Pre-heating method of sulfate slag pellet ore

A technology of sulfuric acid slag pellets and sulfuric acid slag raw pellets, which is applied in the preheating field of pellets, and can solve the problems of affecting the process, cracks, and easy formation of over-wet layers by pellets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

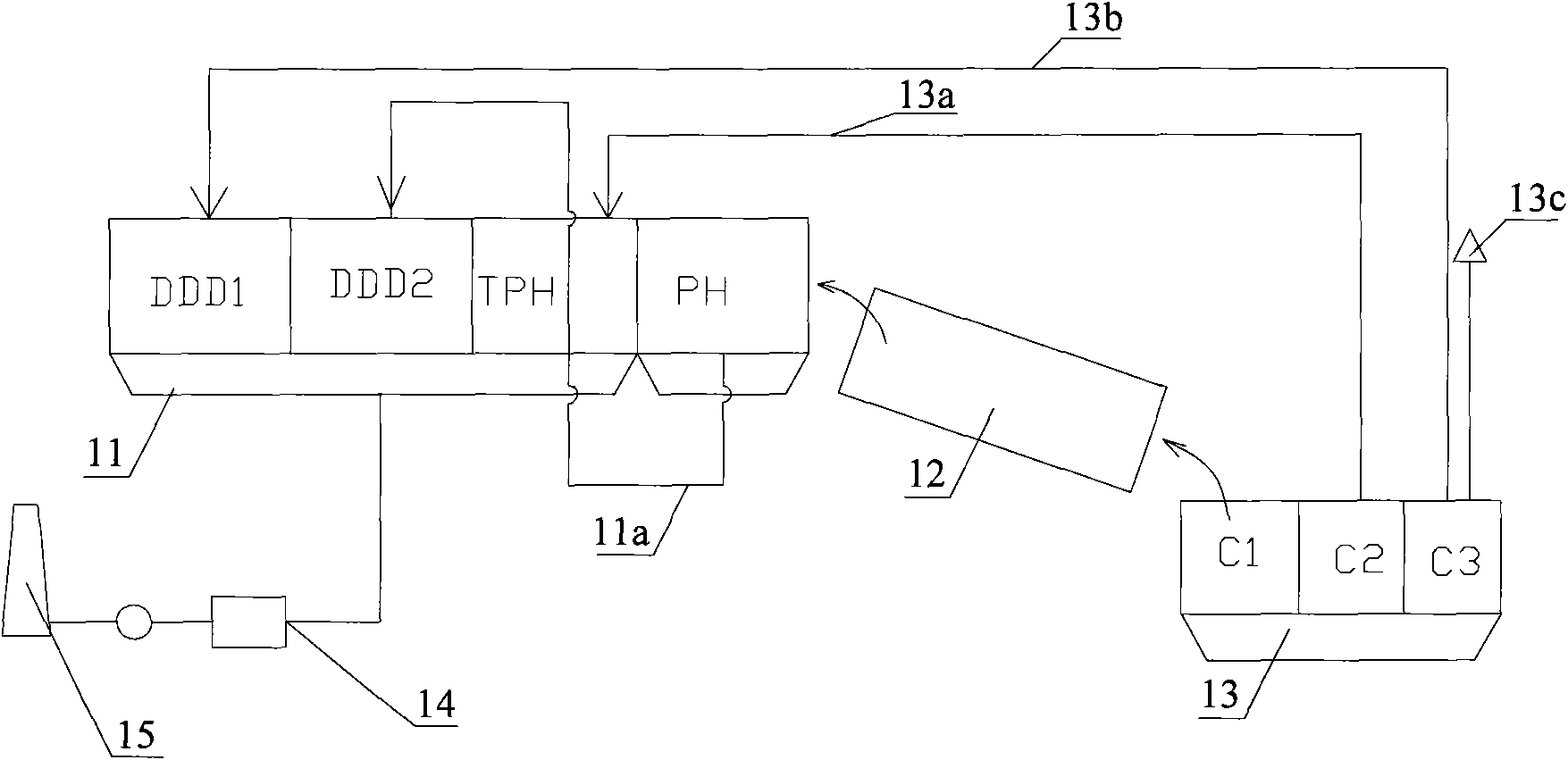

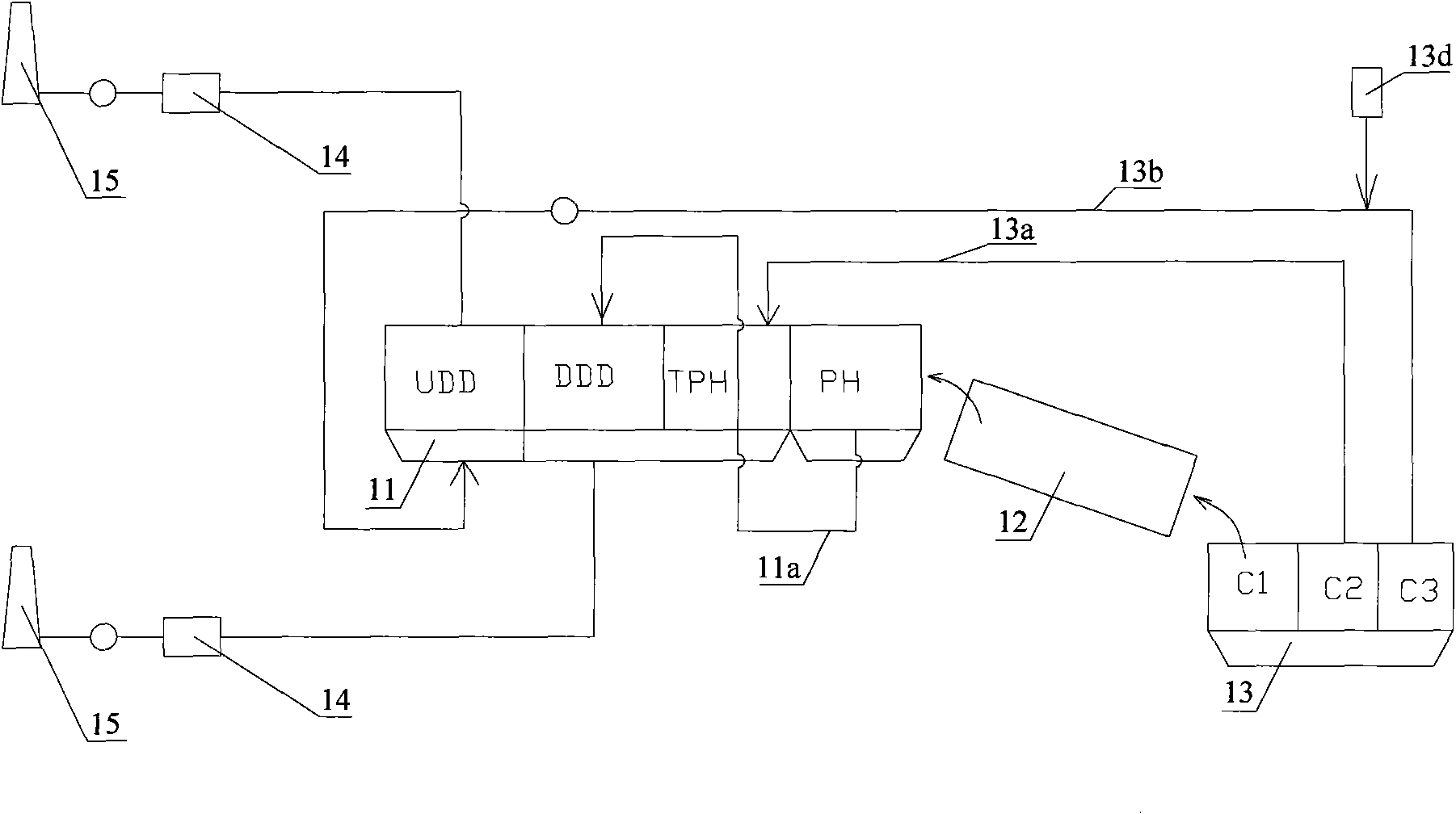

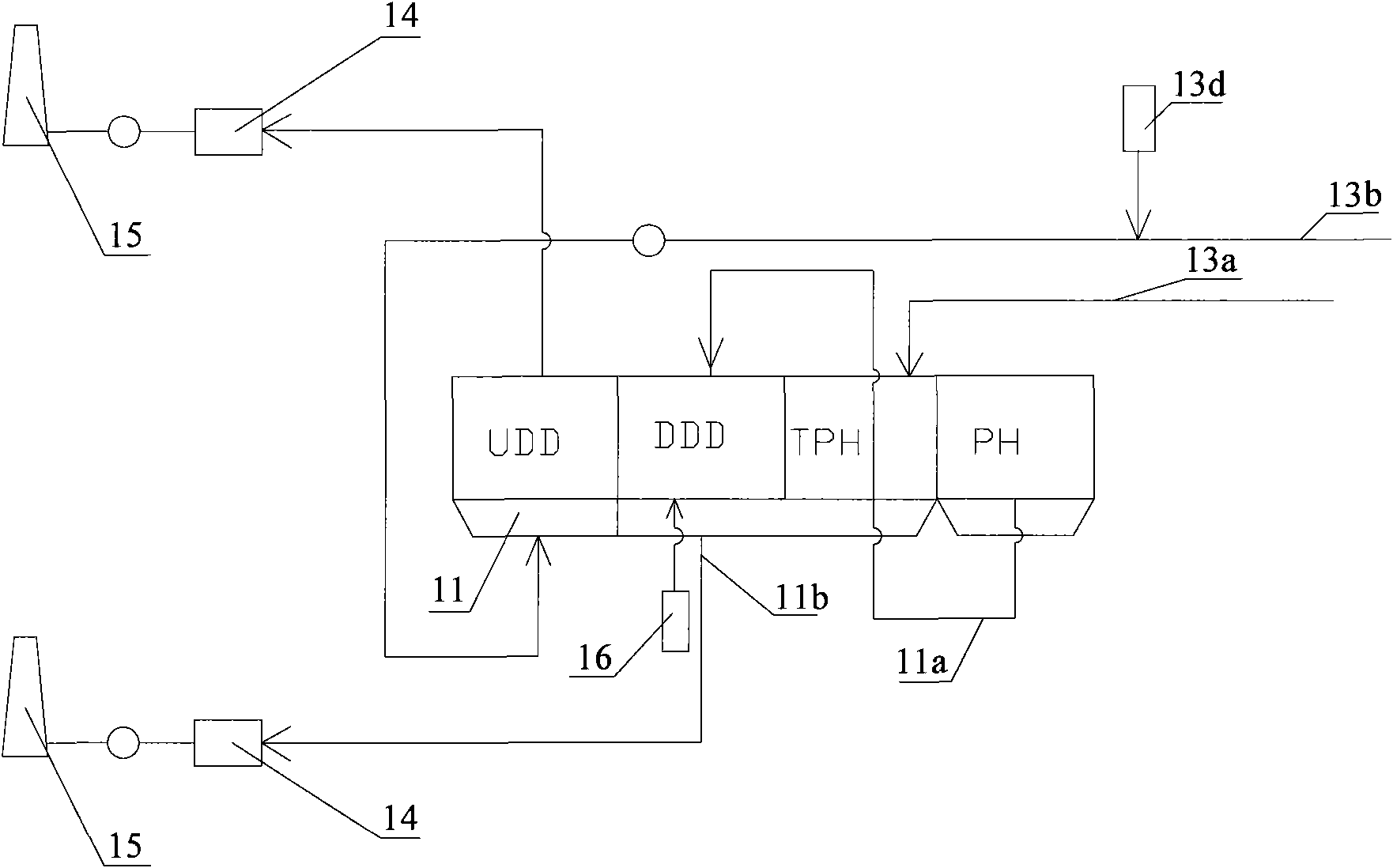

[0072] The main design parameters of the grate-rotary kiln are as follows:

[0073] Grate machine specifications: 4m (width) × 37.5m (length), blast drying section length 7.5m, set temperature 230°C, material surface wind speed 1.5m / s; suction drying section length 7.5m, set temperature 360°C , the wind speed at the material surface is 1.2m / s; the length of the first preheating section is 7.5m, the set temperature is 700°C, and the wind speed at the material surface is 1.0m / s; the length of the second preheating section is 15m, and the set temperature is 1200°C. The surface wind speed is 0.7m / s.

[0074] Rotary kiln set temperature: 1350°C.

[0075] Ring cooler specifications: diameter 12.5m, width 2.2m, effective cooling area 68m 2 ; The cooling area of the first cooling section C1 is 25m 2 , the cooling area of the second cooling section is 23m 2 , the cooling area of the third cooling section is 20m 2 .

[0076] The flue gas discharged from the first cooling sec...

Embodiment 2

[0081] The difference from Example 1 is that the following process design parameters have been changed: the set temperature of the blast drying section is 220°C, and the wind speed of the material surface is 1.4m / s; the set temperature of the draft drying section is 340°C, and the wind speed of the material surface is 1.3m / s ,; The set temperature of the first preheating section is 750°C, and the wind speed of the material surface is 1.1m / s; the set temperature of the second preheating section is 1200°C, and the wind speed of the material surface is 0.7m / s; ; Other parameters are identical with embodiment 1.

[0082] Raw materials: take 30 parts by weight of sulfuric acid slag after roller milling, 70 parts by weight of hematite, 1 part by weight of bentonite, 6 parts by weight of limestone and water to make pellets in a disc granulator. The obtained green pellets were tested, and the performance indexes were as follows: the drop strength was 7.3 times / 0.5m, the water content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst temperature | aaaaa | aaaaa |

| Burst temperature | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com