Asphalt pavement reflection crack propagation analog experiment device

A technology for reflective cracks and asphalt pavement, applied in measurement devices, material inspection products, instruments, etc., can solve the problem of incompletely revealing the damage, fatigue and fracture mechanism of asphalt mixture, and cannot fully and truly reflect the formation and expansion of reflective cracks in pavement structures. and fracture laws, etc., to achieve the effect of facilitating the approximate simulation of coupled stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

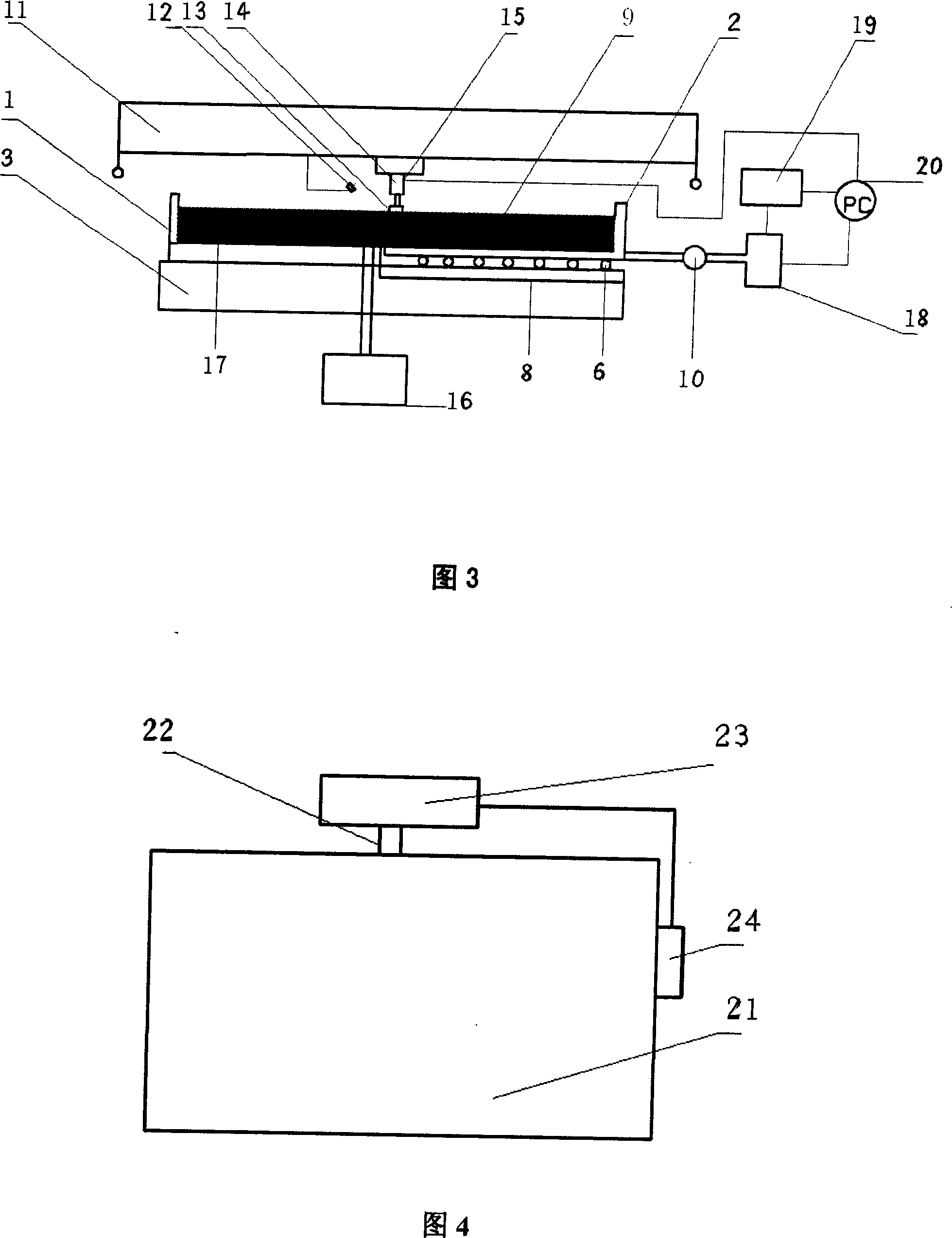

[0024] The invention mainly includes a temperature control box, an asphalt pavement simulation platform and a reflective crack tester placed in the temperature control box.

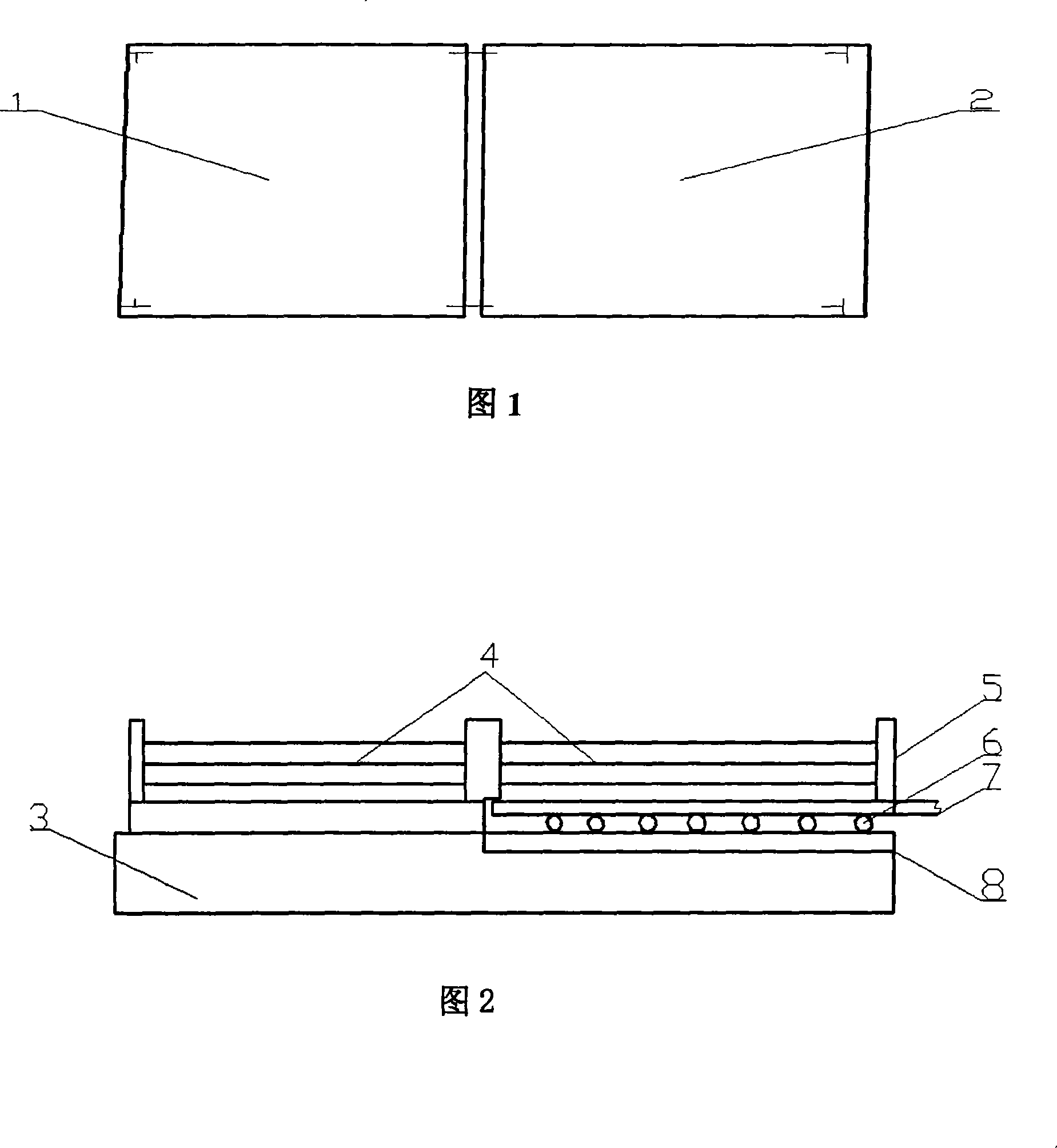

[0025] Referring to Figures 1 and 2, the asphalt pavement simulation platform includes a fixed test feeder 1 welded together with a feeder base 3, a guide rail 8 is provided on the base 3, a roller 6 is provided on the guide rail 8, and the movable test feeder 2 can be Through the roller 6 moving on the guide rail 8, the movable test material car 2 also has a connecting beam 7, so as to be connected with the horizontal transmission device. The fixed test material car 1 and the movable test material 2 are respectively provided with a material car baffle 4 and a baffle slot 5. When forming the road surface test structure layer, the material car baffle 4 is inserted into the material car baffle slot 5, and its height It can be adjusted according to the thickness of the pavement test structure layer 9 . Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com