Exposure method for large-sized spliced product

An exposure method and large-scale technology, applied in the field of integrated circuit manufacturing, can solve the problem of high cost of photomasks, achieve the effects of reduced work intensity, good overlay accuracy and splicing alignment accuracy, and cost savings of photomasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

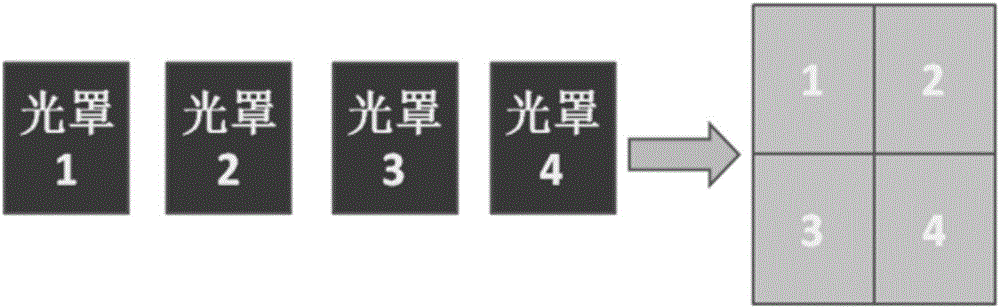

[0030] A method for exposing large-scale spliced products, comprising the following steps:

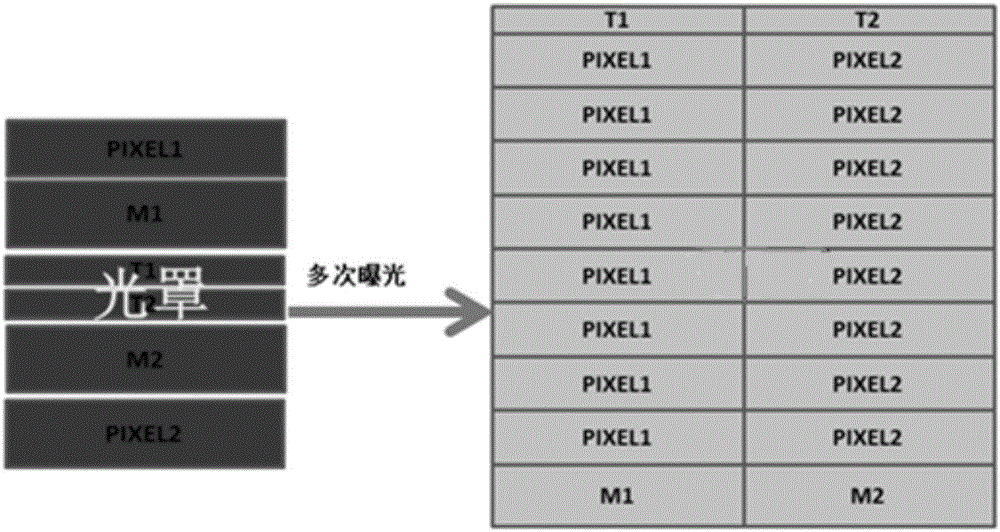

[0031] S1: Divide the rectangular mask into six areas from top to bottom, which are PIXEL1 area, M1 area, T1 area, T2 area, M2 area and PIXEL2 area from top to bottom. The lengths of the six areas are equal to the length of the mask. width with a blackout band between each area.

[0032] The size of each area in the photomask is smaller than the maximum exposure size of the photolithography machine, the size of the entire photomask is larger than the maximum exposure size of the photolithography machine, and the M1 area, T1 area, T2 area and M2 area are all placed with overlay alignment marks, Used to monitor in-wafer overlay accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com