Resin modification and preparation method for producing wrapping film from biodegradable material

A biodegradable material, wrapping film technology, applied in the direction of coating, can solve difficult production process, environmental pollution, difficult problems and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

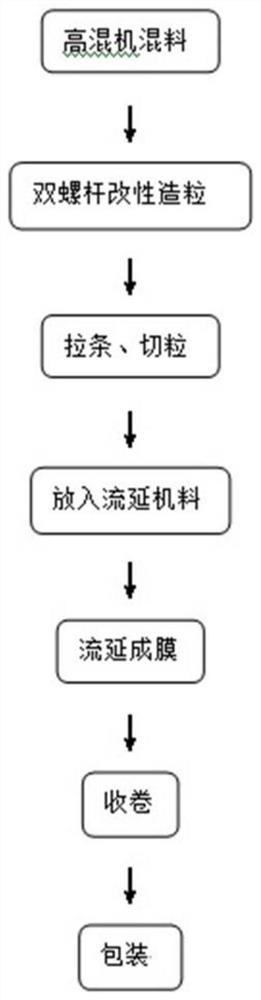

Method used

Image

Examples

preparation example Construction

[0052] A kind of resin modification of biodegradable materials to produce stretch film and its preparation method, the materials used in it include the following components, calculated by weight parts:

[0053] Polylactic acid (PLA) 2-10 parts

[0054] 90-98 parts of polyadipate / butylene terephthalate (PBAT)

[0055] Nano calcium carbonate 2-5 parts

[0056] Octadecyl acrylate - 0.2-0.5 parts of maleic anhydride

[0057] Chain extender 0.2-0.6 parts

[0058] Antioxidant 0.2-0.8 parts

[0059] Lubricant 0.2-0.5 parts

[0060] The above materials are added in different ratios to prepare A group materials, B group materials, and C group materials, and the specific ratios are as follows:

Embodiment 1

[0062] Group A

[0063] Polylactic acid (PLA) 5-10 parts

[0064] 90-95 parts of polyadipate / butylene terephthalate (PBAT)

[0065] Nano calcium carbonate 2-5 parts

[0066] Octadecyl acrylate - 0.2-0.5 parts of maleic anhydride

[0067] Chain extender 0.2-0.6 parts

[0068] Antioxidant 0.2-0.8 parts

[0069] Lubricant 0.2-0.5 parts

Embodiment 2

[0071] Group B material

[0072] Polylactic acid (PLA) 1-4 parts

[0073] 96-99 parts of polyadipate / butylene terephthalate (PBAT)

[0074] Nano calcium carbonate 2-5 parts

[0075] Octadecyl acrylate - 0.2-0.5 parts of maleic anhydride

[0076] Chain extender 0.2-0.6 parts

[0077] Antioxidant 0.2-0.8 parts

[0078] Lubricant 0.2-0.5 parts

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com