Method for producing graphene functionalized nitrile flocked gloves

A flocked glove, ene-functional technology, applied in the field of gloves, can solve the problems of poor dispersion and compatibility, low performance of glove products, achieve strong tensile properties and wear resistance, wide use value, resistance to cutting and puncture The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

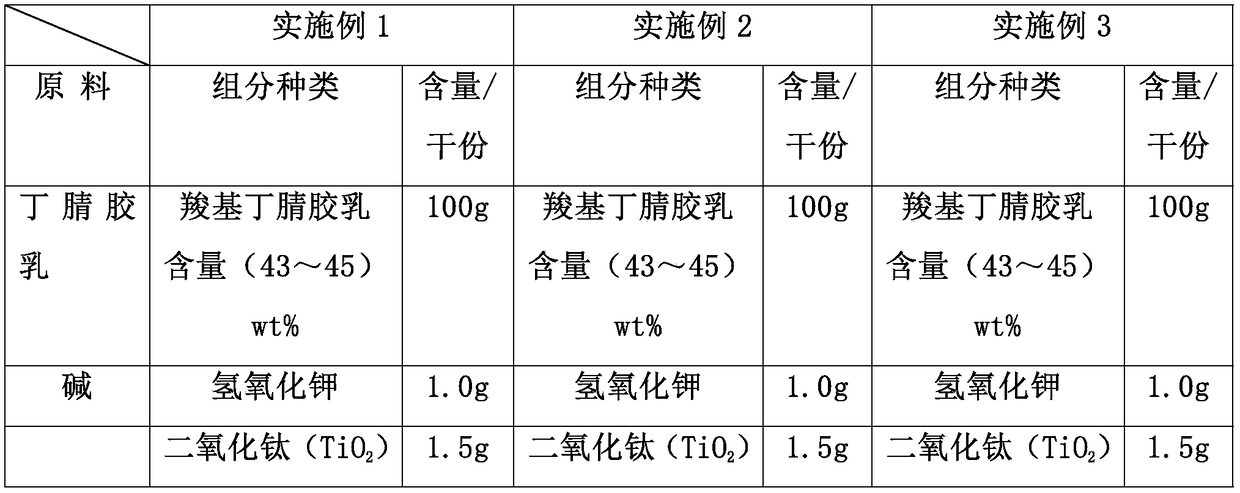

Embodiment 1~3

[0054] Embodiments 1 to 3 respectively provide a technical solution for the preparation of nitrile flocked gloves functionalized with graphene as shown in Table 1, wherein on the premise that other raw materials remain the same, with the amount of graphene added as a variable, the graphene The effect of the ratio on glove performance. Specific steps are as follows:

[0055] Step 1: Prepare a coagulation bath (agent) according to the ratio of the coagulant in Table 1, stir well and set aside;

[0056] Step 2: pickling, water washing, alkali washing, scrubbing and drying the hand model in turn for later use;

[0057] Step 3: According to the parts by weight of the auxiliary materials described in Table 1, prepare auxiliary materials with a solid content of 50%, and grind for 48 to 72 hours, so that the particle size of each component is below 5um;

[0058] Step 4: the alkali is added in the nitrile latex, and the pH value is adjusted to two parts of nitrile latex; in this step...

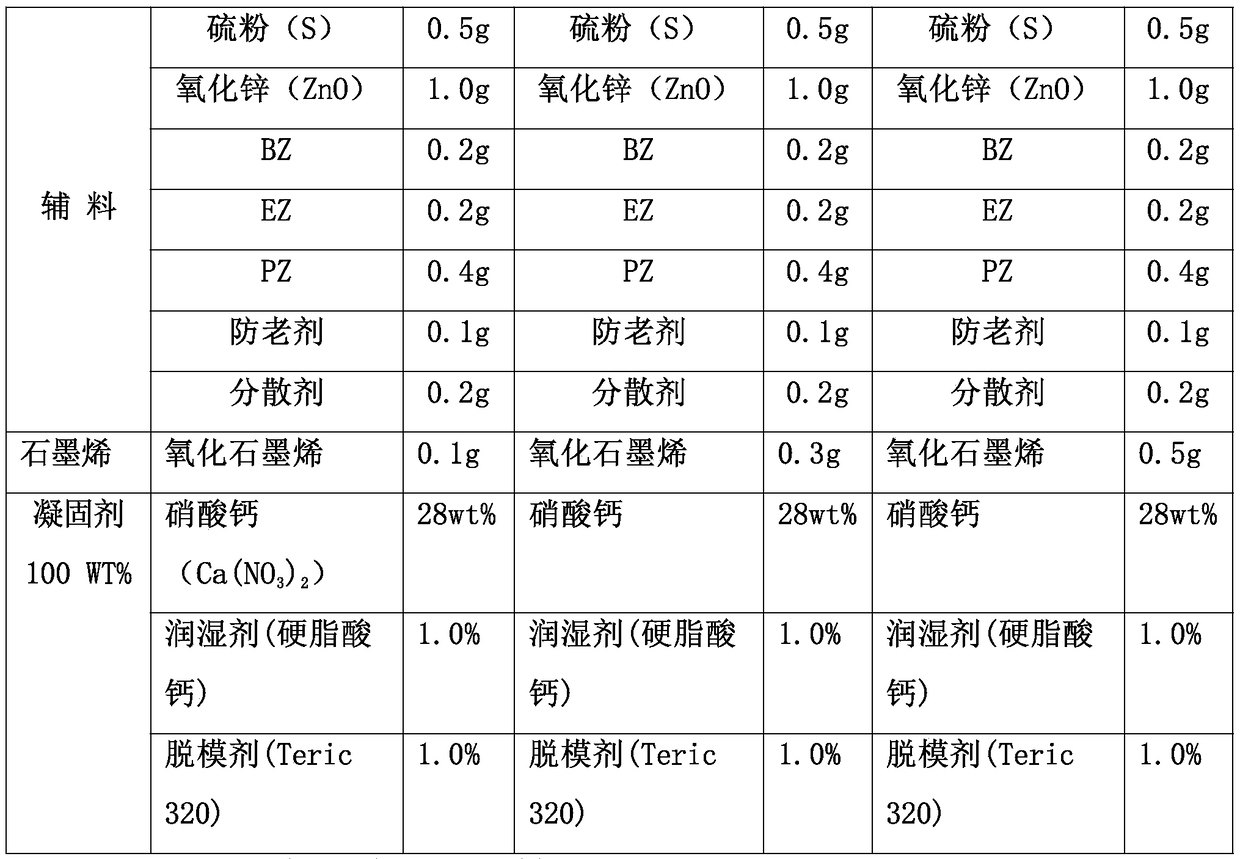

Embodiment 4~6

[0071] Embodiments 4 to 6 respectively provide a technical solution for the preparation of nitrile flocked gloves functionalized with graphene as shown in Table 2, wherein under the premise that other raw materials are kept the same, the addition amount of graphene reducing agent is used as a variable. Effect of reducing agent proportion on glove performance. Specific steps are as follows:

[0072] Step 1: prepare materials according to the parts by weight described in Table 2;

[0073] Step 2: adding the alkali into the nitrile latex, and adjusting the pH value of two parts of nitrile latex; in this step, the pH of the nitrile latex after the alkali (potassium hydroxide) treatment is above 9;

[0074] Step 3: Add the ground auxiliary components to the alkalized nitrile latex. In this step, the grinding time is 48-72 hours, and the particle size of each component is below 5um;

[0075] Step 4: adding the grinding auxiliary material into the alkalized nitrile latex;

[0076]...

Embodiment 7~9

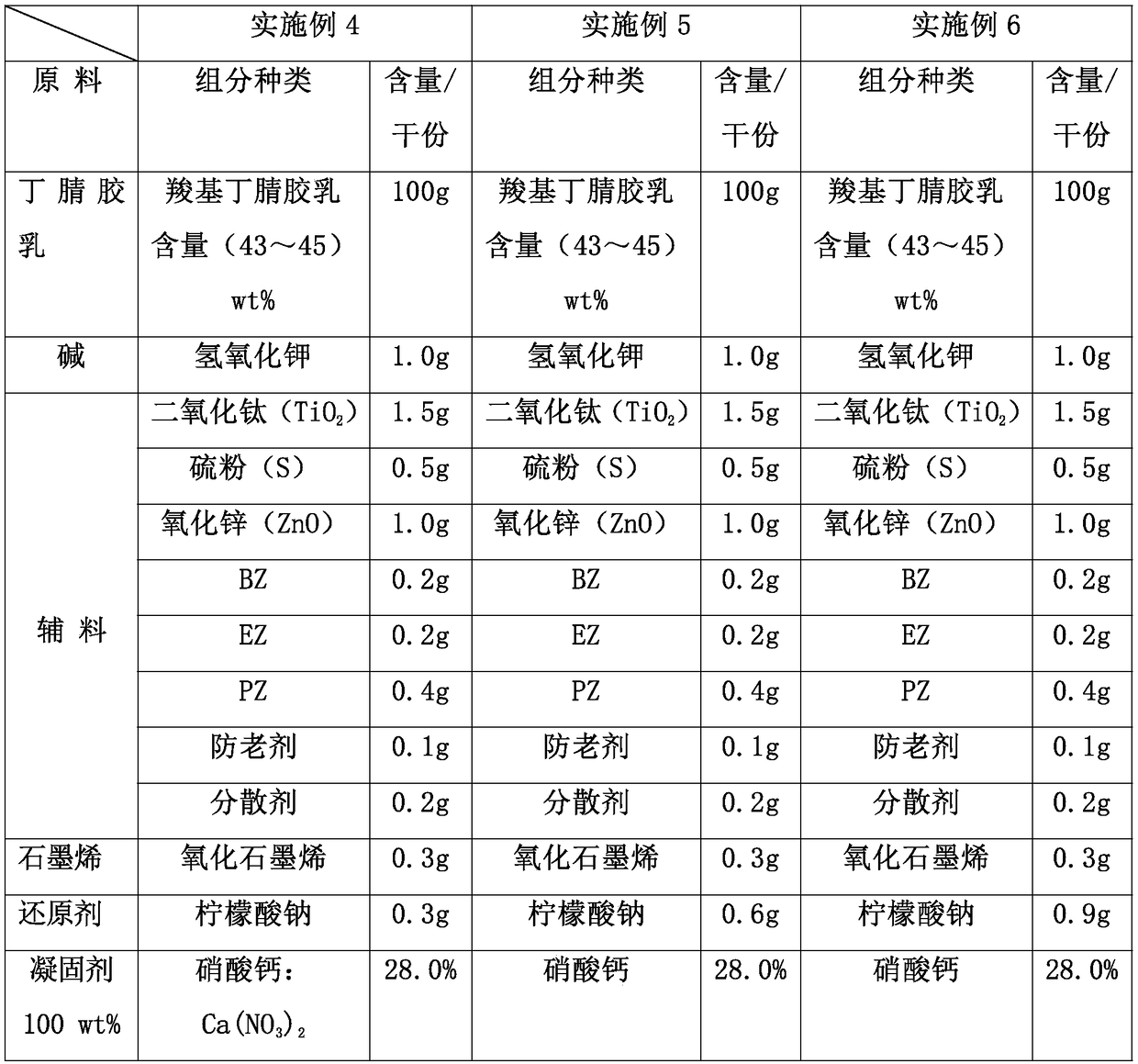

[0089] Embodiment 7~9 provides a kind of preparation technology scheme of the nitrile flocking glove functionalized with graphene shown in table 3 respectively, wherein under the premise that other raw materials keep the same, the kind of graphene (oxidation-reduction method, mechanical exfoliation method and electrochemical stripping method) as variables, the effects of three types of graphene on glove performance were studied. Specific steps are as follows:

[0090] Step 1: prepare materials according to the parts by weight described in Table 3;

[0091] Step 2: adding the alkali into the nitrile latex, and adjusting the pH value of two parts of nitrile latex; in this step, the pH of the nitrile latex after the alkali (potassium hydroxide) treatment is above 9;

[0092] Step 3: Add the ground auxiliary material components to the alkalized nitrile latex. In this step, the grinding time is 48 to 72 hours, and the particle size of each component is below 5um;

[0093] Step 4: a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com