Coarse grain type stress absorption structure layer asphalt mixture and design method thereof

An asphalt mixture and stress absorption technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of not being able to be used as a pavement structural layer, the crack resistance effect is not ideal, the phenomenon of weak interlayer, etc., to achieve good resistance to rutting deformation. , The effect of improving anti-cracking effect and strong tensile deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

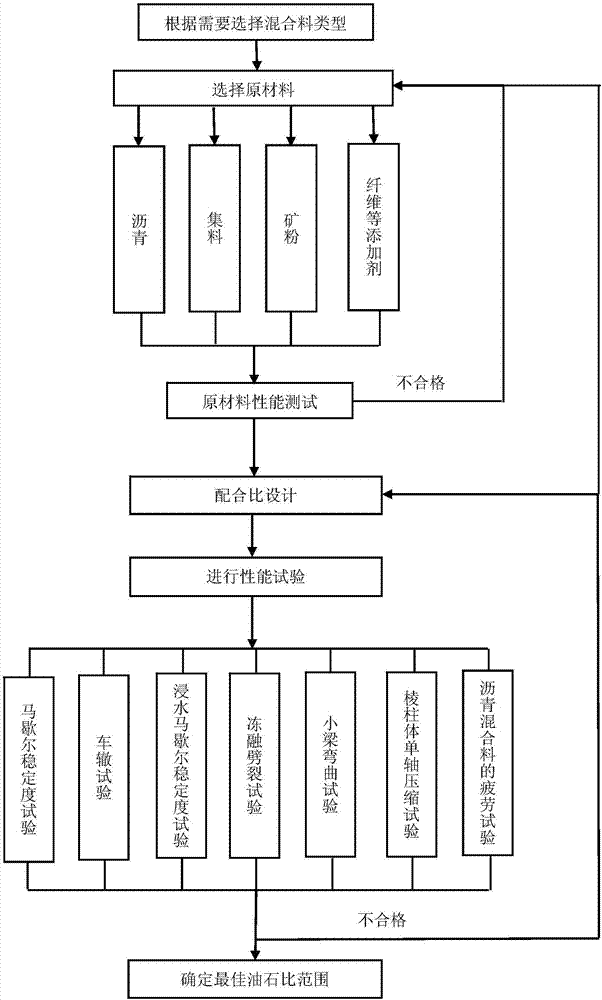

[0050] In this embodiment, a dense rubber asphalt mixture with a large asphalt ratio and skeleton is used as an example to design the stress-absorbing structural layer. The specific steps are as follows:

[0051] 1. Select the type of asphalt mixture according to the project requirements, which is a dense rubber asphalt mixture with a large asphalt ratio.

[0052] 2. Raw material selection and performance testing;

[0053] Rubber asphalt: It is prepared by adding rubber powder to base asphalt (mass ratio of base asphalt to rubber powder is 82:18) and reacting in a stirring container. Among them, the basic properties of rubber asphalt are shown in Table 1.

[0054] The coarse aggregate of the skeleton dense rubber asphalt mixture is diabase, and the fine aggregate is granite. The gradation range of the coarse aggregate is 13.2, 9.5 and 4.75mm (square hole particle size), and the apparent relative density is 2.718g / cm 3 ; The gradation range of fine aggregate is 0.075, 0.15,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com