Asphalt modified by epoxy resin and rubber powder

A technology of epoxy resin and rubber powder, used in building components, building insulation materials, buildings, etc., can solve problems such as reflection cracks in asphalt concrete, and achieve the effects of slowing down the reflection cracks on the road surface, good high temperature fluidity resistance, and increasing fatigue life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

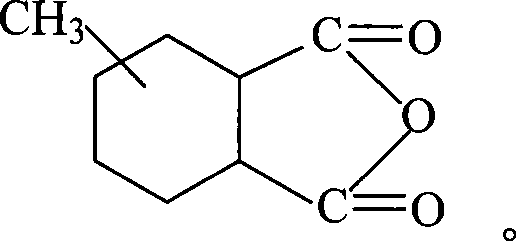

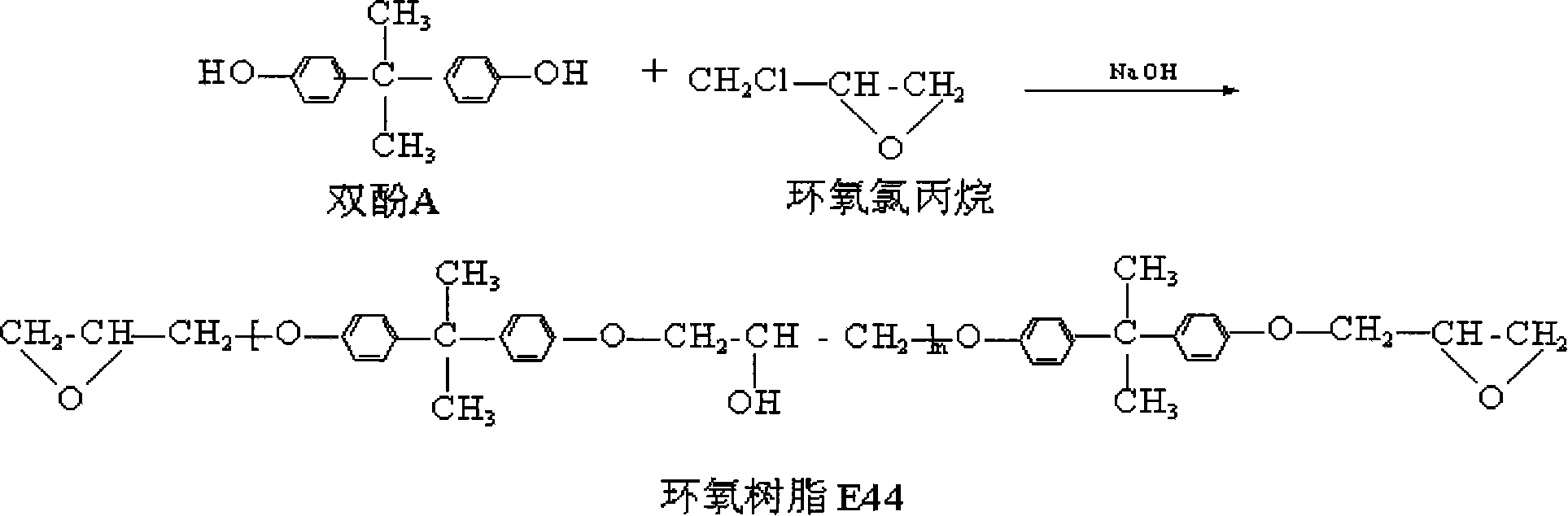

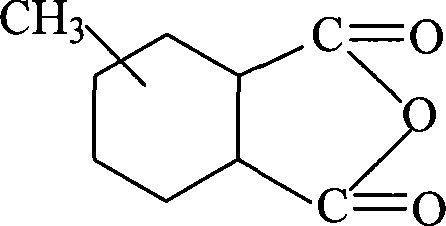

[0030] The invention is an asphalt modified by epoxy resin and rubber powder. The main materials are road petroleum asphalt, rubber powder, epoxy resin emulsion and curing agent, wherein the rubber powder, epoxy resin and curing agent are modified materials. The asphalt is modified with the above-mentioned modified materials, and the incorporation amount of the modified materials, namely rubber powder, epoxy resin and curing agent in the asphalt is determined. The weight percent of each component is as follows: 100 parts of asphalt, 3-20 parts of rubber powder, 1-5 parts of epoxy resin, and 15 percent of the curing agent of the epoxy resin.

[0031] 1. First, mix the epoxy resin and curing agent according to the ratio, inject it into the asphalt solution, grind and stir well, and the mixing temperature should be kept at 170°C.

[0032] 2. Add rubber powder with a particle size of no more than 40 meshes to the above-mentioned modified asphalt, control the temperature at 180°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com