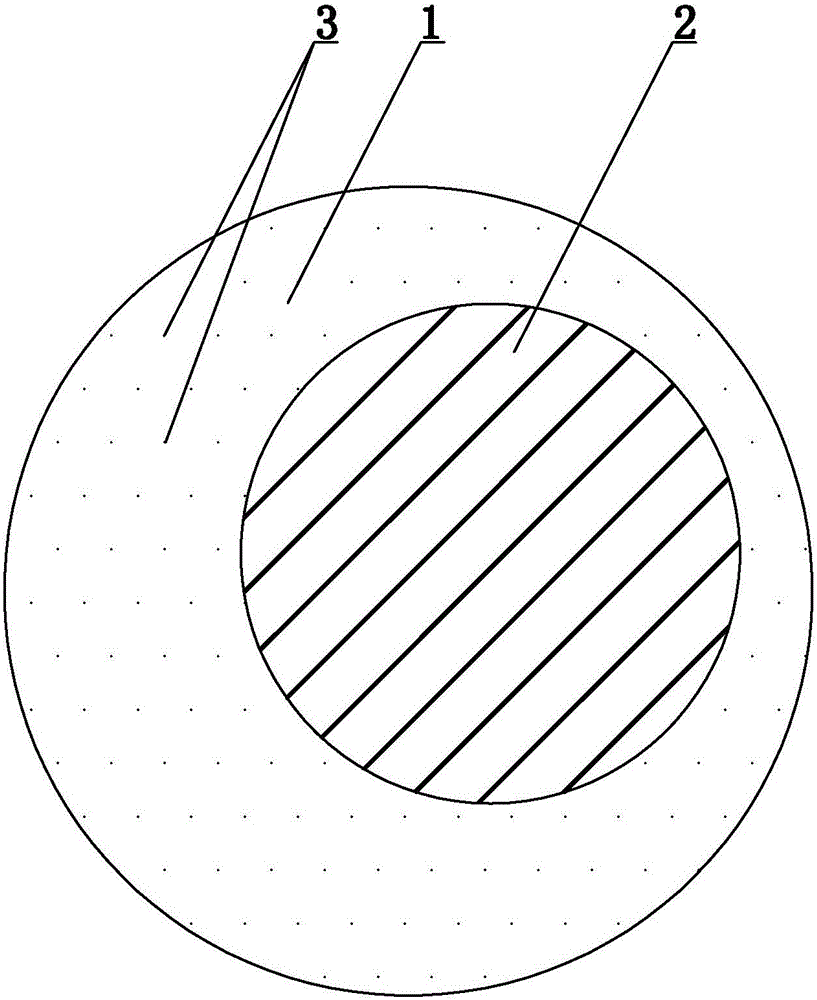

Self-crimping composite filament and processing process thereof

A composite filament, processing technology, applied in the direction of conjugated synthetic polymer artificial filament, filament/wire forming, conductive/antistatic filament manufacturing, etc., to achieve reduced addition, good elastic elongation and elasticity Restoration of performance and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

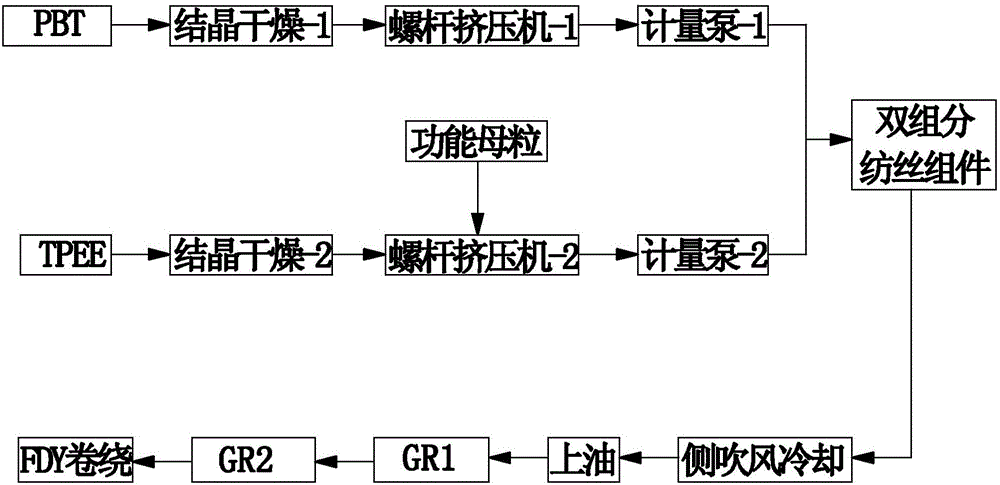

Method used

Image

Examples

Embodiment 1

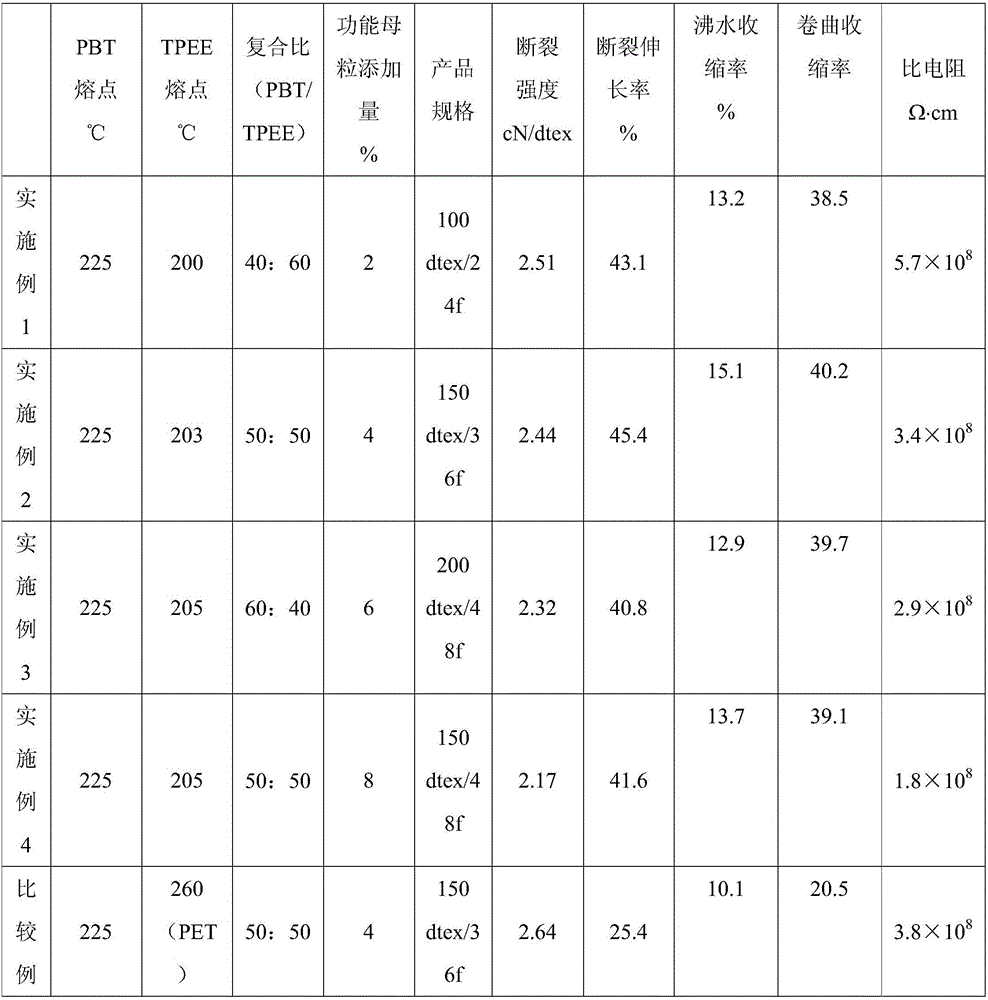

[0032] In this embodiment, a processing technology of self-crimping composite filaments, the intrinsic viscosity of PBT (according to GB / T14190-2008, using phenol and tetrachloroethane 1:1 as a solvent for detection) is 1.00 dl / g, the melting point is 225 ° C, The moisture content of dry slices is less than 50ppm, the temperature of each zone of the screw is 250~270℃; the intrinsic viscosity of TPEE (according to GB / T 14190-2008, using phenol and tetrachloroethane 1:1 as solvent) 1.10dl / g, melting point 200°C, the moisture content of dry slices is less than 50ppm, and the temperature of each zone of the screw is 250-270°C.

[0033] The compound ratio of PBT and TPEE is 40:60 (mass percentage, the same below), the addition amount of functional masterbatch is 2%, the temperature of the spinning box is 270°C, the side blowing wind speed is 0.4m / s; the spinning speed of the first hot roller is 2000m / min, temperature 70°C; second hot roll speed 4000m / min, temperature 100°C.

[00...

Embodiment 2

[0036] This example has the same setup and working principle as Example 1, except that the intrinsic viscosity of TPEE is 1.10dl / g, the melting point is 203°C, the moisture content of dry slices is less than 50ppm, and the temperature of each zone of the screw is 250-270°C.

[0037]The composite ratio of PBT and TPEE is 50:50, the addition of functional masterbatch is 4%, the temperature of the spinning box is 275°C, the side blowing wind speed is 0.5m / s; the spinning speed of the first hot roller is 2200m / min, and the temperature is 80°C; The speed of the second hot roll was 4200m / min, and the temperature was 110°C.

[0038] The size of the self-crimping composite filament formed by the above process is 150dtex / 36f.

Embodiment 3

[0040] This example has the same setup and working principle as Example 1, except that the intrinsic viscosity of TPEE is 1.10 dl / g, the melting point is 205°C, the moisture content of dry slices is less than 50ppm, and the temperature of each zone of the screw is 250-270°C.

[0041] The compound ratio of PBT and TPEE is 60:40, the addition of functional masterbatch is 6%, the temperature of the spinning box is 280°C, the side blowing wind speed is 0.6m / s; the spinning speed of the first hot roller is 2400m / min, and the temperature is 90°C; The speed of the second hot roll was 4400 m / min, and the temperature was 120°C.

[0042] The size of the self-crimping composite filament formed by the above process is 200dtex / 48f.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com