Smelting method for separating value metals from anode mud by firing process and device thereof

A technology of valuable metals and smelting methods, applied in the direction of improving process efficiency, etc., can solve the problems of prolonging the service life of the anode mud fire method precious lead furnace, dispersing the distribution of valuable metals, increasing the processing capacity, etc., and achieving the slagging interval time The effects of long life, heat balance and heat utilization rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

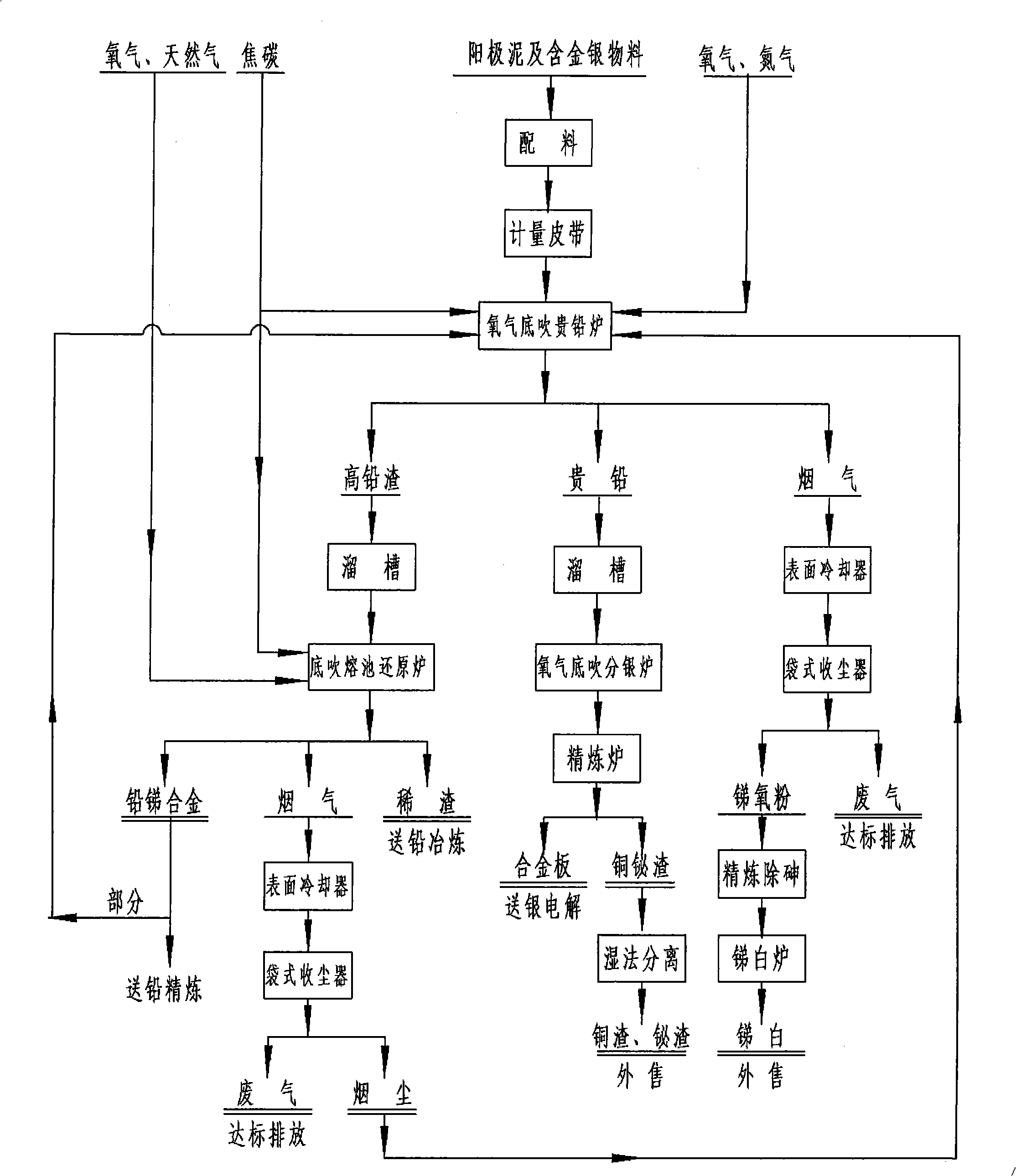

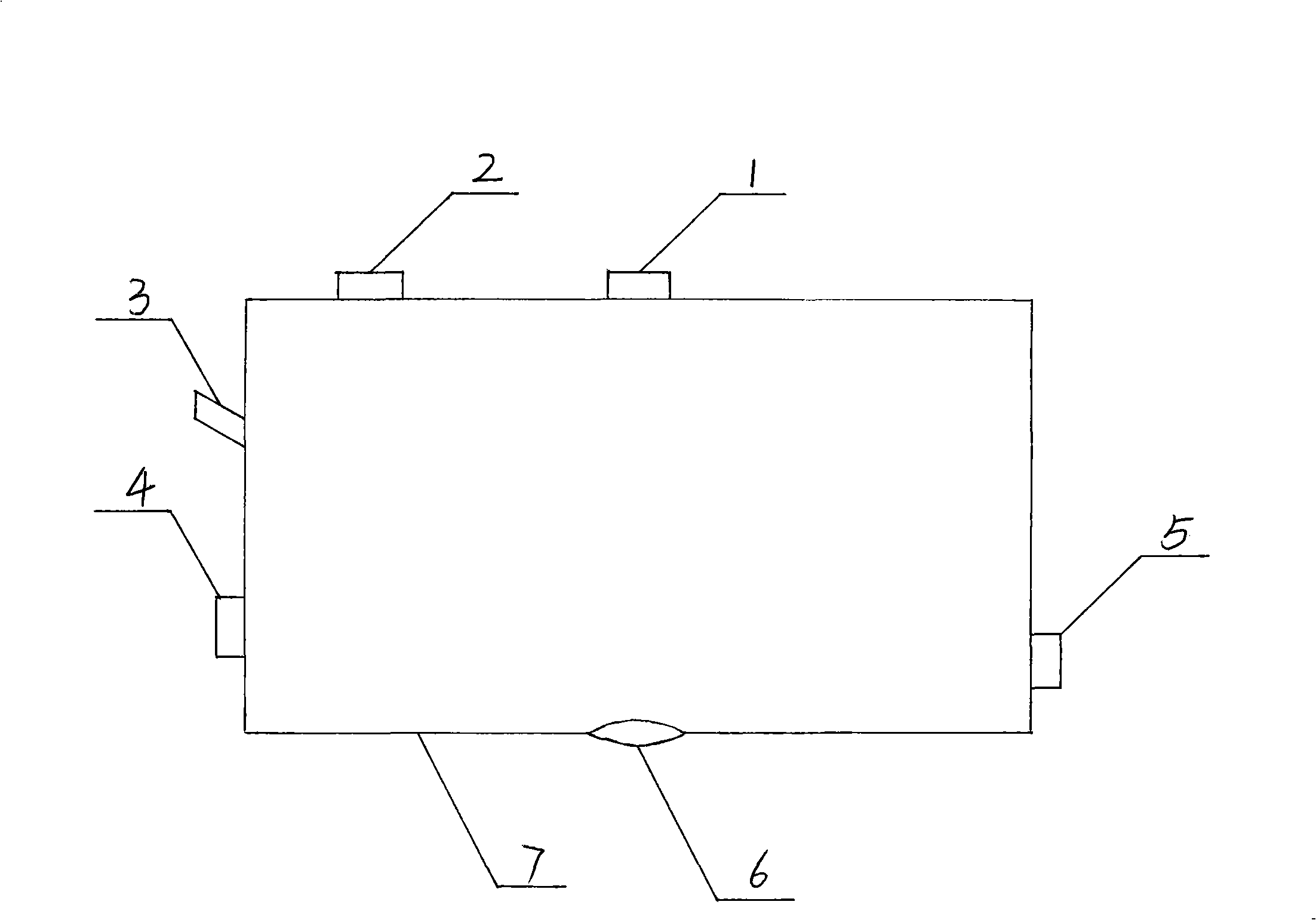

[0044] Such as figure 1 As shown in the figure, the anode slime is mixed with a grab bucket, and the anode slime and coke powder are evenly mixed in the pit, and the anode slime and coke powder are quantitatively and continuously entered into the precious lead furnace with an oxygen injection port at the bottom for oxidation, slagging and reduction. Volatile cyclic compound process. Negative pressure is maintained in the noble lead furnace, and natural gas is used as fuel, which is fed into the furnace for combustion through the natural gas burner. There is a molten pool with a certain depth in the noble lead furnace. Under the stirring action of the spray gun, the materials entering the furnace Melting, reduction, volatilization and oxidation slagging, on the one hand, the easily oxidizable lead, arsenic, antimony in noble lead reacts with oxygen to form slagging, floats up to the slag layer, and consumes the noble lead layer; on the other hand, part of the anode slime in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com