Construction method of stress absorbing layer for road repairing

A stress-absorbing layer and construction method technology, applied in the direction of roads, roads, and on-site coagulation pavement, can solve the problems of inconsistent deformation of concrete panels and joint concrete, weakening shrinkage cracks and reflection cracks, and panel cracking, etc. Achieve the effect of facilitating mechanized operation, extending road function and service life, and improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

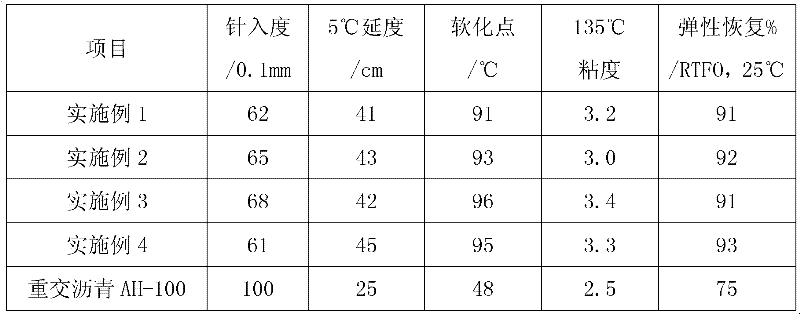

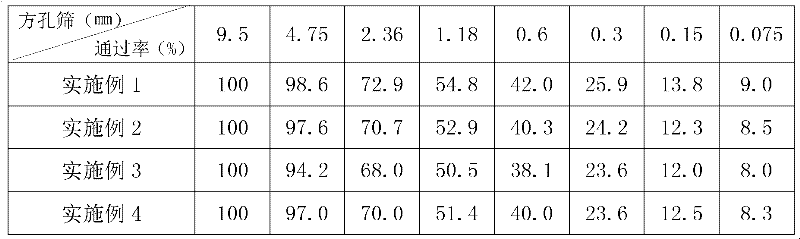

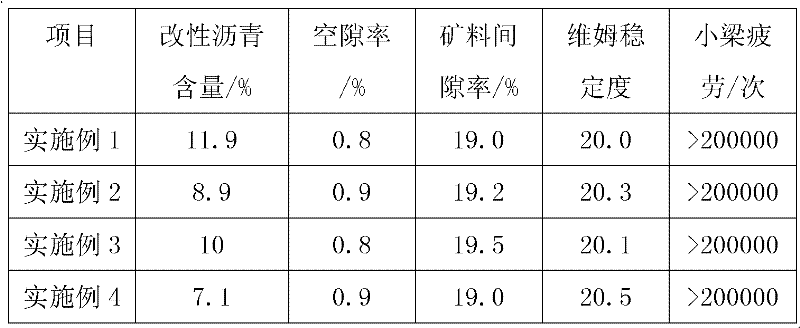

[0060] 1. Preparation of modified asphalt

[0061] 1) Put heavy traffic asphalt AH-70 in a mixer, heat it at 120°C to melt, add modifier and stabilizer, heat and keep stirring at 140°C to prepare asphalt mixture, in which the modifier is made of star Type SBS (commercially available various types of star SBS, such as SBS4303 produced by Yanshan Petrochemical), linear SBS (commercially available various types of linear SBS, such as Yueyang Petrochemical produced YH791) and styrene-butadiene latex (solid content 65%), the weight ratio of star SBS, linear SBS and styrene-butadiene latex is 3:2:2; the stabilizer is composed of calcium chloride and polyacrylamide with a weight ratio of 1:1, asphalt, The weight ratio of modifier and stabilizer is 92.5:7.0:0.5, and the stirring time is 60min;

[0062] In the embodiment of the present invention, heavy traffic asphalt AH-70 is used as the base asphalt, except for heavy traffic asphalt AH-70, other pavement asphalts are suitable for th...

Embodiment 2

[0092] In the process of preparing modified asphalt, except that the weight ratio of asphalt, modifier and stabilizer is 90:8.5:1.5, the asphalt is selected from heavy traffic asphalt AH-90, and the modifier is composed of star SBS, linear SBS and butyl Composed of benzene latex, the weight ratio of star SBS, linear SBS and styrene-butadiene latex is 3: 2: 1, and the stabilizing agent is 2: 1 dicumyl peroxide (DCP) and 4 , 4'-dithiodimorpholine (DTDM), the melting temperature of asphalt is 145°C, the stirring temperature is 145°C, and the stirring time is 60min; the temperature of high-speed shearing treatment is 170°C, and the rotation speed is 1200r / min , the time is outside 45min, all the other are identical with embodiment 1;

[0093] In this embodiment, the content of the modifier in the asphalt mixture is 8.5%, and the content of the modifier in the asphalt mixture is 8%-9%, which are all suitable for the present invention;

[0094] The technical indicators of high elas...

Embodiment 3

[0101] In the process of preparing modified asphalt, except that the weight ratio of asphalt, modifier and stabilizer is 87.5:10:2.5, the asphalt is selected from heavy traffic asphalt AH-90, and the modifier is composed of star SBS, linear SBS and butyl Composed of benzene latex, the weight ratio of star SBS, linear SBS and styrene-butadiene latex is 1:4:2, the stabilizer is sodium carboxymethyl cellulose, the heating and melting temperature of asphalt is 145°C, and the stirring temperature is 160°C ℃, stirring time is 50min; the temperature of high-speed shearing treatment is 160 ℃, and the rotating speed is 800r / min, and the time is 30min, all the other are identical with embodiment 1;

[0102] In this embodiment, the content of the modifier in the asphalt mixture is 10%, and the content of the modifier in the asphalt mixture is 9%-10%, which are all suitable for the present invention;

[0103] The technical indicators of high elastic SBS modified asphalt are shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal particle size | aaaaa | aaaaa |

| Nominal particle size | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com