Biodegradable aliphatic-aromatic copolyester composition and application thereof

A biodegradable and aliphatic technology, applied in the field of polyester composition, can solve the problems of reduced heat preservation, moisturizing effect, puncture, insufficient tear resistance, etc., so as to reduce the probability of puncture and prevent puncture. , the effect of reducing the water vapor transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

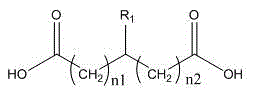

[0053]Put 8.73 Kg of dimethyl terephthalate and 9 Kg of 1,4-butanediol into the reaction kettle, replace the air in the reaction kettle with nitrogen, raise the temperature to 170°C, and wait until the dimethyl terephthalate is completely After melting, 10 g of isopropyl titanate was added, and the temperature was gradually raised to 180° C. for esterification. After the methanol slipping out reaches the theoretical amount, add 7.96 Kg of adipic acid and 142 g of dodecenylsuccinic acid, continue the reaction until the slipping out water reaches the theoretical amount, add 10 g of isopropyl titanate, and gradually heat up to 230~ 250 ° C, about 30 minutes to reduce the pressure in the reactor to below 60Pa, and continue to react under this condition until the power of the stirring motor reaches the set value. The reaction kettle is filled with high-purity nitrogen, and the melt is extruded through a mouth die, and then drawn and pelletized to obtain an aliphatic-aromatic copoly...

Embodiment A2

[0055] Put 11.64Kg of dimethyl terephthalate, 9Kg of 1,4-butanediol, 5.40Kg of adipic acid, and 630g of octenylsuccinic anhydride into the reactor, and gradually raise the temperature to 170 o C, add 20g of n-butyl titanate, after methanol and water have slipped out to reach the theoretical amount, gradually raise the temperature to 230~250 o C, reduce the pressure in the reactor to below 60Pa for about 30 minutes, and continue to react under this condition until the power of the stirring motor reaches the set value; fill the reactor with high-purity nitrogen, press the melt out through the mouth mold, and then pull it Copolyester base material A20 is obtained by stripping and pelletizing; A20 is dried, mixed with 0.6% hexamethylene diisocyanate, reacted in a twin-screw extruder, and pelletized to obtain alkyl side chain aliphatic - Aromatic copolyesters.

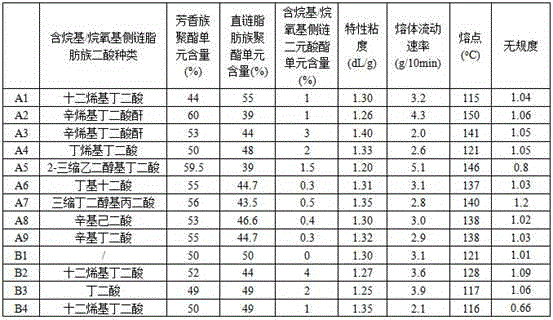

[0056] Change the ratio of aromatic dibasic acid, aliphatic dibasic acid and aliphatic dibasic acid containing alkyl / alk...

Embodiment 1~9 and comparative example 1~4

[0061] Mix the aliphatic-aromatic copolyester A containing alkyl / alkoxy side chains, polylactic acid, and the compatibilizer as a compatibilizer in a high-speed mixer according to the ratio in Table 2, and then use a weighing scale to add In the twin-screw extruder, at 170~220 o C Extrusion granulation to obtain biodegradable aliphatic-aromatic copolyester composition.

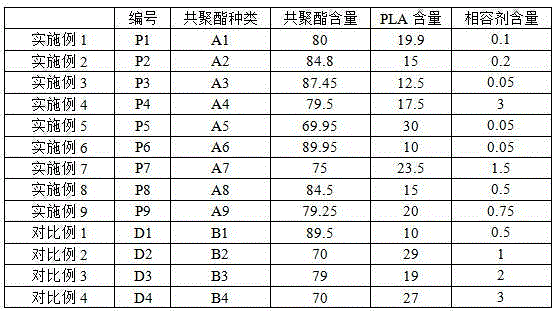

[0062] Table 2 The ratio of biodegradable aliphatic-aromatic copolyester composition P

[0063]

[0064] Table 3 Performance test results of biodegradable aliphatic-aromatic copolyester composition P

[0065]

[0066] As can be seen from Table 2 and Table 3, due to the addition of a specific ratio of alkyl / alkoxy side chain-containing aliphatic dibasic acid ester units, the biodegradation of the film produced by the aliphatic-aromatic copolyester composition The yield strength is improved, which is conducive to improving the puncture performance of agricultural mulch films against crops and weeds, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com