A preparation method of a silicon-based microneedle array patch

A microneedle array, silicon-based technology, applied in the field of microneedles, can solve the problems of complex process, poor puncturing ability, and difficult processing, and achieve the effects of simple process, simple processing and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

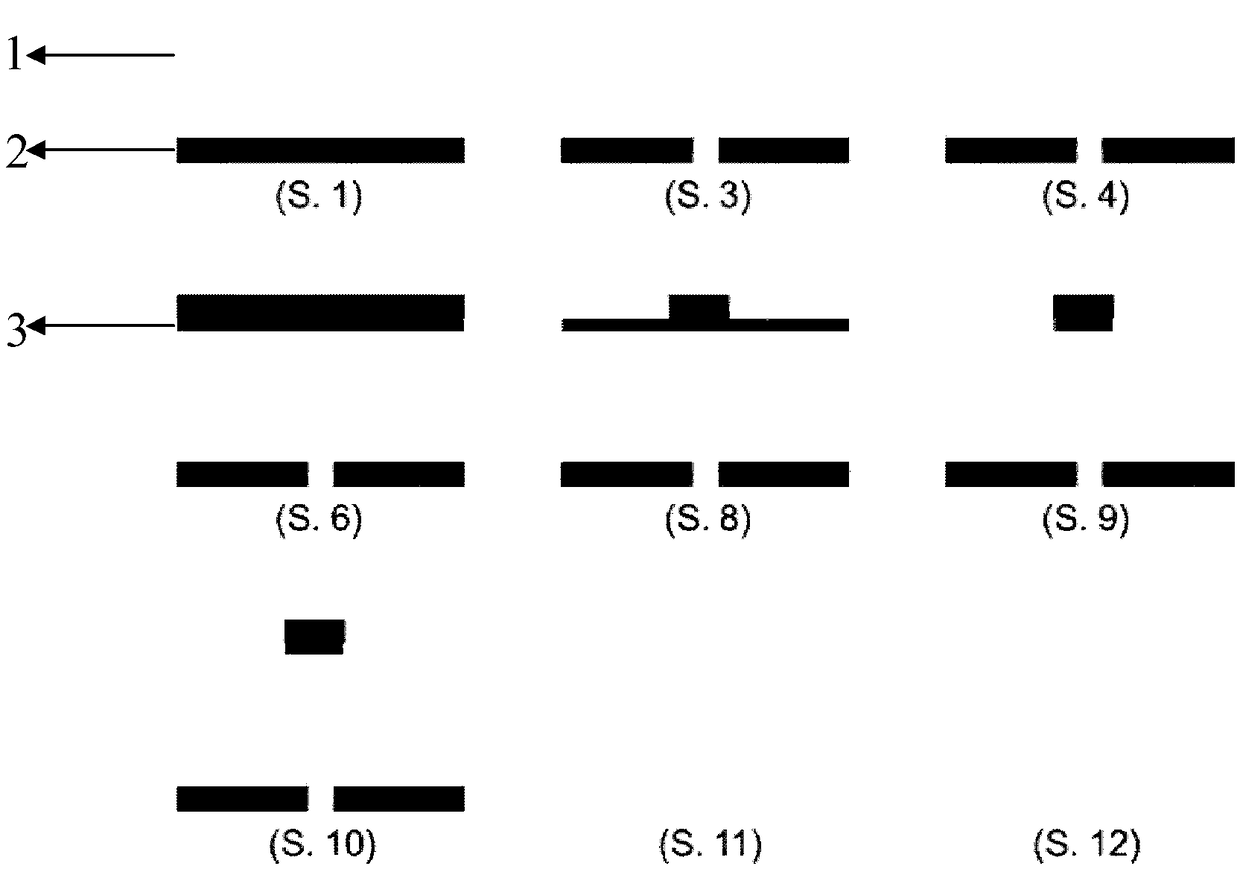

[0041] A method for preparing a silicon-based microneedle array patch, the preparation method comprising preparation of micropores and preparation of needle tips, wherein:

[0042] Micropores are prepared by the following steps:

[0043] S.1 Coating AZP 4620 positive photoresist on the back of the silicon wafer;

[0044] S.2 Put the silicon wafer coated with AZP 4620 positive photoresist on the backside and bake it on a hot plate at 90°C for 5 minutes, and the thickness of the photoresist obtained is 5 microns;

[0045] S.3 The photolithography light intensity is 2.7mW / cm 2 , photolithographic exposure was carried out under the condition of lithography time 250s, and then developed with AZ300 MIF developer for 100s, after the development was completed, rinsed with deionized water for 1 minute to prepare a hole array with a hole diameter of 30 microns;

[0046] S.4 Deep silicon etching, forming deep holes in the silicon wafer;

[0047] The needle tip is prepared by the followi...

Embodiment 2

[0057] A method for preparing a silicon-based microneedle array patch, the preparation method comprising preparation of micropores and preparation of needle tips, wherein:

[0058] Micropores are prepared by the following steps:

[0059] S.1 Coating AZP 4620 positive photoresist on the back of the silicon wafer;

[0060] S.2 Put the silicon wafer coated with AZP 4620 positive photoresist on the backside and bake it on a hot plate at 110°C for 1 minute, and the thickness of the obtained photoresist is 15 microns;

[0061] S.3 The photolithography light intensity is 3.0mW / cm 2 , photolithographic exposure was carried out under the condition of lithography time 150s, and then developed with AZ300 MIF developer for 100s, after development, rinsed with deionized water for 3 minutes to prepare a hole array with a hole diameter of 30 microns;

[0062] S.4 Deep silicon etching, forming deep holes in the silicon wafer;

[0063] The needle tip is prepared by the following steps:

[...

Embodiment 3

[0073] A method for preparing a silicon-based microneedle array patch, the preparation method comprising preparation of micropores and preparation of needle tips, wherein:

[0074] Micropores are prepared by the following steps:

[0075] S.1 Coating AZP 4620 positive photoresist on the back of the silicon wafer;

[0076] S.2 Put the silicon wafer coated with AZP 4620 positive photoresist on the backside and bake it on a hot plate at 100°C for 2 minutes, and the thickness of the obtained photoresist is 8 microns;

[0077] S.3 The photolithography light intensity is 2.8mW / cm 2 , photolithographic exposure was carried out under the condition of lithography time 200s, and then developed with AZ300 MIF developer for 200s, after the development was completed, rinsed with deionized water for 2 minutes to prepare a hole array with a hole diameter of 30 microns;

[0078] S.4 Deep silicon etching, forming deep holes in the silicon wafer;

[0079] The needle tip is prepared by the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com