Shoe sole with a loose fill comfort support system

a technology which is applied in the field of comfort support and shoe sole in the sole of shoes, can solve the problems of complex air and fluid system, nothing advanced and innovative, and the manufacture of shoes using conventional construction methods is a complicated and expensive process, and achieves the effect of reducing the force of the sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

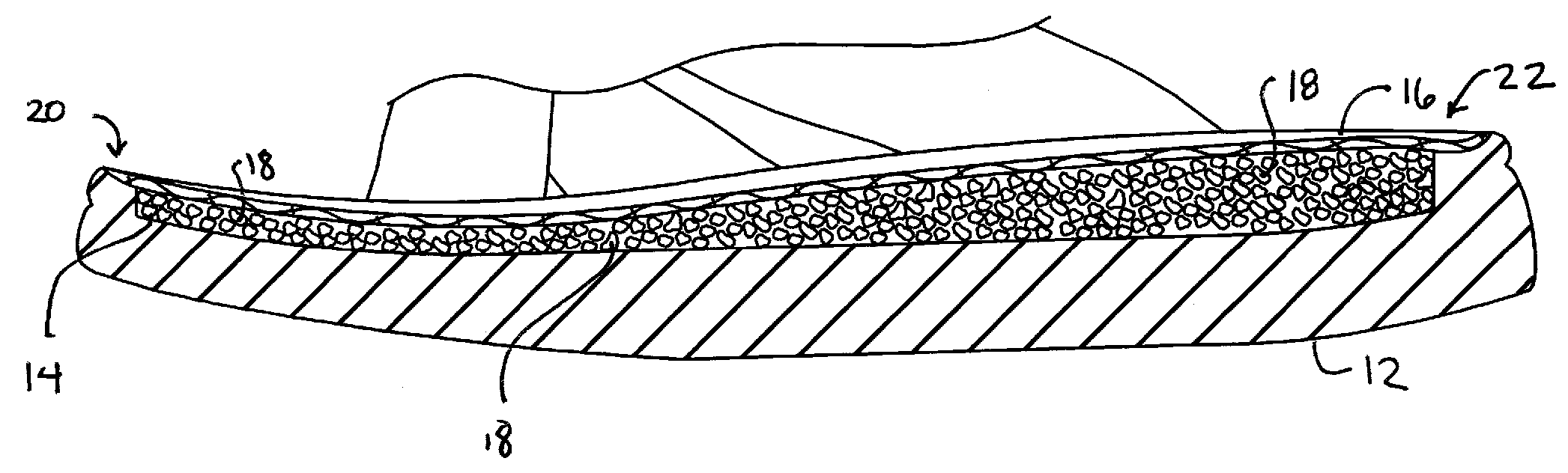

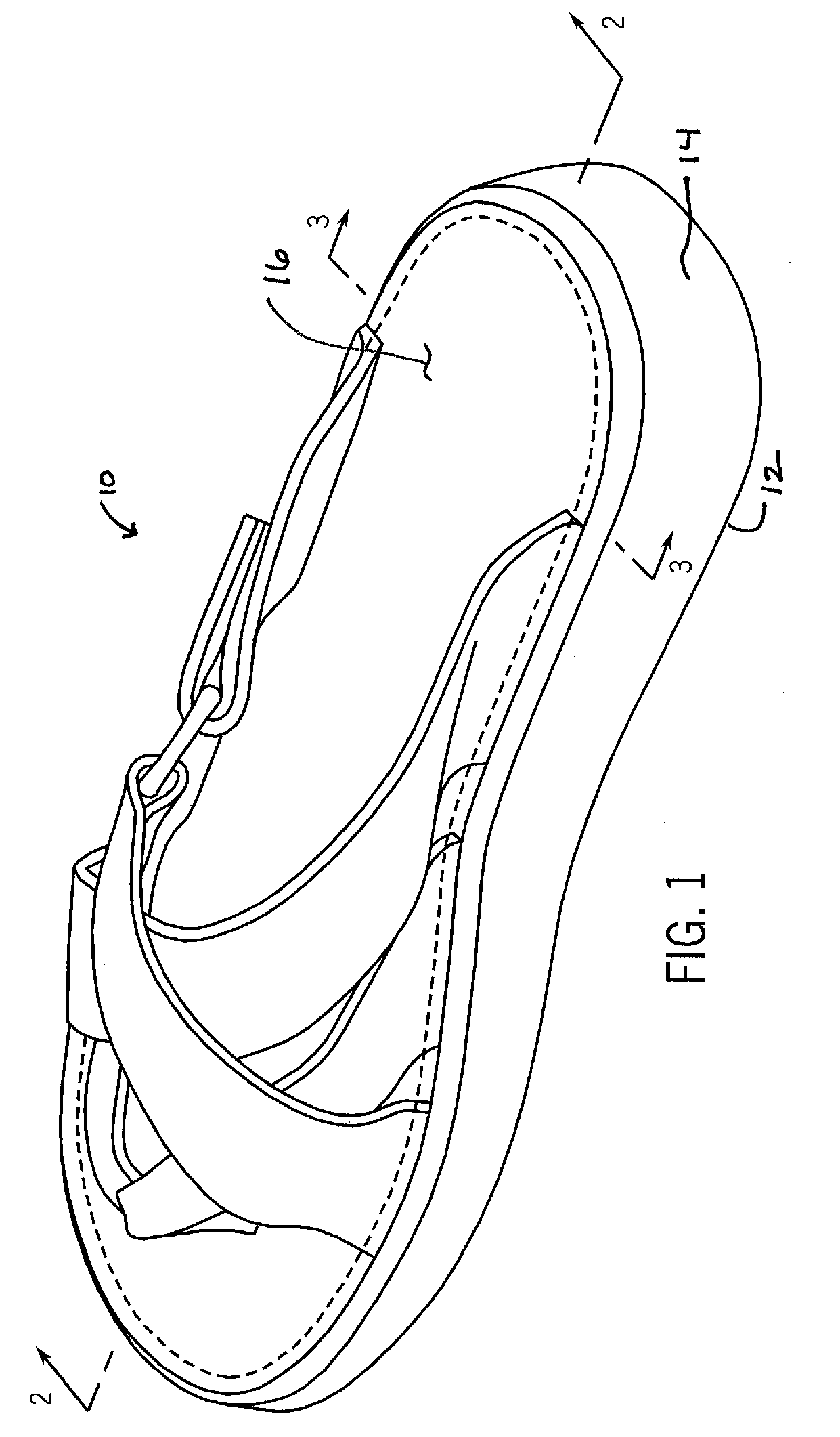

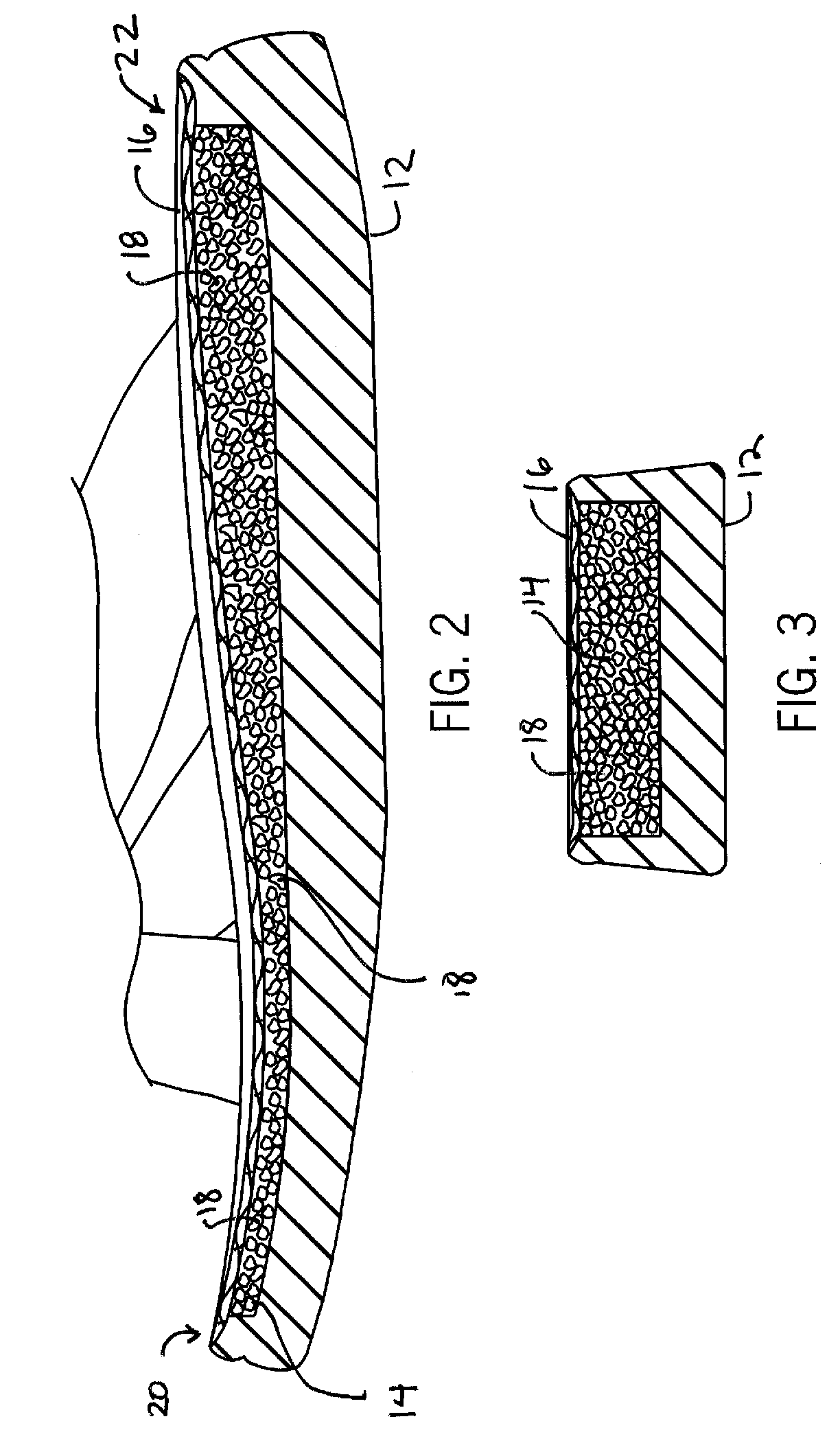

[0021] Referring to FIG. 1, the present invention includes generally a shoe 10 having an outsole 12, a midsole 14, and an insole 16. In the preferred embodiment of the present invention, shoe 10 is any shoe including but not limited to an athletic shoe, a casual shoe, a boot, a sandal, a dress shoe, etc.

[0022] Outsole 12 of shoe 10 is commonly made from a variety of materials including elastomer styrene-butadiene rubber or a carbon fiber rubber. Lying on the bottom side of shoe 10, outsole 12's main purpose is to provide friction and durability. Different treads on outsoles 12 define shoe 10's purpose. For example, on an athletic shoe, waffle-studded treads act like support columns to absorb and dissipate impact.

[0023] Just above outsole 12 is midsole 14. Midsole 14 absorbs impact by cushioning but also returns energy to the person wearing shoe 10 (e.g., a runner). The most common material used in the manufacturing of midsoles is a plastic foam consisting of ethylene, vinyl, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com