Technique for refined production of antiacid pipeline steel through VD-LF-VD

A VD-LF-VD, pipeline steel technology, applied in the direction of process efficiency improvement, manufacturing converters, etc., can solve the problem of not being able to meet the design requirements of high-grade pipeline steel anti-HIC and SCC components, so as to reduce production burden and eliminate The adverse effects of carburization and the effect of increasing furnace life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

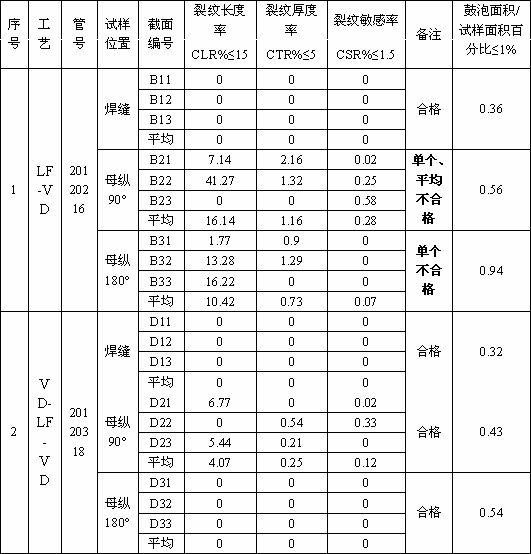

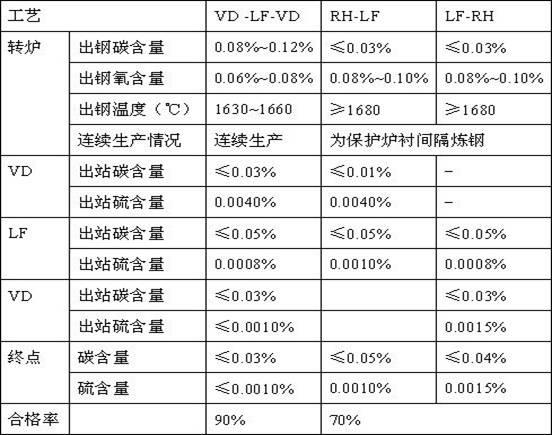

[0036] Implementation example: A steel plant in the Central Plains of my country applies the process of the present invention to smelt acid-resistant (HIC and SCC) X65 pipeline steel. The specific process: hot metal pre-desulfurization-converter smelting-VD refining (decarburization and deoxidation)-LF refining (heating desulfurization) - VD refining (decarburization and degassing) - slab continuous casting - hot rolling production of acid-resistant X65 pipeline steel with a thickness of 25.2mm, the carbon content of the finished steel is controlled at <0.04%, the sulfur content is less than 0.0009%, and the steel plate is rolled into a tube Finally, it fully meets the requirements of the acid resistance test. See the table below for the quality comparison of the single vacuum (LF-VD) process and the double vacuum (VD-LF-VD) process pipeline steel pipe after sampling.

[0037] Table 1

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com