Wafer transfer box and control method thereof

A wafer transfer box and wafer technology, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of wafer transfer box and wafer contamination, scratches on adjacent wafers, etc., to ensure cleanliness environment, the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the current semiconductor manufacturing, the mechanical arm of the machine reaches into the FOUP to grab the wafers. When the robotic arm grabs the wafers in the FOUP, the remaining particles may contaminate the FOUP, and even Due to the fluctuation of the wafer and the robotic arm, scratches to other adjacent wafers are caused during the grabbing process.

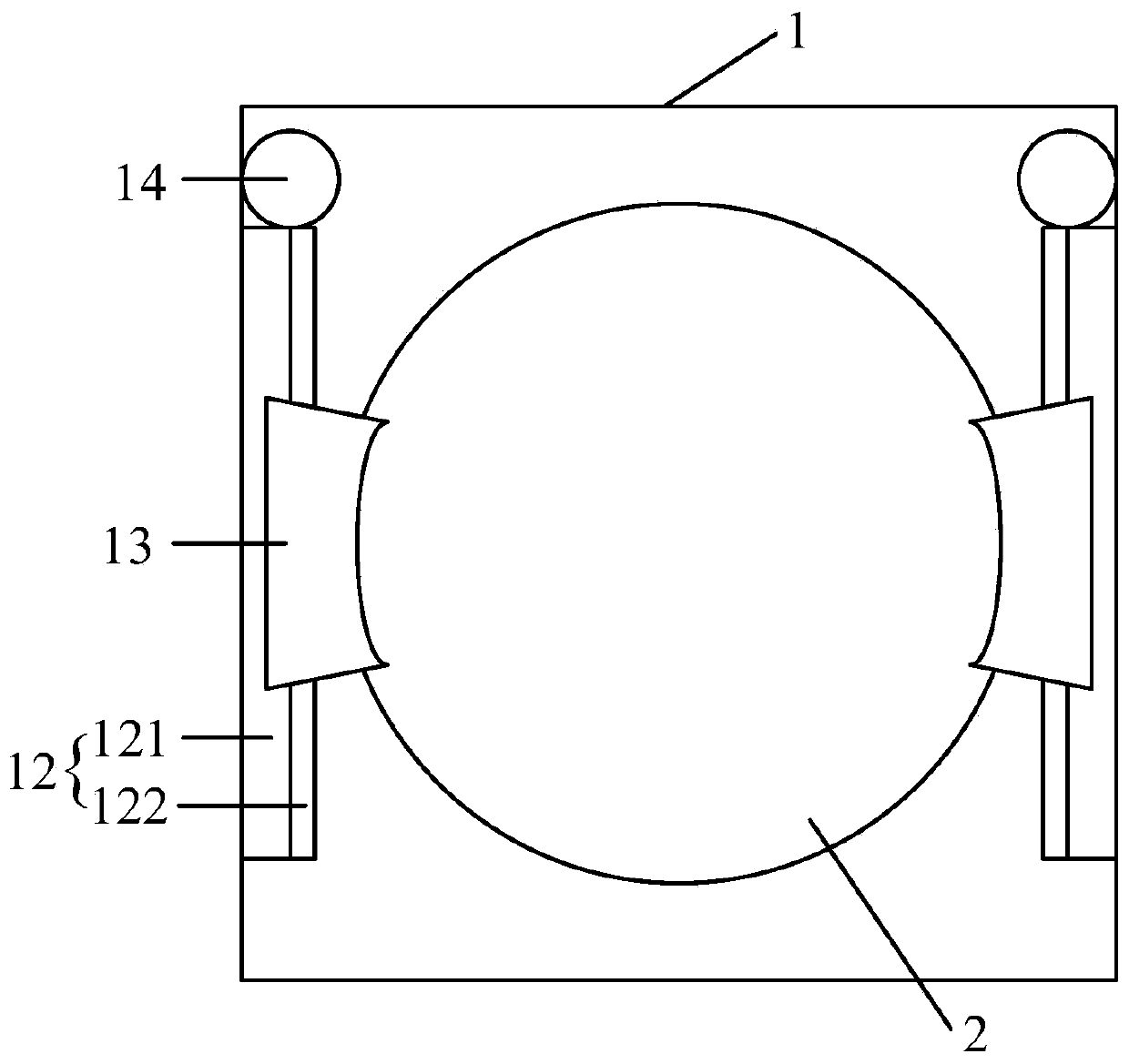

[0023] Based on this, the technical solution of the present invention proposes a FOUP, the inner wall of the FOUP is provided with a sliding fit mechanism, the sliding fit mechanism is used to move the wafer out of the FOUP and then the robotic arm grabs the wafer, thus There will be no residual particles in the box to contaminate the FOUP, nor will it scratch other wafers stored in the box.

[0024] The technical solution of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

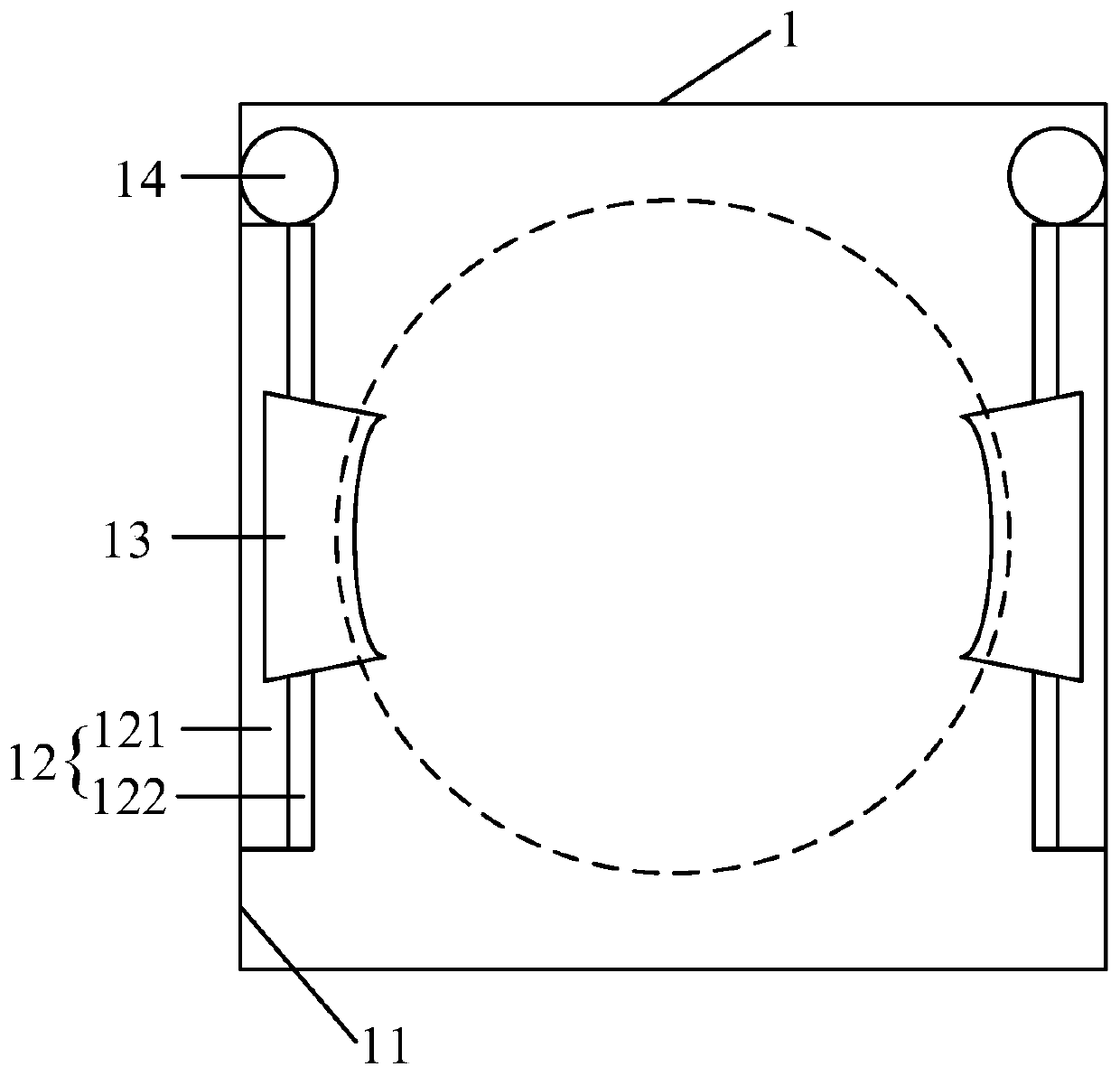

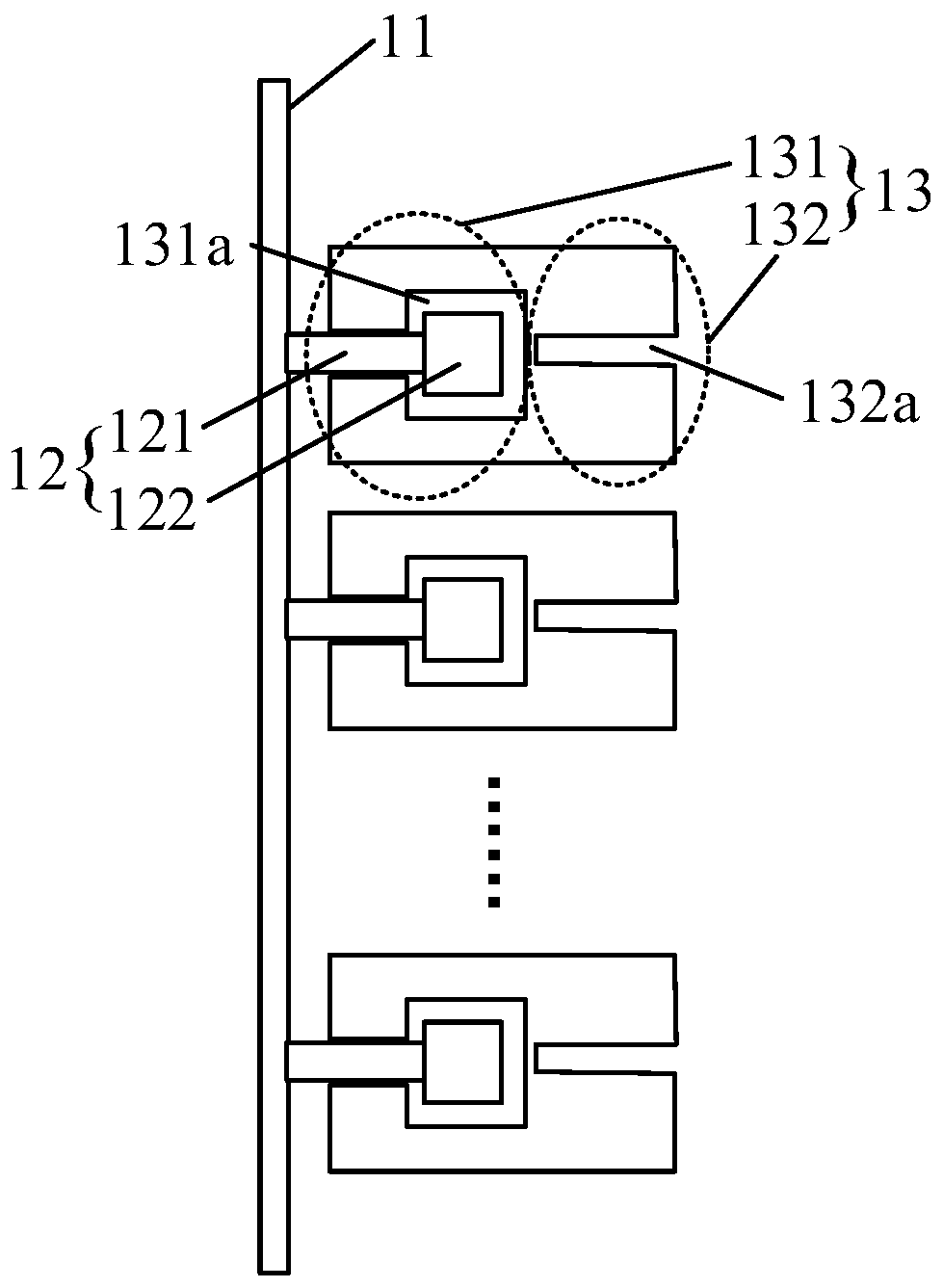

[0025] Please refer to figure 1 and figure 2 , the FOUP 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com