Repairing and transforming method of old cement concrete pavement

A technology of concrete pavement and old cement, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve problems such as reflection cracks, and achieve the effect of improving performance, low cost and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

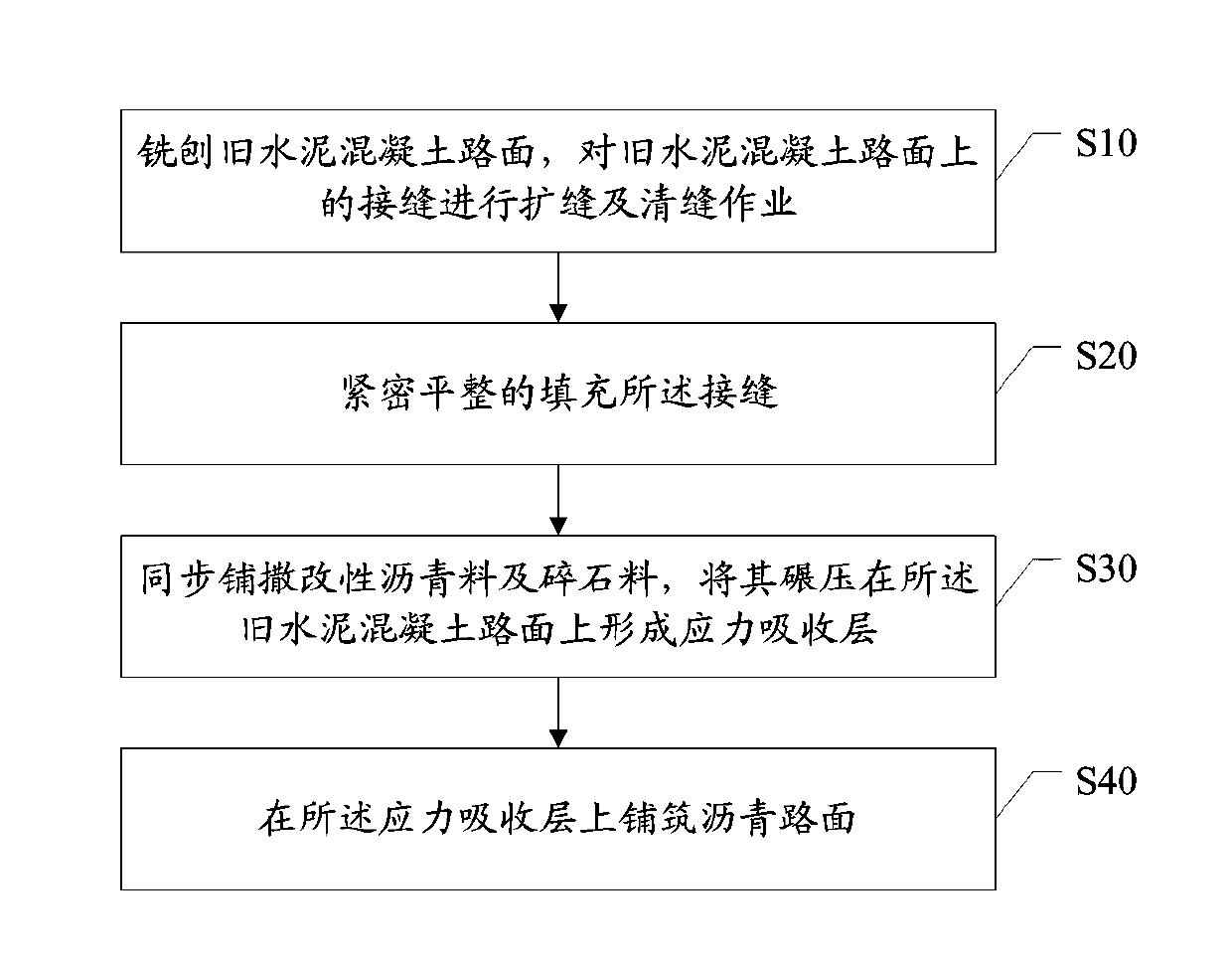

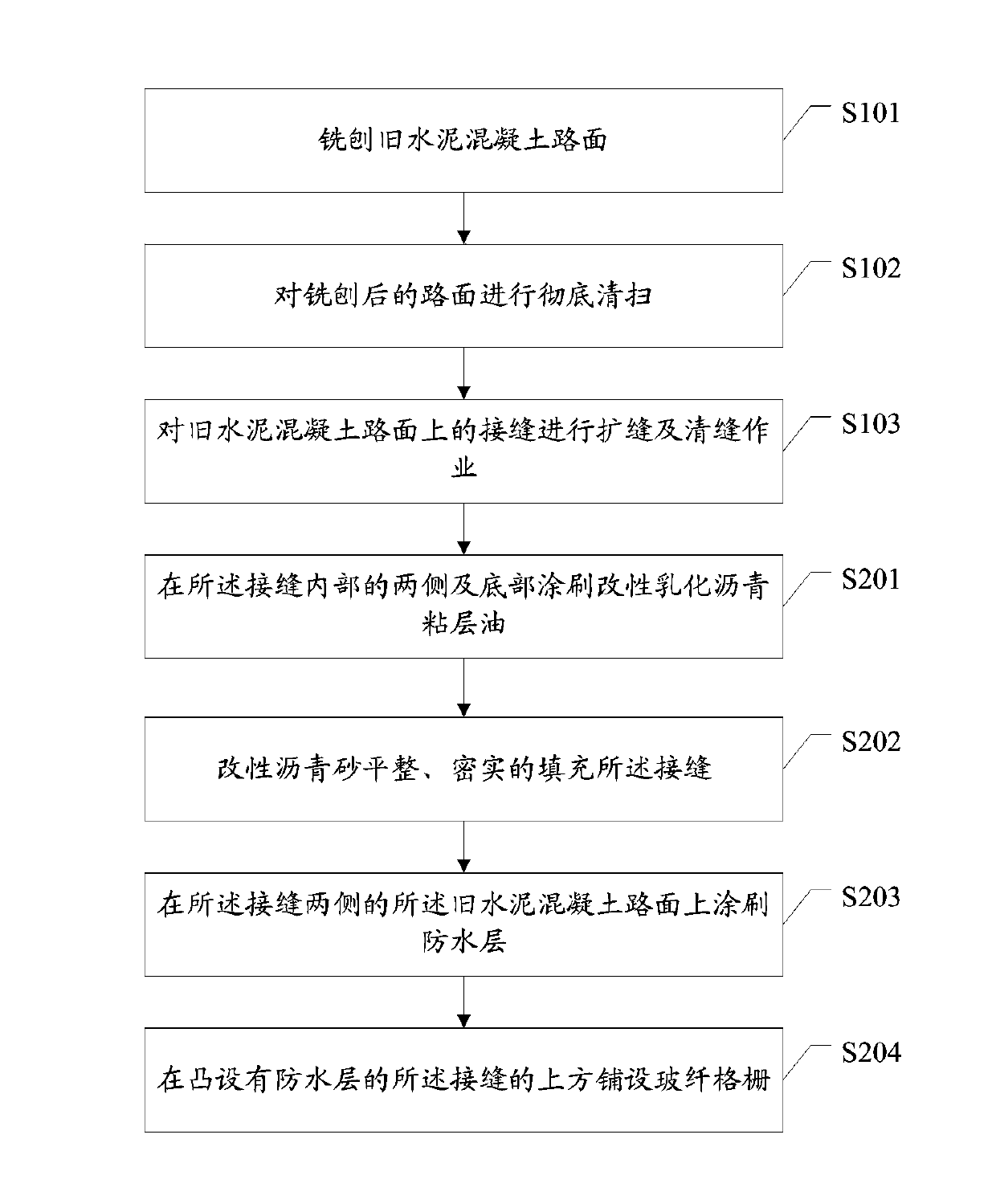

[0022] see in conjunction figure 1 , figure 2 Shown is Embodiment 1 of the old cement concrete pavement repairing method of the present invention.

[0023] Such as figure 1 As shown, the repairing method of the old cement concrete pavement in the present embodiment comprises:

[0024] Step S10, milling the old cement concrete pavement, and performing joint expansion and seam cleaning operations on the joints on the old cement concrete pavement;

[0025] Step S20, filling the seam tightly and flatly;

[0026] Step S30, spreading modified asphalt material and gravel material synchronously, and rolling them on the old cement concrete pavement to form a stress absorbing layer;

[0027] Step S40, paving asphalt pavement on the stress absorbing layer.

[0028] During specific implementation, the implementation process of step S10 is as follows, as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com