Demister for wet desulphurization tower and wet desulphurization tower

A wet desulfurization and demister technology, applied in the field of demisters and wet desulfurization towers, can solve the problems of the quality and service life of the demister, the adjustment of the distance and length of the demister, and the high technical requirements of welding workers. , to achieve the effects of increasing production burden, efficient defogging, and improving defogging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

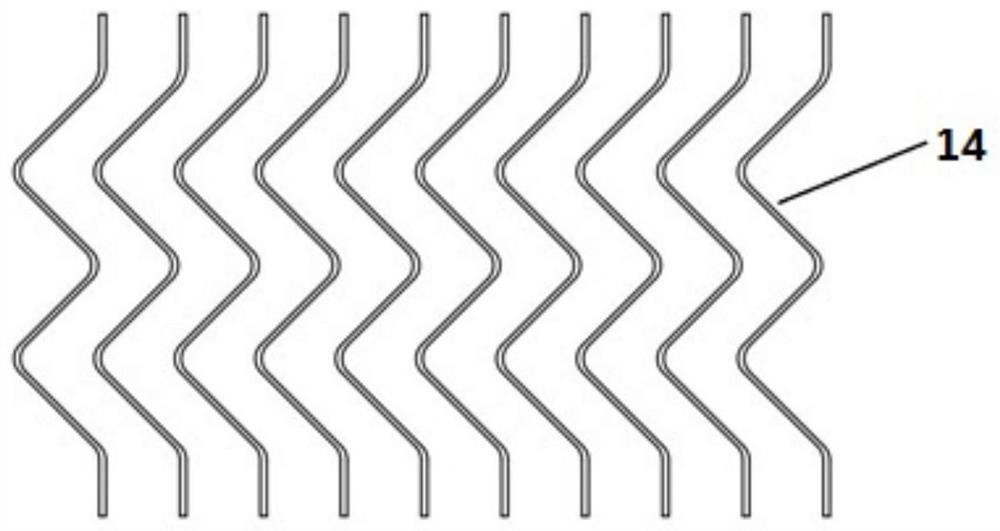

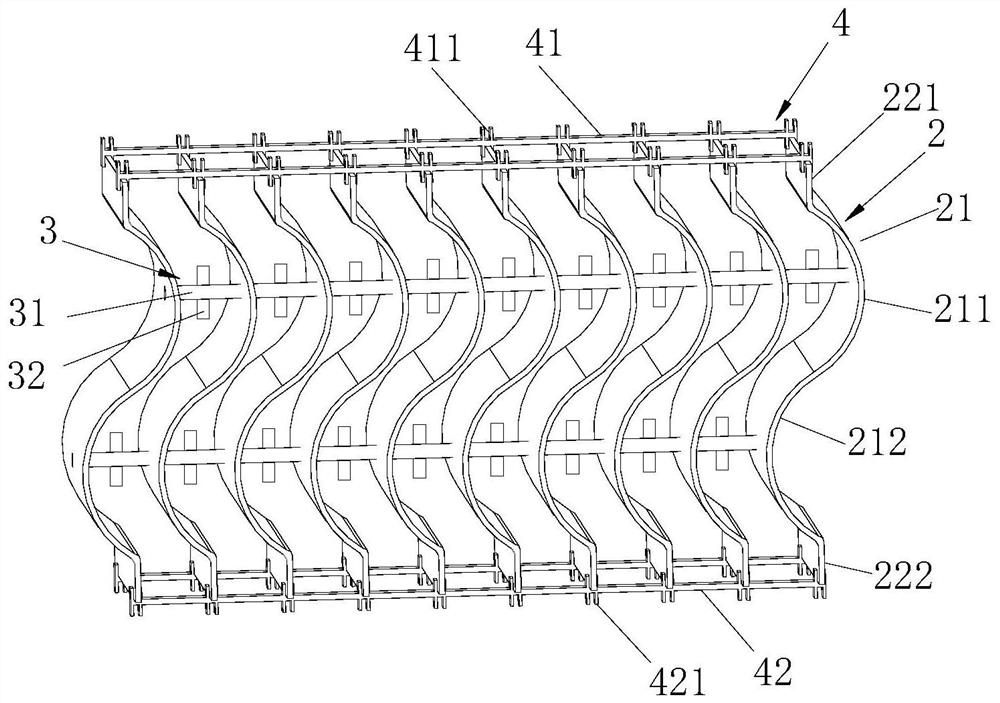

[0027] Embodiment one: if image 3 , 4 , 5, the present embodiment comprises several defogging blades 2 arranged side by side to form, and each defogging blade 2 is vertically arranged, and the defogging blade 2 is divided into two equal-length defogging sections 21 from bottom to top, each section The vertical cross-section of the defogging section 21 has a circular arc structure, and the centers of the circular arc structures on adjacent defogging sections 21 are alternately located on both sides of the defogging blade 2 . Here, the number of defogging sections 21 at the same defogging blade 2 can be adjusted as required. In this embodiment, there are two sections, namely an upper defogging section 211 and a lower defogging section 212 (the upper and lower positions are separated by Figure 5 in the middle direction as an example). The tangents of the upper defogging section 211 and the lower defogging section 212 at the joint are parallel to each other, that is, the tange...

Embodiment 2

[0032] Embodiment two: if Image 6 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment further includes a terminal defogging device 5 installed above the defogging blade 2 . The terminal defogging device 5 includes a base 51 erected on the upper end of each defogging blade 2, on which a number of wool-like glass fibers 52 arranged obliquely upward are fixed, and on the same base 51, the wool-like glass fibers 52 Set across the gap between the upper ends of two adjacent defogging blades 2, as shown in the figure, across the gap where the base 51 is located; the diameter of the hairy glass fiber 52 is 0.8mm, and the diameter of the hairy glass fiber 52 on the same base 51 The quantity is 8 pieces per cm length. Wherein, the effect of hairy glass fiber 52 is to increase the catch area to the droplet in the flue, with respect to the mist eliminator in the embodiment one, the mist eliminator equipped with this end demister device 5, its demist...

Embodiment 3

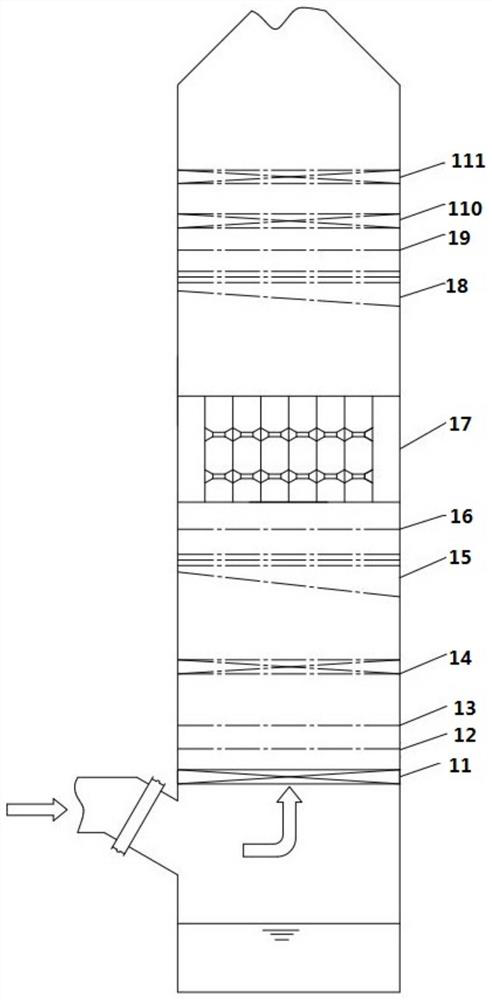

[0033] Embodiment 3: This embodiment protects a wet desulfurization tower, which includes a wet desulfurization tower body with a flue, and a flue gas inlet connected to the flue is provided on the wet desulfurization tower body and flue gas outlet, the wet desulfurization tower body is also installed with a demister, and the demister adopts the demister disclosed in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com