Carding plate

A carding board and frame technology, which is applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of high production cost, low work reliability, and low production rate, and achieve less fiber damage and sharp needle points Penetration property and the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

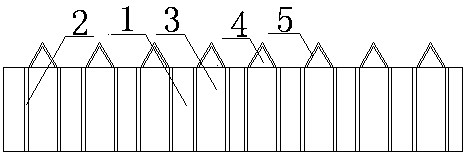

[0009] Such as figure 1 It is a schematic diagram of the structure of the present invention, a carding board, including a skeleton 1, a threaded hole 2, a needle body 3, a needle point 4 and a non-stick layer 5, the skeleton 1 is provided with a threaded hole 2, and the threaded hole 2 is provided with a needle body 3. The needle body 3 is provided with a needle point 4, and the needle point 4 is covered with a non-stick layer 5.

[0010] During use, frame 1 is provided with threaded hole 2, and threaded hole 2 is provided with needle body 3, and needle body 3 is threadedly connected with frame 1 through threaded hole 2, so each comb needle can be replaced separately, and needle body 3 is provided with There is a needle point 4 covered with a layer of non-stick layer 5, which improves the carding effect. This kind of carding board has a simple, compact and reasonable structure, convenient and fast assembly, reliable connection, sharp needle point and strong puncture performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com