Puncture-resistant BOPET film for aluminizing and preparation method thereof

A puncture-resistant, thin film technology, applied in the field of plastic film manufacturing, to achieve excellent performance, reduce production costs, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

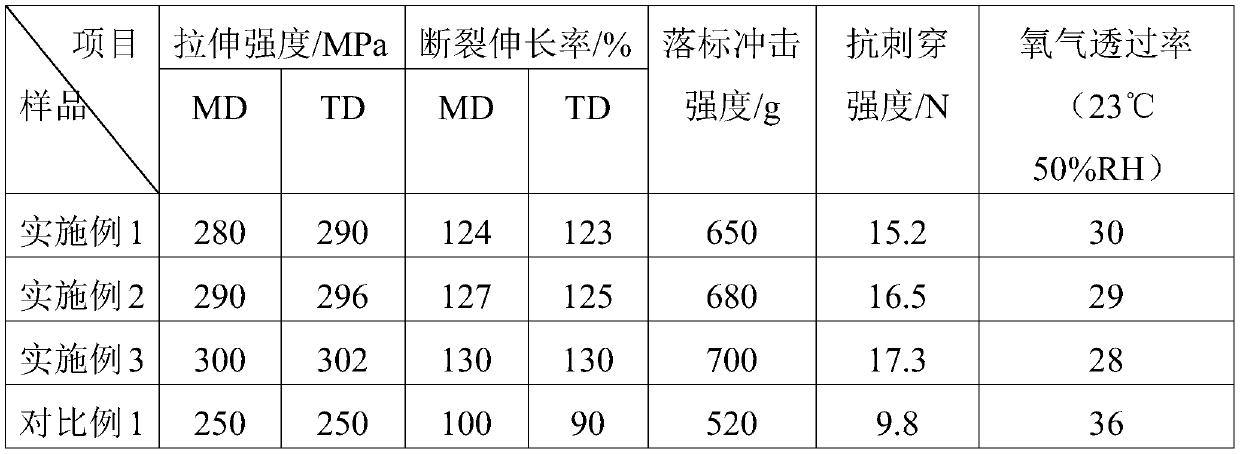

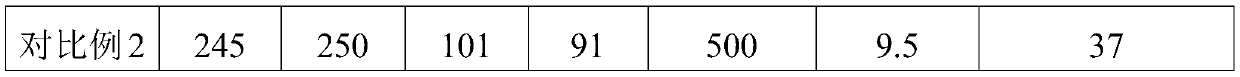

Examples

Embodiment 1

[0024] A puncture-resistant BOPET film for aluminum plating, which consists of an upper surface layer, a core layer and a lower surface layer; in terms of mass percentage, the core layer is made of the following raw materials: 80% PET polyester chips, ENBA copolymerized modified PET polyester 20% slices, the upper surface layer is made of the following raw materials: 5% PET polyester chips, 10% ENBA copolymerized modified PET polyester chips, 85% PET polyester anti-adhesive masterbatch, and the lower surface layer is made of the following raw materials: 30% of PET polyester chips, 70% of PET polyester anti-adhesive masterbatch.

[0025] ENBA copolymerized modified PET polyester chips are made of the following raw materials in terms of mass percentage: ENBA 10%, PET chips 90%.

[0026] Wherein, the thickness of the upper surface layer accounts for 8.3%-9.0% of the total film thickness, and the thickness of the lower surface layer accounts for 8.3%-9.0% of the total film thickne...

Embodiment 2

[0035] A puncture-resistant BOPET film for aluminum plating, which consists of an upper surface layer, a core layer and a lower surface layer; in terms of mass percentage, the core layer is made of the following raw materials: 70% PET polyester chips, ENBA copolymerized modified PET polyester 30% slices; the upper surface layer is made of the following raw materials: 10% PET polyester chips, 15% ENBA copolymerized modified PET polyester chips, 75% PET polyester anti-adhesive masterbatch; the lower surface layer is made of the following raw materials: 32% of PET polyester chips, 68% of PET polyester anti-adhesive masterbatch.

[0036] ENBA copolymerized modified PET polyester chips are made of the following raw materials in terms of mass percentage: ENBA 20%, PET chips 80%.

[0037] Wherein, the thickness of the upper surface layer accounts for 9.0%-9.5% of the total film thickness, and the thickness of the lower surface layer accounts for 8.3%-9.0% of the total film thickness....

Embodiment 3

[0046]A puncture-resistant BOPET film for aluminum plating, which consists of an upper surface layer, a core layer and a lower surface layer; in terms of mass percentage, the core layer is made of the following raw materials: PET polyester chip 60%, ENBA copolymerized modified PET polyester 40% slices; the upper surface layer is made of the following raw materials: PET polyester chips 10%, ENBA copolymerized modified PET polyester chips 20%, PET polyester anti-adhesive masterbatch 70%; the lower surface layer is made of the following raw materials: 35% of PET polyester chips, 65% of PET polyester anti-adhesive masterbatch.

[0047] ENBA copolymerized modified PET polyester chips are made of the following raw materials in terms of mass percentage: ENBA 30%, PET chips 70%.

[0048] Wherein, the thickness of the upper surface layer accounts for 9.5%-10.0% of the total film thickness, and the thickness of the lower surface layer accounts for 8.3%-9.0% of the total film thickness. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com