Blowing needle mechanism for single blowing hole of blowing mold

A technology of blowing holes and blowing molds, which is applied in the field of blowing needles for blowing molds, which can solve problems such as troublesome installation and maintenance, reduced use stability, and increased product costs, so as to achieve low maintenance costs, prevent heat concentration, reduce volumetric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

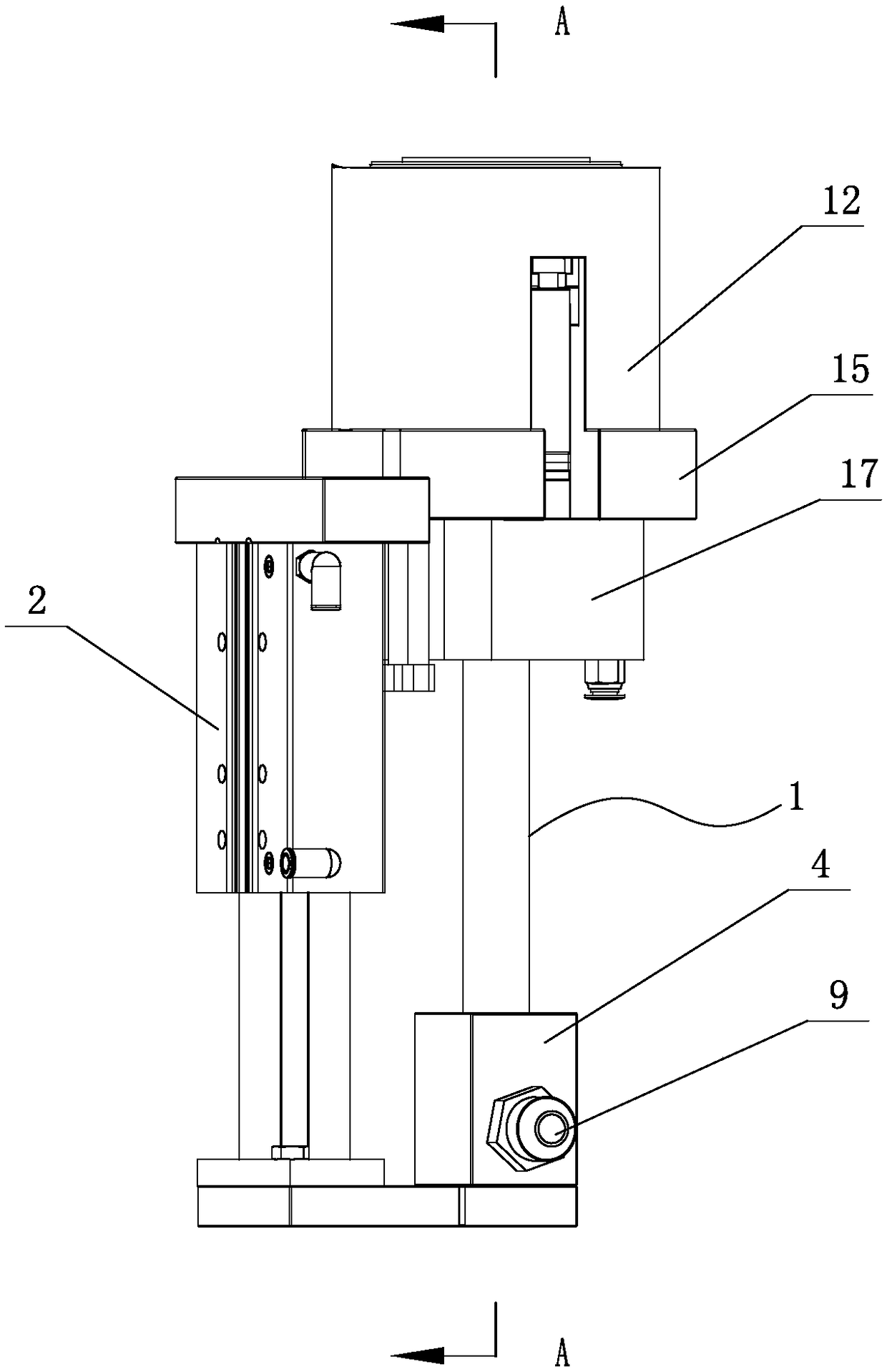

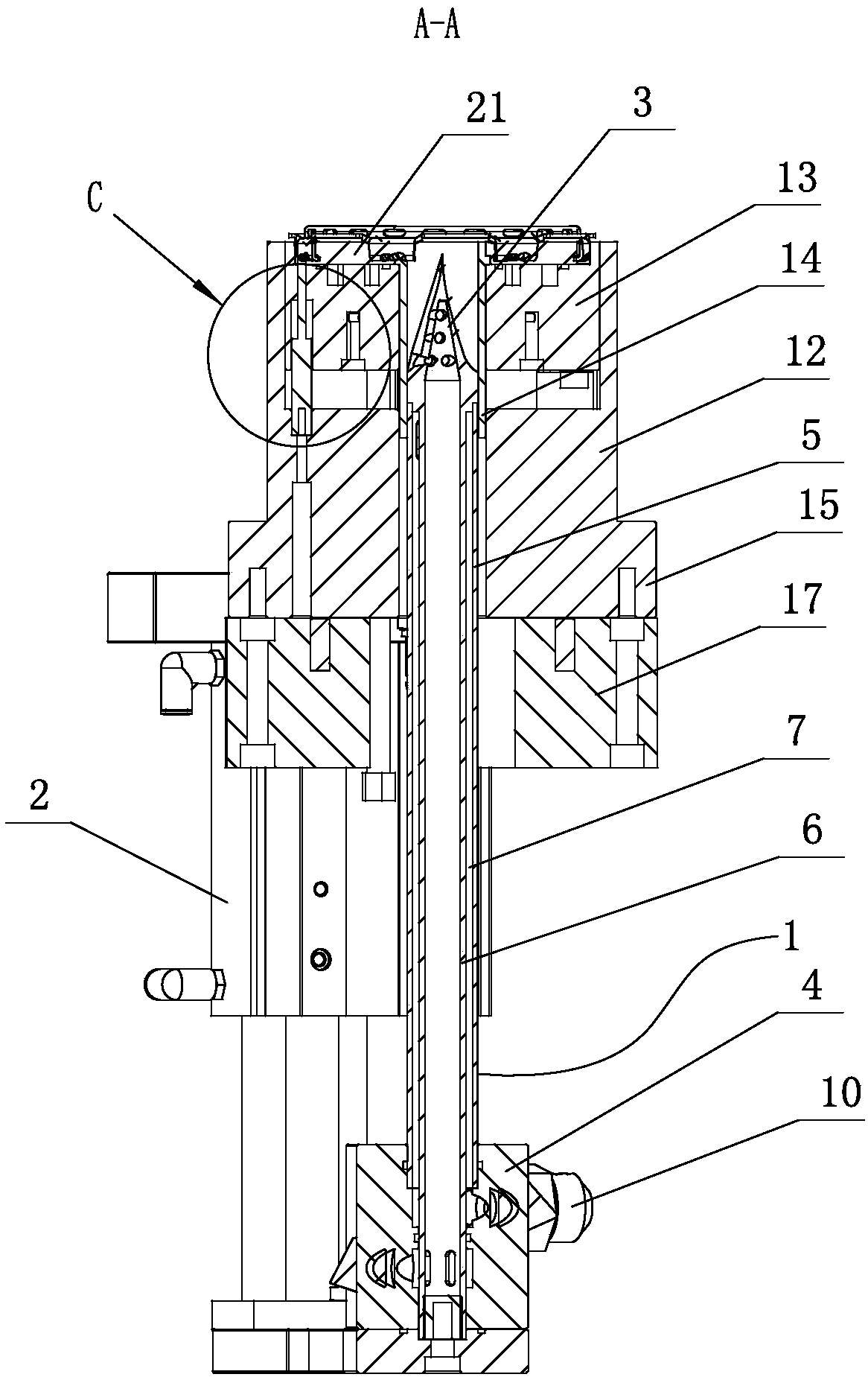

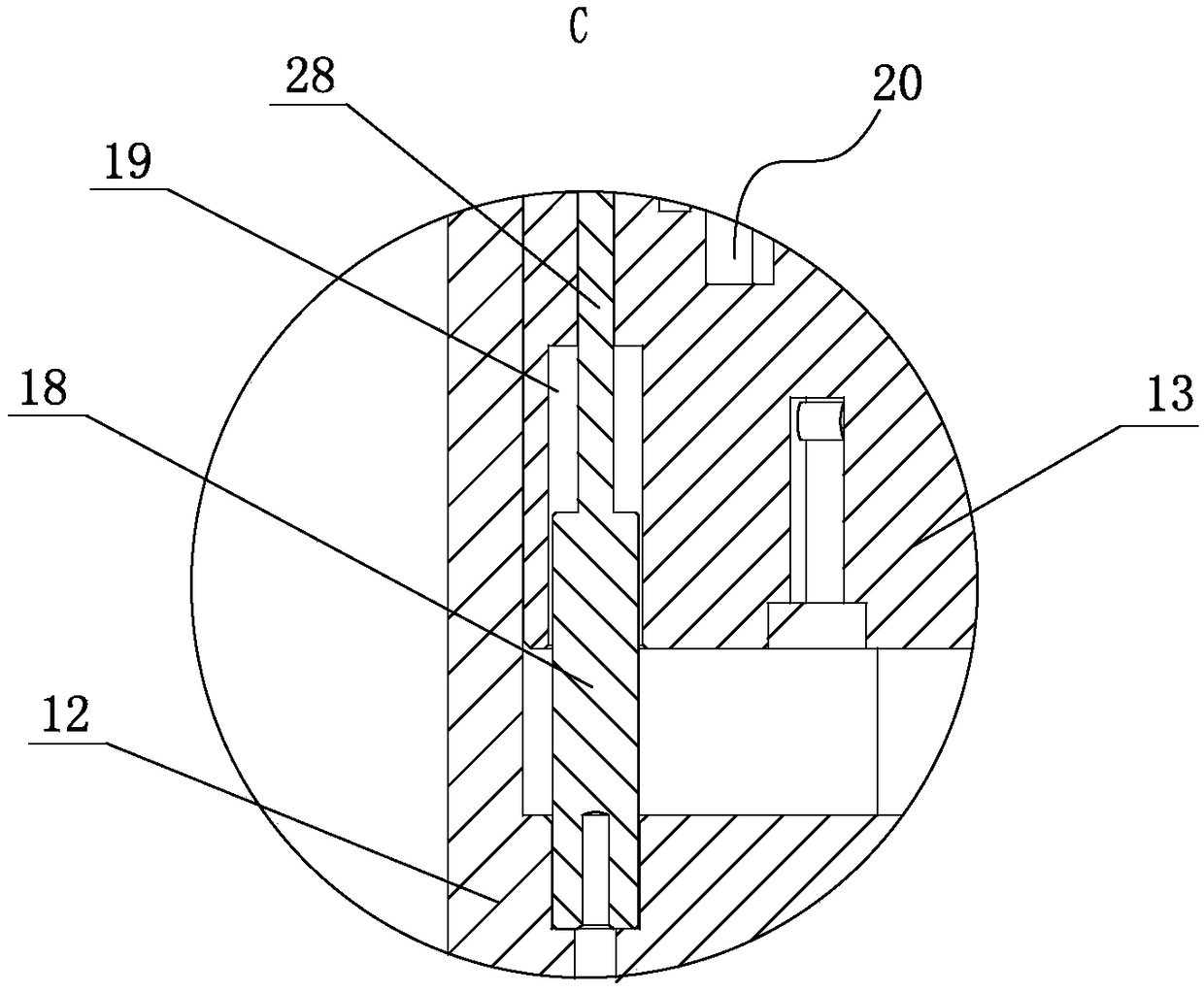

[0029] combine Figure 1-10, a blowing needle mechanism for a single blowing hole in a blow mold, which includes a blowing needle 1 connected to an air source, a push-pull cylinder 2 fixed on a mold base, and a blowing needle guide mechanism (of course also including other parts, but due to lack of It relates to the invention point of the present invention, so it will not be repeated here), the piston rod of the push-pull cylinder 2 is connected to the blowing needle 1, and the blowing needle 1 includes a needle head 3, a needle body and a needle seat 4; the needle body Including an outer tube 5 and an inner tube 6, the needle seat 4 is fixedly connected with the piston rod of the push-pull cylinder 2 through a connecting plate, the inner tube 6 is located in the outer tube 5, and the axis of the inner tube 6 is at the same axis as the outer tube 5 On a straight line, the inner wall of the outer tube 5 and the outer wall of the inner tube 6 form a channel 7; the upper end of t...

Embodiment 2

[0038] A blowing needle mechanism for a single blowing hole in a blow mold, which includes a blowing needle 1 connected to an air source, a push-pull cylinder 2 fixed on a mold base, and a blowing needle guide mechanism (of course also includes other parts, but since it is not involved Invention point created by the present invention, so no more details here), the piston rod of the push-pull cylinder 2 is connected with the blowing needle 1, and the blowing needle 1 includes a needle head 3, a needle body and a needle seat 4; the needle body includes The outer tube 5 and the inner tube 6, the needle seat 4 is fixedly connected with the piston rod of the push-pull cylinder 2 through the connecting plate, the inner tube 6 is located in the outer tube 5, and the axis of the inner tube 6 is on the same line as the axis of the outer tube 5 Above, the inner wall of the outer tube 5 and the outer wall of the inner tube 6 form a channel 7; the upper end of the inner tube 6 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com