Needle machine

A technology of acupuncture machines and needles, applied in the field of acupuncture machines, can solve the problems of easy breakage of needles and low service life of needles, and achieve the effects of improving puncture effect, service life and contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solutions and advantages of the present application clearer, the present application will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

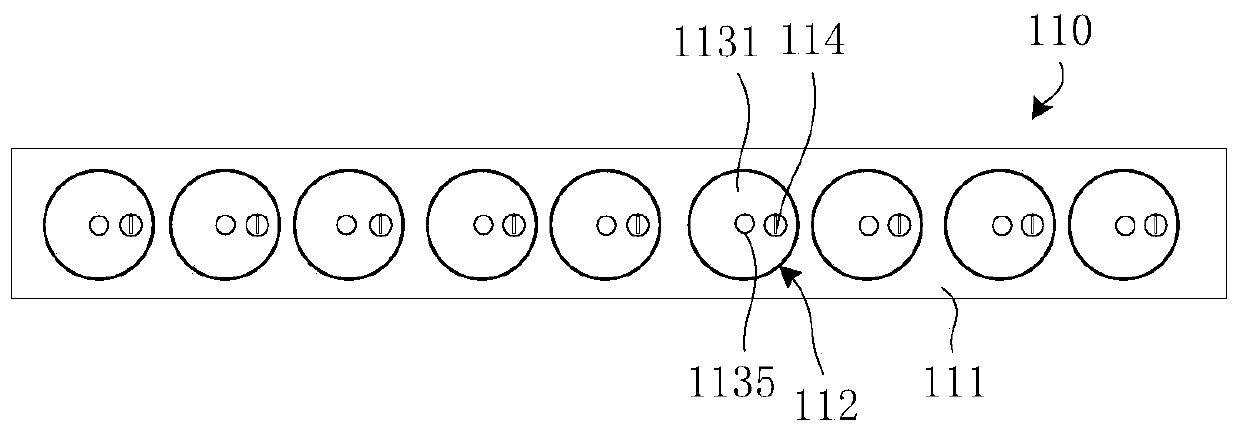

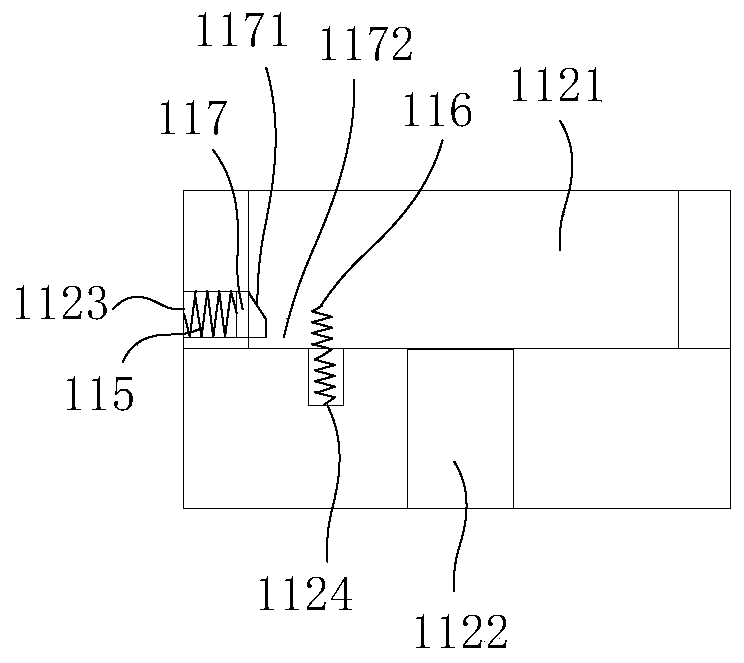

[0033] In an exemplary embodiment of the present disclosure, a needle plate 100 is provided, and each component of this embodiment is described in detail below:

[0034] In this example of the application:

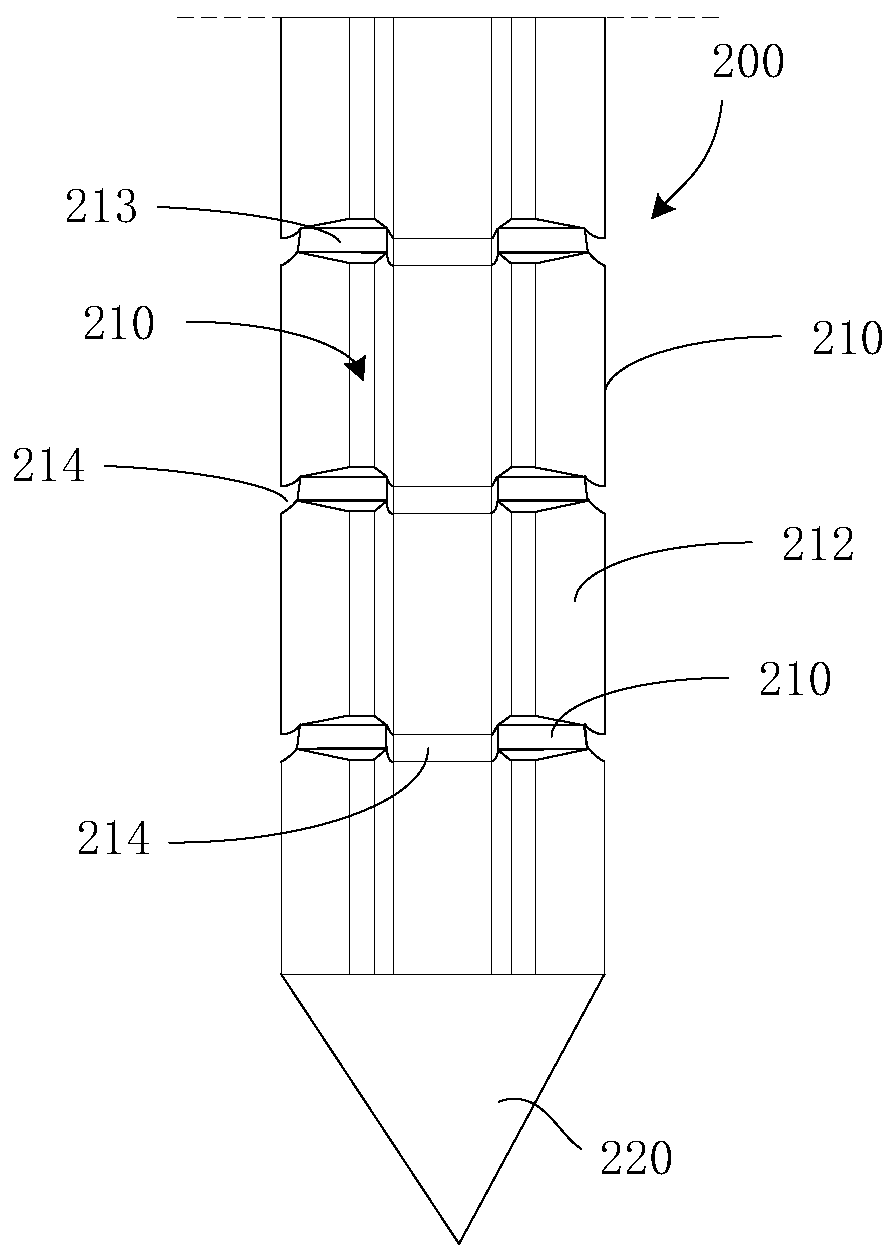

[0035] Please refer to the attached figure 1 , the present embodiment provides an acupuncture machine, including a needle 200, the needle 200 includes a working section 210 and a needle tip section 220 located below the working section 210, the working section 210 includes a body, and the body is provided with more than two grooves along the circumference 211, the groove portion 211 extends along the axial direction of the body, wherein any two adjacent grooves are separated by a side wall portion 212; the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com