Flat plate filtration lotion circulating system for aluminum oxide

A recycling system, alumina technology, applied in filtration and separation, aluminate/alumina/aluminum hydroxide purification, fixed filter element filters, etc., can solve the problem of increasing production consumption and operating costs, increasing the production burden of subsequent processes, Atmospheric pollution and other problems, to achieve the effect of saving condensed water consumption, avoiding volatilization of hot and strong alkali water vapor, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the following specific embodiments are only used to illustrate the technical solutions of the present invention, not to limit them.

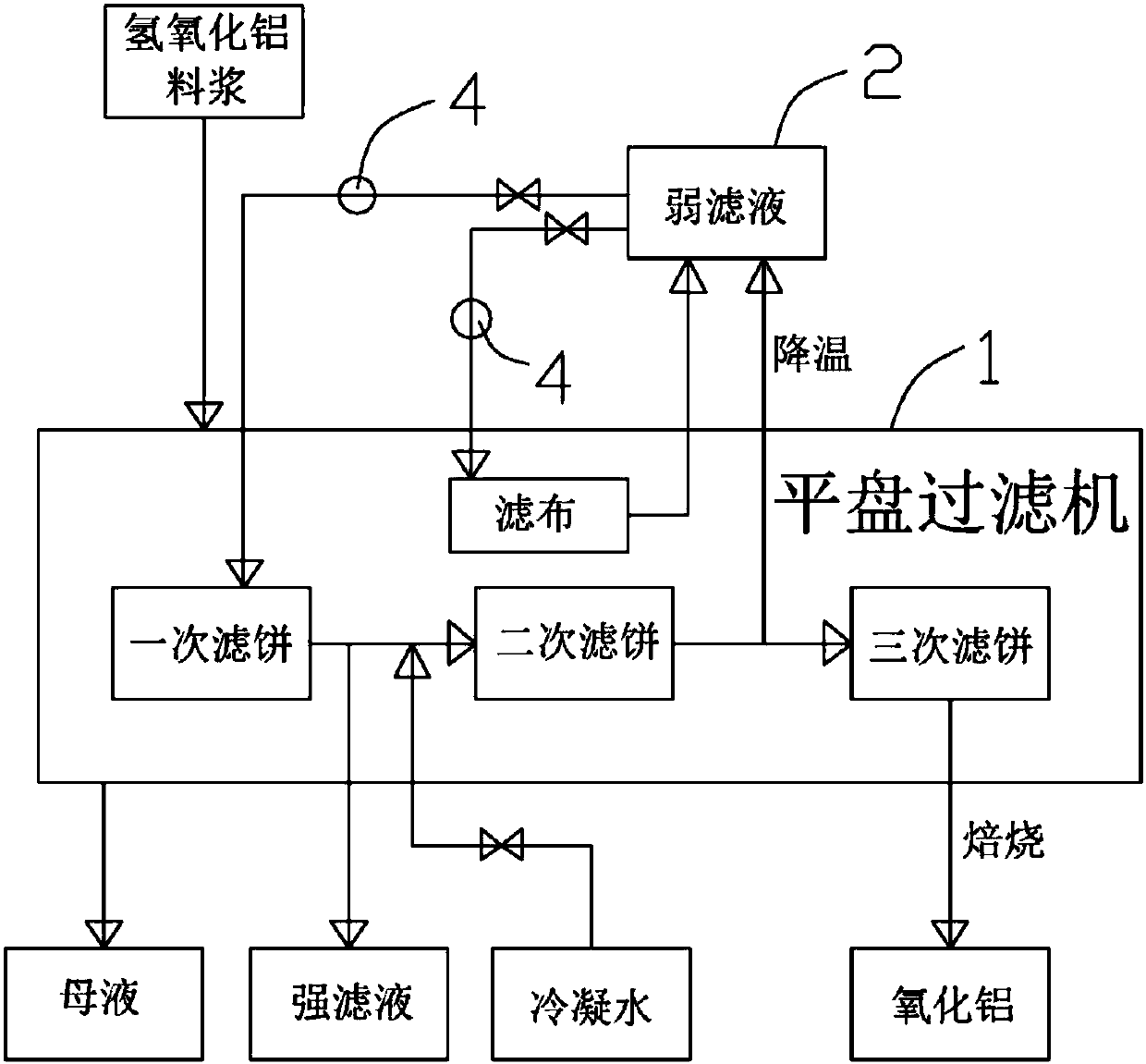

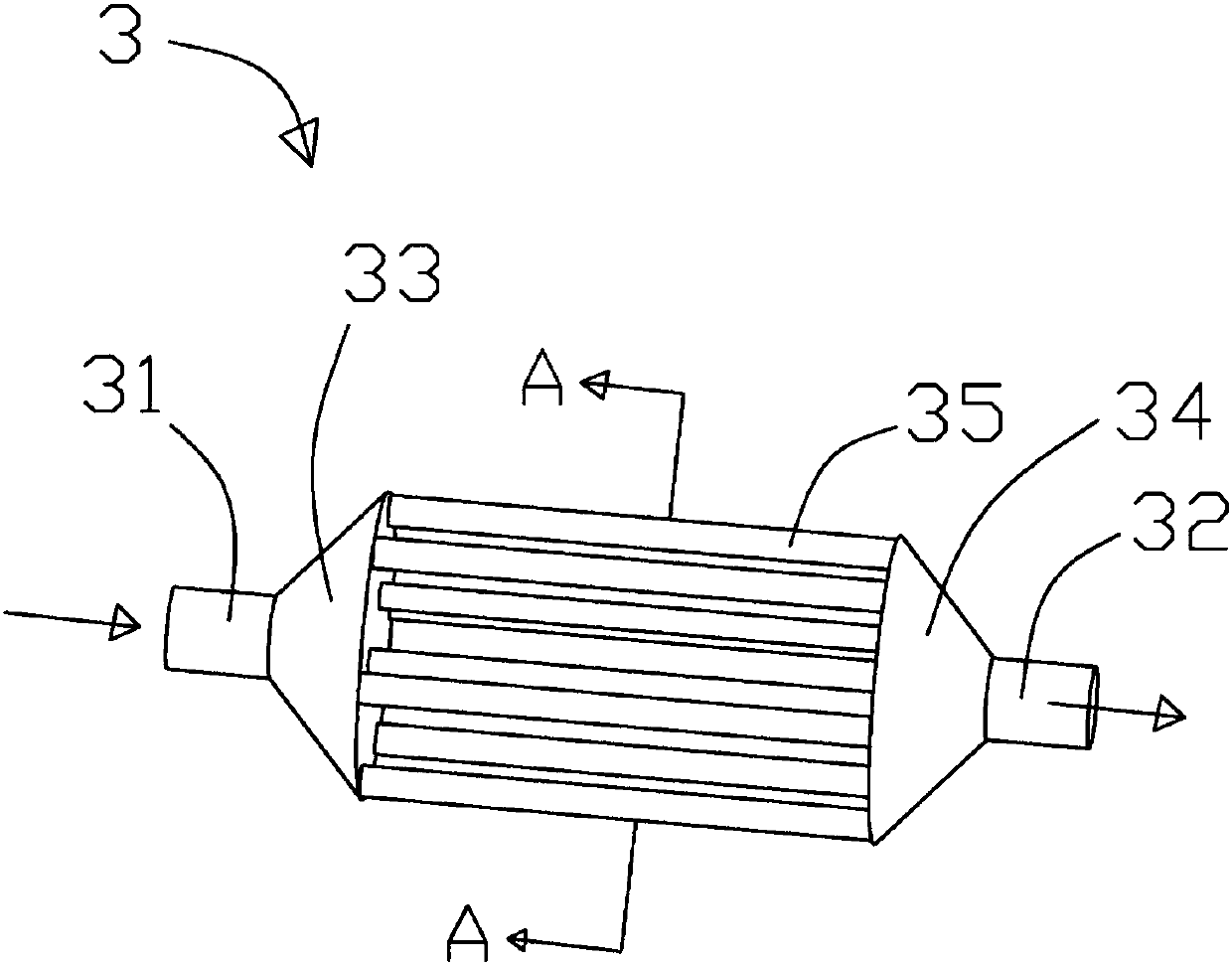

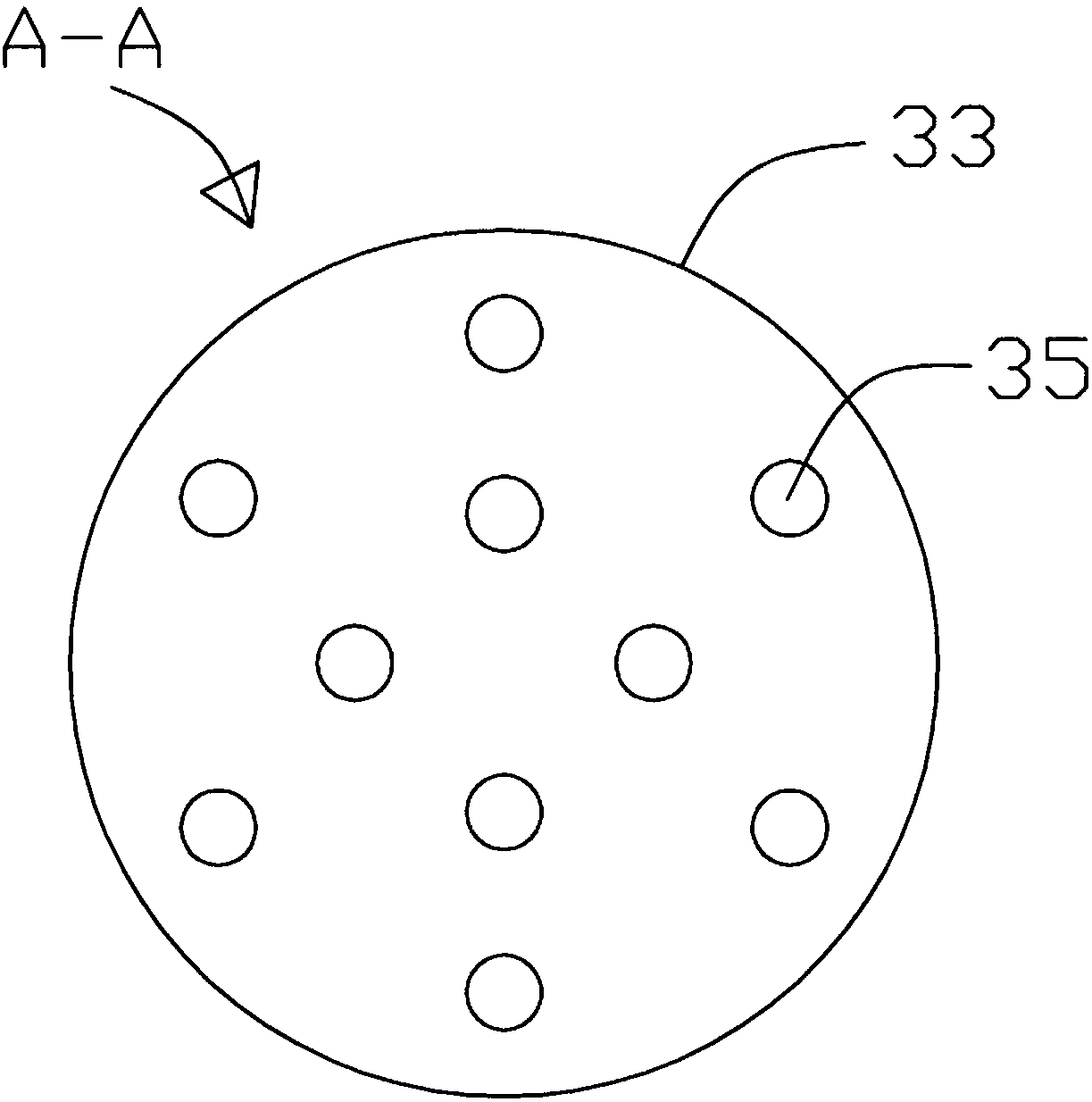

[0016] see figure 1 -3, an alumina flat plate filter lotion circulation system, including a flat plate filter 1, a weak filtrate storage tank 2, a cooling device 3 and several pipelines; the upper part of the flat plate filter 1 is provided with a slurry inlet pipe, the The slurry inlet pipe is used to send the aluminum hydroxide slurry into the flat filter 1, the aluminum hydroxide slurry enters the flat filter for filtration, the mother liquor is separated and the primary filter cake is left; the upper part of the flat filter is also equipped with The condensed water enters the pipe and the weak filtrate enters the pipe; the weak filtrate enters the pipe for sending the weak filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com