Puncture-resistant two-way stretching nylon film of three-layer structure and preparation method thereof

A technology of biaxially stretched nylon and three-layer structure, which is applied in the field of nylon film packaging to meet quality assurance requirements, high barrier performance and puncture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

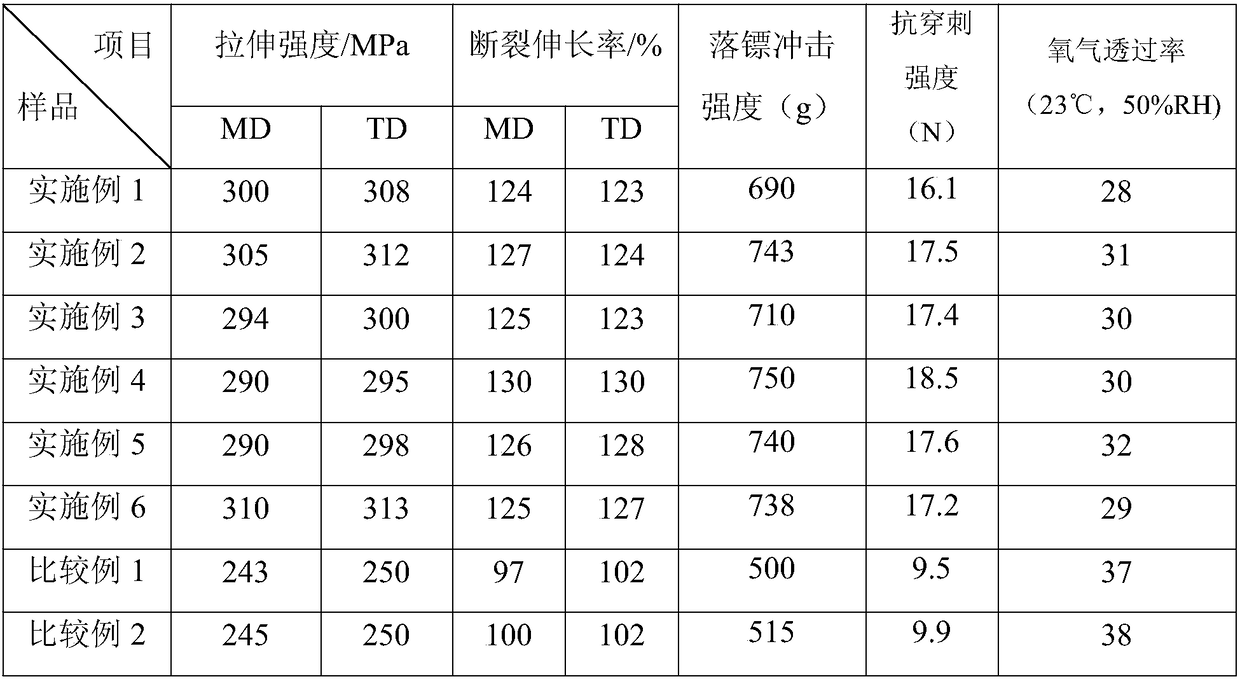

Examples

Embodiment 1

[0034] A three-layer puncture-resistant biaxially stretched nylon film, in terms of mass percentage, the upper surface layer 1 is composed of 10% copolymerized nylon PA6 / 66, 89.5% PA6, 0.2% silicon dioxide and 0.3% oleic acid amide; the core layer is composed of Composed of 100% copolymerized nylon PA6 / 66; the lower surface layer 2 is composed of 10% copolymerized nylon PA6 / 66, 89.5% PA6, 0.2% talcum powder, and 0.3% oleic acid amide.

[0035] The sample was prepared according to the aforementioned preparation method, and the total thickness of the obtained film was 15 μm, and the thickness of the core layer was 3 μm.

Embodiment 2

[0037] A three-layer puncture-resistant biaxially oriented nylon film, the upper surface layer 1 is composed of 20% copolymerized nylon PA66 / 6, 79.5% PA6, 0.2% silica, 0.3% oleic acid amide; the core layer is composed of 100% copolymerized nylon Composed of PA66 / 6; the lower surface layer 2 is composed of 20% copolymerized nylon PA66 / 6, 79.5% PA6, 0.2% talc, and 0.3% oleic acid amide.

[0038] The sample was prepared according to the aforementioned preparation method, and the total thickness of the obtained film was 15 μm, and the thickness of the core layer was 5 μm.

Embodiment 3

[0040] A three-layer puncture-resistant biaxially oriented nylon film, in terms of mass percentage, the upper surface layer 1 is composed of 30% copolymerized nylon PA1010 / 6, 69.5% PA6, 0.2% silicon dioxide, and 0.3% oleic acid amide; the core layer It is composed of 80% copolymerized nylon PA1010 / 6, 20% copolymerized nylon PA6 / 66; the lower surface layer 2 is composed of 30% copolymerized nylon PA54, 69.5% PA6, 0.2% talcum powder, and 0.3% oleic acid amide.

[0041] The sample was prepared according to the aforementioned preparation method, and the total thickness of the obtained film was 15 μm, and the thickness of the core layer was 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com