Preparation method of crosslinked low density polyethylene (LDPE)

A technology based on low-density polyethylene and octavinyl, applied to plastic/resin/wax insulators, organic insulators, etc., can solve problems affecting product performance, molecular chain extension, long cross-linking time, etc., to achieve convenient operation and cross-linking The effect of short linking time and high degree of crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Take the L-0.5P-0.2D system (L stands for LDPE, P stands for OVPOSS, D stands for DCP, the overall meaning is LDPE containing OVPOSS 0.5%, DCP 0.2%) as an example:

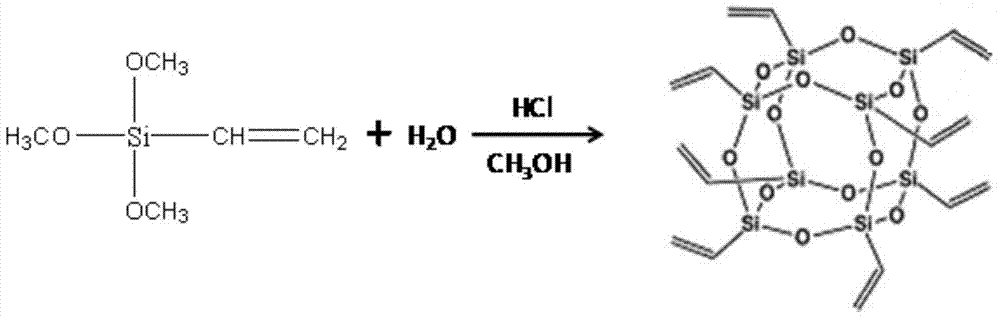

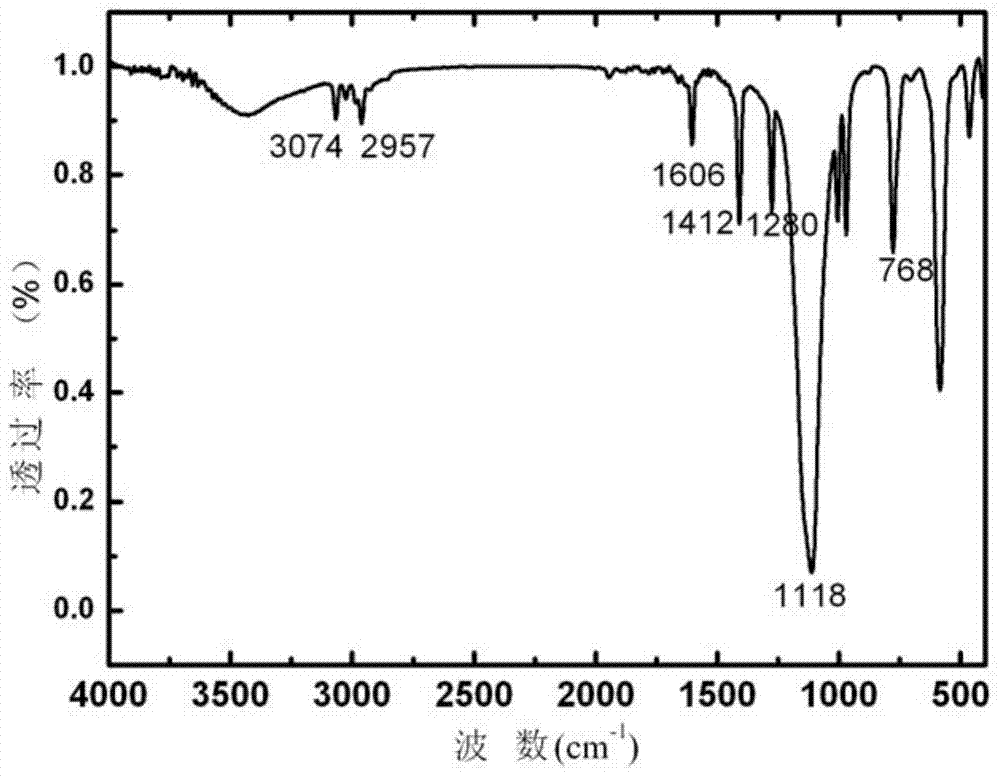

[0056] (1) Mix anhydrous methanol, ultrapure water, and concentrated hydrochloric acid to obtain solution I; mix vinyltrimethoxysilane and anhydrous methanol to obtain solution II; add solution II dropwise to solution I, and hydrolysis and condensation reactions occur at 50°C 6d, after washing, filtering, and drying, and then through the process of product dissolution and reprecipitation, OVPOSS powder is obtained; the molar ratio of ultrapure water to vinyltrimethoxysilane is 5:1; the volume ratio of concentrated hydrochloric acid to solution I is 0.25:100; the volume ratio of vinyltrimethoxysilane to anhydrous methanol is 7:93;

[0057] (2) According to the mass ratio: LDPE 95% and DCP 5% were diffused and mixed at 80°C for 2 hours, and the mixture was extruded and granulated by a twin-screw extruder at 1...

Embodiment 2

[0064] Take the L-0.2P-0.2D system (LDPE containing OVPOSS 0.2%, DCP 0.2%) as an example:

[0065] (1) OVPOSS preparation method is identical with that in embodiment 1;

[0066] (2) According to the mass ratio: LDPE 95% and DCP 5% were diffused and mixed at 80°C for 2 hours, and the mixture was extruded and granulated by a twin-screw extruder at 100-120°C to obtain masterbatch 1.

[0067] (3) According to the mass ratio: LDPE 90% and OVPOSS 10% are extruded and granulated by a twin-screw extruder at 110-135°C to obtain masterbatch 2.

[0068] (4) 4% master batch 1, 2% master batch 2, and 94% LDPE are uniformly mixed according to the mass ratio, and then extruded, blended and granulated through twin-screws. The extrusion temperature in the twin-screw is 115-135°C, and the rotation speed is 40rpm. After extrusion, it is water-cooled and directly enters the pelletizer for granulation.

[0069] (5) Take an appropriate amount of sample in the mold, and press it into a disc-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com