Puncture-resistant electrolyte-resistant casting polypropylene film, aluminum-plastic film and application of puncture-resistant electrolyte-resistant casting polypropylene film and aluminum-plastic film

A technology of casting polypropylene and electrolyte, which is applied in the field of aluminum-plastic film, can solve the problems of corroding aluminum-plastic film, accelerating electrolyte penetration rate, leakage, etc. The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

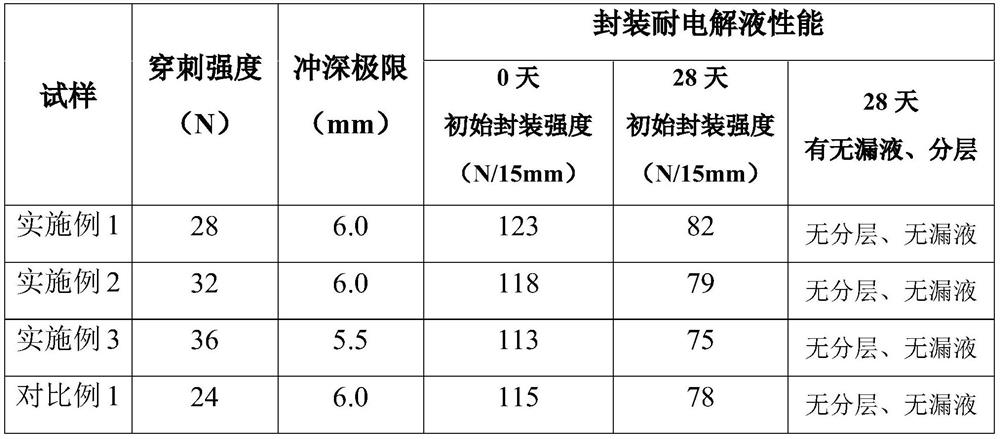

Embodiment 1

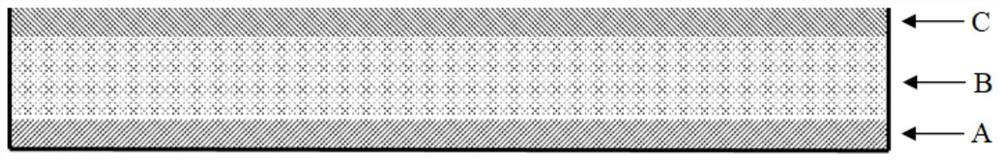

[0031] Such as figure 1 As shown, the puncture-resistant and electrolyte-resistant cast polypropylene film of this embodiment includes a heat-sealing base layer A, a core layer B and a corona layer C that are sequentially stacked and distributed.

[0032] Wherein, the heat-sealing base layer A includes 20 parts by mass of random copolymerized heat-sealable polypropylene, 0.5 parts by mass of a slip agent and 0.1 parts by mass of an antistatic agent;

[0033] Core layer B comprises the nano-silicon nitride of the polypropylene copolymer of 80 mass parts and 0.5 mass part;

[0034] The corona layer C included 20 parts by mass of random copolymerized polypropylene.

[0035] In addition, the preparation process of the puncture-resistant and electrolyte-resistant cast polypropylene film of this embodiment includes:

[0036] Mix the materials of each layer with a high-speed mixer to disperse them evenly, and put them into three extruders for melting and plasticization. The heating...

Embodiment 2

[0040] The difference between the puncture-resistant and electrolyte-resistant cast polypropylene film of the present embodiment and that of Example 1 is:

[0041] Core layer comprises the nano-silicon nitride of the polypropylene copolymer of 80 mass parts and 2 mass parts;

[0042] Other components and technology are with embodiment 1;

[0043] The heat-sealing layer of the aluminum-plastic film of this embodiment adopts the puncture-resistant and electrolyte-resistant cast polypropylene film of this embodiment, and other structures are the same as that of Embodiment 1.

Embodiment 3

[0045] The difference between the puncture-resistant and electrolyte-resistant cast polypropylene film of the present embodiment and that of Example 1 is:

[0046] Core layer comprises the nano-silicon nitride of the polypropylene copolymer of 80 mass parts and 5 mass parts;

[0047] Other components and technology are with embodiment 1;

[0048] The heat-sealing layer of the aluminum-plastic film of this embodiment adopts the puncture-resistant and electrolyte-resistant cast polypropylene film of this embodiment, and other structures are the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com