Microneedle arrays and methods of manufacturing the same

a technology of microneedle arrays and needles, which is applied in the field of microneedle arrays, can solve the problems of difficult manufacturing of passageways, difficult to manufacture passageways, and easy obstruction or clogging of passageways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

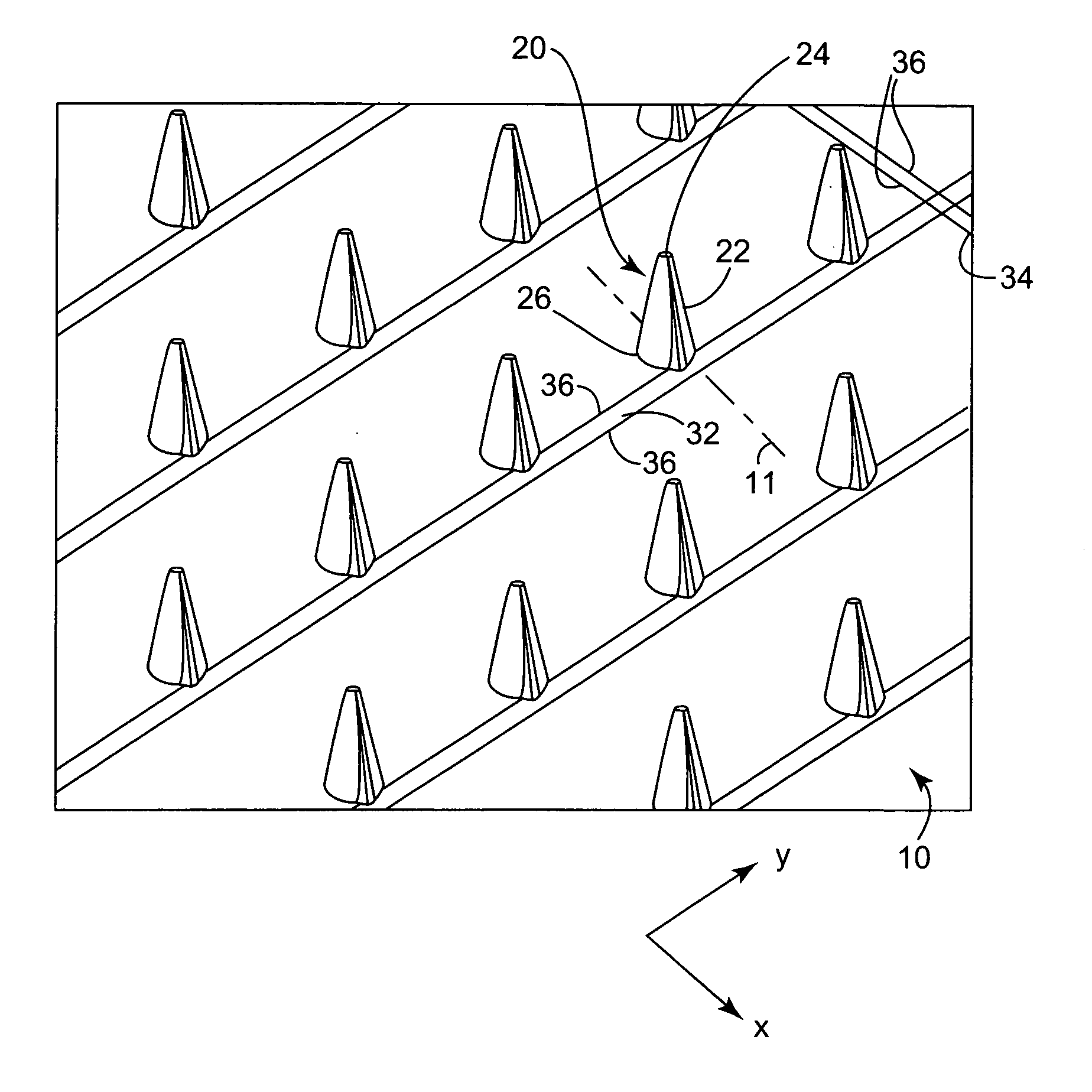

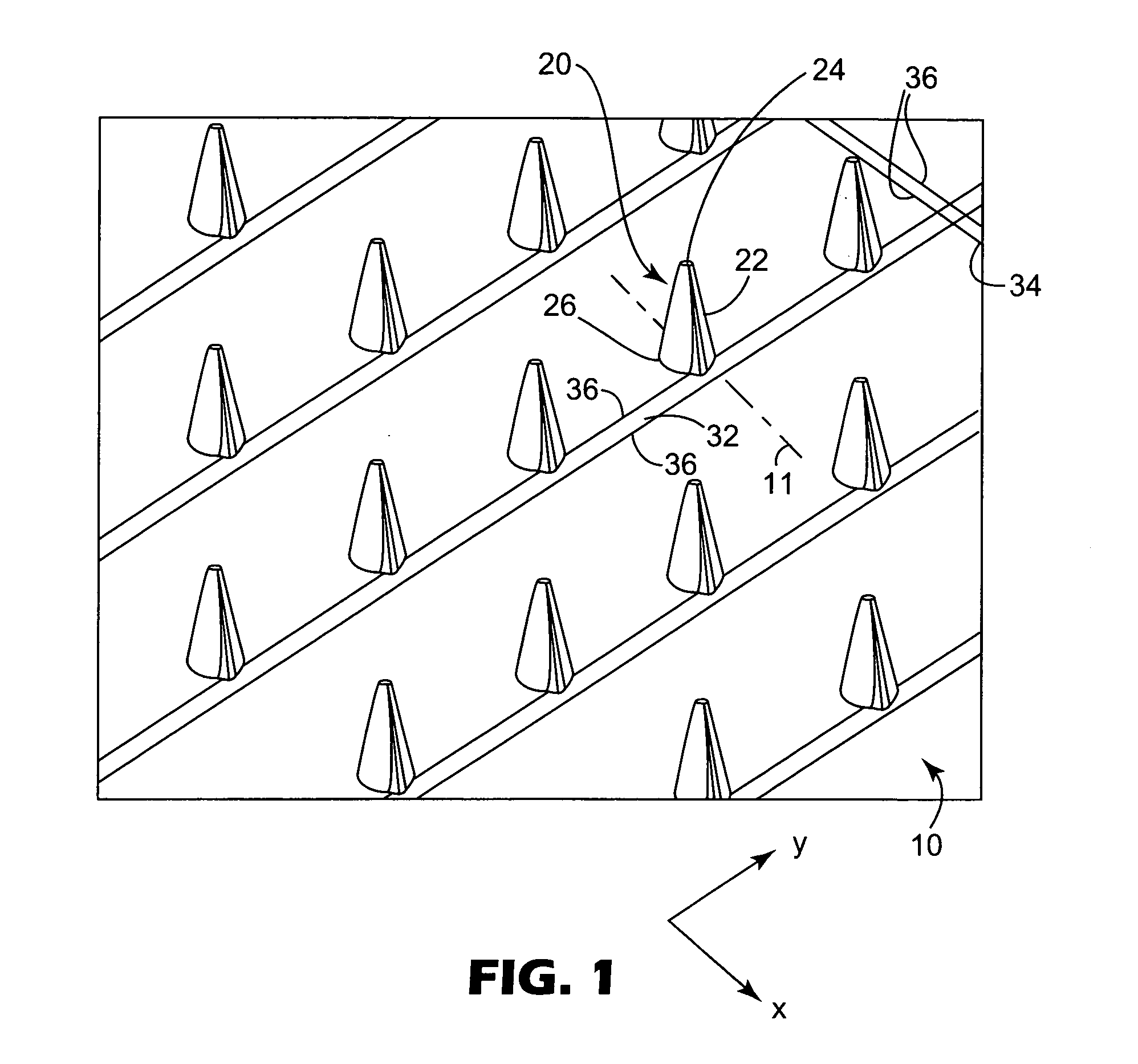

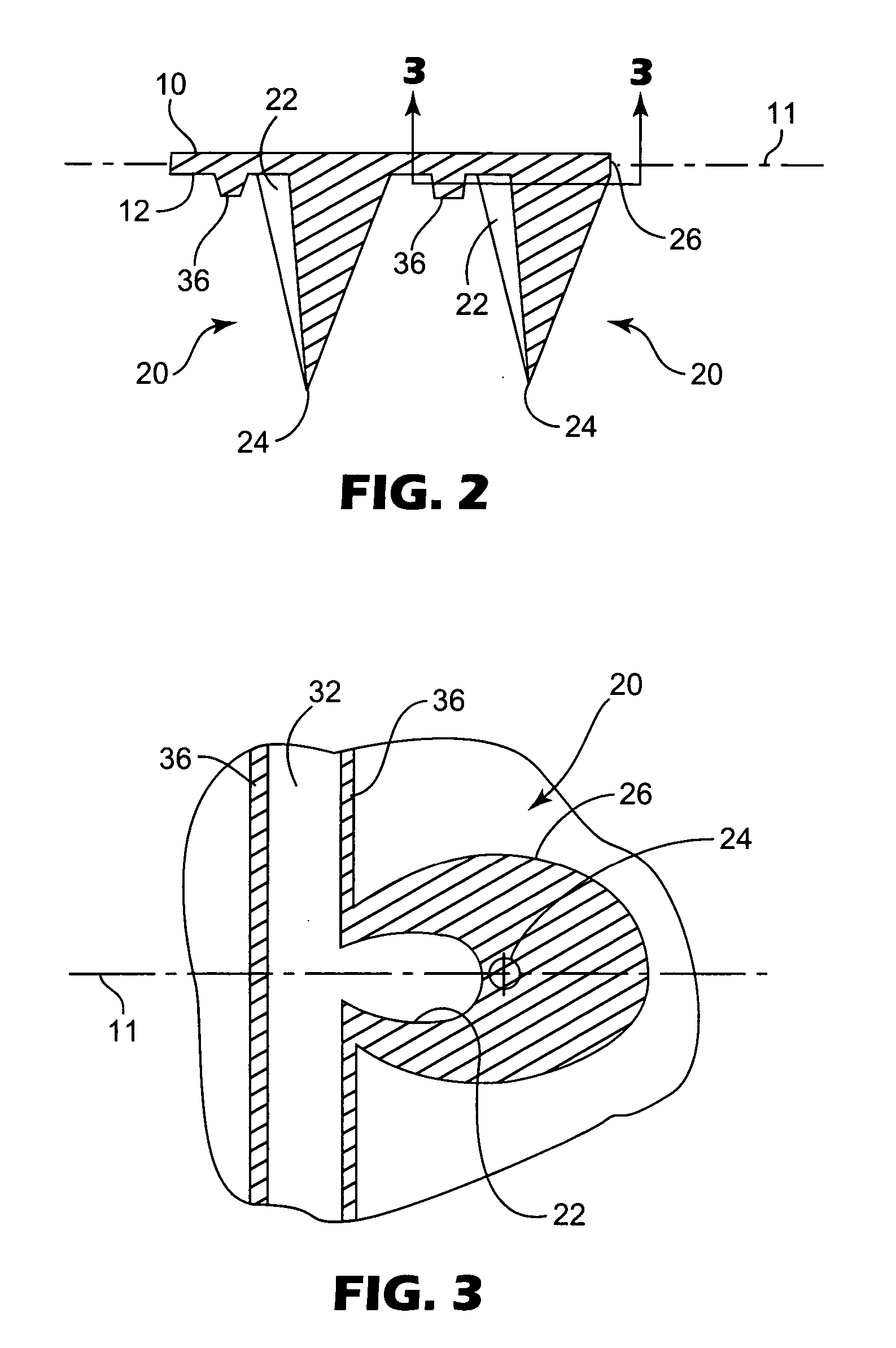

[0035] The present invention provides a microneedle array that may be useful for a variety of purposes. For example, the microneedles may be used to deliver or remove fluids from the point at which they are inserted. To accomplish that goal, the microneedles include a channel formed in the outer surface of a tapered structure. The channel extends from a base or near a base of the microneedle towards the tip of the microneedle. The channel is typically formed as a void running along the side of the microneedle. In some embodiments, the channel may extend to the tip of the microneedle and, in other embodiments, the channel may terminate before reaching the tip.

[0036] The channels formed in microneedles of the present invention can be distinguished from bores or vias formed in known microneedles because they are open along substantially their entire length, e.g., from the base of the microneedle to the terminus of the channel. In contrast, bores or vias formed in known microneedles ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com