Insole for a shoe

a technology for shoes and soles, applied in the field of soles, can solve the problems of insufficient absorption of pressure shocks on different pressure portions of the foot soles, inability to effectively reflect or cope on the soles of a single material, and foot pain, etc., to achieve the effect of improving air permeability, promoting dryness of sweat, and easy exhaustion or suppression of bad smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Technical Problem

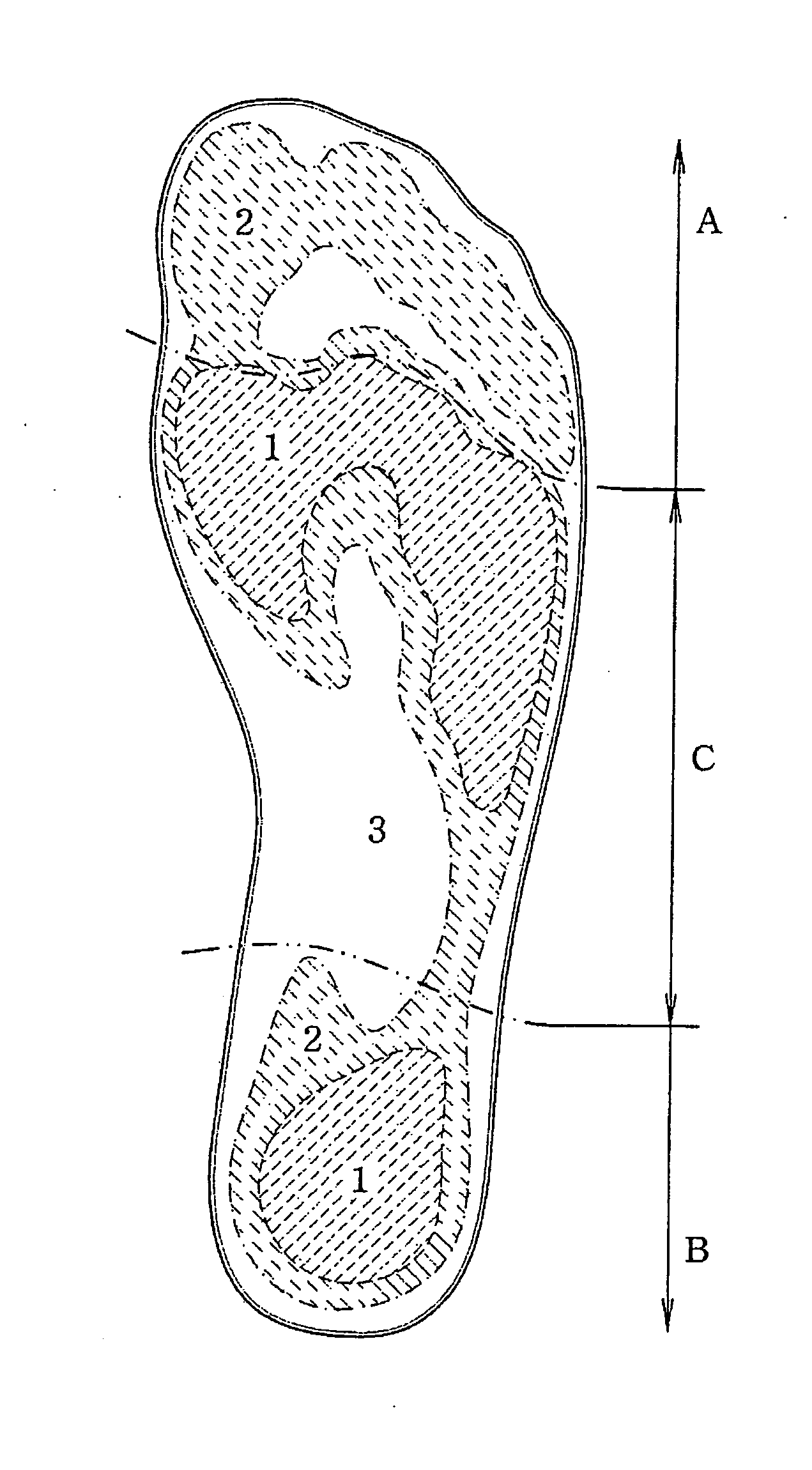

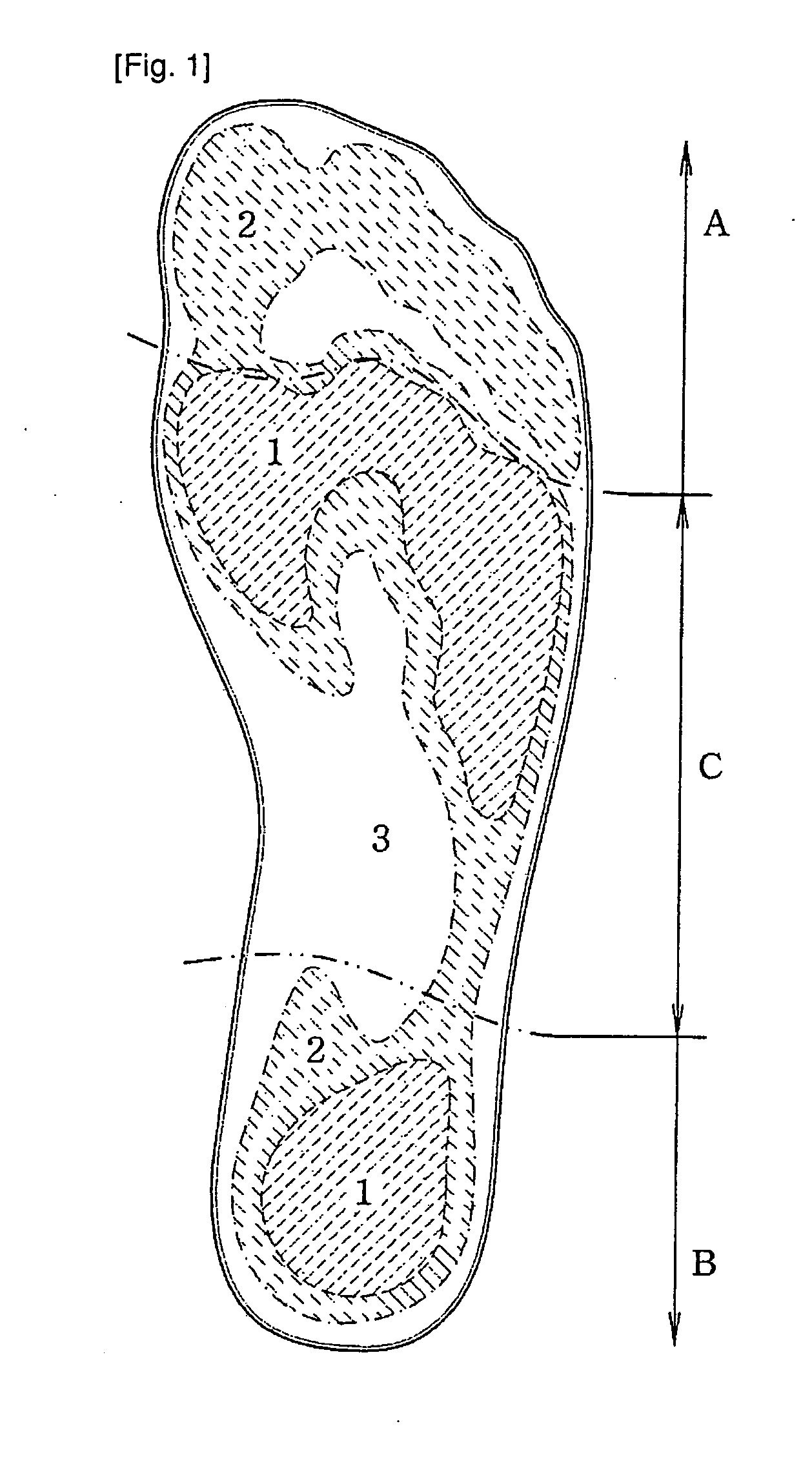

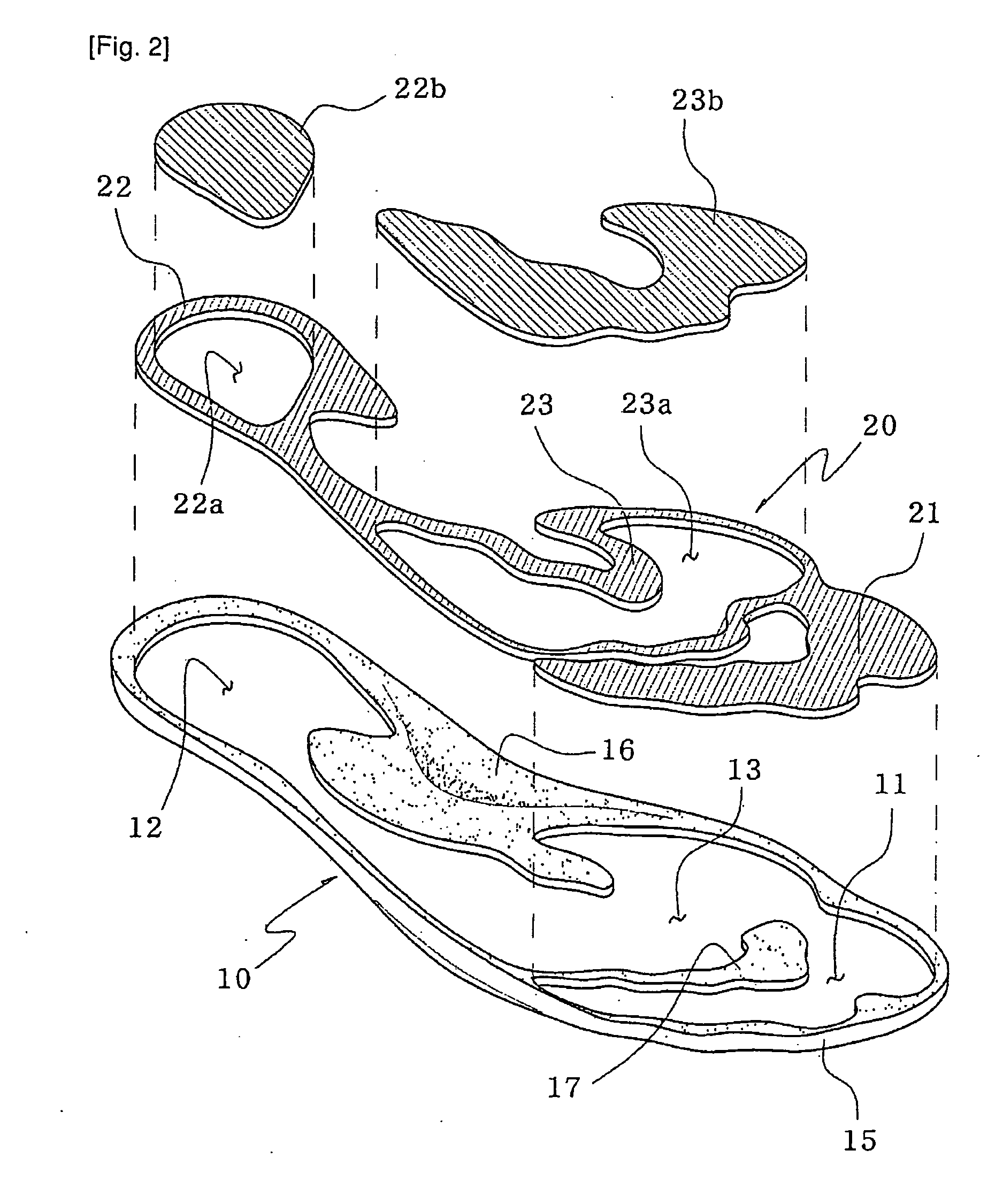

[0008]In order to solve the problems of prior arts as mentioned, the present inventors have conducted extensive studies the changes of the pressure and shape of the foot when wearing on shoe in aspect of biomechanics, and as a result have found that the said drawback can be removed by providing an insole preparing by a plurality of materials having varying degrees of hardness depending on the insole region. Accordingly, the purpose of the present invention provides an insole wherein the insole is made of a plurality of materials having varying degrees of depending on the insole region, and the respective materials are combined to form a single layer, and the upper surface of the insole has a shape corresponding complementarily in shape to a sole of human foot such that the insole has complementary shapes corresponding to the rearfoot, the midfoot and the forefoot thereby providing almost bare-foot sensation on insole installed inside shoe of the present invention.

So...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com