A method for protecting the mirror area of a cob mirror aluminum substrate

A technology of mirror aluminum substrate and area protection, which is applied in the bonding method of adhesive heating, film/sheet adhesive, film/sheet without carrier, etc., which can solve the problem of heat-resistant adhesive residue and substrate temperature. Problems such as unevenness, warping and peeling can be avoided to avoid warping, realize equipment operation, and improve efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

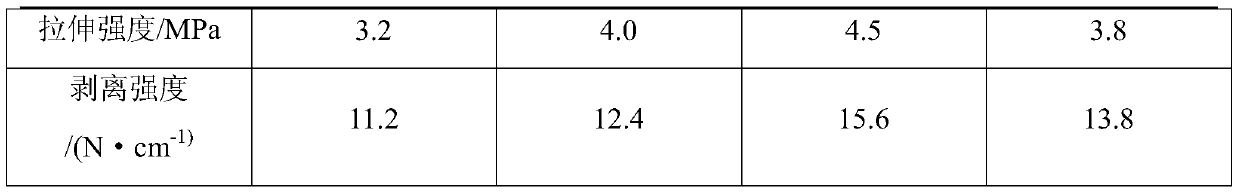

Embodiment 1

[0021] A method for protecting the mirror area of a COB mirror aluminum substrate, comprising the following steps:

[0022] Step 1. Preparation of heat-resistant glue: Weigh the following components in parts by weight: 60 parts of vinyl resin, 18 parts of curing agent, 8-parts of phthalate, 2 parts of lubricant and 2.5 parts of pigment system ; Heating the vinyl acetate resin, the curing agent and the phthalate to 55°C, stirring evenly, then adding the lubricant and the pigment system, stirring thoroughly, and cooling to room temperature, that is The heat-resistant glue can be obtained; the curing agent includes the following parts by weight: 10 parts of epoxy resin, 8 parts of resole phenolic resin; the lubricant includes the following parts by weight: hard 1 part of barium fatty acid, 1 part of triphenyl phosphate. The pigment system comprises the following components in parts by weight: 1 part of calcium carbonate, 1 part of silicon dioxide, and 0.5 part of phthalocyanin...

Embodiment 2

[0028] A method for protecting the mirror area of a COB mirror aluminum substrate, comprising the following steps:

[0029] Step 1. Preparation of heat-resistant glue: Weigh the following components in parts by weight: 62 parts of vinyl resin, 20 parts of curing agent, 9 parts of phthalate, 3 parts of lubricant and 3 parts of pigment system; Heat the vinyl acetate resin, the curing agent, and the phthalate to 60°C, stir evenly, then add the lubricant and the pigment system, stir well, and cool to room temperature. Prepare the heat-resistant glue; the curing agent includes the following parts by weight: 11 parts of epoxy resin, 9 parts of resole phenolic resin; the lubricant includes the following parts by weight: stearin 1 part of barium acid, 2 parts of triphenyl phosphate; the pigment system includes the following components in parts by weight: 1 part of calcium carbonate, 1 part of silicon dioxide, and 1 part of phthalocyanine blue.

[0030] Step 2. Silk screen printing:...

Embodiment 3

[0035] A method for protecting the mirror area of a COB mirror aluminum substrate, comprising the following steps:

[0036] Step 1. Preparation of heat-resistant glue: Weigh the following components in parts by weight: 65 parts of vinyl resin, 22 parts of curing agent, 10 parts of phthalate, 5 parts of lubricant and 5 parts of pigment system; Heat the vinyl acetate resin, the curing agent, and the phthalate to 65°C, stir evenly, then add the lubricant and the pigment system, stir well, and cool to room temperature. Prepare the heat-resistant glue; the curing agent includes the following parts by weight: 12 parts of epoxy resin, 10 parts of resole phenolic resin; the lubricant includes the following parts by weight: stearin 2 parts of barium acid, 3 parts of triphenyl phosphate; the pigment system includes the following components in parts by weight: 2 parts of calcium carbonate, 2 parts of silicon dioxide, and 01 part of phthalocyanine blue.

[0037] Step 2, silk screen pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com