Glass automatic processing device after active reagent coating and processing method thereof

A technology of active reagents and processing devices, which is applied in the field of automatic processing devices after glass active reagents are coated, can solve the problems of insufficient time, time-consuming, paper scratches on glass, etc., so as to improve yield rate, reduce labor costs, and improve glass quality. The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

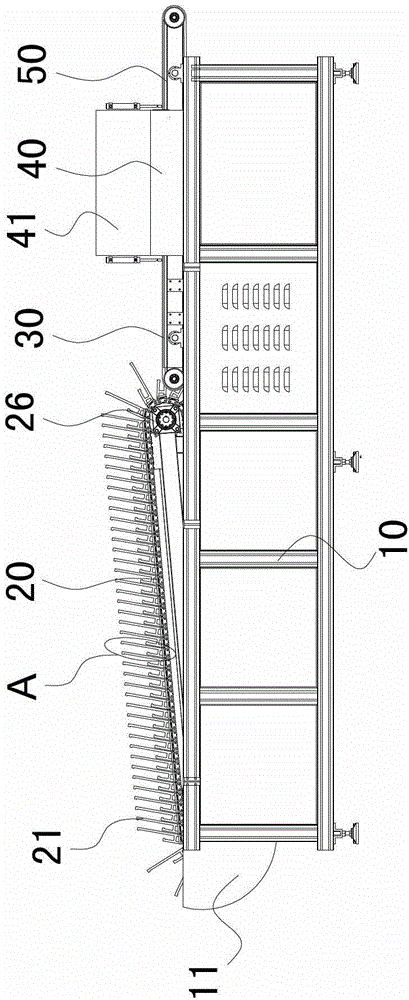

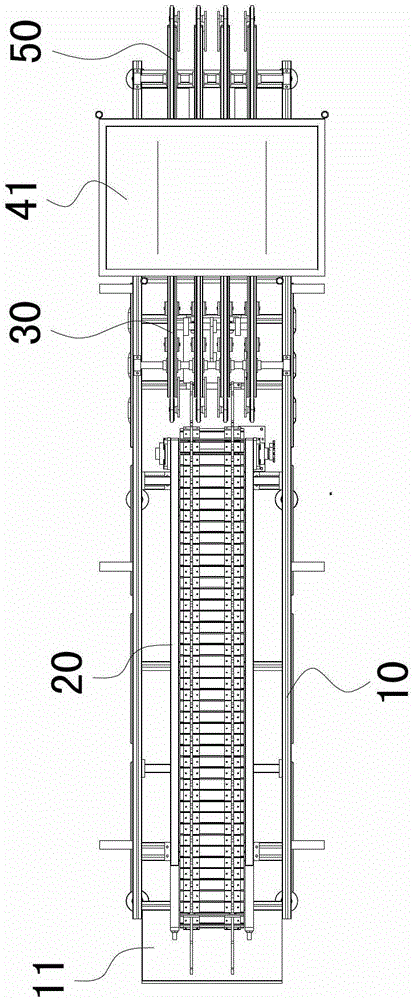

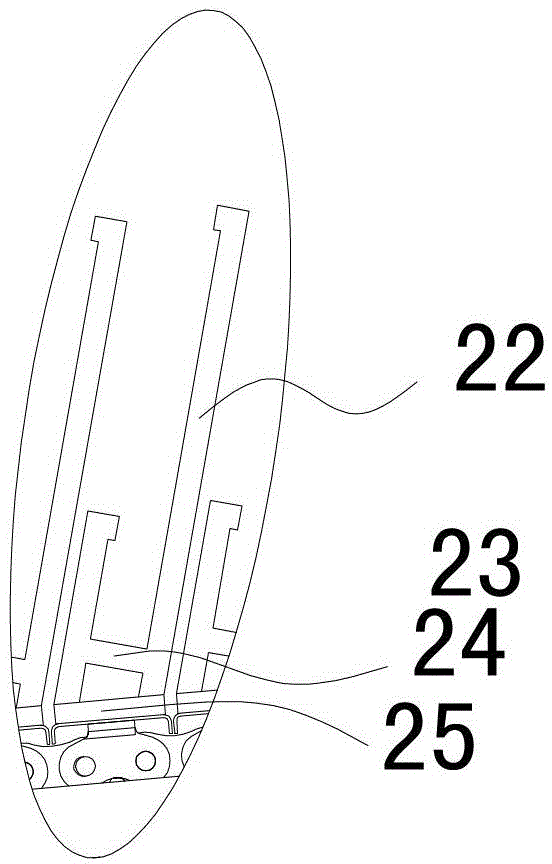

[0031] like figure 1 and figure 2 As shown, the automatic processing device of the present invention after the glass active reagent is coated includes a base frame 10 and a control device, and the base frame 10 is provided with a drying transfer device 20, a film transfer device 30, a heating device 40 and a lower frame. Sheet transfer device 50. The glass sequentially passes through the drying transfer device 20, the sheet transfer device 30, the heating device 40 and the lower sheet transfer device 50, and the drying transfer device 20, the sheet transfer device 30, the Both the heating device 40 and the lower sheet conveying device 50 are connected to the control device. In this preferred embodiment, the drying transfer device 20, the sheet transfer device 30 and the lower sheet transfer device 50 are all transfer belts, and the user can rotate multiple sets of transfer belts side by side or separately according to their different functions. a conveyor belt.

[0032] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com