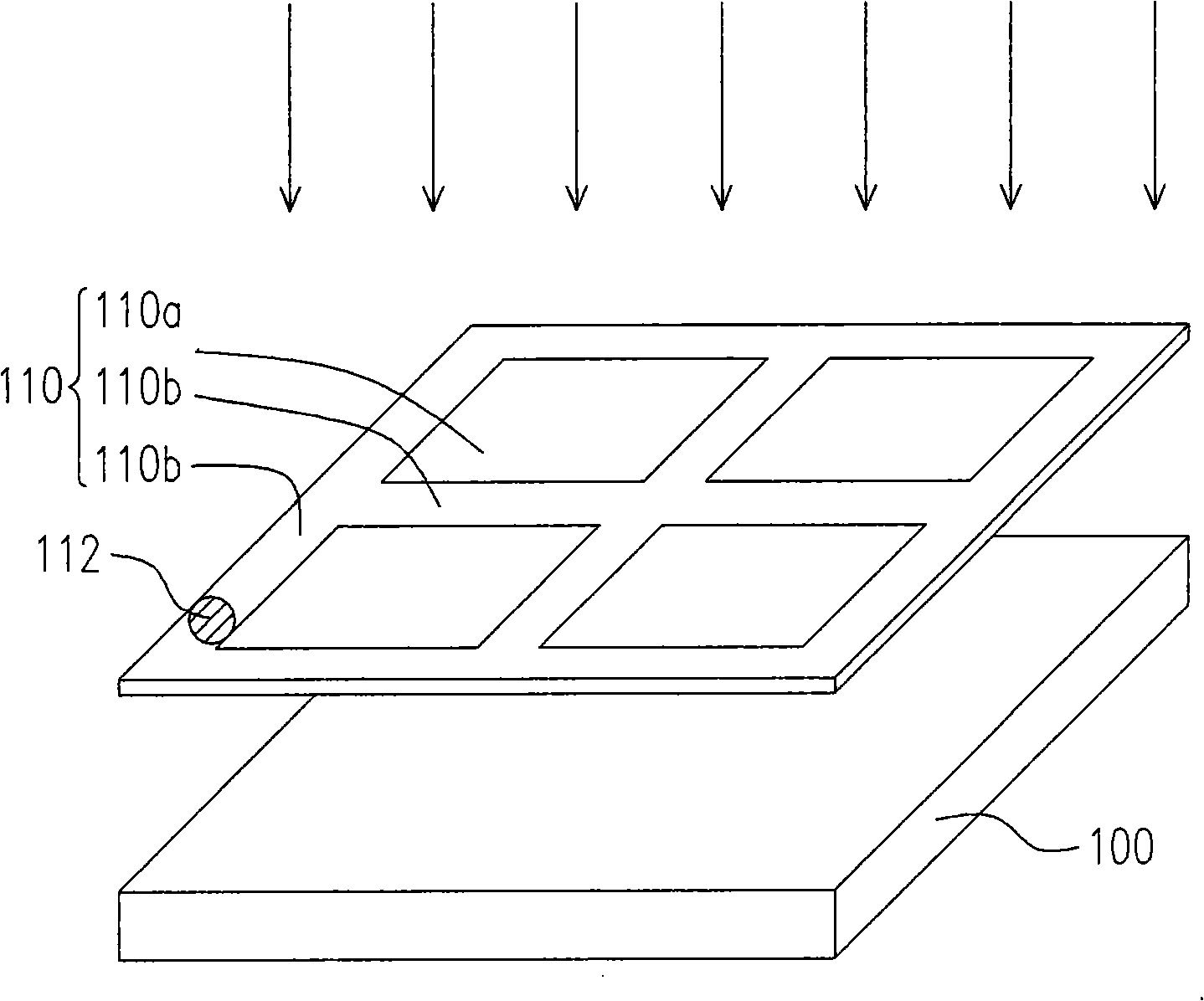

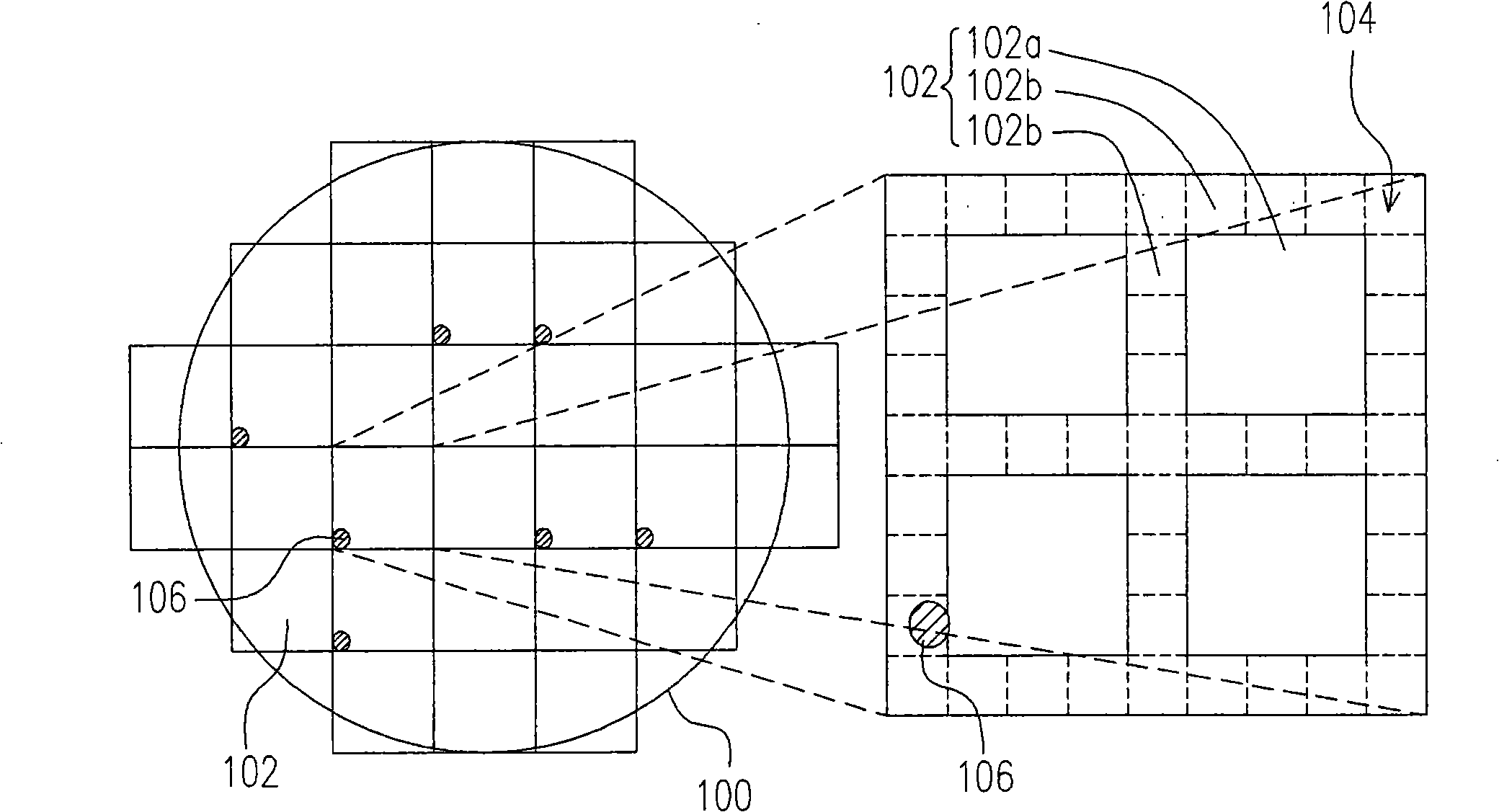

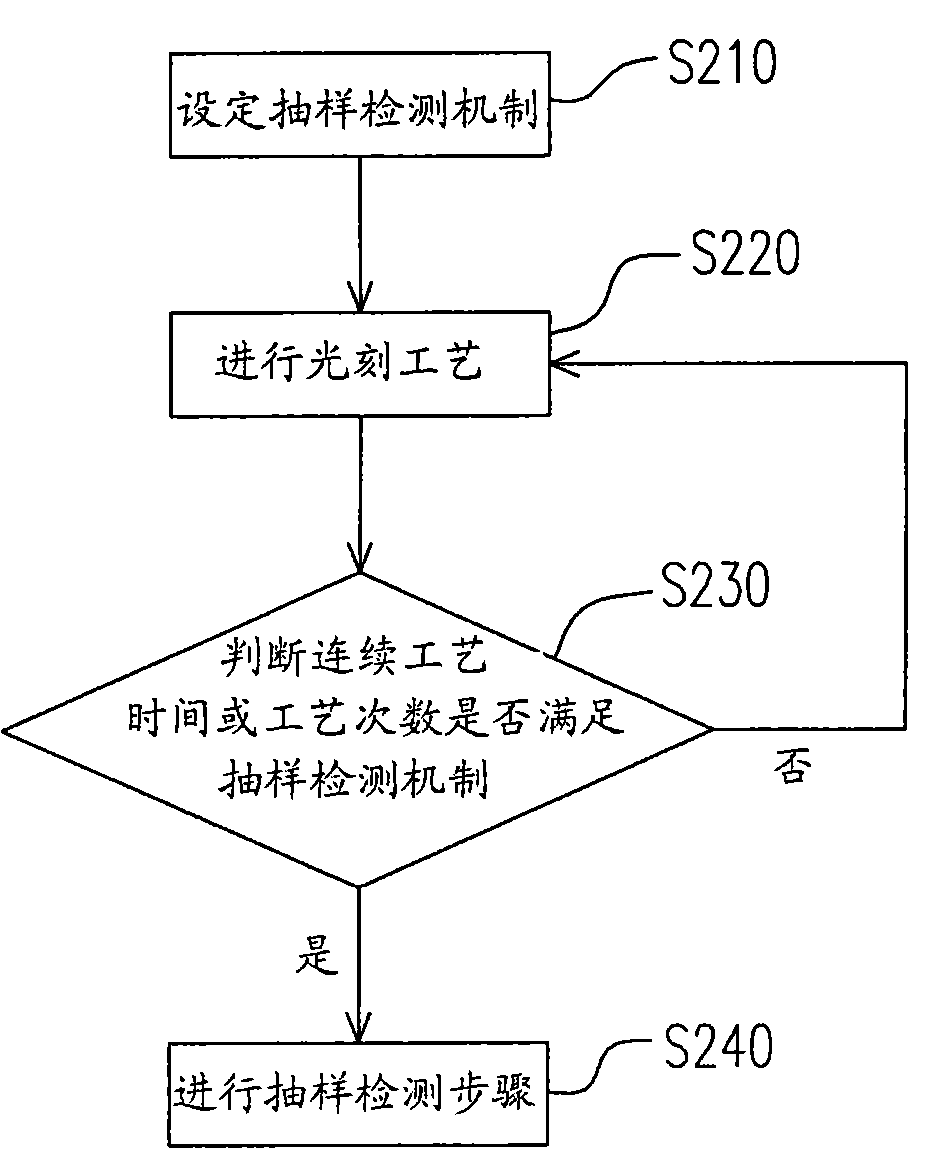

Photomask detection method and on-line immediate photomask detection method

ActiveCN101344715AAvoid affecting subsequent processesOriginals for photomechanical treatmentLithography processWafering

The invention discloses a photomask detecting method which is applicable to the photomasks provided with a pattern zone and a blank zone. Firstly, a chip for carrying out lithography in virtue of the photomask is provided. The chip is provided with a plurality of exposure zones and each exposure zone is provided with a component pattern zone, wherein, each component pattern zone is surrounded by a cutting channel zone and corresponds to the photomask pattern zone and the cutting channel zone corresponds to the photomask blank zone. Secondly, the cutting channel zone is divided into a plurality of virtual pattern zones. Then a step of two-two overlapping comparison is carried out for the virtual pattern zones, and when at least one of the virtual pattern zones dose not fully overlap with other virtual pattern zones, a photomask shadow appears on parts of the blank zone of the photomask corresponding to the virtual pattern zone without full overlapping.

Owner:UNITED MICROELECTRONICS CORP

Efficient desulfurization activated carbon preparation system

PendingCN113457840AImprove adsorption efficiencyAvoid affecting subsequent processesMagnetic separationActivated carbonElectric machine

The invention relates to the technical field of activated carbon, and particularly relates to an efficient desulfurization activated carbon preparation system. The system comprises a first groove, a conductive copper sheet, a conveyor belt, an electromagnet and a conductive column. A motor drives the conveyor belt to rotate, the conductive column enters the first groove, the first column makes contact with the conductive copper sheet, the electromagnet generates magnetism to adsorb iron molecules in the activated carbon raw materials, and when the electromagnet moves to the lower surface of the conveyor belt along with the conveyor belt, the conductive column on the electromagnet is separated from the first groove, and the electromagnet is demagnetized; and iron molecules adsorbed on the electromagnet fall off from the electromagnet under the action of self gravity so that the adsorption efficiency of the electromagnet is improved, and the influence of scrap iron in the activated carbon raw material on subsequent procedures is avoided.

Owner:吴琦

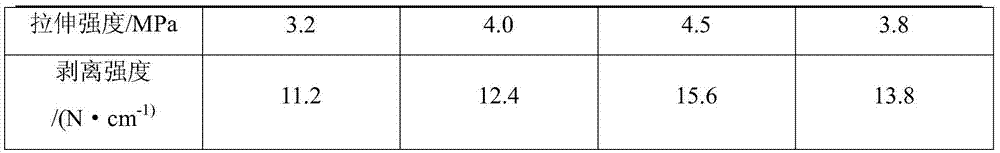

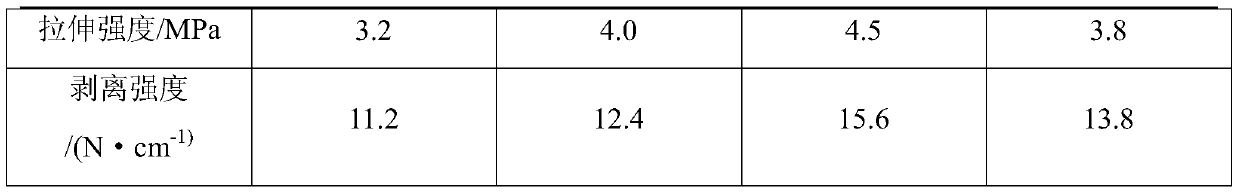

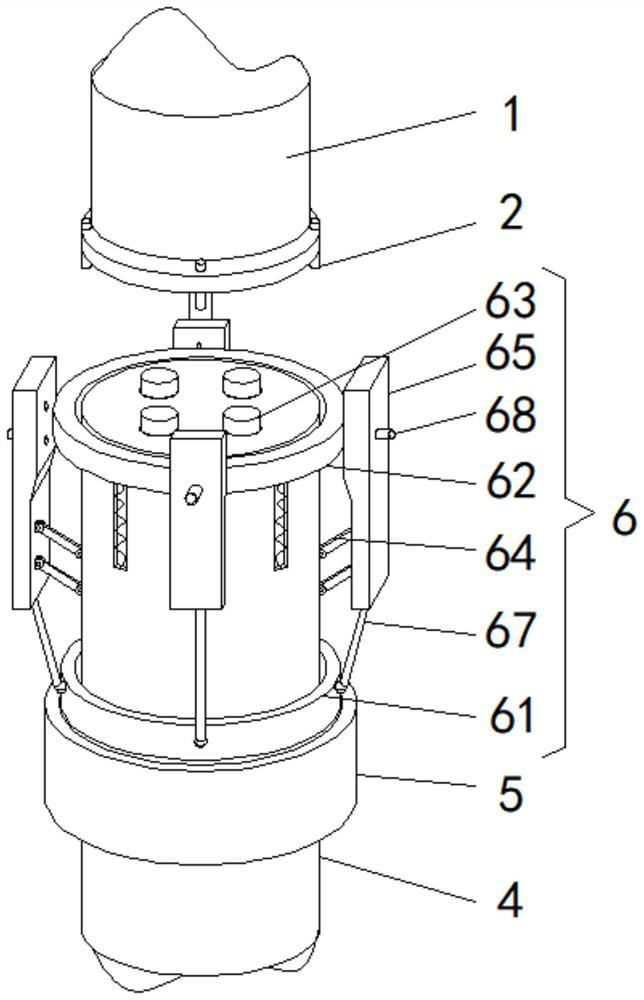

Waste cylinder lithium battery pretreatment device and method

ActiveCN109904547AHigh degree of automationSimple structureWaste accumulators reclaimingProcess efficiency improvementPretreatment methodControl system

The invention discloses a waste cylinder lithium battery pretreatment device and method, and belongs to the technical field of waste lithium battery recycling. The waste cylinder lithium battery pretreatment device includes an automatic sorting device, a conveying mechanism, an electric quantity monitoring actuator, a nondestructive testing system, a flexible clamping jaw mechanism, an automatic cutting mechanism, an automatic detaching mechanism, a recycling dust collecting system, and a control system, wherein the automatic sorting device, the conveying mechanism, the flexible clamping jaw mechanism, the automatic cutting mechanism, the automatic detaching mechanism, and the recycling dust collecting system are connected in sequence, the electric quantity monitoring actuator and the nondestructive testing system are both arranged above the conveying mechanism, and the control system realizes information receiving and instruction sending of the parts. The waste cylinder lithium battery pretreatment device is simple in structure, high in automatic degree, convenient and quick to operate, and high in disassembling efficiency, and has the characteristics of greenization, intellectualization, and flexibility.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

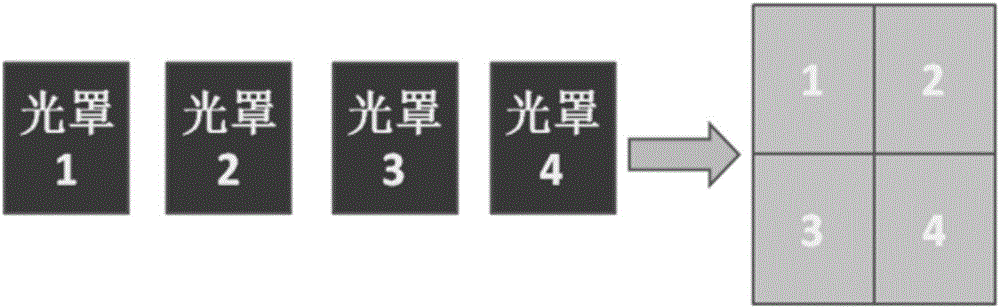

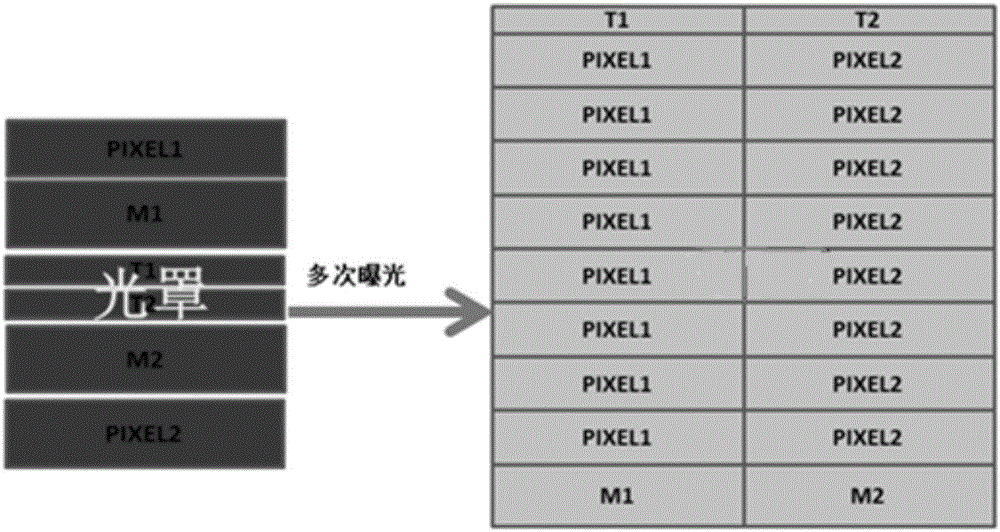

Exposure method for large-sized spliced product

ActiveCN106842826ALow costMeet functional requirementsPhotomechanical exposure apparatusMicrolithography exposure apparatusComputer sciencePhotomask

The invention discloses an exposure method for a large-sized spliced product. The exposure method comprises the following steps: dividing a photomask into six areas; selecting a functional part and a nonfunctional part from a wafer, wherein the functional part is formed by splicing and exposing complete functional units, and the nonfunctional part is formed by splicing and exposing incomplete functional units; splicing and exposing the complete functional units; splicing and exposing the incomplete functional units; completely splicing and exposing the functional part and the nonfunctional part in the wafer, wherein the incomplete functional units and the complete functional units are the same in size, but the exposure times of the incomplete functional units are far less than the exposure times of the complete functional units. The exposure method for the large-sized spliced product, provided by the invention, has good properties of reducing the exposure times, improving alignment precision and splicing alignment, and avoiding a sun-shading belt from forming a long line.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Wood raw material stacking device for wood product production

The invention discloses a wood raw material stacking device for wood product production, and relates to the technical field of wood product manufacturing. The wood raw material stacking device for wood product production comprises a U-shaped plate, wherein a steering translation mechanism, a distance adjusting mechanism, a lifting mechanism, a clamping mechanism, a turnover mechanism and a workbench are arranged on the U-shaped plate, the workbench is of a hollow structure with a bottom opening, a fixing ring is fixedly mounted on the outer wall of the workbench, and a mounting plate is fixedly mounted on the outer wall of one side of the U-shaped plate. According to the wood raw material stacking device for wood product production, the stacking direction of wood raw materials can be flexibly and variably adjusted, for example, a transverse and vertical stacking mode is adopted, the cylindrical wood raw materials can be stacked together more stably, the situation of slipping and collapsing is not liable to occur when workers conduct the next operation on the wood raw materials, the workers are prevented from being hurt by dropping of the wood raw materials, the safety of life and property of the workers is guaranteed, and promotion and use are facilitated.

Owner:浙江金隆木业有限公司

Automatic washing machine of vibrating motor rotor assemblies

PendingCN108566057AAvoid displacementAvoid affecting subsequent processesManufacturing stator/rotor bodiesCleaning using gasesOperating speedForeign matter

The invention provides an automatic washing machine of vibrating motor rotor assemblies. The automatic washing machine comprises a positioning guide rail, a conveyer belt, adsorbing stickers, a transparent hood body, washing and blowing devices, pressure regulating valves, a delay relay, a drying device, an optical fiber sensor, a belt wheel, a transmission belt, a motor, a water collecting tank and a water leaking pipe, wherein the positioning guide rail is an I-shaped supporting guide rail. According to the automatic washing machine disclosed by the invention, the washing and blowing devices, the delay relay and the optical fiber sensor are arranged, so that when the optical fiber sensor senses that products are in the right place, the delay relay drives the washing and blowing devices to automatically wash the products after receiving a command, and when the washing and blowing devices stop washing, the automatic washing of the rotor assemblies is completed. Due to adoption of the automatic washing machine disclosed by the invention, the operating type of automatic washing of the rotor assemblies is realized, so that staff is saved, and the production efficiency is improved by 60 times, the phenomena that during manual washing, the operating speed is low, the efficiency is low, and when the products are placed in the right place, foreign matters in an inner hole of a bearingcannot be accurately washed out are avoided, the quality of the products is improved, and the production efficiency is improved.

Owner:阜南县特立电子有限公司

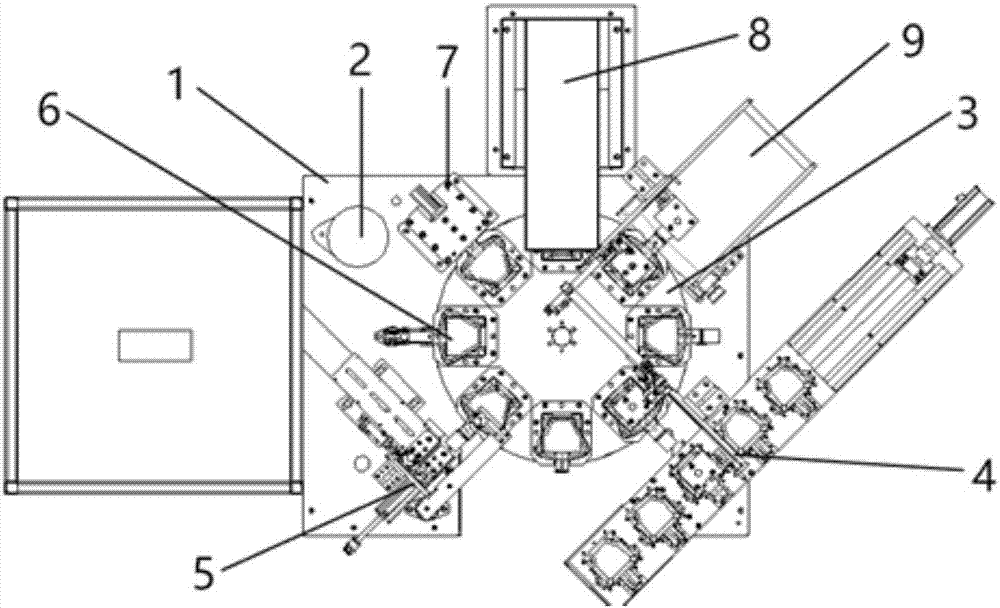

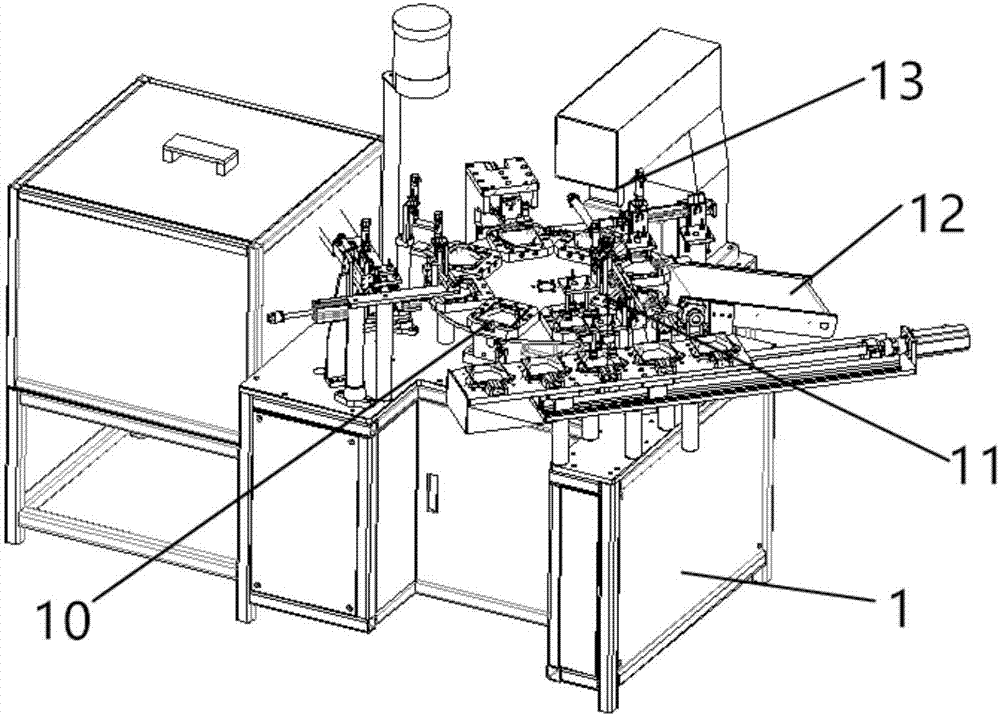

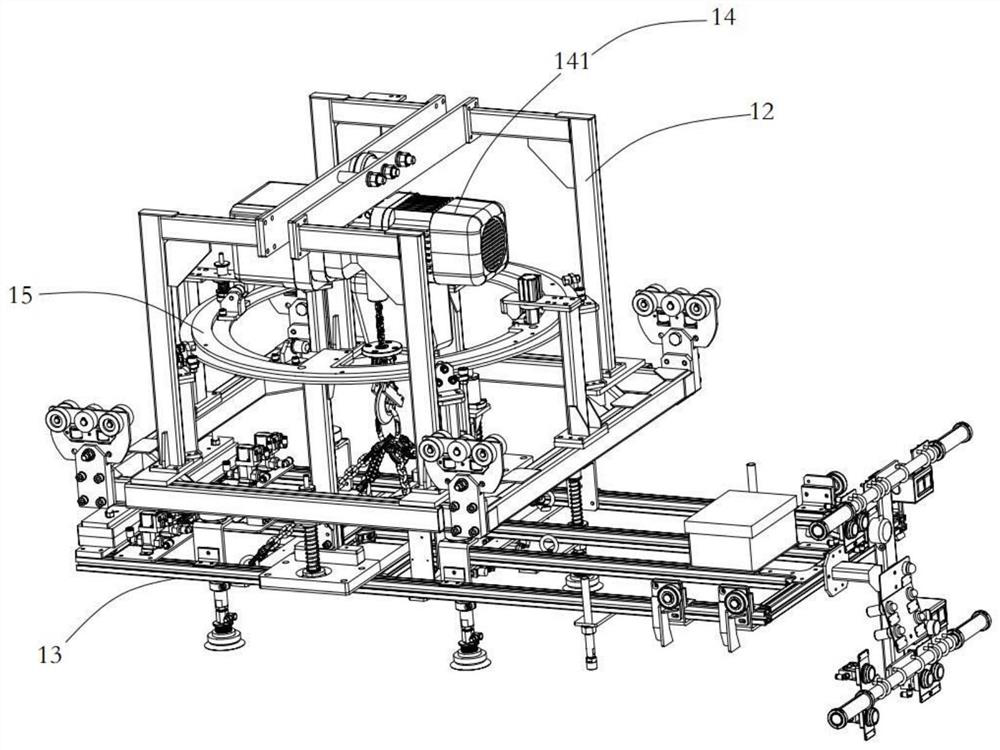

Oven bakeware automatic assembly machine

PendingCN107052755AImprove work efficiencyInnovative designMetal working apparatusProcess equipmentProcess engineering

The invention relates to the field of machinery, in particular to an oven bakeware automatic assembly machine. The oven bakeware automatic assembly machine comprises a rack body and a power supply device mounted on the rack body, and further comprises a vibrating disk mechanism, an automatic bakeware feeding mechanism, a handle feeding mechanism, a PP water spraying mechanism, a fastening mechanism, a printing mechanism and a conveying mechanism. The vibrating disk mechanism is mounted on the rack body and abuts against the power supply device. The vibrating disk mechanism is connected with the automatic bakeware feeding mechanism, the handle feeding mechanism, the PP water spraying mechanism, the fastening mechanism, the printing mechanism and the conveying mechanism correspondingly. The oven bakeware automatic assembly machine is novel in design, is provided with new designed integrated assembly processing units and can complete the processes such as feeding, splicing, printing, spraying, fastening and the like. The labor intensity is greatly reduced. The production efficiency is improved.

Owner:FOSHAN DONGYANG HARDWARE ELECTRIC APPLIANCE CO LTD

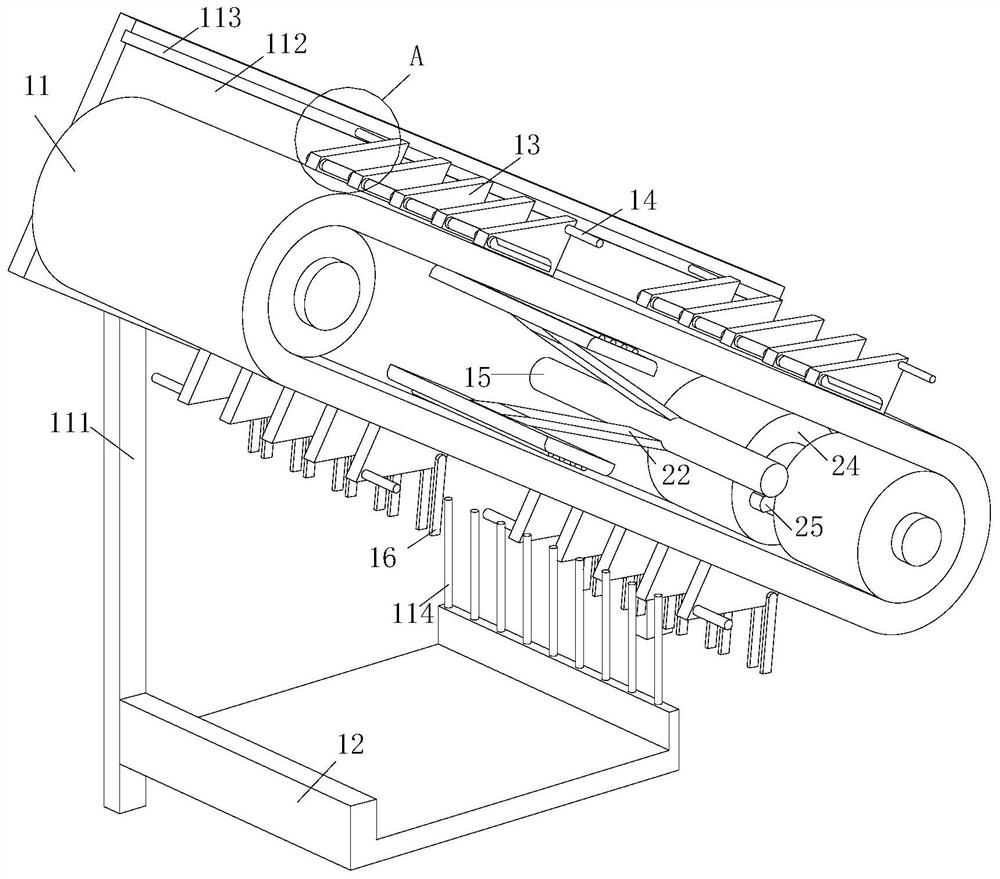

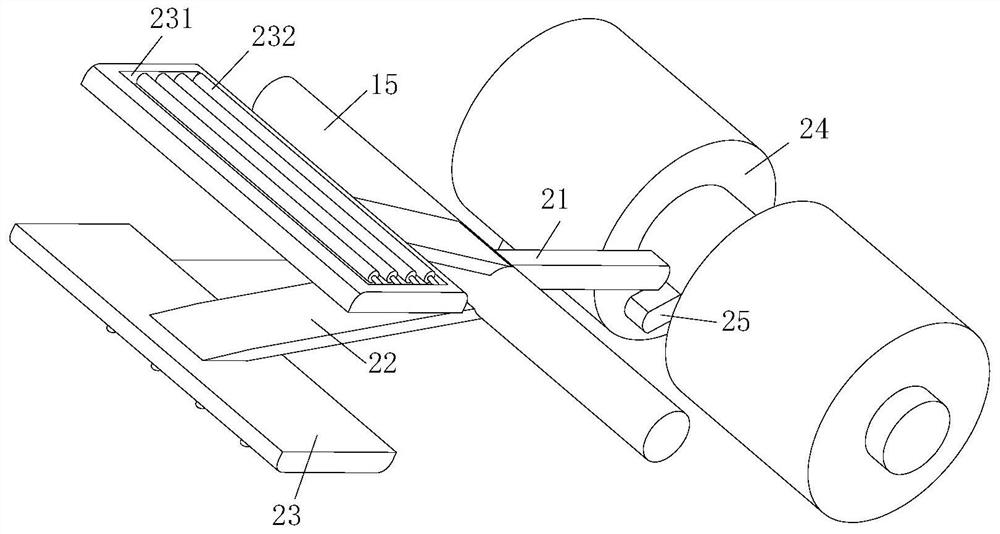

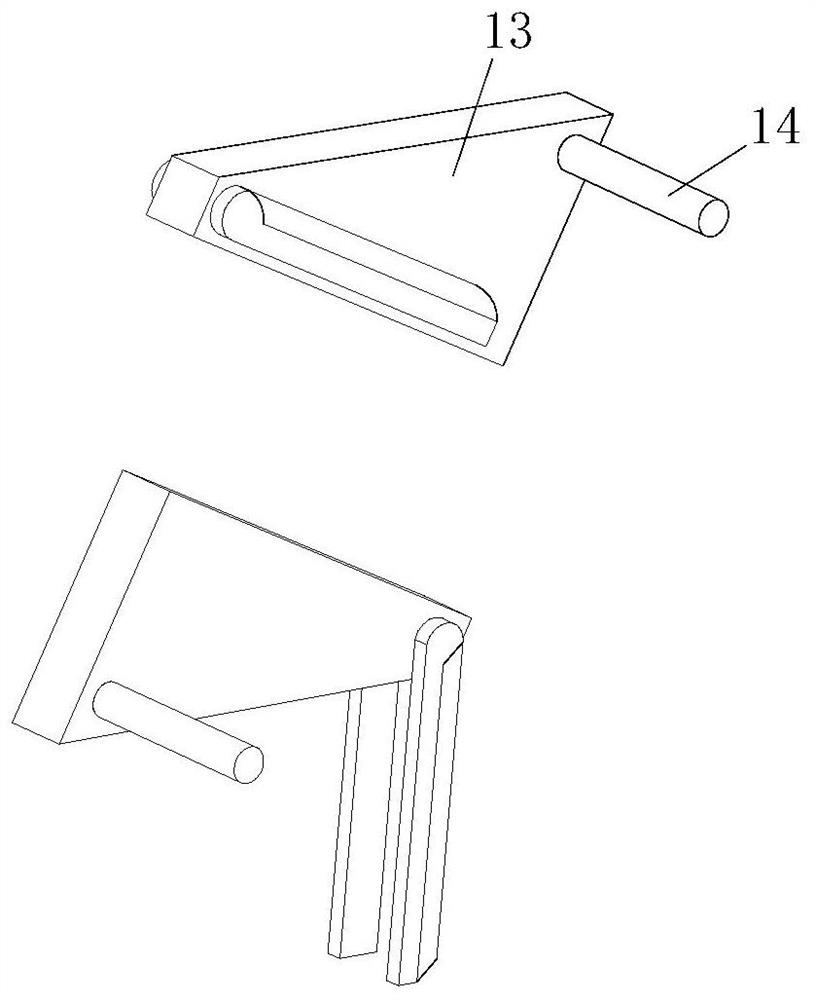

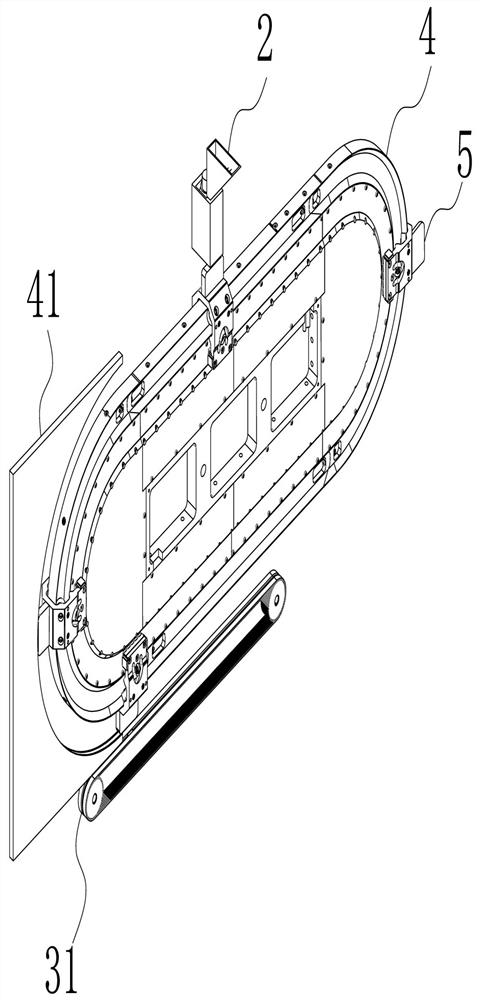

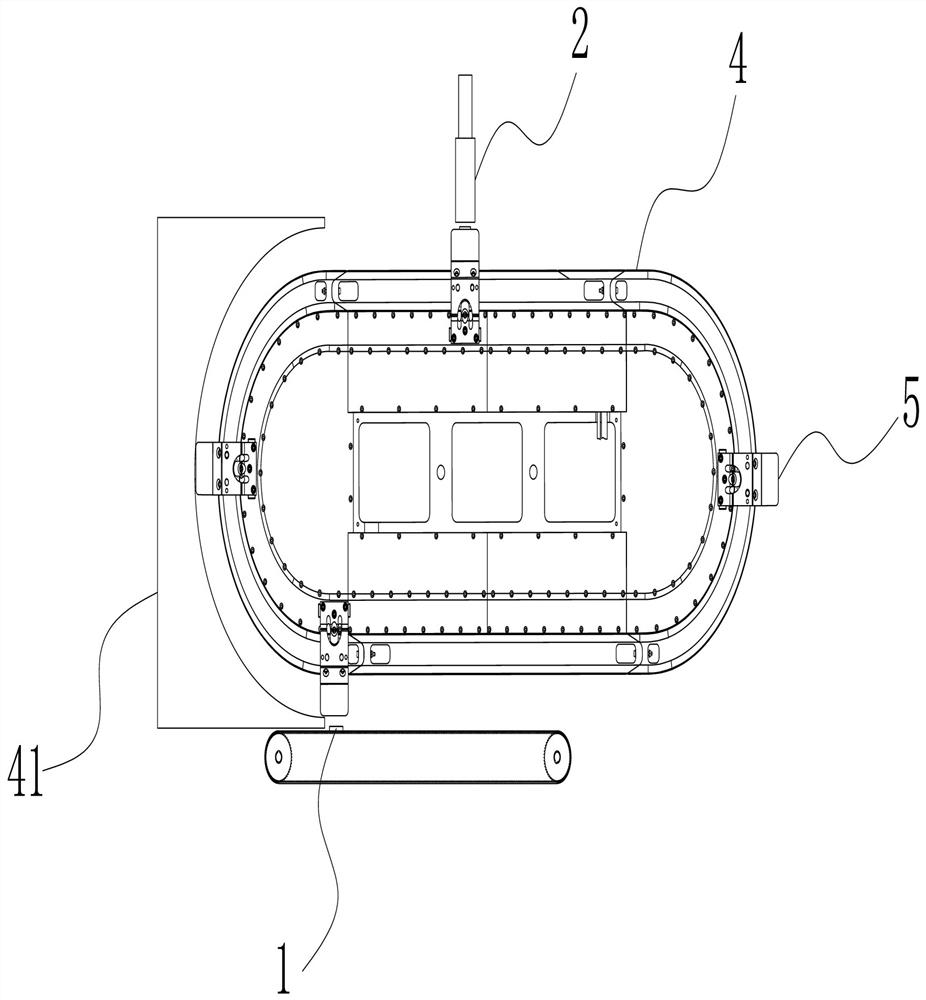

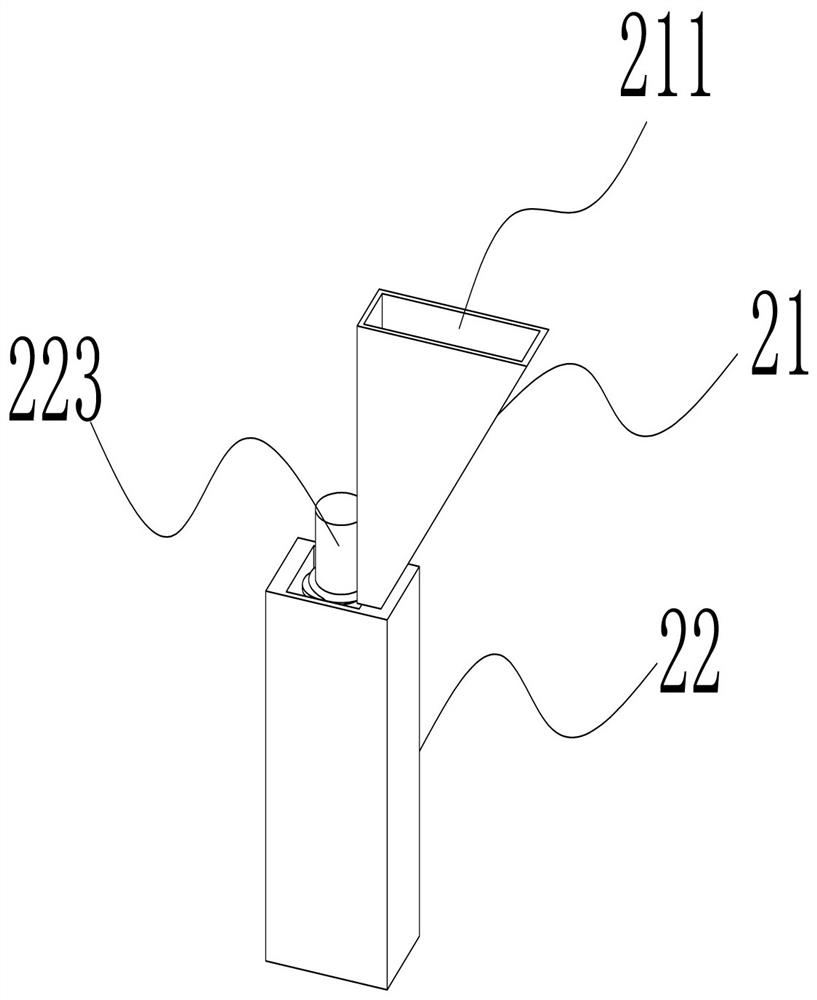

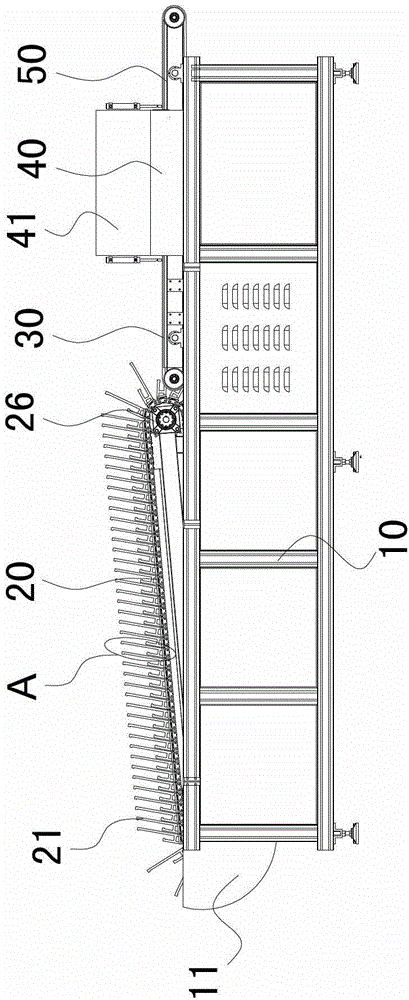

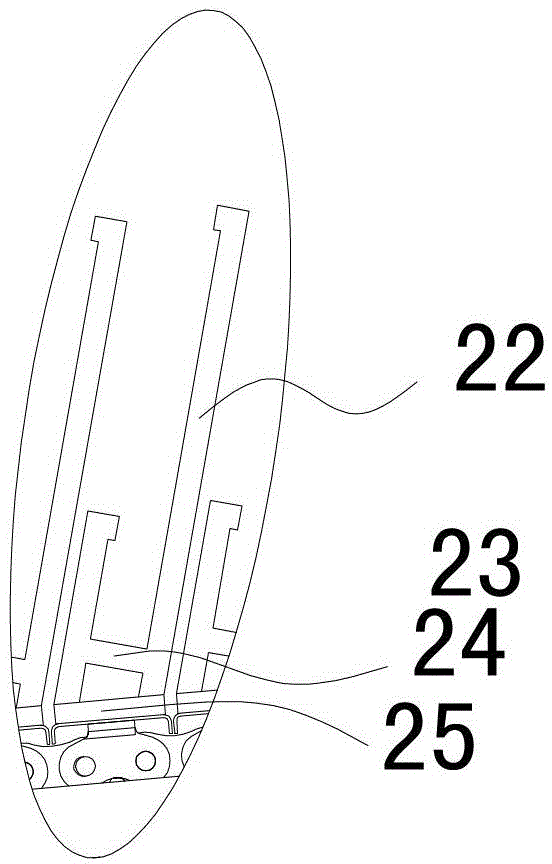

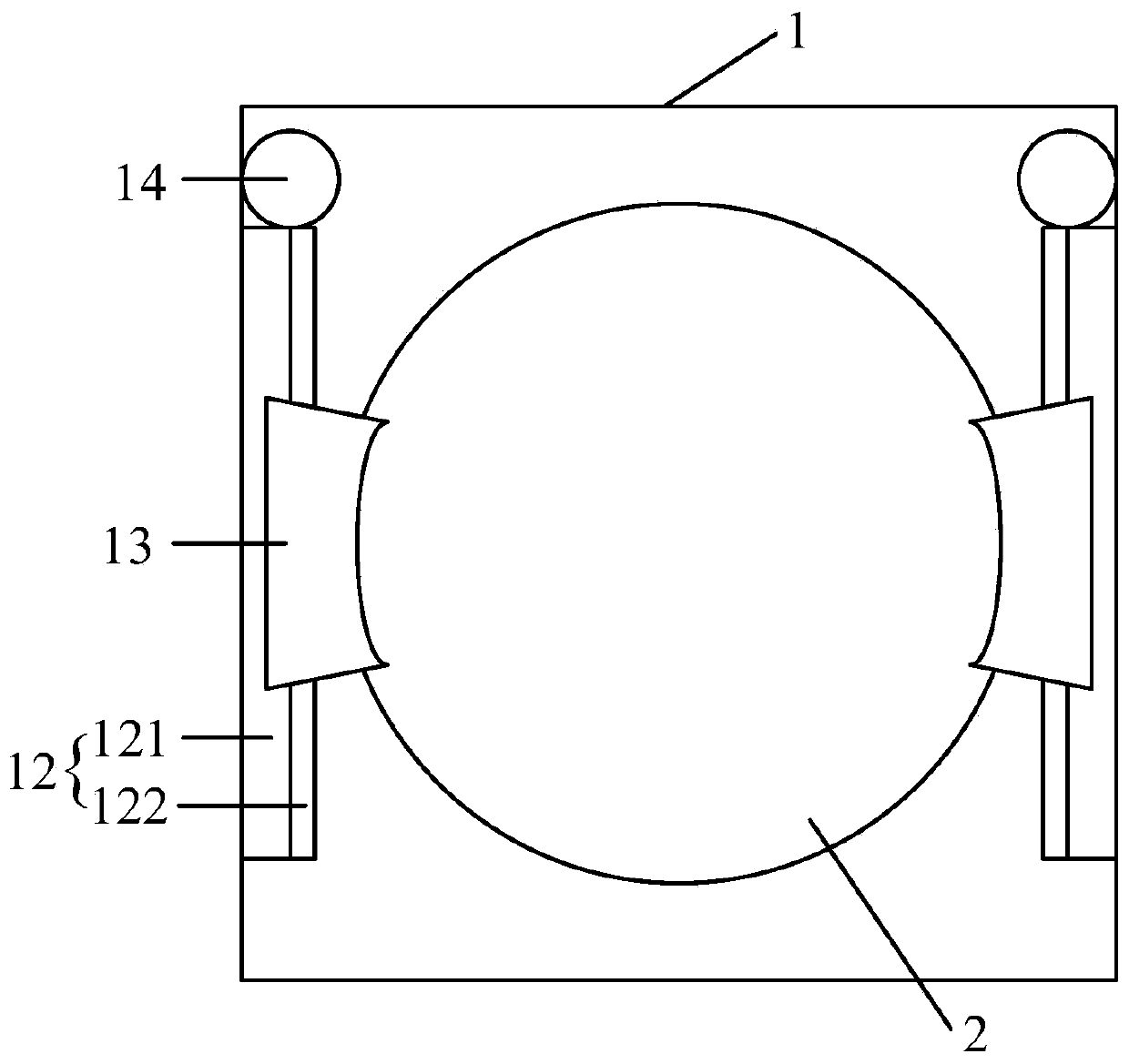

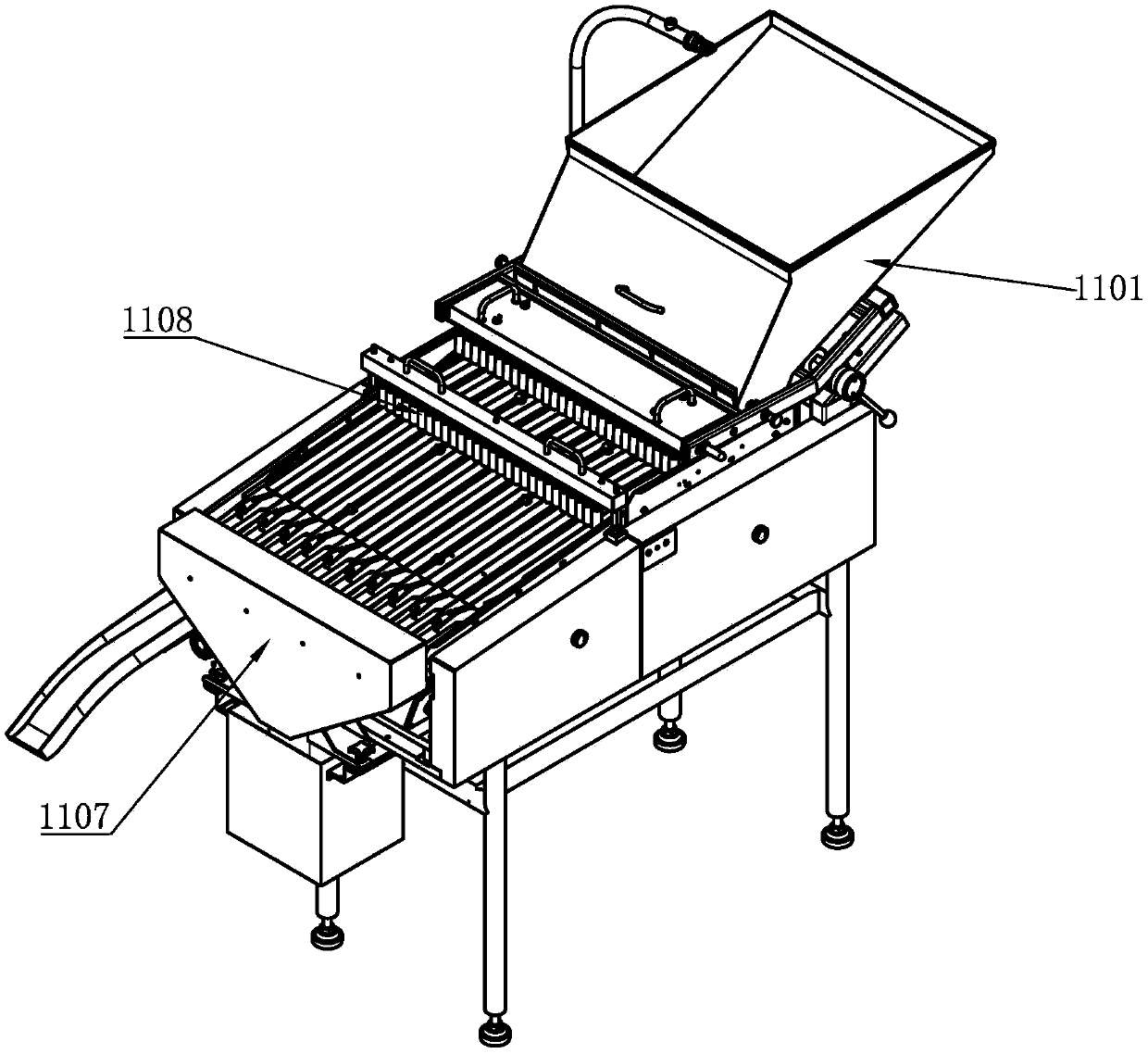

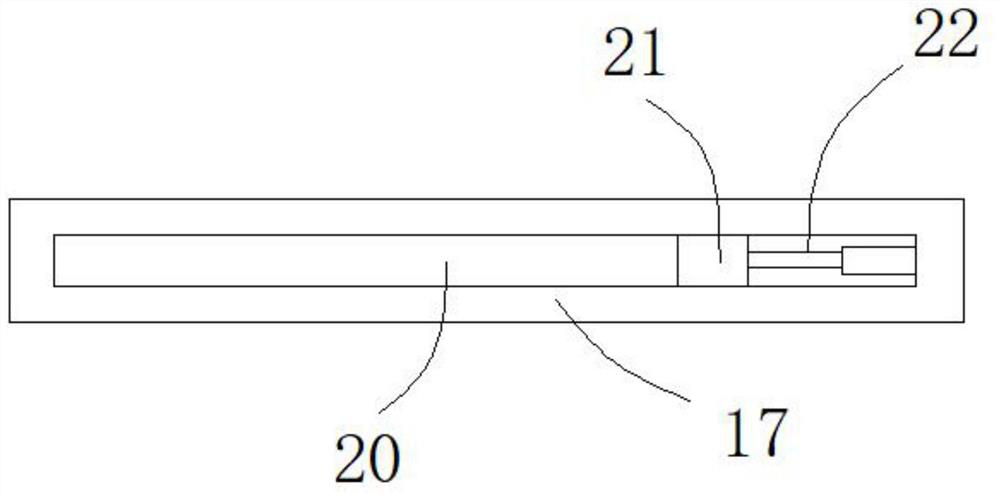

Filter stick arranging and conveying device

InactiveCN113387196ASolve the problem of prone to driftAvoid affecting subsequent processesConveyorsLoading/unloadingEngineeringPhysics

The invention relates to the field of tobacco mechanical devices, in particular to a filter stick arranging and conveying device. The filter stick arranging and conveying device comprises a hopper which is used for controlling blanking speed of the filter sticks, and a conveying belt which is used for conveying the filter sticks to the next working procedure, wherein an annular guide rail and a rotor capable of moving around the annular guide rail are arranged between the hopper and the conveying belt, and the filter sticks fall to a rotor from the hopper and are transferred to the conveying belt through the rotor. The annular guide rail is arranged between the hopper and the conveying belt, so that the problems that when a mounting distance between the hopper and the conveying belt is too large, filter sticks are prone to deviation in the process of falling to the conveying belt from the hopper, and the filter sticks are prone to sliding on the conveying belt due to the fact that the filter sticks do not have the horizontal initial speed in the falling process are solved.

Owner:HUBEI CHINA TOBACCO IND +1

Glass automatic processing device after active reagent coating and processing method thereof

The invention discloses a glass automatic processing device after active reagent coating and a processing method thereof. The automatic processing device comprises a drying delivery unit, a sheet delivery unit, a heating unit and a control unit. Glass passes through the drying delivery unit, the sheet delivery unit and the heating unit successively; and the drying delivery unit, the sheet delivery unit and the heating unit are connected with the control unit. According to the glass automatic processing device after active reagent coating and the processing method thereof, the time for the glass passing through the drying delivery unit and the sheet delivery unit can be controlled, and accordingly, the glass drying time can be controlled. Deficiency or exceeding of time caused by labor tracking is prevented, and automatic control of glass preprocessing is achieved. Base coating and active reagent time of coating of all glass can be further monitored, and delivery speeds of the drying delivery unit is changed, that is, the actual drying time of glass is changed, and accordingly, subsequent processes are prevented from being affected due to deficiency or exceeding of time caused by loose labor operation is avoided.

Owner:GUANGZHOU FUYAO GLASS GRP

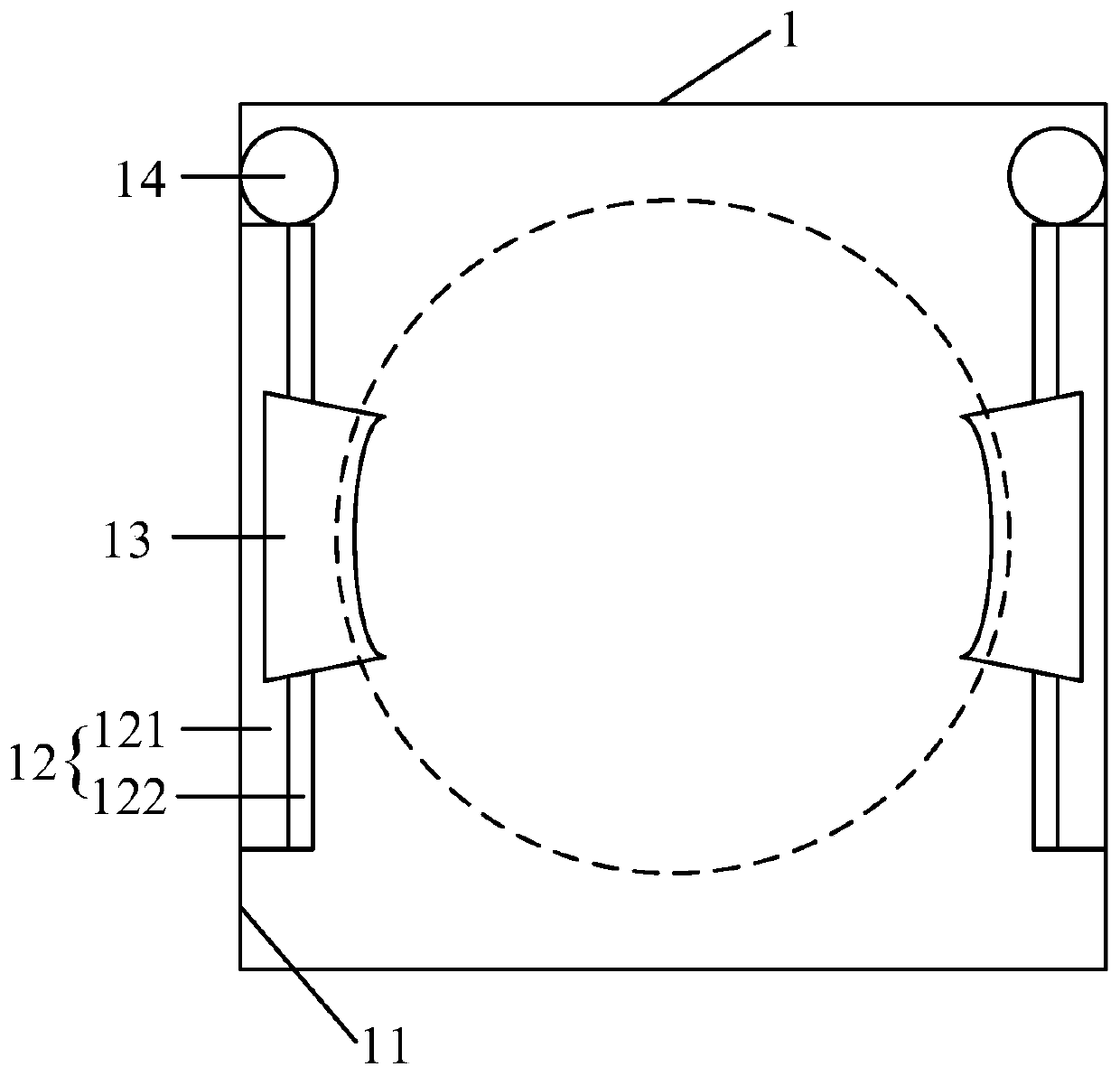

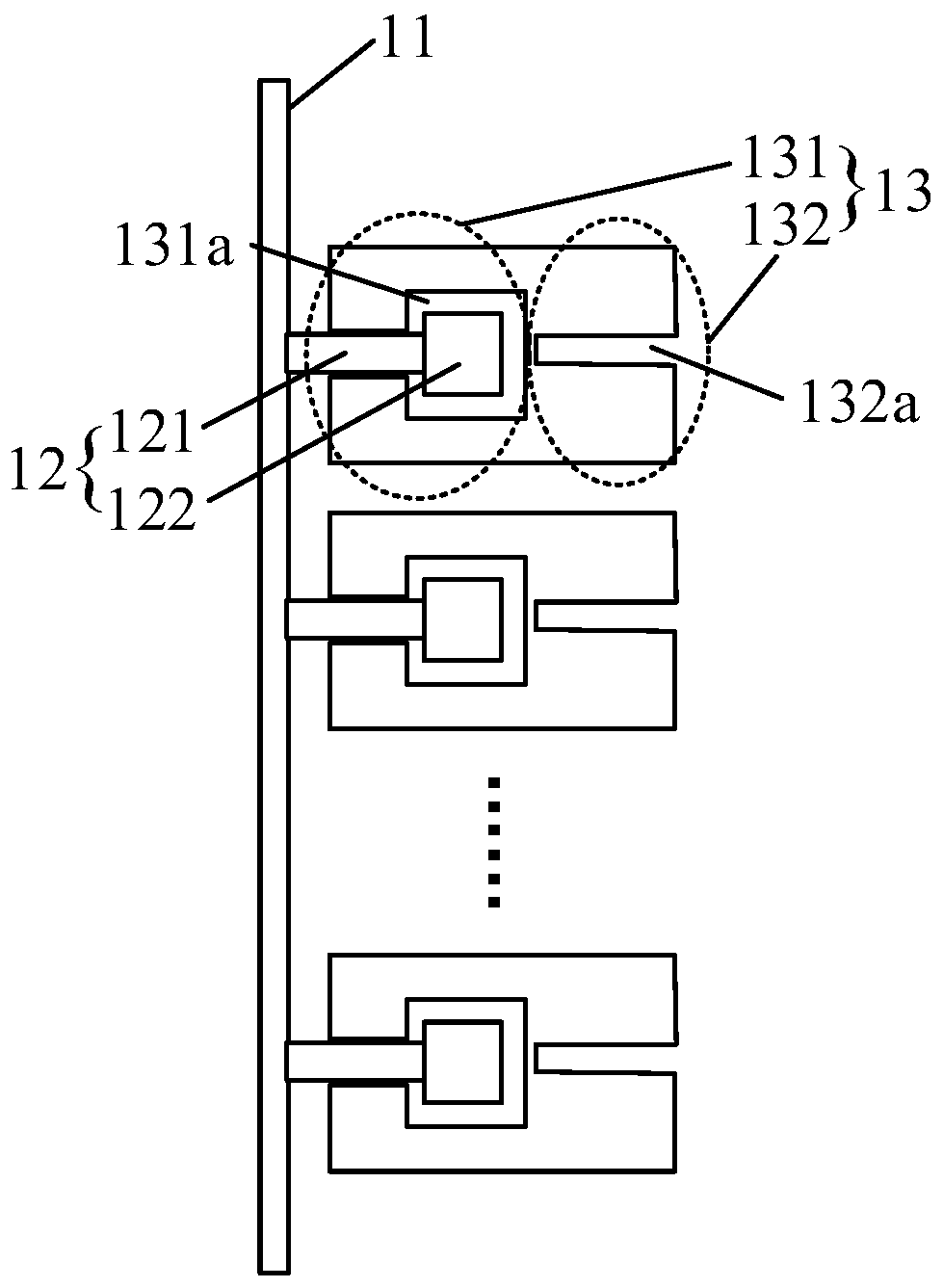

Wafer transfer box and control method thereof

InactiveCN110112087AAvoid pollutionAvoid scratchesSemiconductor/solid-state device manufacturingParticulatesElectrical and Electronics engineering

The technical solution of the invention discloses a wafer transfer box and a control method thereof. The wafer transfer box comprises: a slide rail structural member disposed on the sidewall of the wafer transfer box; a wafer support member having a sliding portion matching a slide rail structural member, and a clamping portion matching a wafer; and a control mechanism connected to the wafer support member to slide the wafer support member along the slide rail structural member. The wafer transfer box of the invention can avoid the influence of the particulate matter pollution of the wafer inthe wafer transfer box caused by a robot arm on the subsequent processes, and can also prevent the robot arm from scratching the wafer in the wafer transfer box, thereby improving the product yield.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

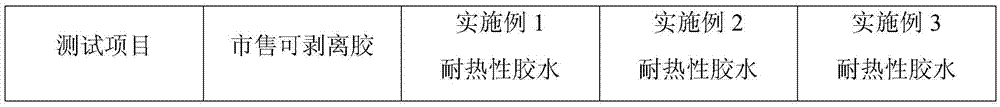

Mirror surface region protection method of COB mirror surface aluminum base plate

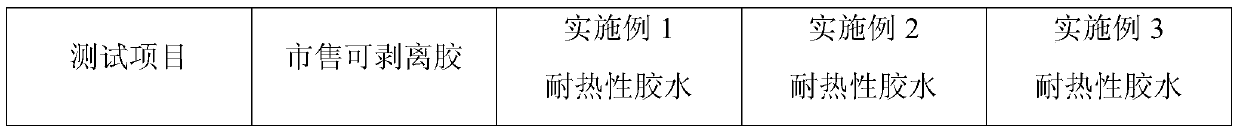

InactiveCN105440964AAvoid warpingAvoid affecting subsequent processesNon-macromolecular adhesive additivesFilm/foil adhesivesTectorial membraneScreen printing

The invention discloses a mirror surface region protection method of a COB mirror surface aluminum base plate, which comprises the following steps: step 1, preparing heat resistant glue: respectively weighing the following components in parts by weight: 60-65 parts of VAGH, 18-22 parts of curing agent, 8-10 parts of phthalate, 2-5 parts of lubricant and 2.5-5 parts of pigment system; heating the VAGH, curing agent and phthalate to 55-65 DEG C, stirring uniformly, then adding the lubricant and the pigment system, after fully stirring and cooling to room temperature to obtain the heat resistant glue; step 2, screen printing: by enabling a prepared screen to correspond to a mirror surface region of the COB mirror surface aluminum base plate, printing the heat resistant glue, and baking; step 3, reflow soldering: performing hot air reflow soldering on the COB mirror surface aluminum base plate; step 4, film tearing: after the reflow soldering is finished, manually tearing a protection film. By performing screen printing of the heat resistant glue in the mirror surface region, during reflow soldering, the mirror surface region is effectively protected.

Owner:XIAMEN UM OPTO TECH

Set-top box production verification method and system

ActiveCN108200474BAvoid affecting subsequent processesUndiscoverable problems will not occurCo-operative working arrangementsProgram loading/initiatingProcess engineeringIndustrial engineering

The invention relates to a set top box production check method and system. According to the method, through preset check configuration, after working processes are finished, working process finishingsituations are checked timely, so the working processes and products in which problems exist are discovered timely, follow-up working processes are prevented from being influenced and undiscoverable problems are avoided. Not all products need to be rechecked and reprocessed, the production load is greatly reduced, and the labor and time cost is reduced.

Owner:SHENZHEN JIUZHOU ELECTRIC

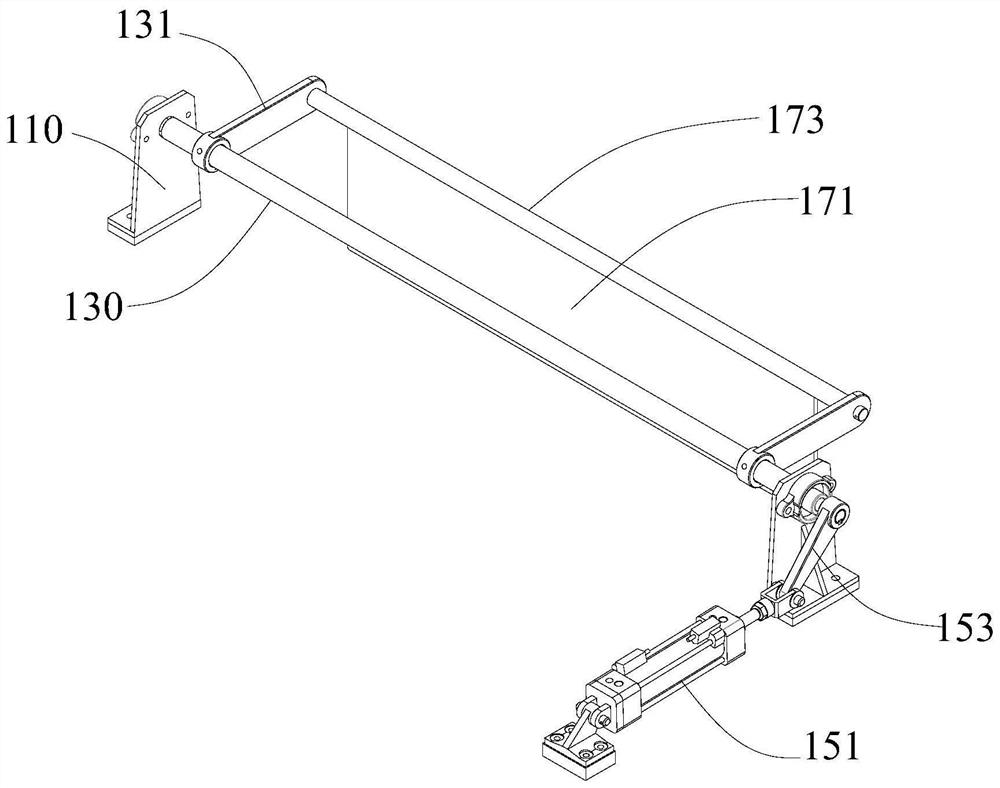

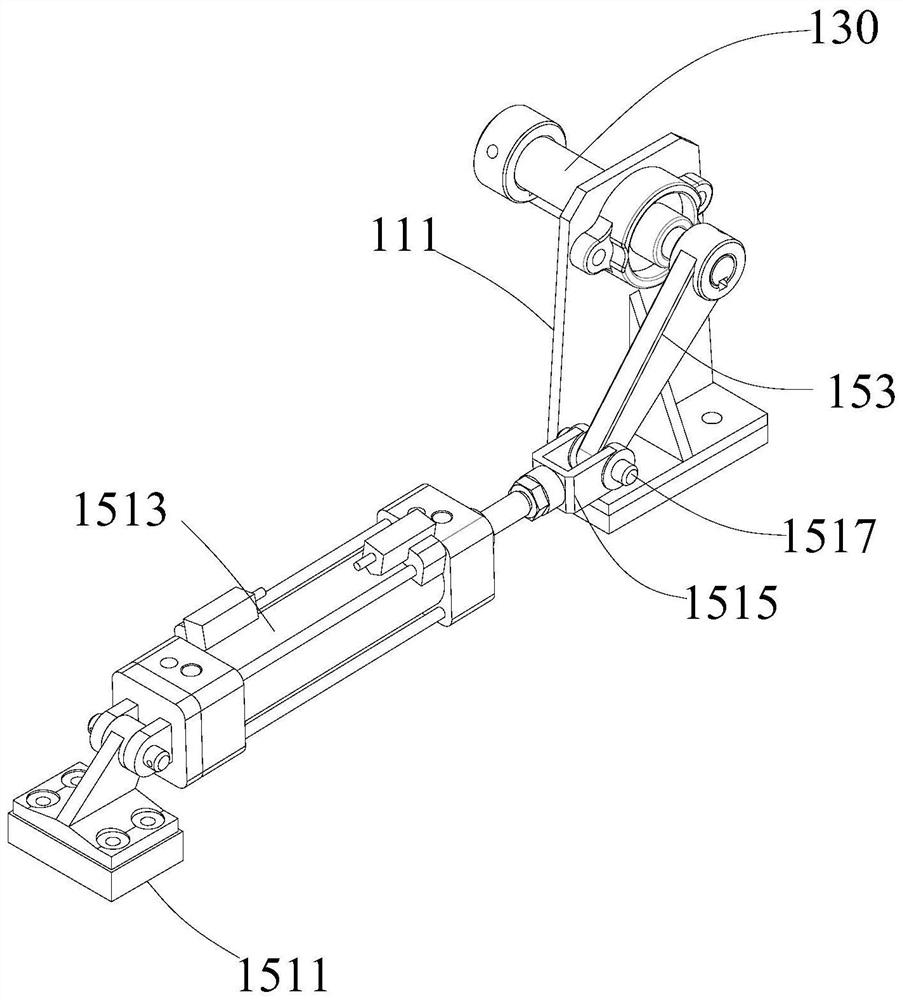

Heating furnace isolation device and heating furnace conveying device

PendingCN111977357AAchieve stopAvoid disorderly scrollingCharge manipulationControl devices for furnacesRotational axisEngineering

The embodiment of the invention provides a heating furnace isolation device and a heating furnace conveying device, and relates to the field of heat treatment equipment. The heating furnace isolationdevice comprises a mounting frame, a transmission rotating shaft, a driving mechanism and a material baffle plate, wherein the mounting frame is used for being mounted on a conveying mesh belt; the transmission rotating shaft is rotatably arranged on the mounting frame and is used for being transversely arranged above the conveying mesh belt; the driving mechanism is in transmission connection with the transmission rotating shaft and is used for driving the transmission rotating shaft to rotate; and the material baffle plate is in transmission connection with the transmission rotating shaft and is used for being driven by the transmission rotating shaft to get close to or away from the conveying mesh belt so as to stop workpieces on the conveying mesh belt or release the stopped workpieceson the conveying mesh belt. Compared with the prior art, the heating furnace isolation device provided by the invention has the advantages that the workpieces on the conveying mesh belt can be prevented from directly rolling into a mesh belt heating furnace, so that the workpiece feeding control degree is improved, the quality of the treated workpieces is improved, and the influence on the subsequent process is avoided.

Owner:江苏丰东热技术有限公司

Photomask detection method and on-line immediate photomask detection method

ActiveCN101344715BAvoid affecting subsequent processesOriginals for photomechanical treatmentLithographic artistEngineering

Owner:UNITED MICROELECTRONICS CORP

Material crushing system for commercial concrete processing

PendingCN114453065AAvoid affecting subsequent processesGrain treatmentsRotational axisArchitectural engineering

The material crushing system for commercial concrete processing comprises supporting legs, electric telescopic rods and a third supporting plate, a sliding rail is arranged on the bottom face of the side face of a device shell, a collecting box is connected with the sliding rail, and push plates are arranged above a first filter screen and a second filter screen correspondingly. And telescopic springs are also connected between the top face of the telescopic plate and the bottom face of the sliding groove, an electric telescopic rod is connected to the side face of the push plate and installed on the outer surface of the device shell, and a third supporting plate is arranged on the bottom face of the electric telescopic rod. The material crushing system for commercial concrete processing is provided with a crushing roller, a rotating shaft is arranged in the middle of the crushing roller, connecting blocks are arranged at the two ends of the rotating shaft, fixing supports are arranged on the outer surfaces of the connecting blocks, and the fixing supports form a left-right moving structure on the upper surface of a first supporting plate through threaded rods; and the distance between the crushing rollers can be adjusted according to the size of raw materials.

Owner:江苏晨马建筑科技有限公司

Method for preparation of activated alumina from suspended solids in mother liquor

ActiveCN104512918AEfficient use ofAvoid affecting subsequent processesAluminium oxide/hydroxide preparationMuffle furnaceBoehmite

The invention discloses a method for preparation of activated alumina from suspended solids in mother liquor. The method comprises the steps of: (1) recovering suspended solids in seed precipitation mother liquor by a leaf filter, then conducting washing with water 2-3 times, and performing drying for standby use: (2) adding the dried suspended solids into a rapid dehydration process directly; (3) carrying out granulation after cooling, adding pseudo-boehmite accounting for 10-20% of the mass of the rapidly dehydrated suspended solids, and making the mixture into spherical particles with a diameter of 5-10mm; (4) drying the well made particles into an oven to conduct drying; (5) putting the completely dried particles into a 600-900DEG C muffle furnace to perform calcination for 2-6h, and controlling the heating rate in stages so as to obtain an activated alumina product. Compared with the prior art, the method provided by the invention has the advantages of short process and simple operation, can effectively utilize the suspended solids in the seed precipitation mother liquor, prevents the suspended solids from entering the evaporation process to influence the subsequent process, reduces evaporation and scab formation, improves equipment operation rate, and increases the economic benefits of alumina plants.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

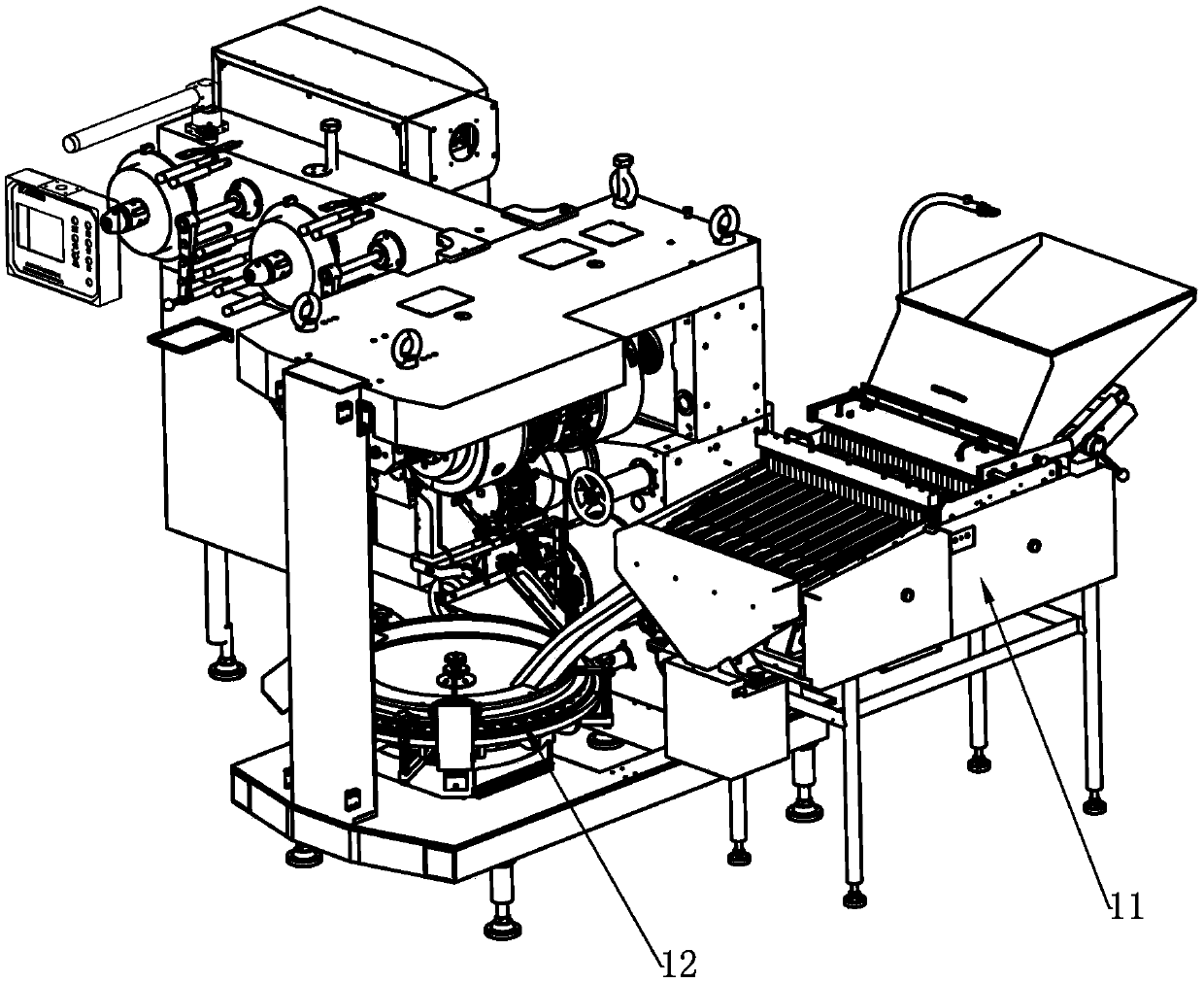

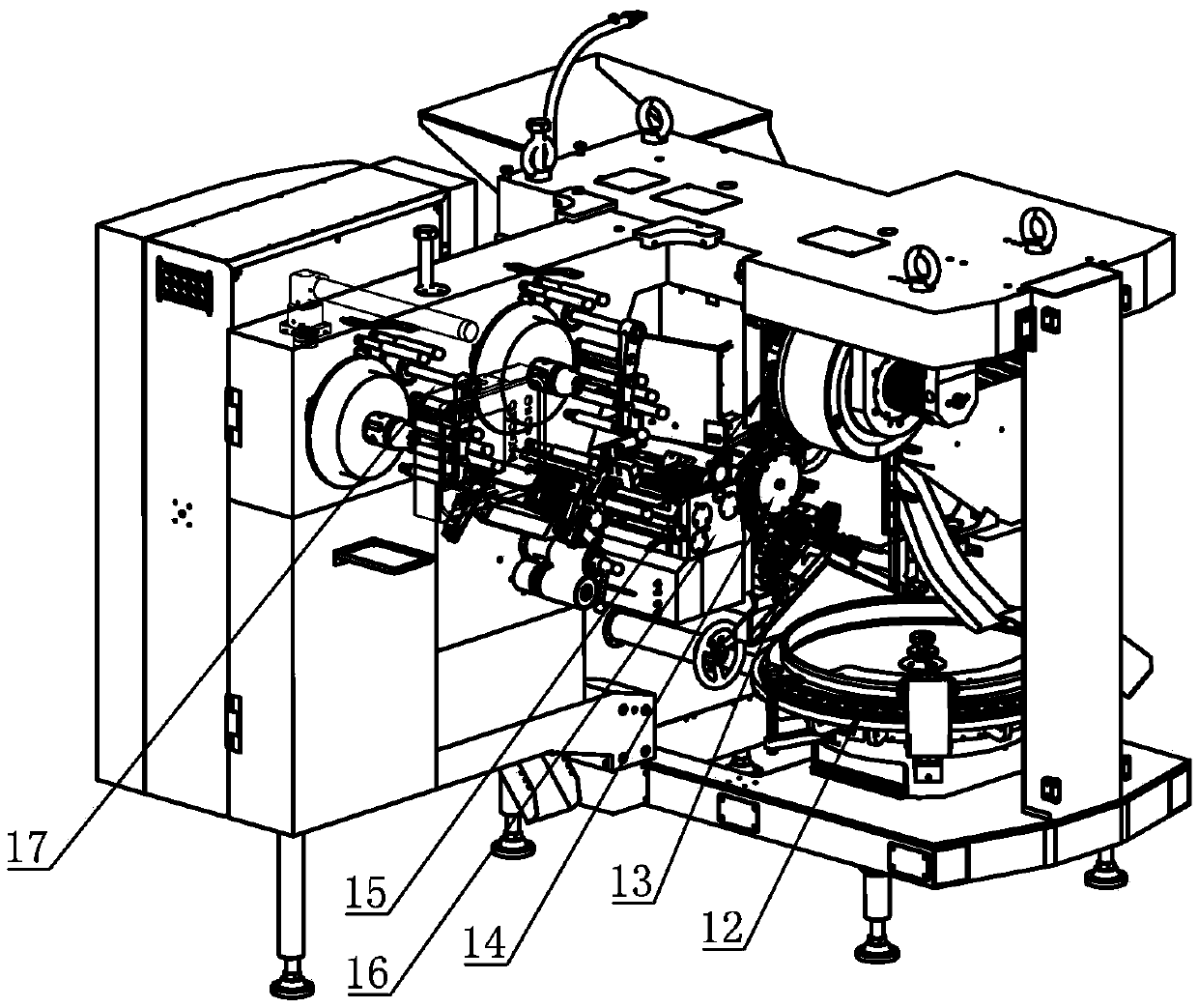

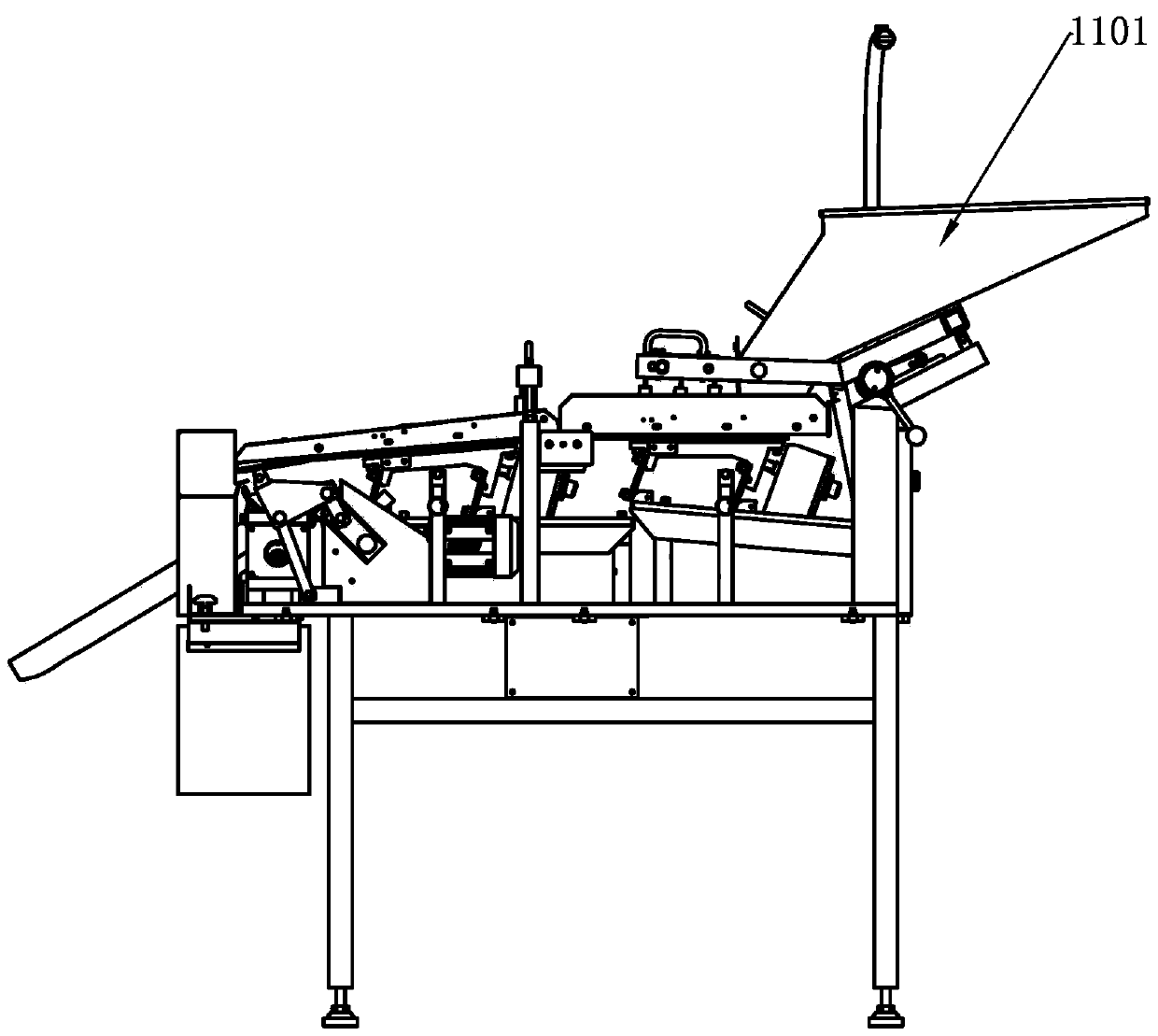

Granular candy packaging machine

PendingCN109606792AEfficient and continuous packagingFast packConveyor wrappingBio-packagingTransfer mechanismPower output

The invention discloses a granular candy packaging machine comprising a main machine, a discharging mechanism, a candy managing mechanism, a candy clamping mechanism, a transferring mechanism, a papertwisting mechanism, a paper conveying mechanism, a paper feeding mechanism and a candy discharging mechanism; and the main machine comprises a main machine rack and a main machine power output device, candies are conveyed to the candy managing mechanism through the discharging mechanism, are clamped by the candy clamping mechanism from the candy managing mechanism and are transferred to the transferring mechanism, packing paper is transferred to the transferring mechanism through the paper conveying mechanism and the paper feeding mechanism, the candies are attached to the interiors of the packaging paper at the position of the transferring mechanism, then the candies and the packaging paper enter the paper twisting mechanism to complete side face wrapping and packaging paper two end twisting, and finally the candies and the packaging paper enter the candy discharging mechanism. On the whole, the granular candy packaging machine is compact in structure and high in work efficiency, andis worthy of promotion in the industry.

Owner:成都三可实业有限公司

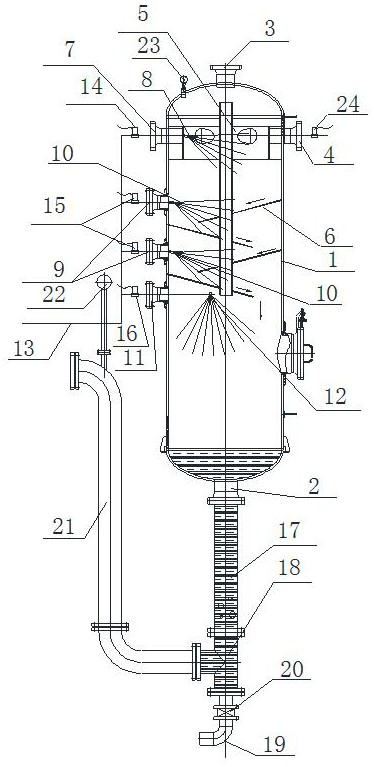

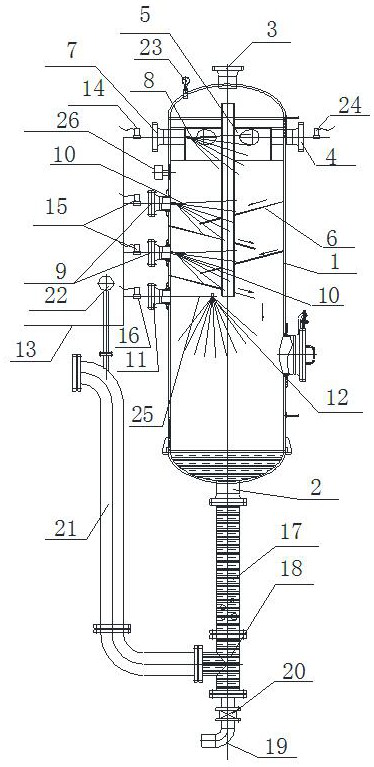

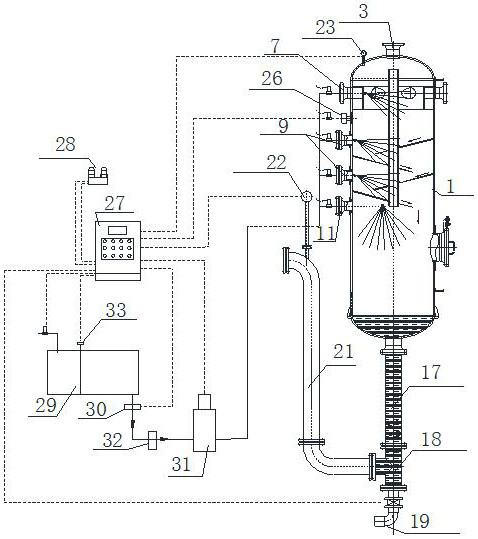

A self-cleaning safety separator, an integrated separation and cleaning system using the separator, and a method for using the system

ActiveCN113058293BPressure is easy to monitor at any timeQuick washLiquid degasificationHollow article cleaningWell drillingWater resources

The invention discloses a self-cleaning safety type separator and an integrated separation and cleaning system using the separator, belonging to the technical field of petroleum drilling, and can solve the problem that the liquid-gas separator in the prior art is inconvenient to clean and difficult to clean , long cleaning time, labor-intensive and other problems, the structure is ingenious, and can be directly improved and optimized on the previous equipment. In addition, a method of using the system is provided, so that the self-cleaning safety separator can efficiently complete the separation task. , can quickly complete the cleaning of the equipment, and save water resources as much as possible.

Owner:广汉市思明石油钻采设备配套有限公司

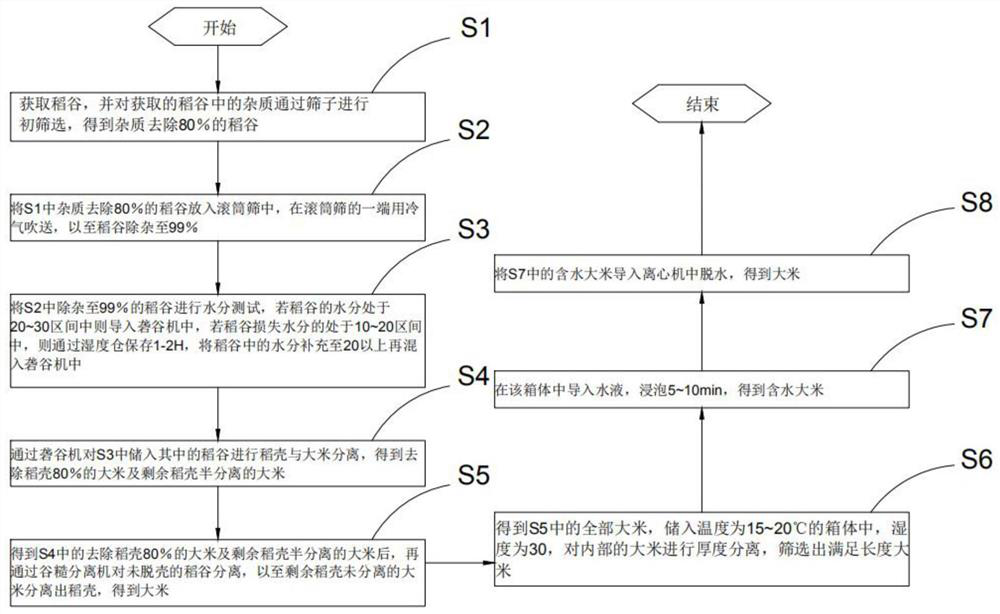

Rice processing method capable of improving integrity rate

The invention provides a rice processing method capable of improving the integrity rate. The rice processing method is applied to the technical field of rice processing. In an impurity removal process, most of rice is filtered through a sieve and the like, fine filtration is performed through some instruments after filtration, and in the filtration process, certain heat energy is generated due to mutual movement friction among the rice; in step 2, mutual friction heat generated after a coarse screening process in step 1 is cooled through cold air pushing, and the situation that the water content is reduced and subsequent procedures are affected due to local high heat energy generated by mutual movement friction among the rice is avoided; and the temperature among the rice can be controlled between 15 DEG C and 25 DEG C through temperature control of 10-15 DEG C and fine screening, and therefore, the situation of cracking or serious nutrition loss caused by over-high heat and over-low water content in the subsequent process is avoided.

Owner:勐海曼香云天农业发展有限公司

Automobile skylight assembling equipment and assembling method thereof

ActiveCN113635997ACompact and stable structureGuaranteed cleanlinessLiquid surface applicatorsCoatingsMechanical engineeringHoist device

The invention relates to the technical field of automobile accessory installation, and provides automobile skylight assembling equipment and an assembling method. The equipment comprises a preparation station, a hoisting device, a gluing station, a gluing device, an automobile conveying device and a carrying device, and the preparation station is used for containing a skylight to be cleaned; the hoisting device is used for moving the skylight to the preparation station; the gluing station is used for placing a skylight to be glued or glued; the gluing device is used for transferring the skylight on the preparation station to the gluing station and gluing the skylight to be glued on the gluing station; the automobile conveying device is used for conveying an automobile to a preset position; and the carrying device is used for assembling the glued sunroof on the gluing station to an automobile at a preset position. According to the automobile skylight assembling equipment and the assembling method thereof, the assembling efficiency is high, operation is easy and fast, and damage to the skylight in the assembling process is small.

Owner:广州启研机械设备有限公司

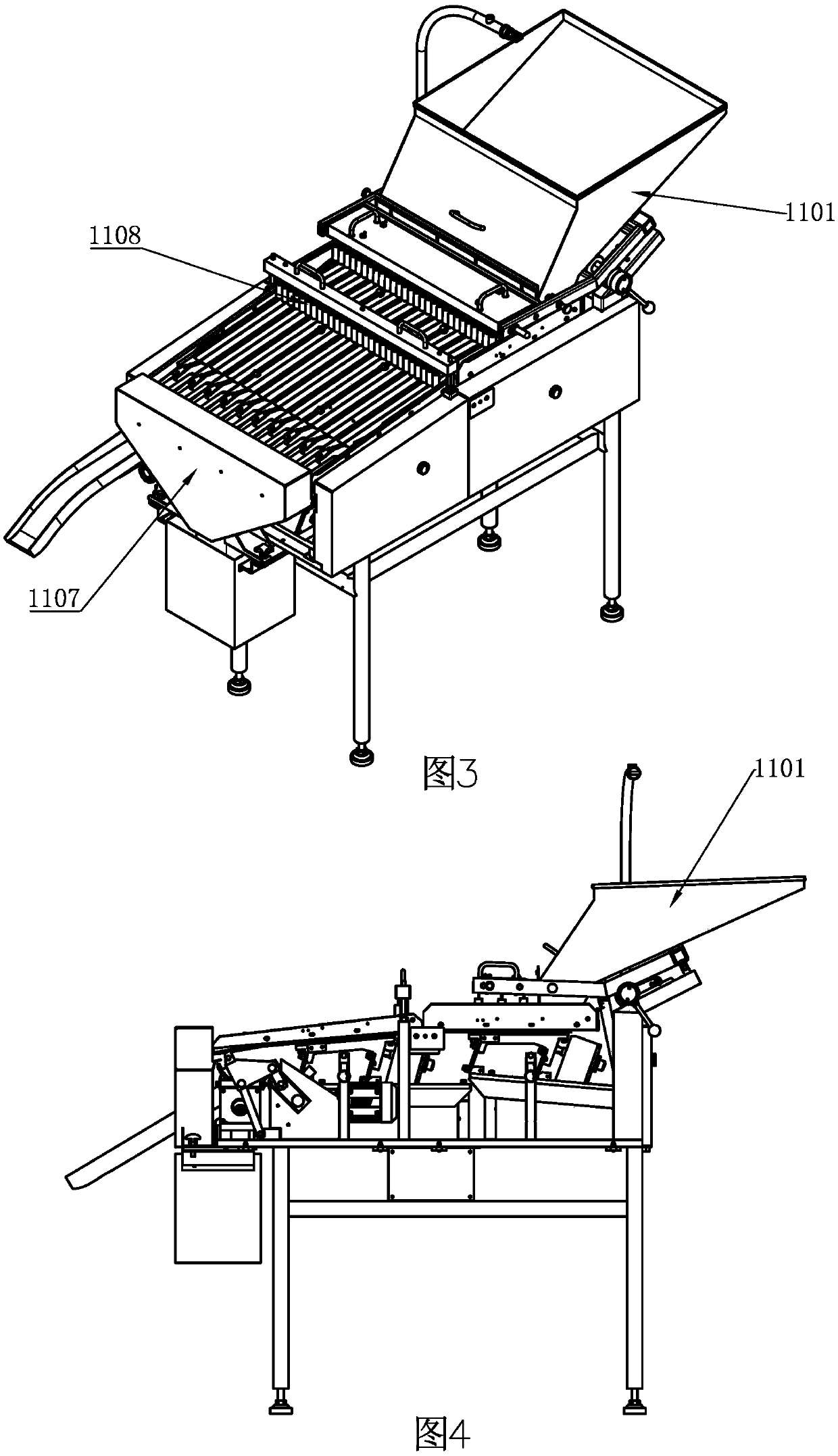

Discharge mechanism for candy wrapping

PendingCN109592103AAvoid affecting subsequent processesCompact structurePackagingMechanical engineeringEngineering

The invention discloses a discharge mechanism for candy wrapping. The discharge mechanism for candy wrapping comprises a rack, a bin, multiple sets of vibration assemblies, a receiving assembly, a poking assembly, a waste bin and a limiting assembly. The multiple sets of vibration assemblies are installed on the rack sequentially from left to right. The bin is installed at one end of the rack andis located above the vibration assemblies. The receiving assembly and the poking assembly are both installed at the other end of the rack and are located below the tail end of the vibration assemblies. The waste bin is installed at the tail end of the rack. The limiting assembly is installed on the rack and is located above the vibration assemblies. On the whole, the discharge mechanism is compactin structure, high in work efficiency and worth popularizing in the industry.

Owner:成都三可实业有限公司

Crayfish deep processing device

InactiveCN112335701ANo manual operationAvoid dangerous situationsOil/fat bakingMoving filtering element filtersHydraulic cylinderElectric machinery

The invention belongs to the field of crayfish processing, and particularly relates to a crayfish deep processing device. The device comprises a heating furnace; a pot groove is formed in the top of the heating furnace; a frying pan is fixedly installed in an inner cavity of the pot groove; mounting grooves are formed in two sides of the top of the heating furnace correspondingly; first hydrauliccylinders are fixedly mounted in inner cavities of the mounting grooves; fixed blocks are fixedly connected to the tops of the first hydraulic cylinders; and a filter screen is mounted in an inner cavity of the frying pan. According to the crayfish deep processing device, crayfish is placed in the filter screen and descend into the frying pan to be fried, after frying is finished, the filter screen is driven by the first hydraulic cylinders to ascend, then a first motor is started to drive the filter screen to rotate, the crayfish is poured out, mechanical operation is achieved, manual operation is not needed, dangerous situations are avoided, and meanwhile the efficiency is effectively improved.

Owner:顺祥食品有限公司

A method for protecting the mirror area of a cob mirror aluminum substrate

InactiveCN105440964BAvoid warpingAvoid affecting subsequent processesNon-macromolecular adhesive additivesAdhesive processes with adhesive heatingCooking & bakingTectorial membrane

The invention discloses a mirror surface region protection method of a COB mirror surface aluminum base plate, which comprises the following steps: step 1, preparing heat resistant glue: respectively weighing the following components in parts by weight: 60-65 parts of VAGH, 18-22 parts of curing agent, 8-10 parts of phthalate, 2-5 parts of lubricant and 2.5-5 parts of pigment system; heating the VAGH, curing agent and phthalate to 55-65 DEG C, stirring uniformly, then adding the lubricant and the pigment system, after fully stirring and cooling to room temperature to obtain the heat resistant glue; step 2, screen printing: by enabling a prepared screen to correspond to a mirror surface region of the COB mirror surface aluminum base plate, printing the heat resistant glue, and baking; step 3, reflow soldering: performing hot air reflow soldering on the COB mirror surface aluminum base plate; step 4, film tearing: after the reflow soldering is finished, manually tearing a protection film. By performing screen printing of the heat resistant glue in the mirror surface region, during reflow soldering, the mirror surface region is effectively protected.

Owner:XIAMEN UM OPTO TECH

Machining die for compression pump shell

PendingCN115415395AFully contactedAvoid the problem that the size must be increased additionallyShaping toolsMetal-working feeding devicesCompression PumpEngineering

The invention discloses a machining die for a compression pump shell, and relates to the technical field of compression pump machining dies. The die head is installed on a machine table in a driving mode, the elastic columns are inserted in the periphery of the die head in a sliding mode, the pin rod is fixedly arranged at the rear end of the die head, the die column is fixedly arranged on the machine table, an air ring is fixedly arranged on the periphery of the die column, and a liquid feeding mechanism used for centering raw materials and coating additives is movably connected between the air ring and the die column. And a switching mechanism for controlling the operation of the liquid feeding mechanism is fixedly arranged at the rear end of the gas ring. According to the invention, after the supporting elastic block is used for carrying out suspension treatment on the material sheet and the liquid feeding mechanism is used for centering the material sheet, an additive is automatically sprayed to the upper area and the lower area of the material sheet, so that the problem that the size of the original material sheet must be additionally increased due to manual positioning deviation is avoided, and the stretching quality and the working efficiency are enhanced; and the switching mechanism is matched and utilized to automatically control the operation state of the liquid feeding mechanism according to the stretching process, so that stable working procedures are ensured.

Owner:金雅豪金属科技(江苏)有限公司

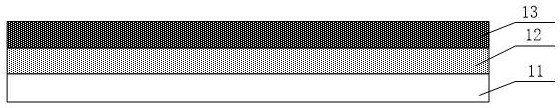

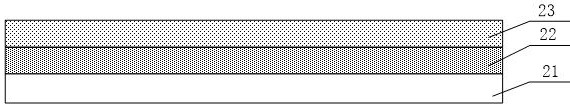

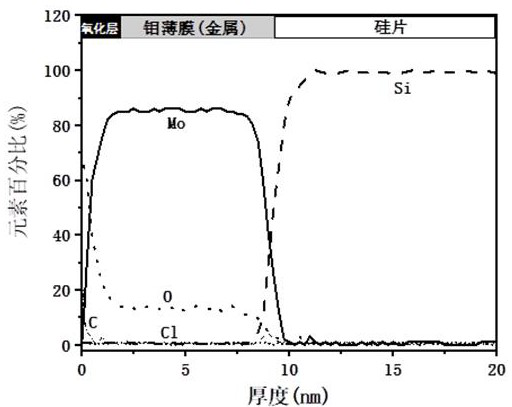

Metal thin film deposition method

ActiveCN114107939BGuaranteed performanceAvoid oxidation pollutionFinal product manufactureChemical vapor deposition coatingDeposition temperaturePhysical chemistry

The invention provides a method for depositing a metal thin film, comprising the steps of: providing a substrate to be deposited, cleaning the substrate and placing it in a vacuum chamber; after the temperature in the vacuum chamber is raised to a preset temperature, depositing a metal thin film on the surface of the substrate; A silicon film is deposited on the surface of the metal film in the vacuum chamber, and the silicon film is used to prevent the metal film from being oxidized; wherein, the preset temperature is the same as that during the deposition of the silicon film. The present invention creatively places the deposition process of the metal film at the deposition temperature of the silicon film, and continuously generates a silicon film on the surface of the metal film after depositing the metal film to protect the metal film, while ensuring the performance of the metal film , can prevent the metal film from being oxidized and polluted during the substrate transfer process, and avoid subsequent adverse effects on the composition characterization analysis of the metal film and affect the subsequent process.

Owner:BETONE TECH SHANGHAI

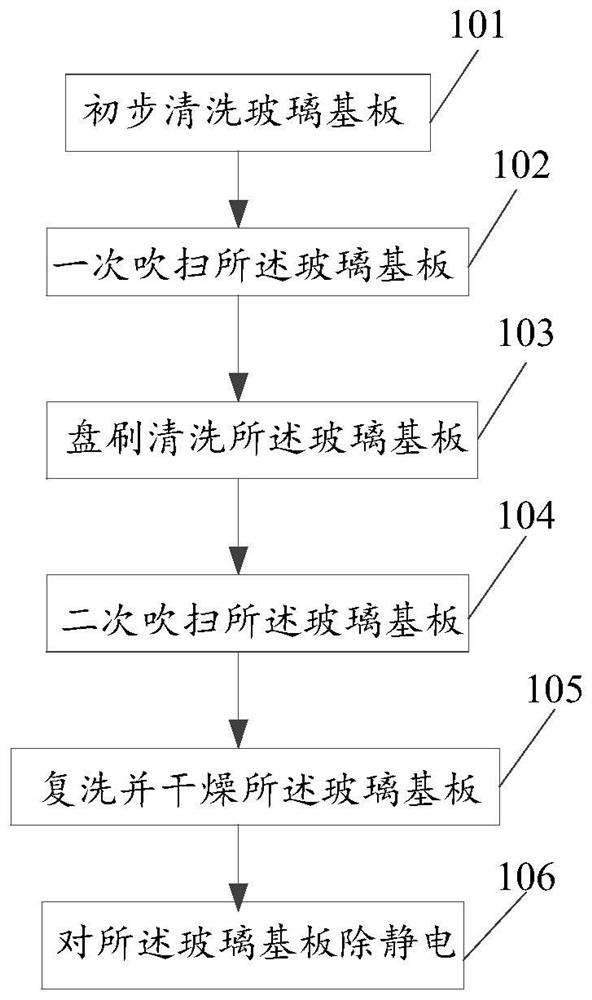

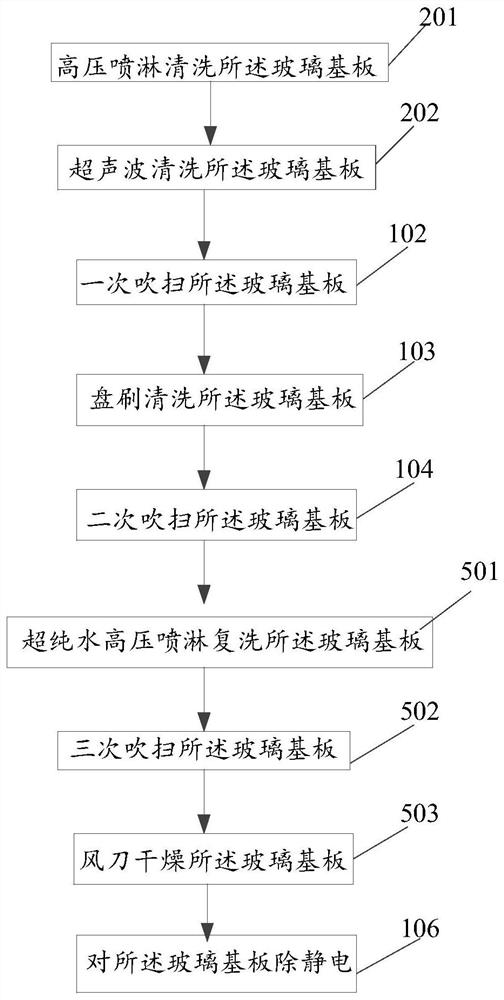

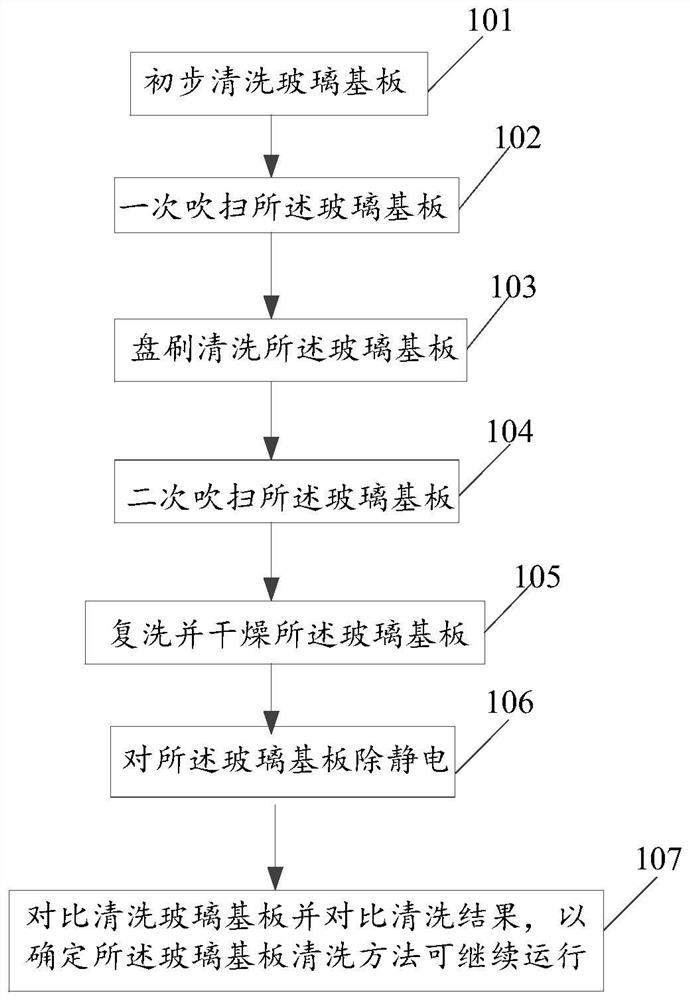

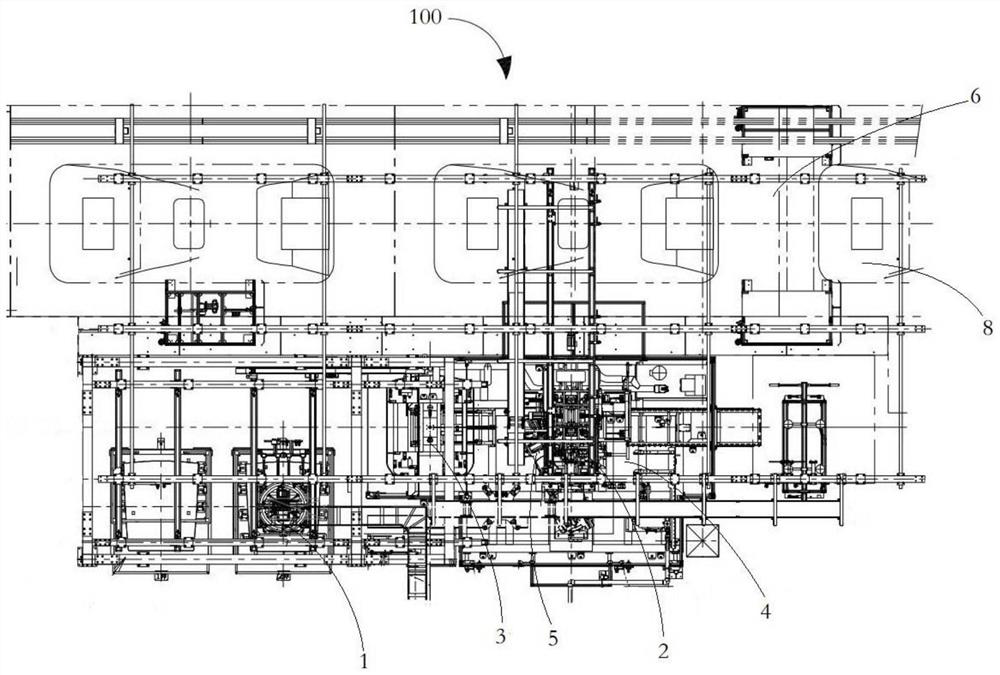

Glass substrate cleaning method and cleaning equipment

PendingCN114392999AGuaranteed cleanlinessEasy to cleanFlexible article cleaningCleaning using toolsCleansing AgentsStatic electricity

The invention discloses a glass substrate cleaning method and cleaning equipment. The glass substrate cleaning method comprises the following steps: preliminarily cleaning a glass substrate; blowing the glass substrate for the first time; cleaning the glass substrate by a disc brush; blowing the glass substrate for the second time; backwashing and drying the glass substrate; and removing static electricity from the glass substrate. The glass substrate is primarily cleaned, and disc brush cleaning is performed after primary blowing, so that particles and impurities on the surface of the glass substrate are primarily removed, and the situation that the particles and the impurities are brought into a disc brush cleaning process to scratch the surface of the glass substrate is avoided; meanwhile, after the disc brush is used for cleaning, the glass substrate is subjected to secondary purging and then is subjected to back washing and drying, so that the cleanliness of the surface of the glass substrate is further guaranteed, the cleaning effect is guaranteed, and the situation that the subsequent process is affected by a residual cleaning agent in the disc brush cleaning process is avoided; and moreover, the arrangement of static electricity removal can prevent the glass substrate from adsorbing impurities, so that the cleaning effect of the glass substrate is improved again.

Owner:WUHU TUNGHSU PHOTOELECTRIC SCI & TECHCO +2

A kind of automobile sunroof assembly equipment and assembly method

ActiveCN113635997BCompact and stable structureGuaranteed cleanlinessLiquid surface applicatorsCoatingsMechanical engineeringSunroof

The invention relates to the technical field of auto parts installation, and provides an automobile sunroof assembly equipment and an assembly method thereof. The preparation station is used to place the skylight to be cleaned; the lifting device is used to move the skylight to the preparation station; the gluing station is used to place the skylight to be glued or glued; the The gluing device is used for transferring the sunroof on the preparation station to the gluing station, and gluing the skylight to be glued on the gluing station; the automobile conveying device is used for conveying the automobile to a preset position; the mounting device is used for assembling the sunroof that has been glued on the gluing station to the car in the preset position. The automobile sunroof assembly equipment and the assembly method of the invention have high assembly efficiency, simple and quick operation, and little damage to the sunroof during the assembly process.

Owner:广州启研机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com