Granular candy packaging machine

A packaging machine, candy technology, applied in packaging, conveyor belt wrapping, etc., can solve the problems of large volume, incapable of high efficiency, single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

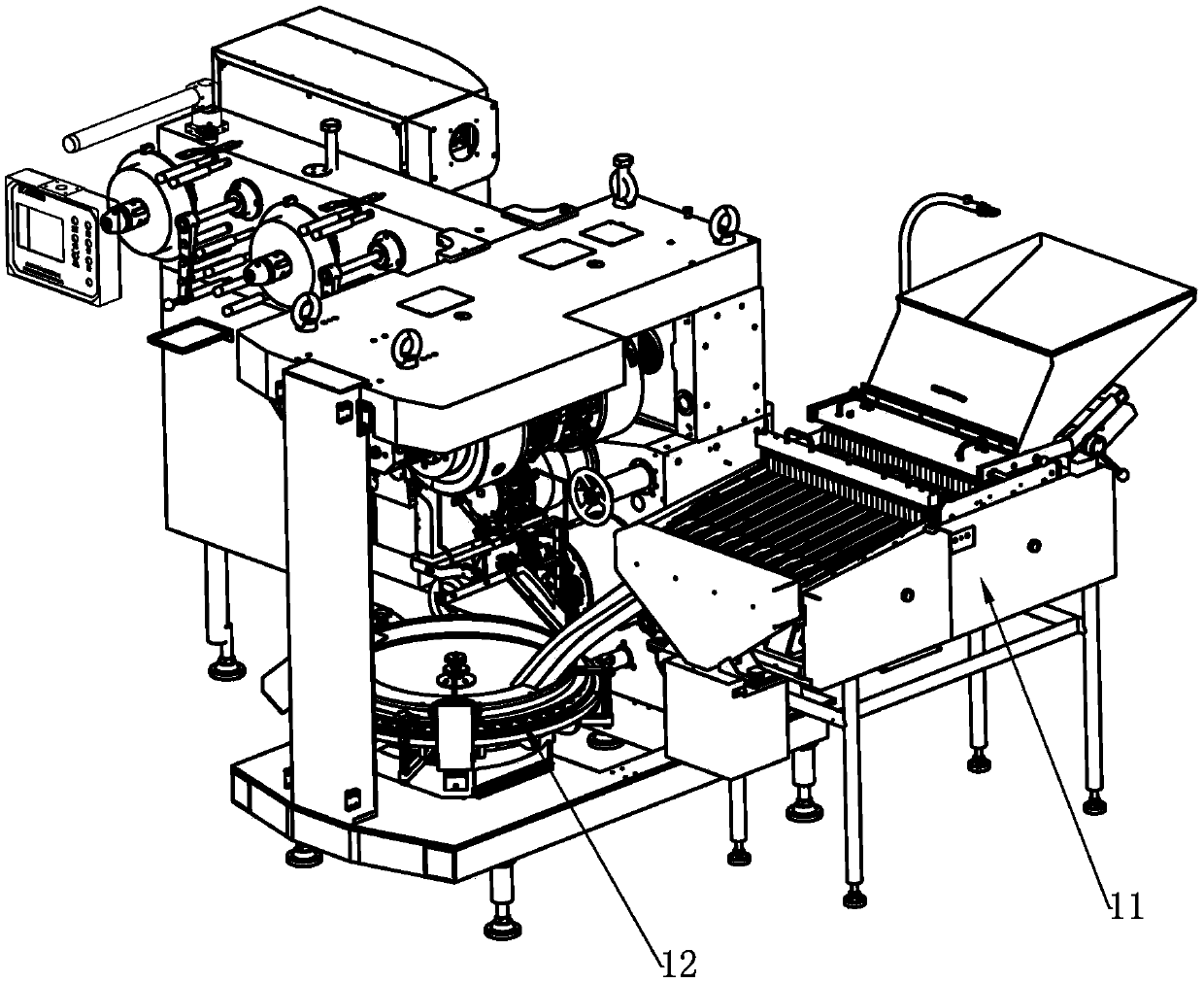

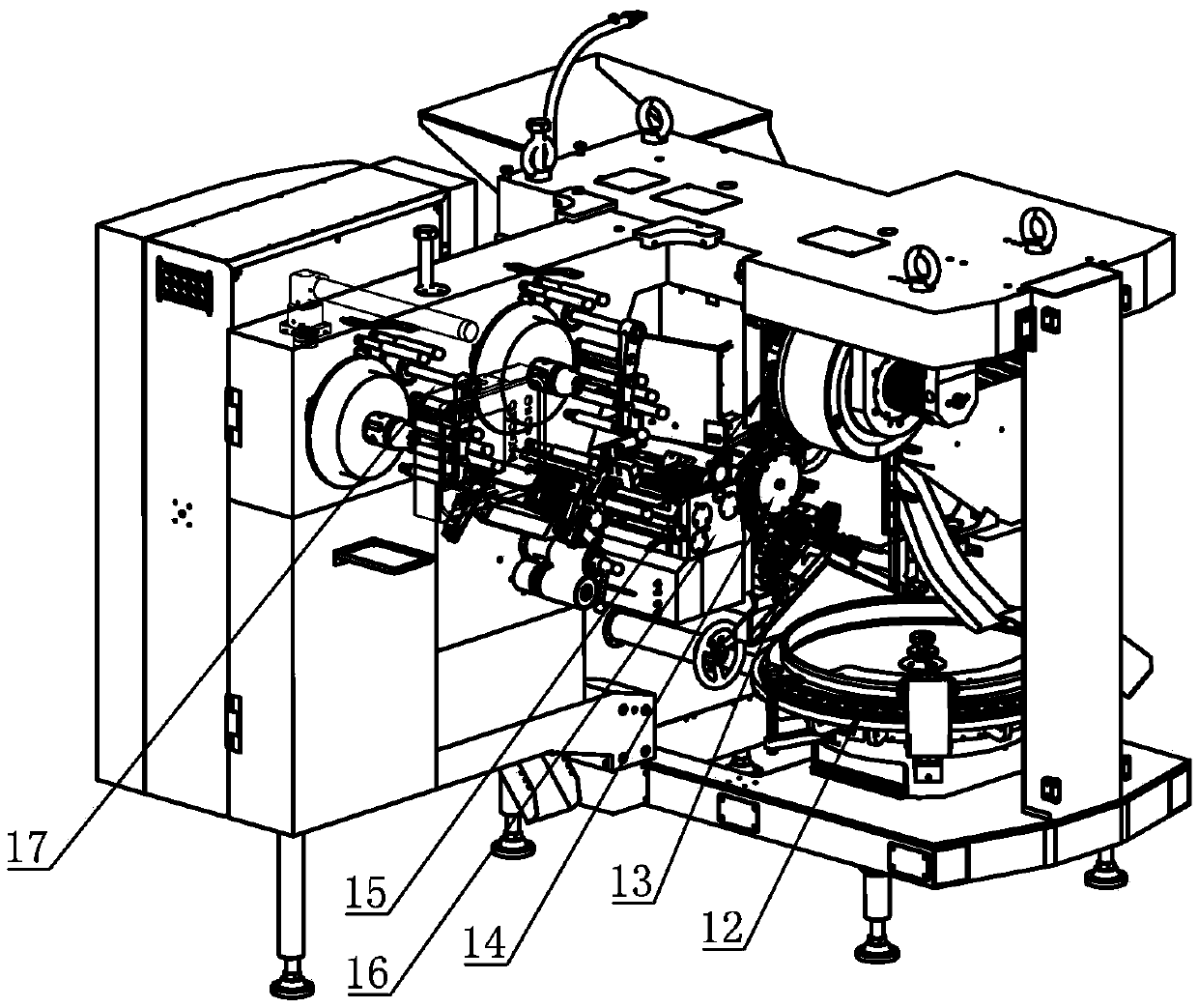

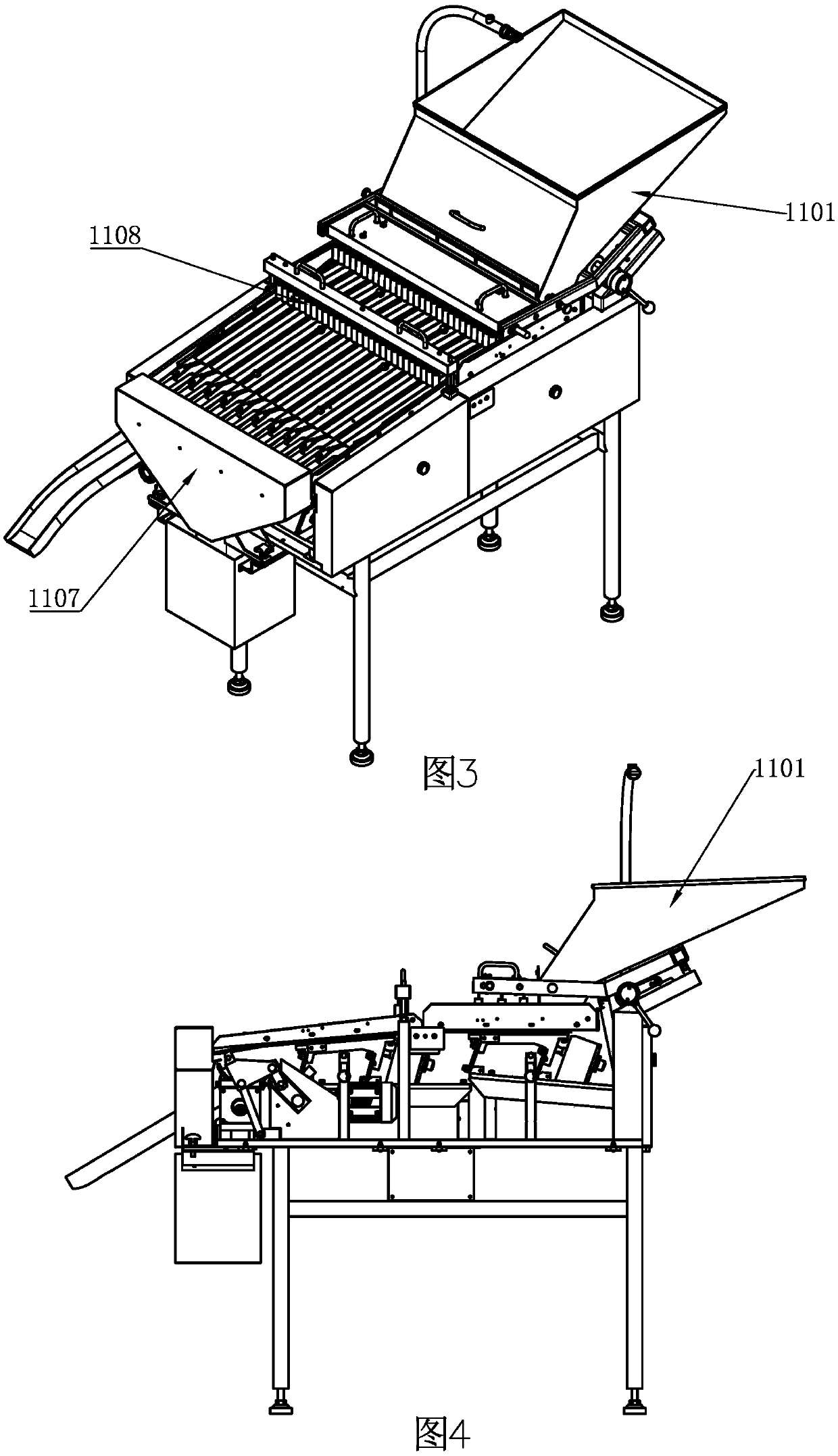

[0091] Such as Figure 1-8 As shown, the granular candy packaging machine of the present invention includes a main machine, a feeding mechanism, a sugar sorting mechanism 12, a sugar clamping mechanism 13, a transfer mechanism 14, a paper twisting mechanism 15, a paper feeding mechanism, a paper feeding mechanism, and a sugar discharging mechanism.

[0092] The main engine includes the main engine frame and the power output equipment of the main engine. The candy is transferred to the sugar sorting mechanism 12 through the feeding mechanism, and then the sugar clamping mechanism 13 picks up the candy from the sugar sorting mechanism 12 and transmits it to the transfer mechanism 14. The wrapping paper passes through the paper conveying mechanism. 1. The paper feeding mechanism is sent to the transfer mechanism 14, and the candy is wrapped in the wrapp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com