Single-slice fireproof glass

A fire-resistant glass, single-piece technology, applied in the field of glass production and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

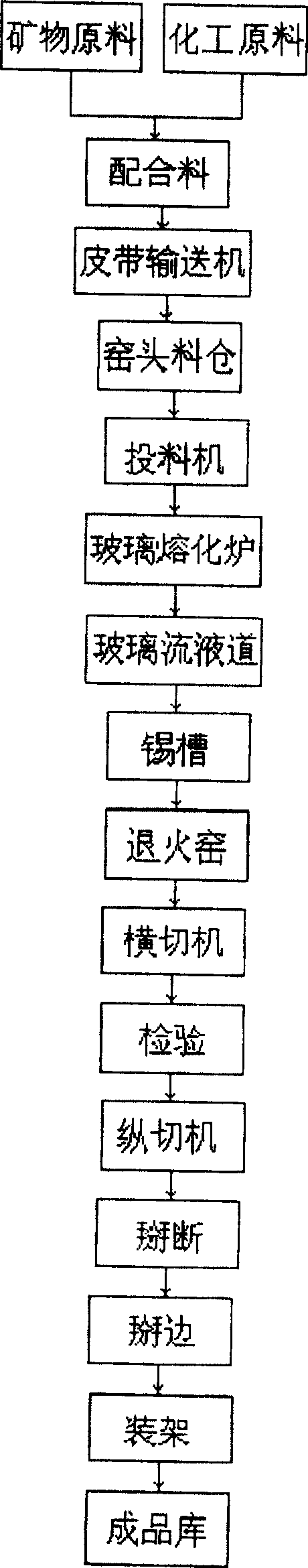

Image

Examples

example 1

[0048] SiO 2 : 70%, Al 2 o 3 : 12.5%, MgO: 2%, CaO: 6%, Na2O: 6%, SrO: 1%, BaO: 0.5%, K 2 O: 0.7%, Li 2 O: 0.7%, and the balance is impurities brought by mineral raw materials or colorants added.

[0049]According to the composition of the glass, sandstone, dolomite, limestone, soda ash, barium salt, strontium salt, alumina, wax stone, lithium salt, potassium salt and appropriate proportion of glass clarifying agent are used to make glass batch materials. Melted at 1580°C and formed by float process, the expansion coefficient α can be obtained 25~400℃ 60~65×10-7 / ℃, the expansion softening temperature exceeds 700℃, the softening temperature exceeds 800℃, and the physical tempering temperature is 740℃.

example 2

[0051] SiO 2 : 67%, Al 2 o 3 : 13.5%, MgO: 2%, CaO: 6%, Na 2 O: 8%, SrO: 1.2%, BaO: 1.2%, K 2 O: 0.1%, Li 2 O: 0.4%, and the balance is impurities brought by mineral raw materials or colorants added.

[0052] According to the composition of the glass, sandstone, dolomite, limestone, soda ash, barium salt, strontium salt, alumina, wax stone, lithium salt, potassium salt and appropriate proportion of glass clarifying agent are used to make glass batch materials. Melting at a temperature of 1550°C, and forming through a float process, the expansion coefficient α can be obtained 25~400℃ 63~68×10-7 / ℃, the expansion softening temperature is over 700℃, the softening temperature is over 800℃, and the physical tempering temperature is 730℃.

example 3

[0054] SiO 2 : 63%, Al 2 o 3 : 19%, MgO: 1%, CaO: 6%, Na 2 O: 6%, SrO: 3%, Ba: O.5%, K 2 O: 1%, the balance is impurities brought in by mineral raw materials or colorants added.

[0055] According to the composition of the glass, sandstone, dolomite, limestone, soda ash, barium salt, strontium salt, aluminum oxide, wax stone, potassium salt and appropriate proportion of glass clarifying agent are used to make glass batch materials. Melted at 1560°C and formed by float process, the expansion coefficient α can be obtained 25~400℃ 60~65×10-7 / ℃, the expansion softening temperature is over 700℃, the softening temperature is over 800℃, and the physical tempering temperature is 730℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com