Process for production of special-shaped high polymer plastic-steel fabric

A technology of plastic-steel fiber and production method, which is applied in fiber processing, filament/line forming, construction, etc., can solve the problems of steel fiber and steel mesh having a large proportion, unsuitable for overhead construction of bridge deck, affecting project quality, etc. High strength, superior comprehensive application performance, and the effect of improving engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

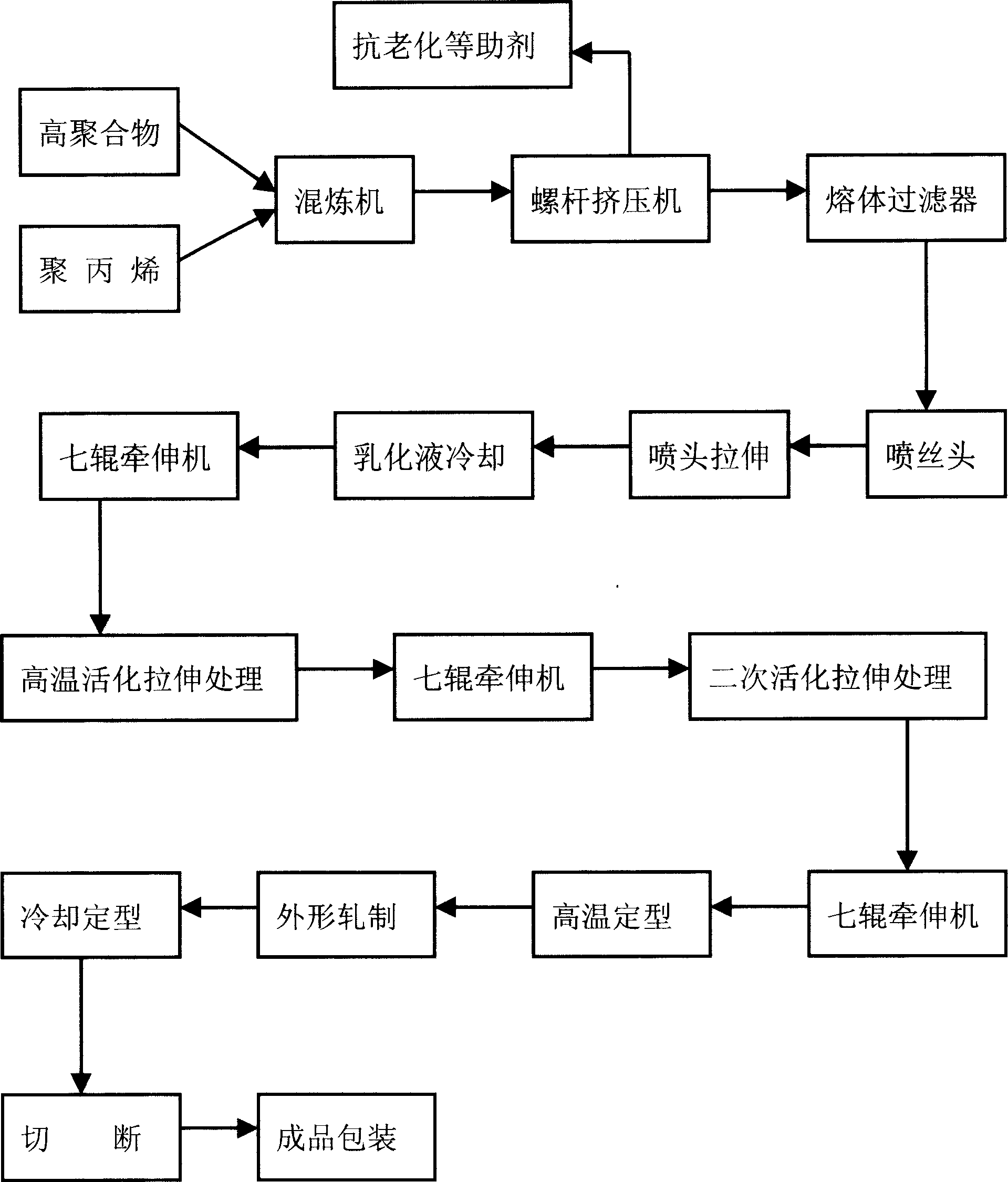

[0017] The method steps of concrete implementation are as follows:

[0018] 1. Add 5-8% copolymer polyethylene with polypropylene or polyester, heat at 150°C-200°C, and knead evenly in a conical twin-screw equipment.

[0019] 2. Add 0.3% to 0.2% PP nucleating agent or PET nucleating agent to the uniformly mixed slurry and inject it into the ordinary screw extruder. Zone 200°C, Zone 3 210°C, Zone 4 230°C, inject spinneret head cover and extrude spinneret.

[0020] 3. Put the spinning monofilament into the emulsion to cool, the temperature of the emulsion is 5°C-10°C, and at the same time stretch the nozzle for the first time, and the stretching ratio is 3-4.5 times.

[0021] 4. Put the monofilament stretched by the nozzle into a seven-roll drafting machine, and then introduce it into a high-temperature activation treatment tank. Stretching, the stretching ratio is 4.8 to 5.5 times.

[0022] 5. The monofilament that has undergone a high-temperature activation treatment and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com