Biodegradable aliphatic-aromatic copolyester and application thereof

An aliphatic polyester and biodegradable technology, applied in the field of polyester, can solve the problems of film rupture, unfavorable industrial production, and limited application, so as to achieve tear resistance, improve the quality of impact damage caused by falling marks, and reduce the phenomenon of perforation Occurrence rate, effect of yield strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

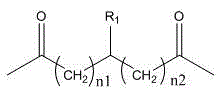

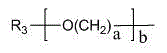

Method used

Image

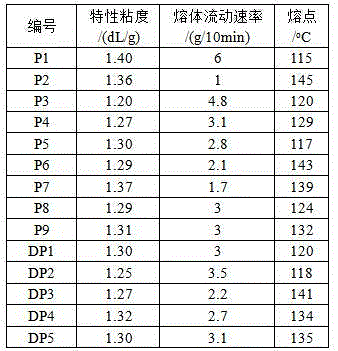

Examples

Embodiment 1

[0039] Put 8.73 Kg of dimethyl terephthalate and 9 Kg of 1,4-butanediol into the reactor. After replacing the air in the reactor with nitrogen, the temperature is raised to 170°C, and the dimethyl terephthalate After it was completely melted, 10 g of isopropyl titanate was added, and the temperature was gradually raised to 180°C for esterification reaction. After the methanol leached out reached the theoretical amount, 7.96 Kg of adipic acid and 97 g of 2-triglycidyl succinic acid were added, and the reaction was continued until the leached water reached the theoretical amount, then 10 g of isopropyl titanate was added, gradually Raise the temperature to 230~250℃, reduce the pressure in the reactor to below 60Pa for about 30min, and continue the reaction under this condition until the power of the stirring motor reaches the set value. Fill the reactor with high-purity nitrogen, extrude the melt through the mouth mold, and then stretch and pelletize to obtain the copolyester, wh...

Embodiment 2

[0041] Put 11.64Kg of dimethyl terephthalate, 9Kg of 1,4-butanediol, 5.40Kg of adipic acid, and 354g of 2-tributylene glycol monomethyl ether succinic anhydride into the reactor, and gradually increase the temperature to 170 o C. Add 20g of n-butyl titanate, and gradually increase the temperature to 230~250 after the methanol and water have reached the theoretical amount. o C. Reduce the pressure in the reactor to below 60 Pa for about 30 minutes, and continue the reaction under this condition until the power of the stirring motor reaches the set value. Fill the reactor with high-purity nitrogen, extrude the melt through the mouth, stretch and pelletize to obtain the copolyester base material P20. After drying the P20, mix it with 0.6% hexamethylene diisocyanate. Reacted in a twin-screw extruder and pelletized to obtain a copolyester, marked as P2.

Embodiment 3

[0043] Put 9.89 Kg of purified terephthalic acid and 9Kg of 1,4-butanediol into the reactor at 230 o C reacted until the amount of leached water reached the theoretical value, 7Kg of adipic acid and 234g of 2-dipropylene glycol monopropyl ether succinic acid were added, and the reaction was continued until the amount of leached water reached the theoretical value. Add 20g of n-butyl titanate and gradually increase the temperature to 230~250 o C. Reduce the pressure in the reactor to below 60 Pa for about 30 minutes, and continue the reaction under this condition until the power of the stirring motor reaches the set value. Fill the reactor with high-purity nitrogen, extrude the melt through the mouth mold, and then stretch and pelletize to obtain the copolyester, which is marked as P3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com