Production method and device of efficient circulating bio-organic fertilizer

A technology of biological organic fertilizer and production device, which is applied in the preparation of organic fertilizer, biological organic part treatment, organic fertilizer and other directions, can solve problems such as uneven effect of stirring raw materials, and achieve the advantages of lightening production burden, good quality and reducing production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

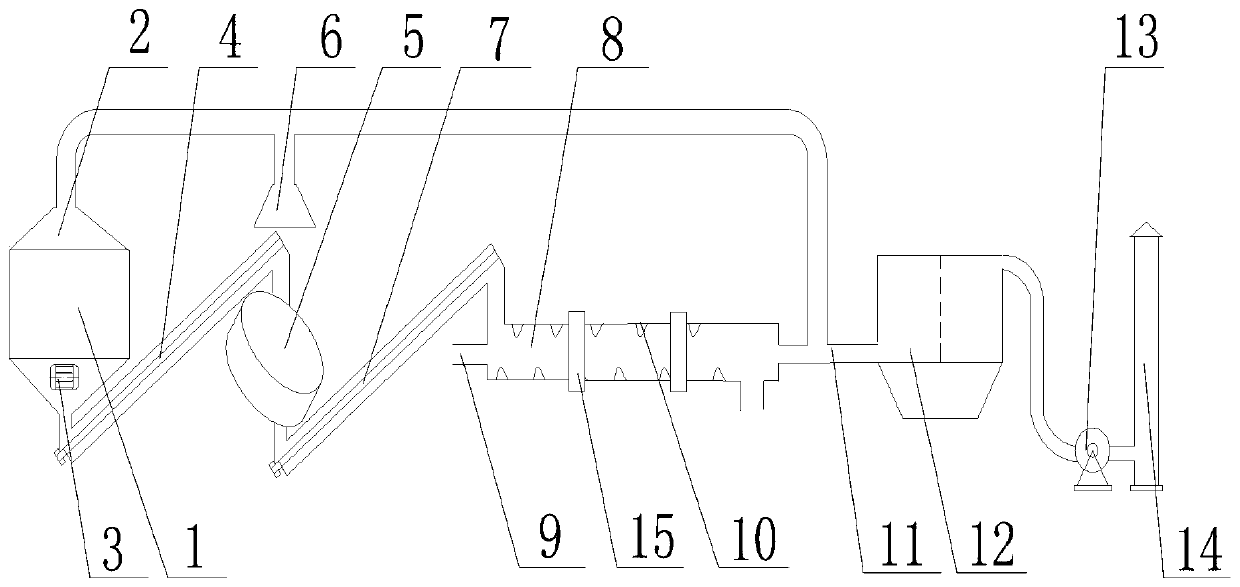

[0030] like figure 1As shown, a production device for high-efficiency circulating bio-organic fertilizers includes a raw material mixing bin 1, a disc mixer 5, a rotary granulation drying drum 8, and a dust collector 12. The feeding port of the raw material mixing bin 1 is connected to the The top of the disc mixer 5 is connected by a lifting belt 4, and the feeding port of the disc mixer 5 is connected with the feeding port of the rotary granulation drying drum 8 by a conveyor belt 7. The flue gas outlet at the rear of the granulation drying cylinder 8 is connected with the dust remover 12 by a pipe, and the dust remover 12 is connected with the dust removal fan 13, and the dust removal fan 13 is connected with the dust removal chimney 14 provided at the rear. The top of the raw material mixing bin 1 is provided with a top dust collection cover 2, and the upper part of the disc mixer 5 is provided with a dust collection cover 6, and the top dust collection cover 2, the dust c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com