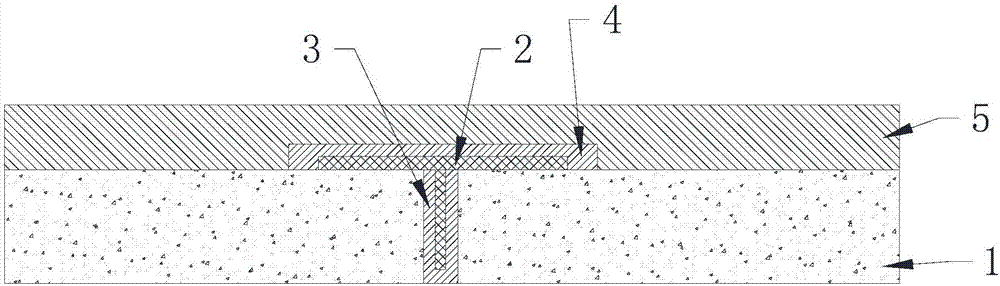

Anti-reflection crack asphalt pavement structure and construction method thereof

A technology of asphalt pavement and construction method, applied in the directions of roads, roads, pavement details, etc., can solve problems such as failure to achieve anti-reflection cracks, low tensile strength of singe geotextiles, and inability to solve waterproof problems, and achieve anti-deformation capabilities. Strong, reliable performance, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the construction method of the anti-reflective crack-resistant asphalt pavement structure includes the following steps:

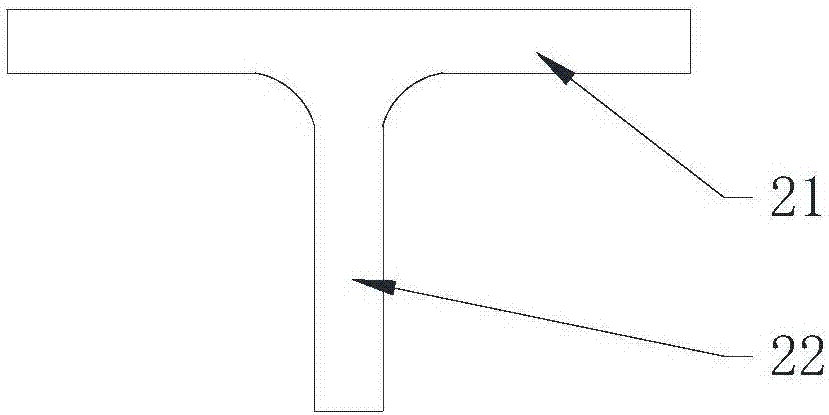

[0037] Step 1: Use a small slotting machine to slot along the surface of the road base layer, and form a slot with a width of 0.5 cm-1 cm and a depth of 0.5 cm-1.5 cm at the opening of the slot. In this embodiment Wherein, the width of the slot is 0.8 cm and the depth is 1.0 cm; the surface of the road base layer and the gaps on the surface of the road base layer are cleaned by means of compressed air blowing or high-pressure vacuum cleaner absorption, etc., and the road is cleaned manually or mechanically The surface of the base layer, to ensure that the inner wall of the gap is dry and clean, and the surface of the road base layer is free of pollution and debris;

[0038] Step 2: Fill the gap with filler to form a layer of asphalt filling material that fills the gap. The gap should be uniform and full so that the filler fills the gap...

Embodiment 2

[0044] In this embodiment, the construction method of the anti-reflective crack-resistant asphalt pavement structure includes the following steps:

[0045] Step 1: Use a small slotting machine to slot along the surface of the road base layer, and form a slot with a width of 0.5 cm-1 cm and a depth of 0.5 cm-1.5 cm at the opening of the slot. In this embodiment Wherein, the slot has a width of 1 cm and a depth of 1.5 cm; the surface of the road base layer and the gaps on the surface of the road base layer are cleaned by means of compressed air blowing or high-pressure vacuum cleaner absorption, etc., and the road is cleaned manually or mechanically The surface of the base layer, to ensure that the inner wall of the gap is dry and clean, and the surface of the road base layer is free of pollution and debris;

[0046] Step 2: Fill the gap with filler to form a layer of asphalt filling material that fills the gap. The gap should be uniform and full so that the filler fills the gap and ...

Embodiment 3

[0051] In this embodiment, the construction method of the anti-reflective crack-resistant asphalt pavement structure includes the following steps:

[0052] Step 1: Use a small slotting machine to slot along the surface of the road base layer, and form a slot with a width of 0.5 cm-1 cm and a depth of 0.5 cm-1.5 cm at the opening of the slot. In this embodiment Wherein, the slot has a width of 0.5 cm and a depth of 0.5 cm; the surface of the road base layer and the gaps on the surface of the road base layer are cleaned by means of compressed air blowing or high-pressure vacuum cleaner absorption, etc., and the road is cleaned manually or mechanically The surface of the base layer, to ensure that the inner wall of the gap is dry and clean, and the surface of the road base layer is free of pollution and debris;

[0053] Step 2: Fill the gap with filler to form a layer of asphalt filling material that fills the gap. The gap should be uniform and full so that the filler fills the gap an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com