Photomask detection method and on-line immediate photomask detection method

A detection method and photomask technology, applied in the field of photomask detection, can solve the problems of increased cost, low sampling rate, time spent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

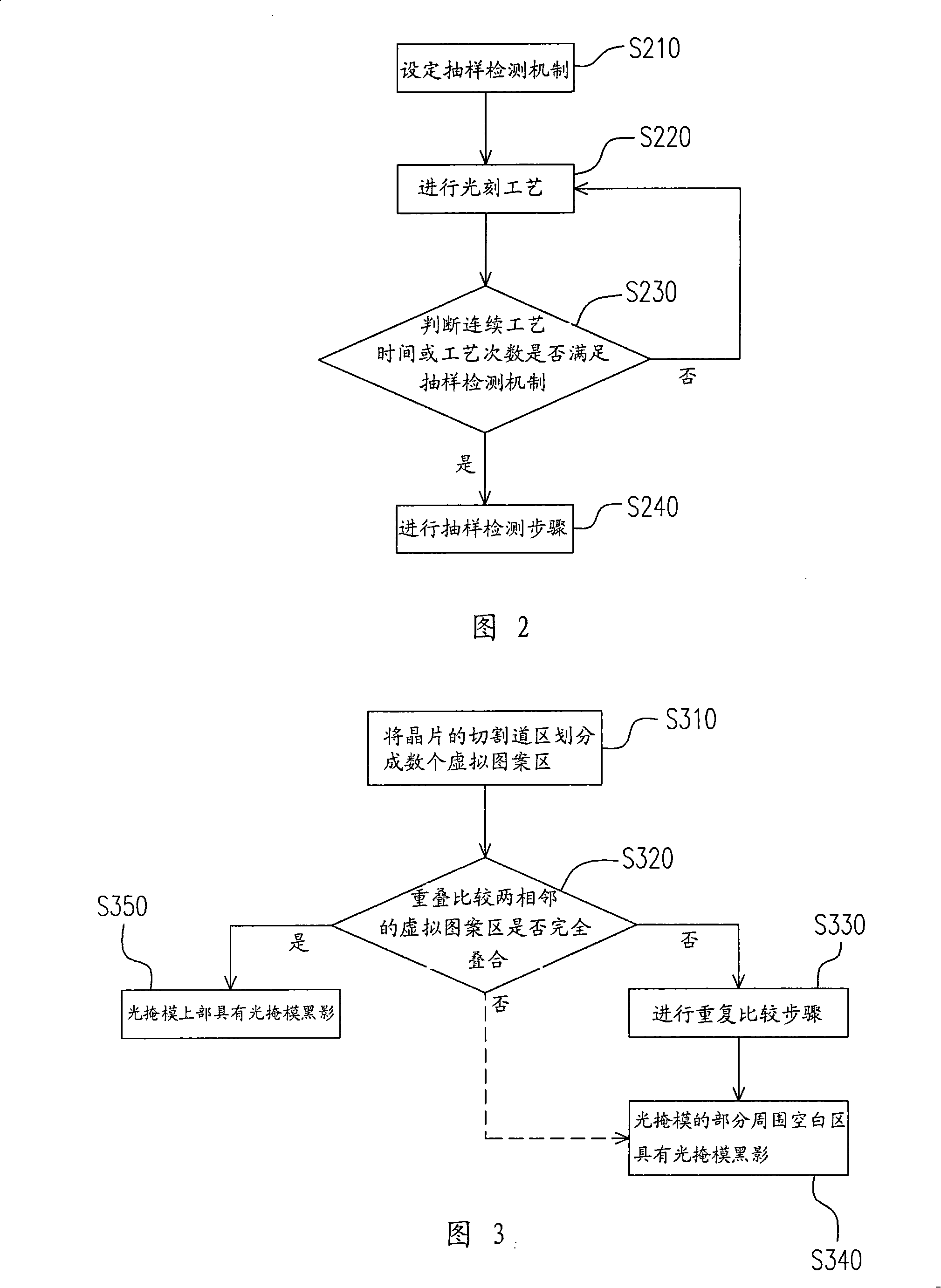

Embodiment Construction

[0041] In the photolithography process, the exposure process will cause photomask shadows on the photomask, and the photomask shadows will gradually expand with the increase of process time, which will not only affect the subsequent process, but also affect the reliability of the process And the cost of many processes. Therefore, when performing the photolithography process, the present invention also considers the influence of the shadow of the photomask on the pattern transfer, compares the wafers that have completed the process steps, and effectively detects whether the shadow of the photomask is formed on the photomask. The implementation of the online real-time photomask inspection method of the present invention will be described below in the form of a flow chart.

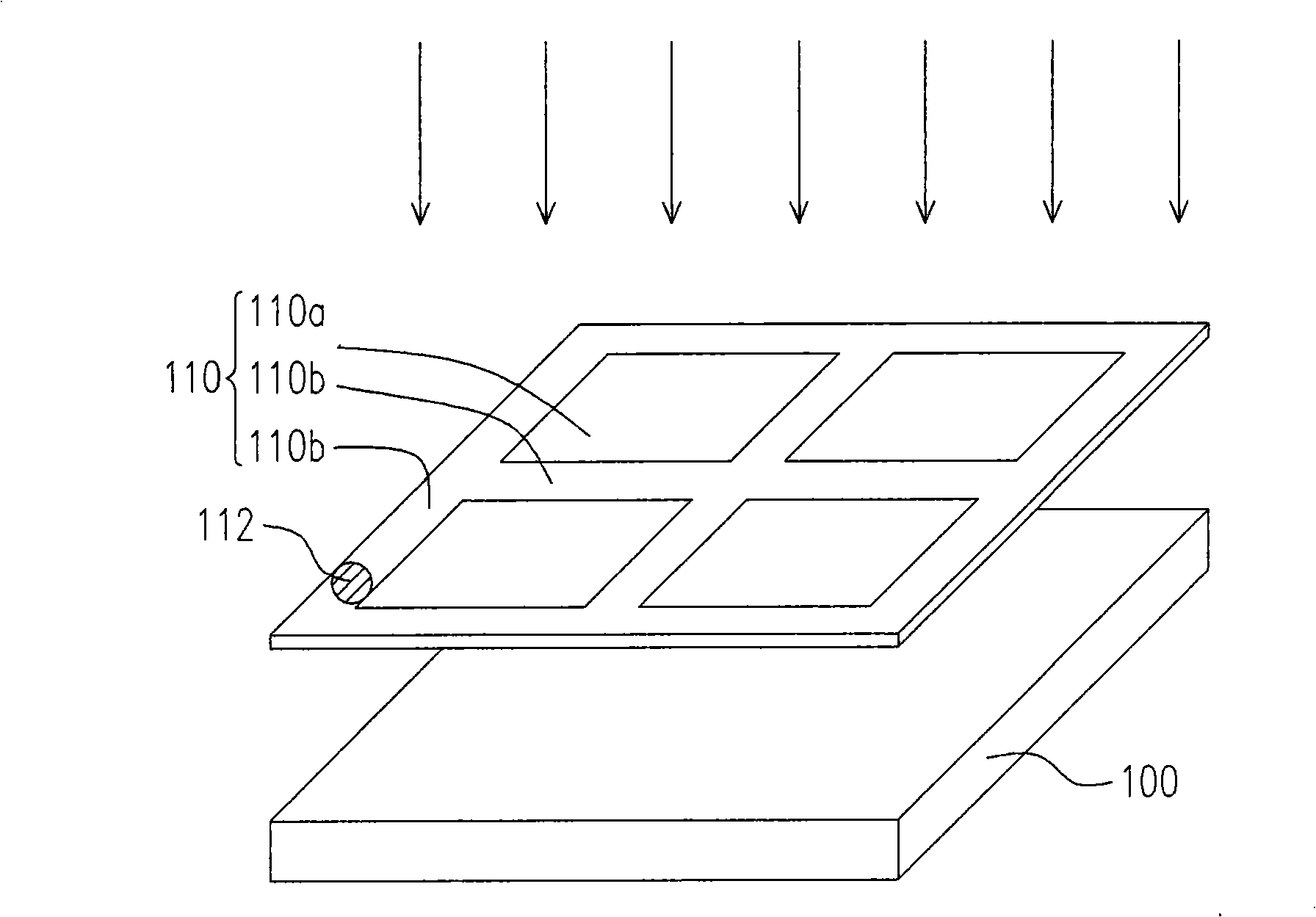

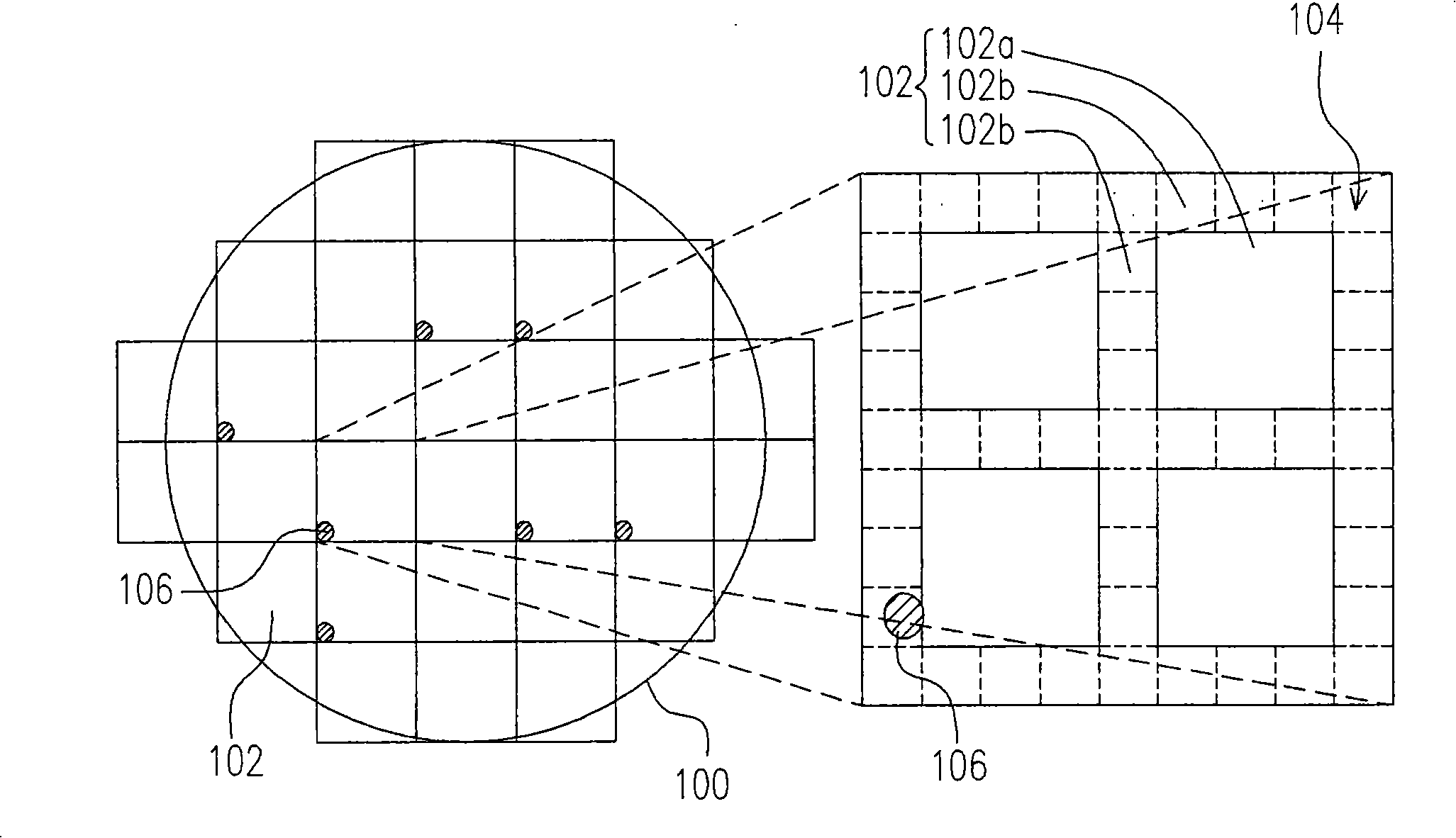

[0042] Figure 1A It is a schematic diagram of a photolithography process according to an embodiment of the present invention. Figure 1B It is a schematic top view of a wafer according to an embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com