Method and equipment for producing flange type lining plastic compound steel pipe

A technology of composite steel pipe and production method, which is applied in the direction of mechanical equipment, chemical instruments and methods, pipes, etc., and can solve the problems of the difference in linear expansion coefficient of the plastic coating layer falling off, the uniformity of the coating layer is difficult to control, and the coating layer is prone to pinhole defects, etc. , to achieve the effect of efficient use of electric energy, high bonding strength, and rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

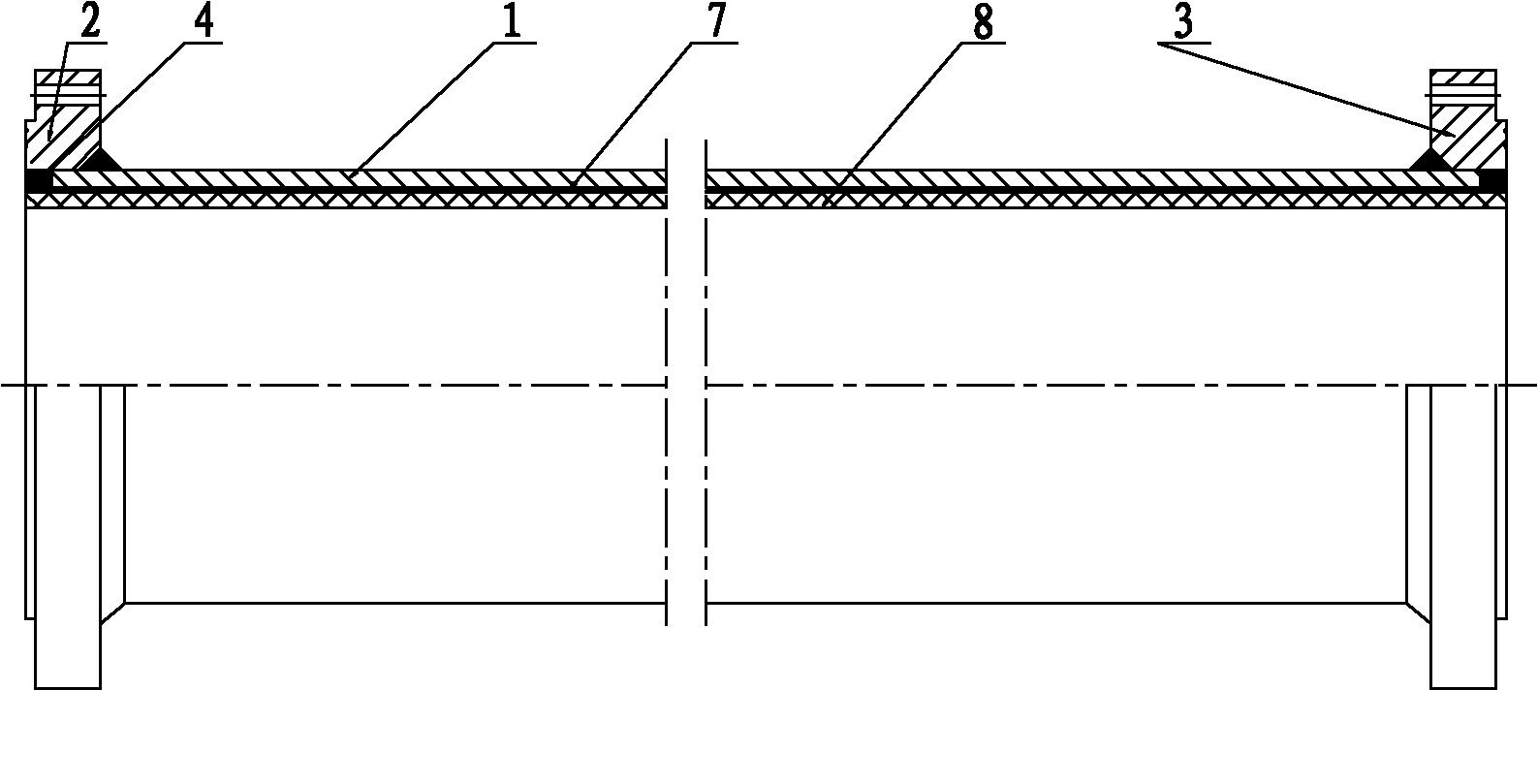

[0044] A. Weld the first end flange 2 and the end flange 3 respectively at both ends of the steel pipe 1;

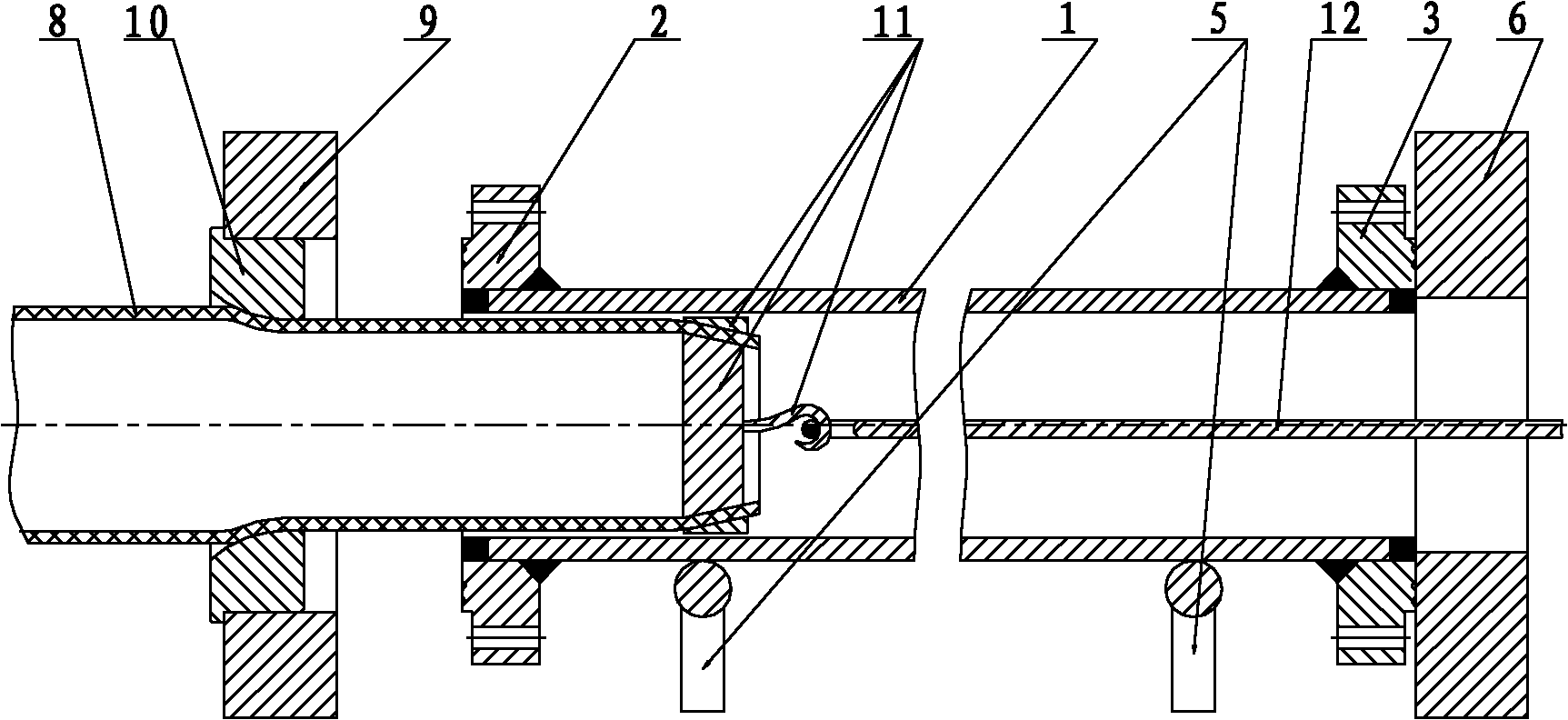

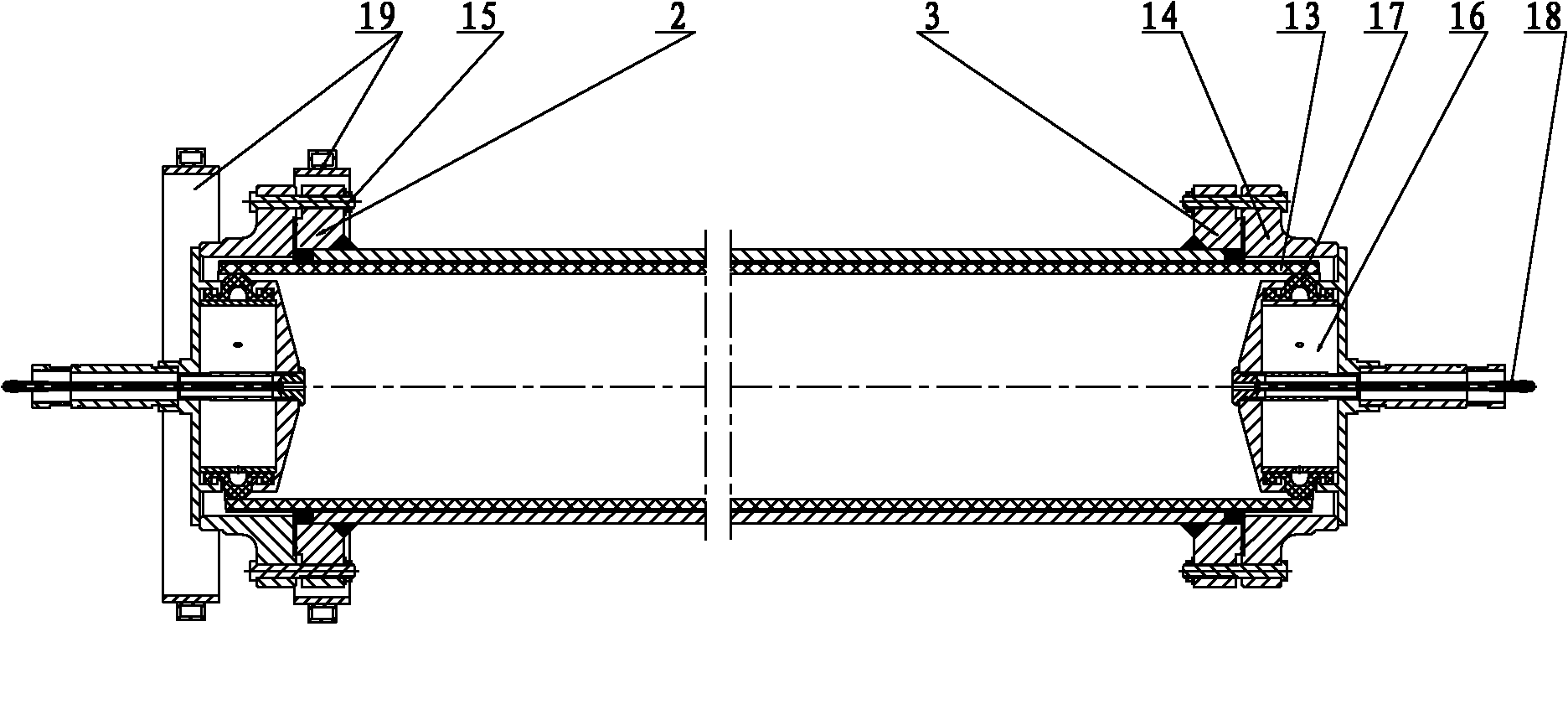

[0045] B. The outer wall is provided with a cutout at one end of the plastic pipe 8 with a layer of hot melt adhesive 7. The outer diameter of the plastic pipe 8 is equal to or slightly smaller than the inner diameter of the steel pipe 1. It is connected with the clamp 11 through the cutout, and the clamp is pulled by the traction rope 12 on the traction device. 11 Make the plastic pipe 8 penetrate the steel pipe 1, and make the outer sides of the first end flange 2 and the end flange 3 protrude out the plastic pipe extension end 13 whose length is compatible with the process sleeve 14, and respectively connect the two process sleeves 14 Connect with the head flange 2 and the end flange 3, so that the plastic pipe extension 13 is placed in the process sleeve 14, and the process sleeve 14 is connected with the head flange 2 and the end flange 3 through flanges and bolts 15...

Embodiment 2

[0051] A. Weld the first end flange 2 and the end flange 3 respectively at both ends of the steel pipe 1;

[0052] B. The outer wall is provided with a cutout at one end of the plastic pipe 8 with a layer of hot melt adhesive 7. The outer diameter of the plastic pipe 8 is equal to or slightly larger than the inner diameter of the steel pipe 1. It is connected with the clamp 11 through the cutout, and the clamp 11 is pulled by the traction rope 12 on the traction device. The diameter of the plastic pipe 8 is reduced through the mold 10, and the steel pipe 1 is penetrated at the same time, and the outer sides of the first end flange 2 and the end flange 3 respectively protrude from the outer sides of the plastic pipe 13 whose length is suitable for the process sleeve 14, Connect the two process sleeves 14 with the head end flange 2 and the end flange 3 respectively, so that the plastic pipe extension 13 is placed in the process sleeve 14, and the process sleeve 14 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com