Production methods for a leadframe and electronic devices

a technology of electronic devices and leadframes, applied in semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve problems such as unusability of electronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

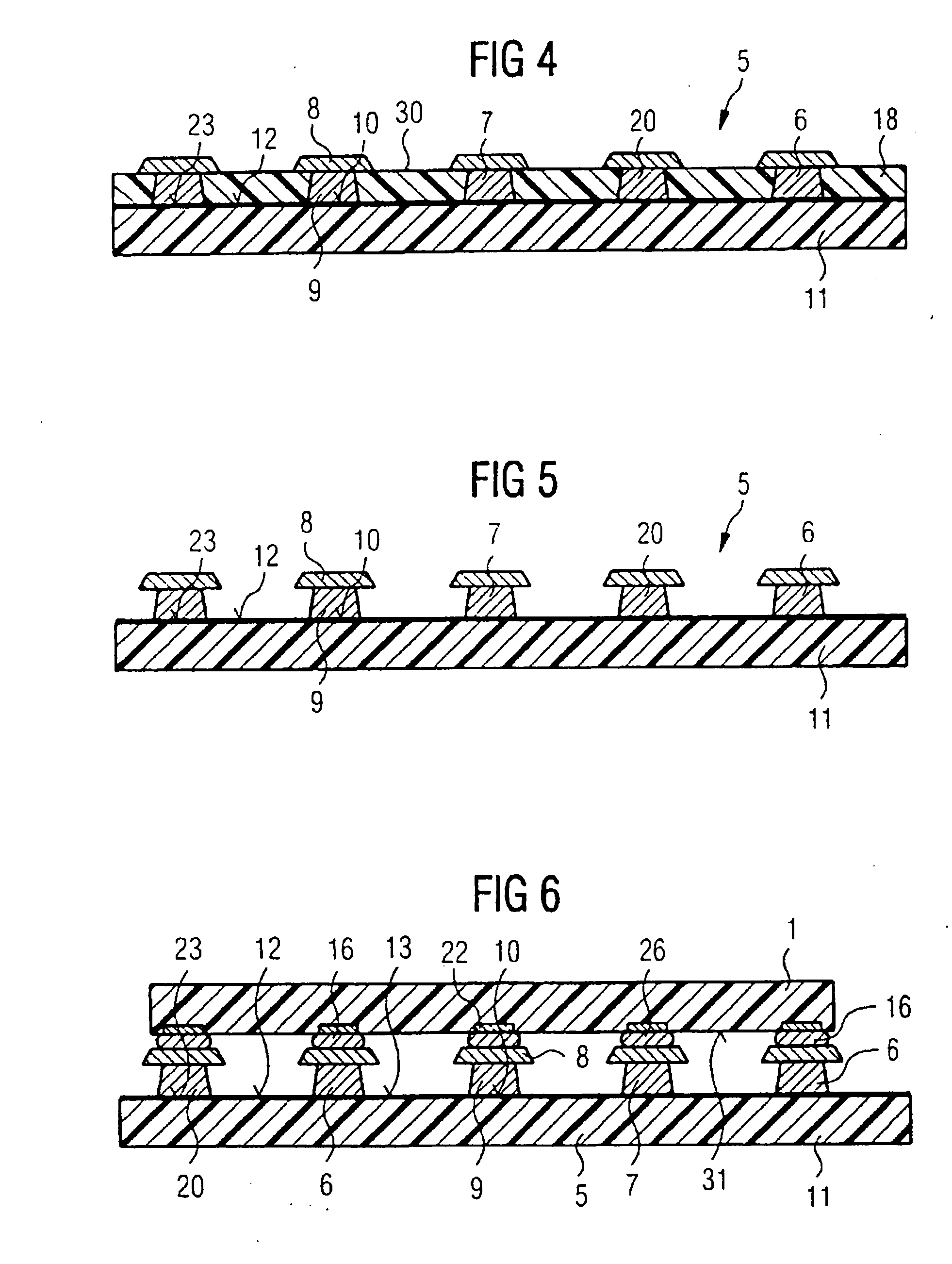

[0073] If the basic substrate 11 is a metallic foil as in the exemplary embodiment of FIG. 6, then the metallic foil can be removed by wet or dry etching after the injection-molding of the plastic before or during the singulation of the electronic devices of a leadframe of the Here, too, it is advantageous if the external contact element 6 has an etching stop layer in the rivet foot region 10.

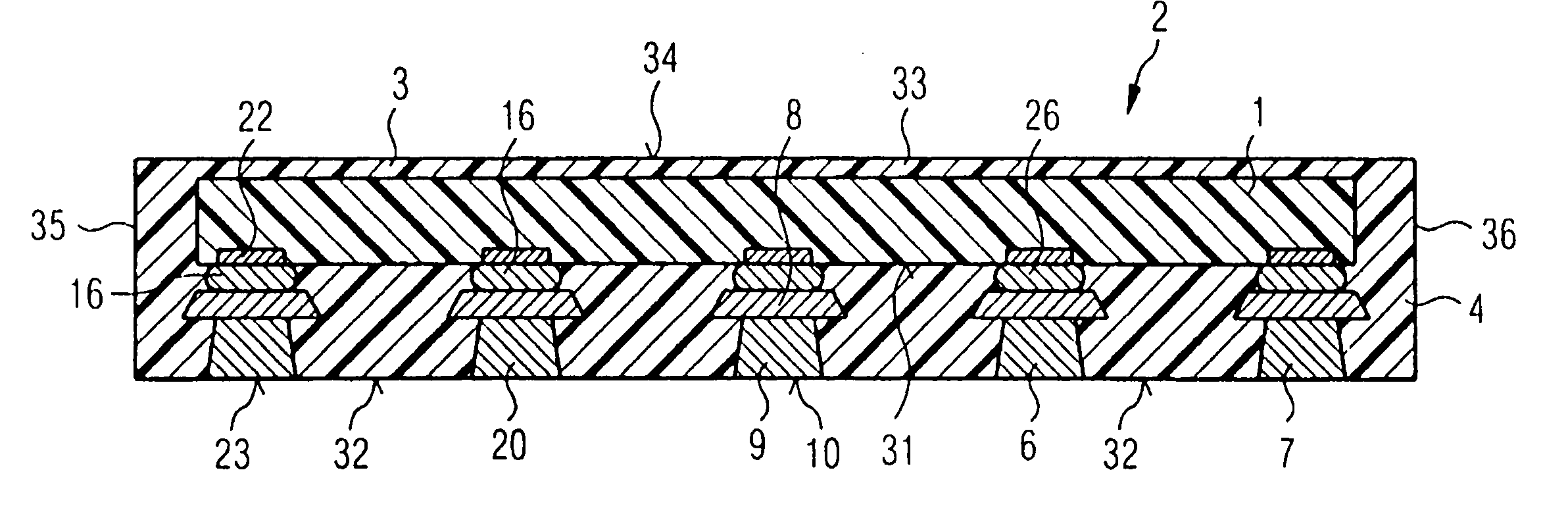

[0074]FIG. 7 shows a diagrammatic cross-section through an electronic device 2 in accordance with a first embodiment of the invention. The electronic device 2 is provided with a housing 3 that is made of plastics compound 4 and is potted on one side, and has a semiconductor chip 1 in the housing 3, which semiconductor chip 1 has contact areas 22 connected to external contact elements 6 through bonding bumps 16 made of soldering balls, for example. The external contact elements 6 have a rivet-shaped cross-section with a rivet foot region 10, a rivet shank region 9, and a rivet head region 8, th...

second embodiment

[0077]FIG. 8 shows a diagrammatic cross-section through a leadframe 5 with an applied semiconductor chip 1 in accordance with the invention. The leadframe 5 differs from the leadframe 5 of FIG. 5 in that a metallic base 17 is applied to the basic substrate 11 in the chip carrier region at the same time as the formation of external contact elements 6. In the embodiment of FIG. 8, the metallic base 17 is made of the same material as the external contact elements 6 and has the same height h. The areal extent of the metallic base 17 is adapted to the size of the semiconductor chip 1 so that the semiconductor chip 1 can be applied completely on the metallic base 17, as shown in FIG. 8. The application can be effected by adhesive bonding using a conductive adhesive or by alloying the semiconductor chip 1 onto the metallic base 17.

[0078] In the second embodiment of the leadframe 5, the semiconductor chips 1 are applied to the metallic base 17 with their passive side 33, which does not carr...

third embodiment

[0081]FIG. 11 shows a diagrammatic cross-section through an electronic device in accordance with the invention. This device is distinguished by its extreme planarity because even the base height h, as is shown in FIG. 8, is additionally obviated. A disadvantage of such a device is that the passive side 33 of the semiconductor chip 1 simultaneously forms the underside 32 of the electronic device. The semiconductor chip 1 is, thus, exposed to ambient influences with its underside 33. The external contact elements 6 are securely anchored in the plastics compound 4 of the housing 3 on account of their rivet-shaped cross-section and have, in their rivet foot region 10, a circular plan that provides a circular contact pad as external contact area 23.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com