Reflection crack resistant asphalt pavement structure and construction method thereof

A technology of asphalt pavement and construction method, which is applied in the direction of roads, roads, on-site paved cohesive pavements, etc., can solve the problems of semi-rigid base reflective cracks, etc., to reduce generation and development, delay generation and development, and improve structural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

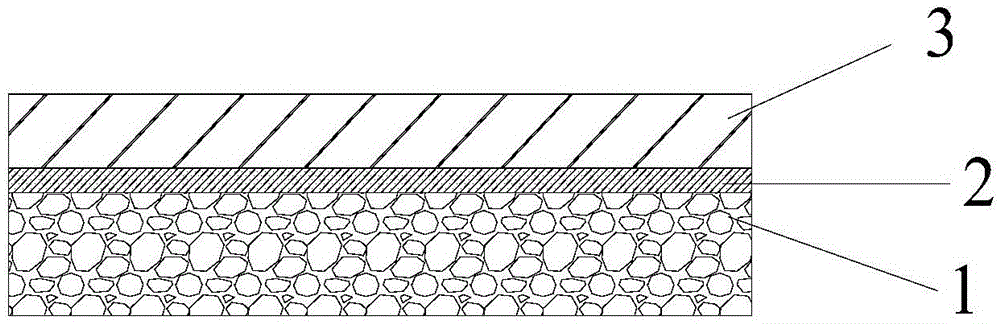

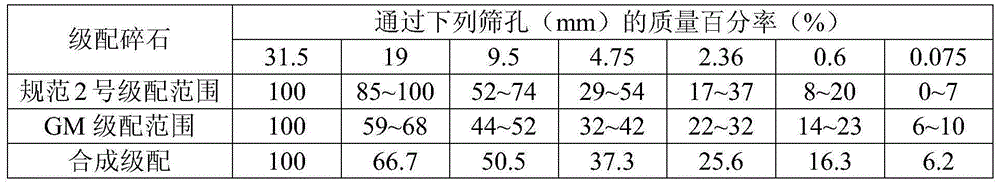

[0031] An anti-reflective cracked asphalt pavement structure, which includes a high-performance graded crushed stone base, a modified emulsified asphalt bonding layer and a rock asphalt layer from bottom to top; the high-performance graded crushed stone base is 96.4% by weight aggregate and 3.6% water, the thickness of the high-performance graded crushed stone base is 40cm; the thickness of the modified emulsified asphalt bonding layer is 0.3cm; the rock asphalt layer consists of the following weight The percentages of materials are mixed: 92.2% of aggregate, 3.5% of ball-milled limestone powder, 4.3% of rock asphalt modified asphalt, and the thickness of the rock asphalt layer is 10cm.

[0032] The construction method of the above-mentioned anti-reflection crack asphalt pavement structure comprises the following steps:

[0033] (1) The cleaning preparation of the lower bearing layer, cleaning the loose particles on the lower bearing layer surface;

[0034] (2) Using a stabil...

Embodiment 2

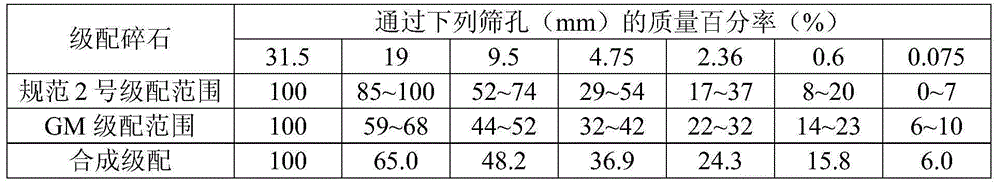

[0056] An anti-reflective cracked asphalt pavement structure, which includes a high-performance graded crushed stone base, a modified emulsified asphalt bonding layer and a rock asphalt layer from bottom to top; the high-performance graded crushed stone base consists of the following materials in weight percentage Mixed, aggregate 95.8%, water 4.2%, the thickness of the high-performance graded crushed stone base is 10cm, and the thickness of the modified emulsified asphalt bonding layer is 0.2cm.

[0057] The rock asphalt layer is formed by mixing the following materials by weight percentage, aggregate 90.0%, ball milled limestone powder 5.0%, rock asphalt modified asphalt 5.0%, and the thickness of the rock asphalt layer is 12cm.

[0058] The construction method of the anti-reflection crack asphalt pavement structure comprises the following steps:

[0059] (1) The cleaning preparation of the lower bearing layer, cleaning the loose particles on the lower bearing layer surface;...

Embodiment 3

[0080] An anti-reflective cracked asphalt pavement structure, which includes a high-performance graded crushed stone base, a modified emulsified asphalt bonding layer and a rock asphalt layer from bottom to top; the high-performance graded crushed stone base consists of the following materials in weight percentage Mixed, aggregate 95.0%, water 5.0%, the thickness of the high-performance graded crushed stone base is 18cm, and the thickness of the modified emulsified asphalt bonding layer is 0.25cm.

[0081] The rock asphalt layer is mixed with the following materials in weight percentage, aggregate 93.0%, ball milled limestone powder 4.0%, rock asphalt modified asphalt 3.0%, and the thickness of the rock asphalt layer is 8cm.

[0082] The construction method of the anti-reflection crack asphalt pavement structure includes the following construction techniques:

[0083] (1) Preparation for cleaning the lower bearing layer, cleaning loose particles on the lower bearing layer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com