Automatic washing machine of vibrating motor rotor assemblies

An automatic cleaning machine and vibration motor technology, applied in the manufacture of stator/rotor body, cleaning method using gas flow, cleaning method and utensils, etc., can solve the problems of slow speed, low efficiency, poor effect, etc., to prevent displacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

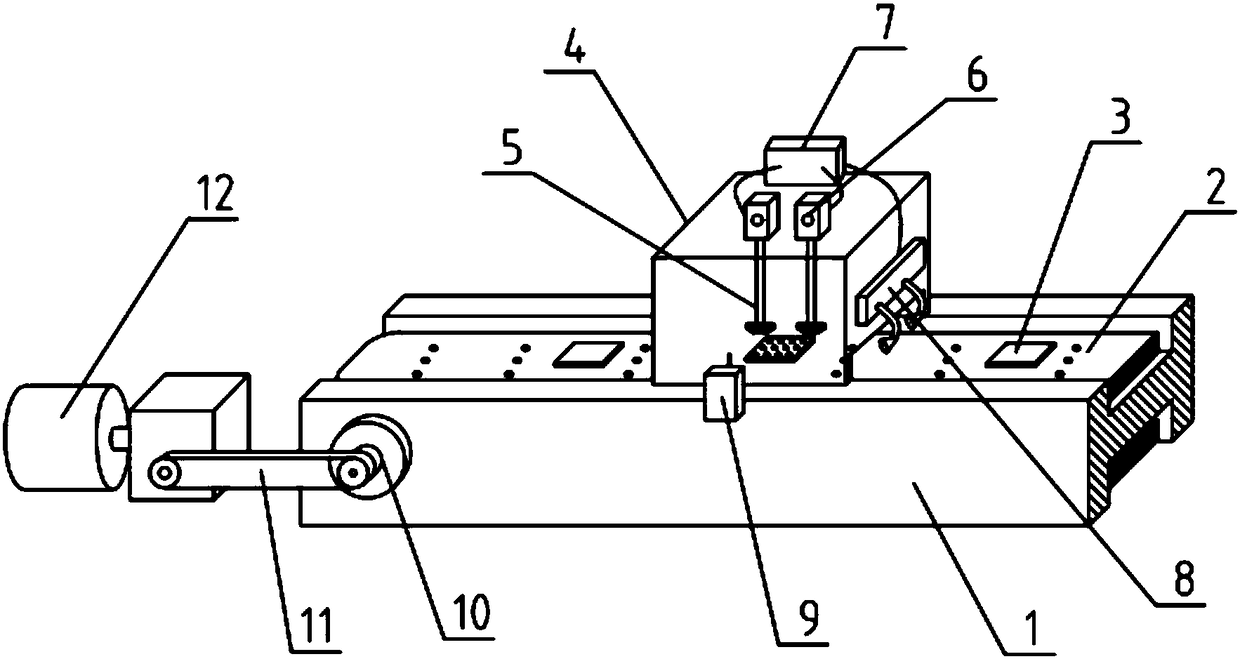

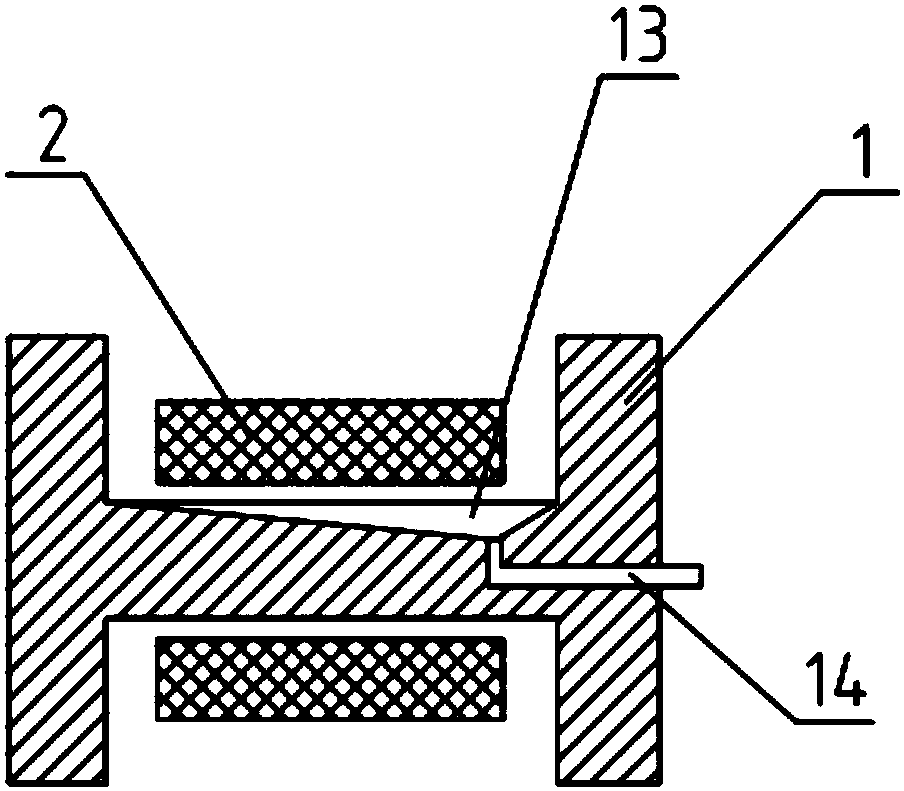

[0019] as attached figure 1 to attach figure 2 shown

[0020] The present invention provides an automatic cleaning machine for a vibration motor rotor assembly, including a positioning guide rail 1, a conveyor belt 2, an adsorption sticker 3, a transparent cover body 4, a cleaning blowing device 5, a pressure regulating valve 6, a delay relay 7, and a drying device 8 , optical fiber sensor 9, pulley 10, conveyor belt 11, motor 12, water collecting tank 13 and leaking pipe 14, described positioning guide rail 1 is set as " I " font support guide rail, and is provided with pulley 10 rotations by its two ends Connected with a conveyor belt 2, the upper part of the conveyor belt 2 is equidistantly provided with adsorption stickers 3 for fixing the rotor jig; the middle part of the upper end of the positioning guide rail 1 is provided with a transparent cover 4, and the inner cavity of the transparent cover 4 Vertically be provided with cleaning air blowing device 5, the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com