Heavy oil lightening method and device

A processing method and lightweight technology, applied in the petroleum industry, cracking, non-catalytic thermal cracking, etc., can solve problems such as difficult control, complicated process flow, and failure of continuous and rapid application development, and achieve wide adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

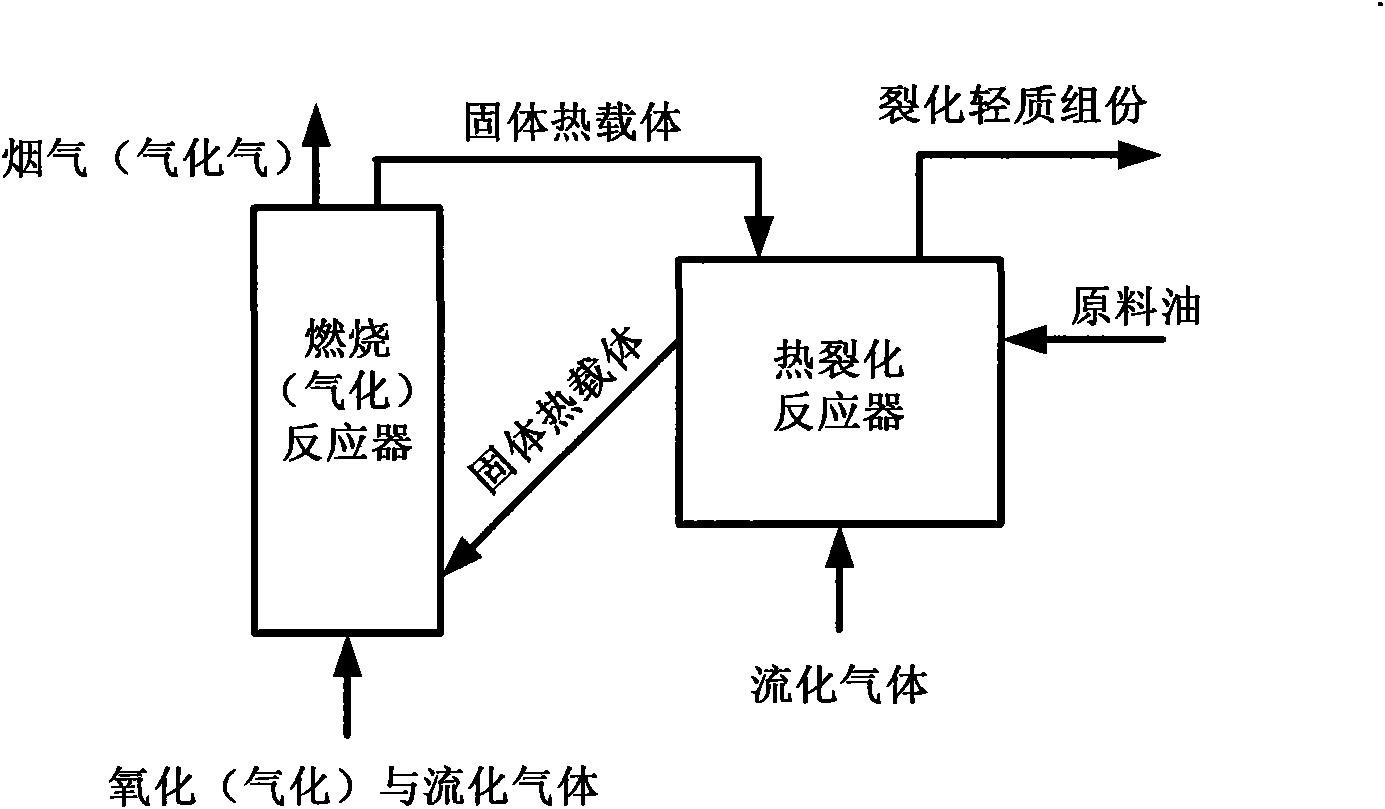

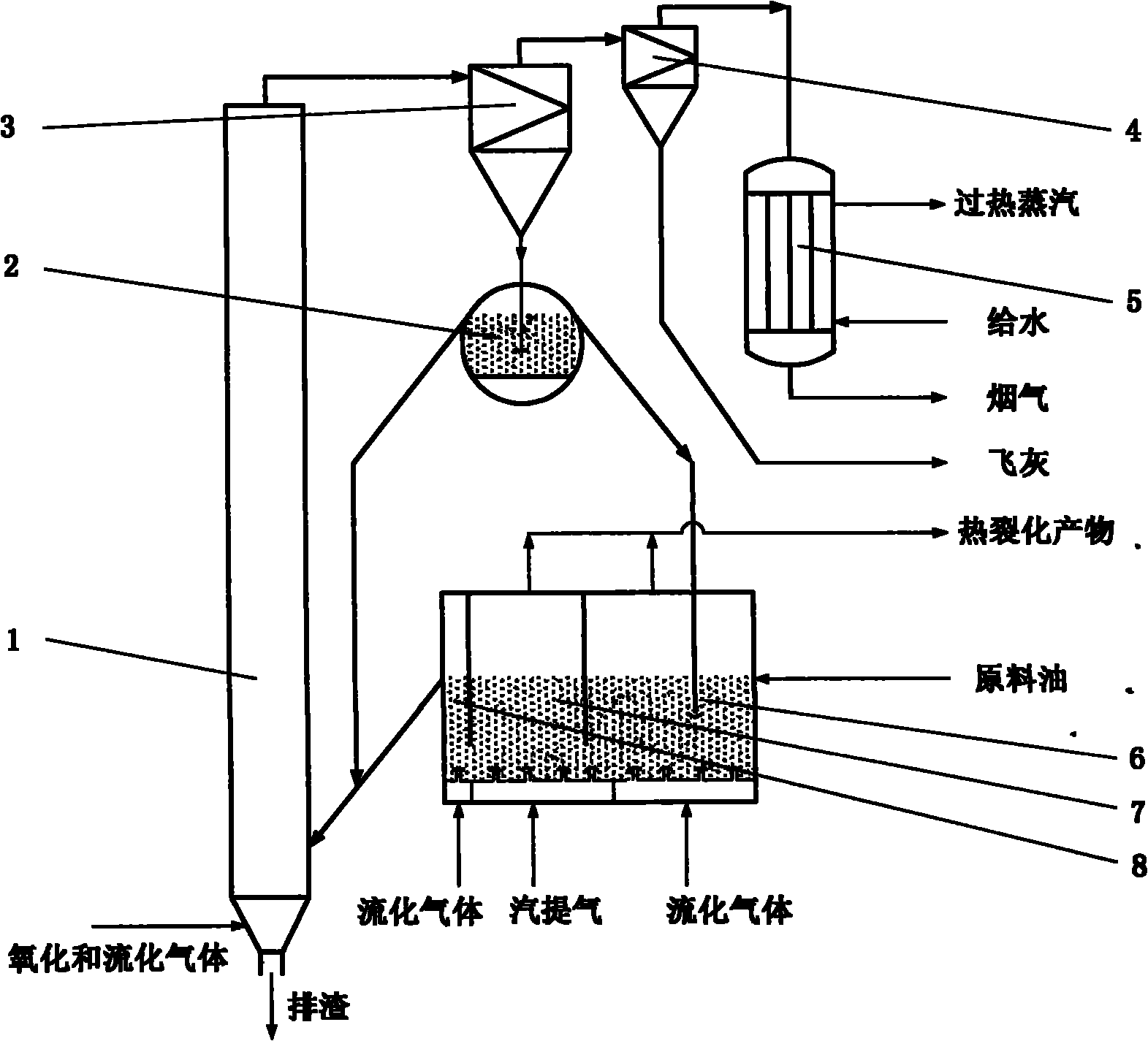

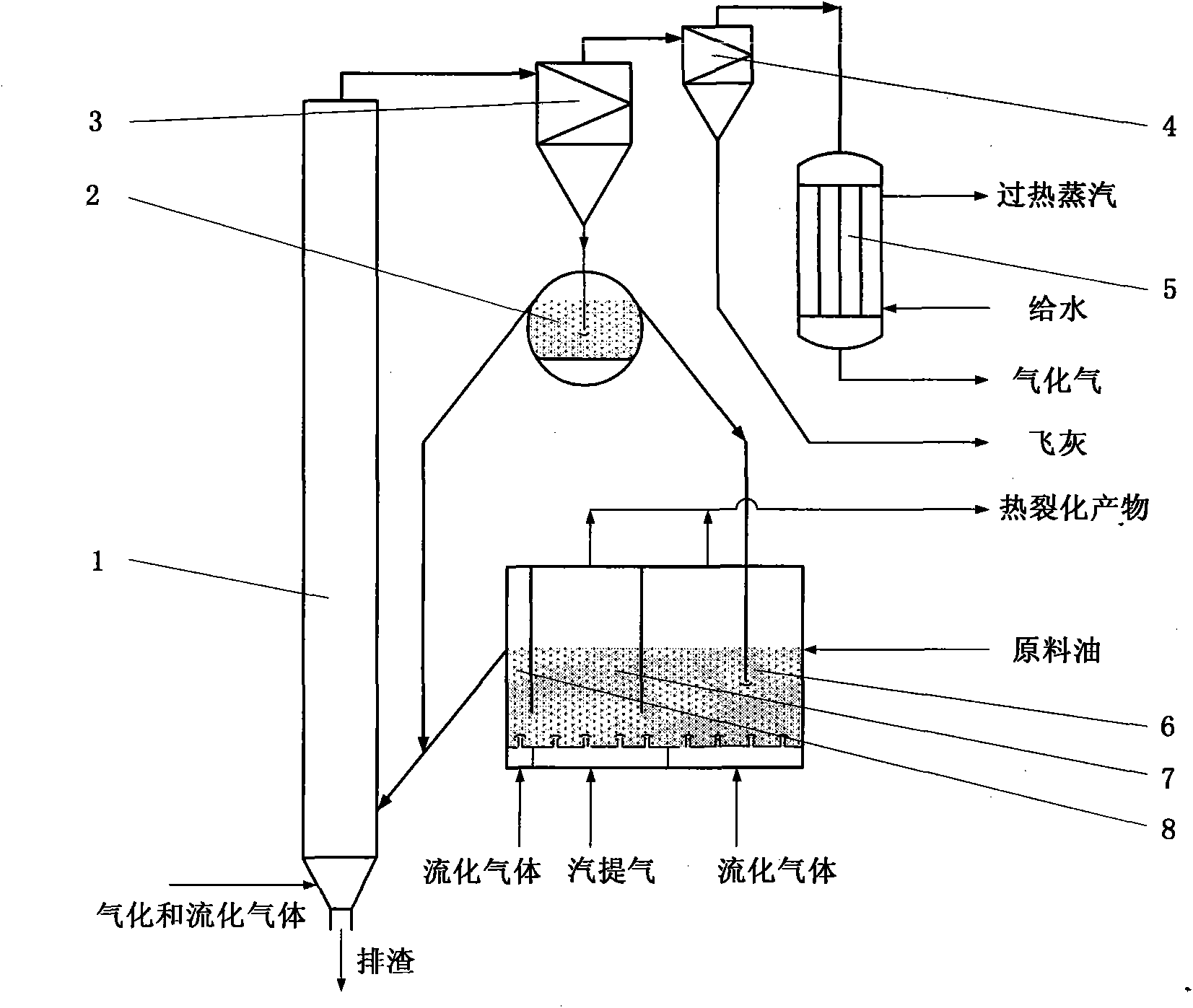

[0048] The specific implementation of the method of the invention is not only applicable to conventional feedstock oils used for catalytic cracking and hydrocracking, but also to the processing of heavy or low-quality feedstock oils with high sulfur, nitrogen, metal and carbon residue content, Among them, attached figure 1 Shown technological process is the basic principle that embodies technical thought of the present invention in a concentrated manner, appended figure 2 It is a kind of technological device process that expresses the technology of the invention, and it is mainly composed of combustion (gasification) reactor 1, distribution valve 2, primary gas-solid separator 3, secondary gas-solid separator 4, waste heat recovery heat exchanger 5 , a thermal cracking reactor 6, a stripping system 7, and a feeding system 8. Wherein the combustion (gasification) reactor 1 is only used for combustion reaction in this embodiment. The specific implementation method is to first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com