Road sealant for use at normal temperature and preparation method thereof

A sealant and road technology, applied in the field of road sealants, can solve the problem that hot-melt sealants cannot be handled, and achieve the effect of good liquid fluidity and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

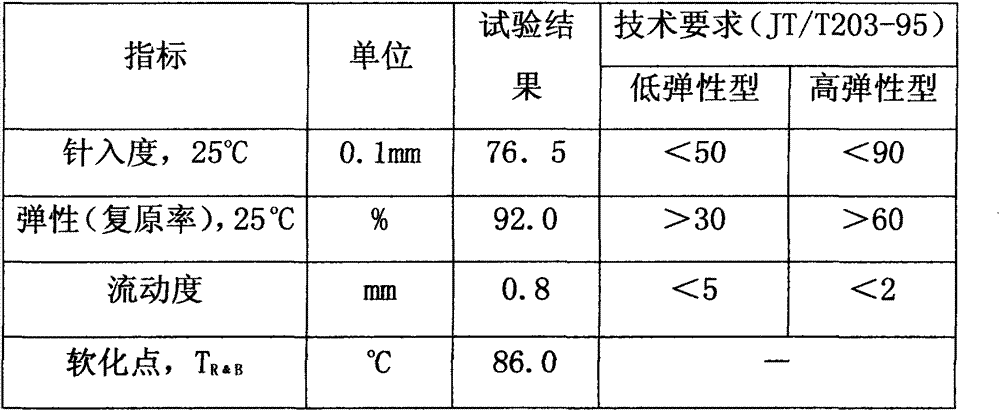

Embodiment 1

[0024] The raw materials used to produce 92.8 kg of road sealant used at room temperature are as follows:

[0025]

[0026] Its preparation method comprises the following steps:

[0027] 1. Put the asphalt in the asphalt tank and heat it to 135°C with a heat conduction oil furnace;

[0028] 2. Put the heated asphalt in step 1 into the asphalt storage tank in the emulsification equipment, add the resin into the heated asphalt and stir evenly;

[0029] 3. Add water to the aqueous solution storage tank in the emulsification equipment and heat it to 70°C, add the emulsifier and stabilizer to the heated water, dissolve them in the water, and form a ready-to-use aqueous solution;

[0030] 4. Emulsify the bitumen added with resin in step 2 and the aqueous solution to be used in step 3 in the emulsification equipment, and put the emulsified material into the storage tank;

[0031] 5. Add the modifier into the storage tank described in step 4, and mix the modifier evenly with the ...

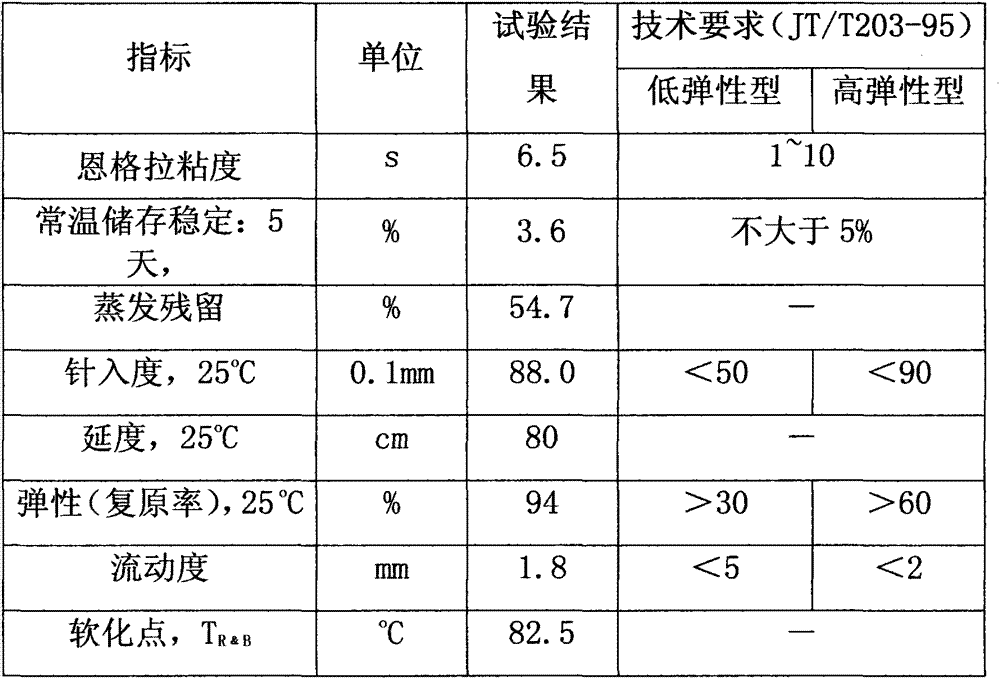

Embodiment 2

[0033] The raw materials used to produce 138.1 kg of road sealant used at normal temperature are as follows:

[0034]

[0035] Its preparation method comprises the following steps:

[0036] 1. Put the asphalt in the asphalt tank and heat it to 145°C with a heat conduction oil furnace;

[0037] 2. Put the heated asphalt in step 1 into the asphalt storage tank in the emulsification equipment, add the resin into the heated asphalt and stir evenly;

[0038] 3. Add water to the aqueous solution storage tank in the emulsification equipment and heat it to 70°C, add the emulsifier and stabilizer to the heated water, dissolve them in the water, and form a ready-to-use aqueous solution;

[0039] 4. Emulsify the bitumen added with resin in step 2 and the aqueous solution to be used in step 3 in the emulsification equipment, and put the emulsified material into the storage tank;

[0040] 5. Add the modifier into the storage tank described in step 4, and mix the modifier evenly with t...

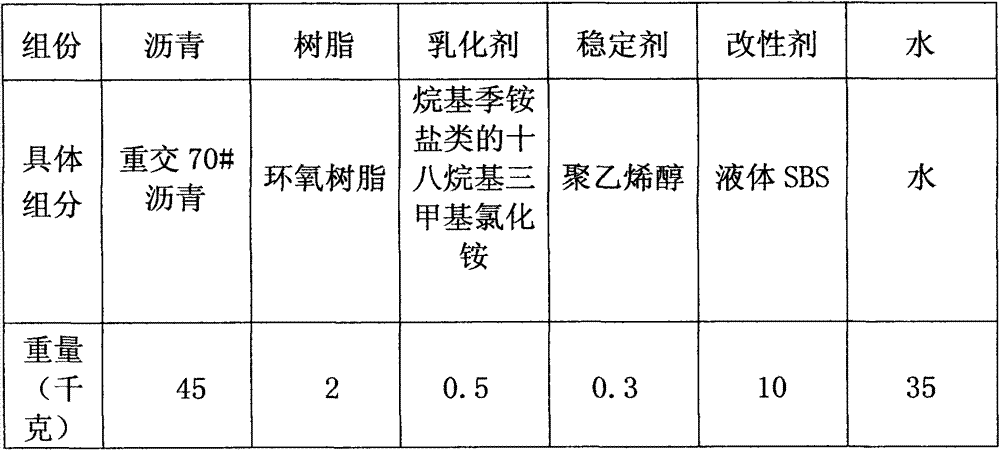

Embodiment 3

[0042] The raw materials used to produce 115.45 kg of road sealant used at normal temperature are as follows:

[0043]

[0044] Its preparation method comprises the following steps:

[0045] 1. Put the asphalt in the asphalt tank and heat it to 140°C with a heat conduction oil furnace;

[0046] 2. Put the heated asphalt in step 1 into the asphalt storage tank in the emulsification equipment, add the resin into the heated asphalt and stir evenly;

[0047] 3. Add water to the aqueous solution storage tank in the emulsification equipment and heat it to 70°C, add the emulsifier and stabilizer to the heated water, dissolve them in the water, and form a ready-to-use aqueous solution;

[0048] 4. Emulsify the bitumen added with resin in step 2 and the aqueous solution to be used in step 3 in the emulsification equipment, and put the emulsified material into the storage tank;

[0049] 5. Add the modifier into the storage tank described in step 4, and mix the modifier evenly with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com