Method for producing chlorfenapyr intermediate pyrrole by replacing acetonitrile with solvent DMF

An intermediate, chlorfenapyr technology, applied in the field of chlorfenapyr production, can solve problems such as ineffective improvement, low yield of intermediate products, increased production costs, etc., so as to reduce the production burden of enterprises, reduce energy consumption for recycling, Effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

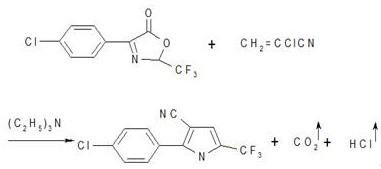

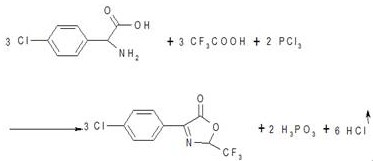

Method used

Image

Examples

Embodiment 1

[0049] A kind of method that solvent DMF replaces acetonitrile to produce chlorfenapyr intermediate pyrrole, adopts DMF to replace acetonitrile as solvent.

[0050] The method that described solvent DMF replaces acetonitrile to produce chlorfenapyr intermediate pyrrole, comprises the following steps:

[0051] (1) After the lactonization reaction, remove acetonitrile; then add benzene-water mixture, heat up to 40°C, and extract to obtain 4-(p-chlorophenyl)-2-trifluoromethyl-3-oxazoline- 5-ketone, content > 90%; then add 2 times the weight of DMF, stir at 85RPM for 30 minutes, and fully mix to obtain a mixed material.

[0052] During the process of removing acetonitrile, the vacuum degree is maintained at -0.1 MPa, and the temperature is slowly raised to 65° C. at a rate of 0.1-1° C. / min.

[0053] The acetonitrile is removed, and when the temperature is raised to 65° C., a sample is taken to detect the acetonitrile content, and the following treatment is carried out according t...

Embodiment 2

[0072] A kind of method that solvent DMF replaces acetonitrile to produce chlorfenapyr intermediate pyrrole, adopts DMF to replace acetonitrile as solvent.

[0073] The method that described solvent DMF replaces acetonitrile to produce chlorfenapyr intermediate pyrrole, comprises the following steps:

[0074] (1) After the lactonization reaction, remove acetonitrile; then add benzene-water mixture, heat up to 40°C, and extract to obtain 4-(p-chlorophenyl)-2-trifluoromethyl-3-oxazoline- 5-ketone, content > 90%; then add 1.8 times the weight of DMF, stir at 75RPM for 20 minutes, and fully mix to obtain a mixed material.

[0075] During the process of removing acetonitrile, the vacuum degree was kept at -0.1 MPa, and the temperature was slowly raised to 65° C. at a rate of 1° C. / min.

[0076] The acetonitrile is removed, and when the temperature is raised to 65° C., a sample is taken to detect the acetonitrile content, and the following treatment is carried out according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com