Pallet with stepped support blocks and related methods

A support block and ladder-shaped technology, applied in the direction of rigid containers, containers, packaging, etc., can solve the problems of increasing the cost of building pallets, achieve low cost, and improve the effect of recovery elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will now be described in more detail with reference to the accompanying drawings, however, the invention may be embodied in many different forms and should not be construed as necessarily limited to the embodiments set forth herein; rather, these embodiments are They are provided so that they will be a thorough and complete description of the present invention, and will fully convey the scope of the present invention to those skilled in the art. Additionally, like symbols refer to like components throughout, and prime and double prime notations are used to indicate similar components in alternative embodiments.

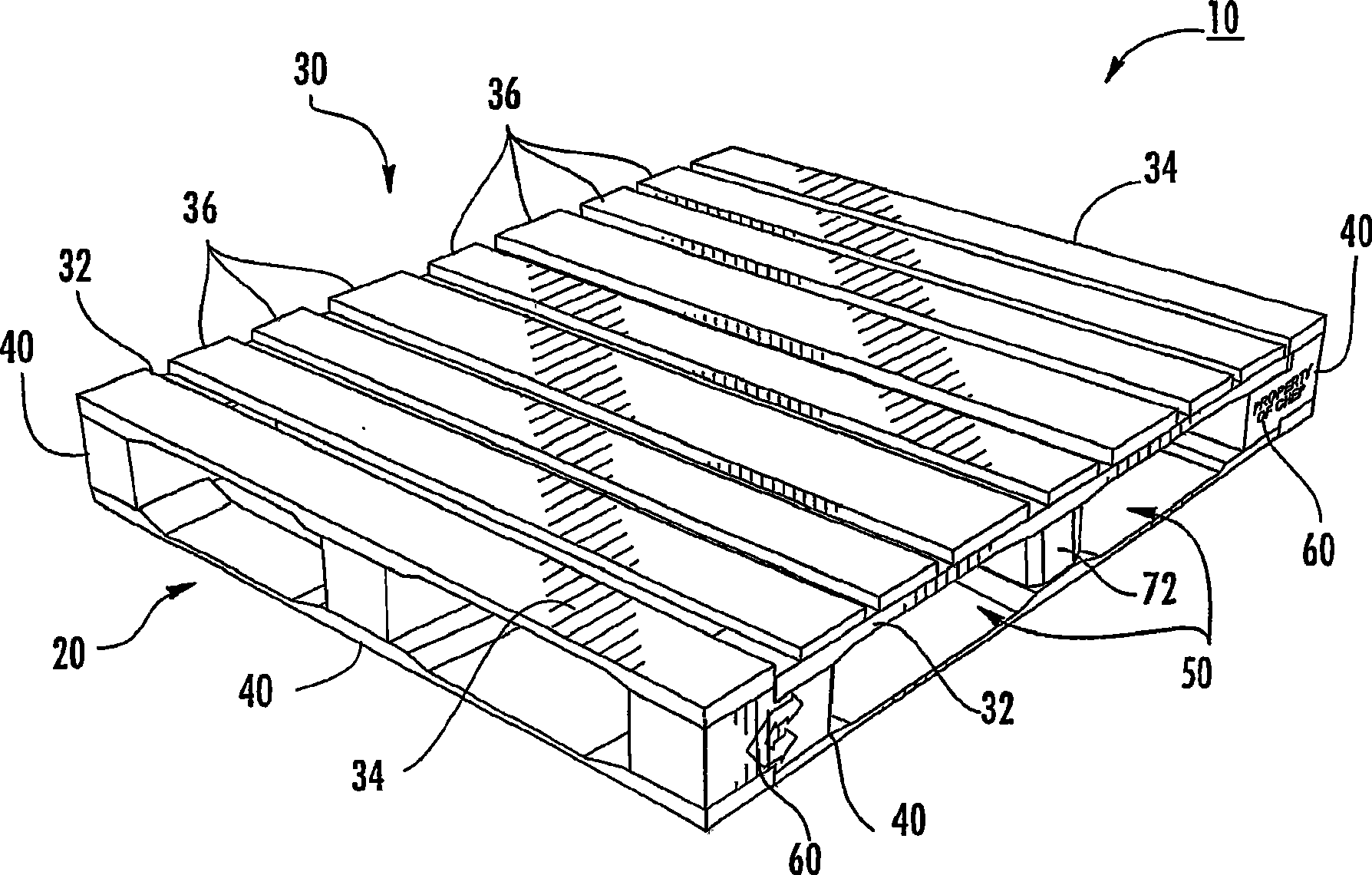

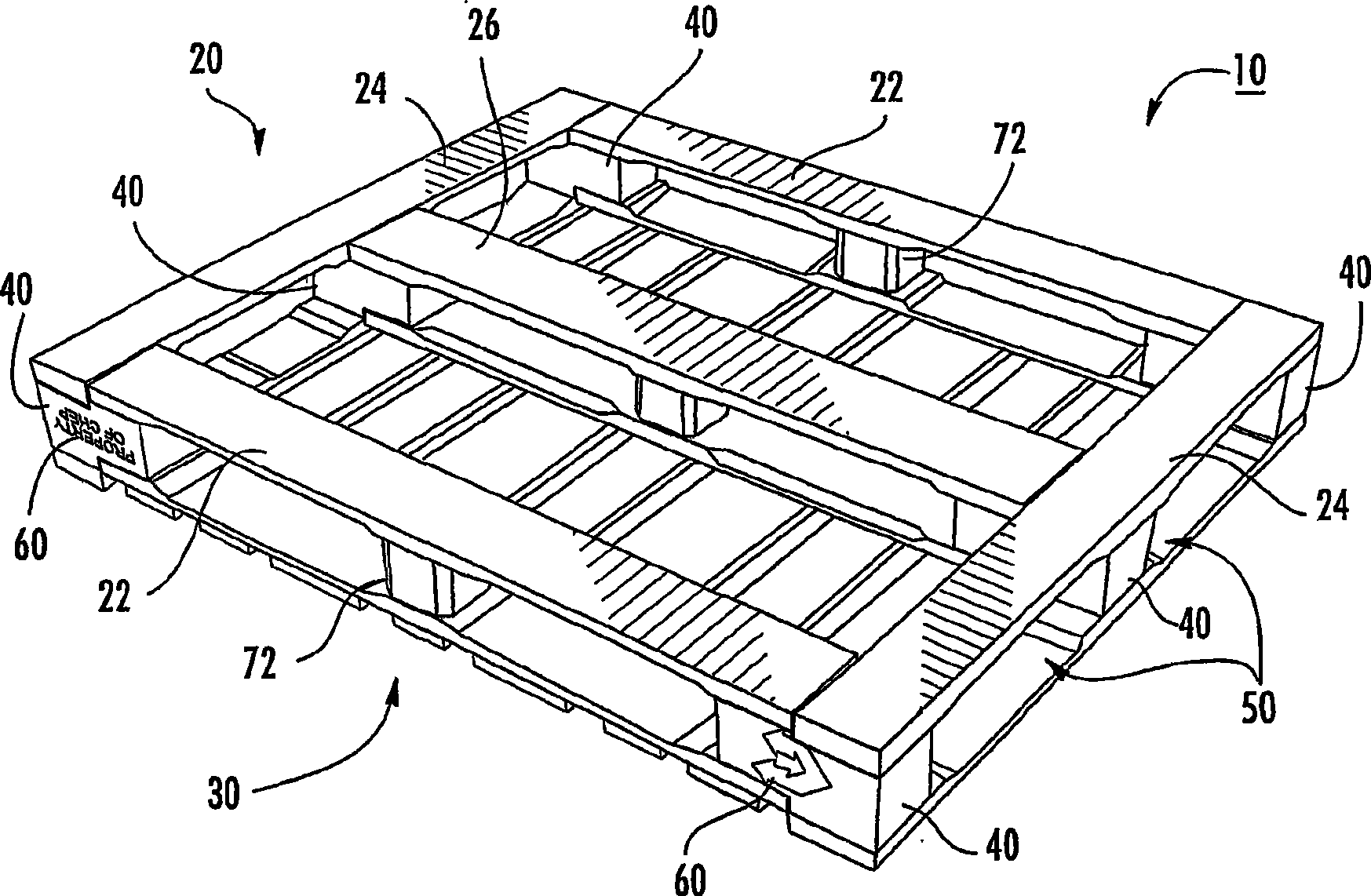

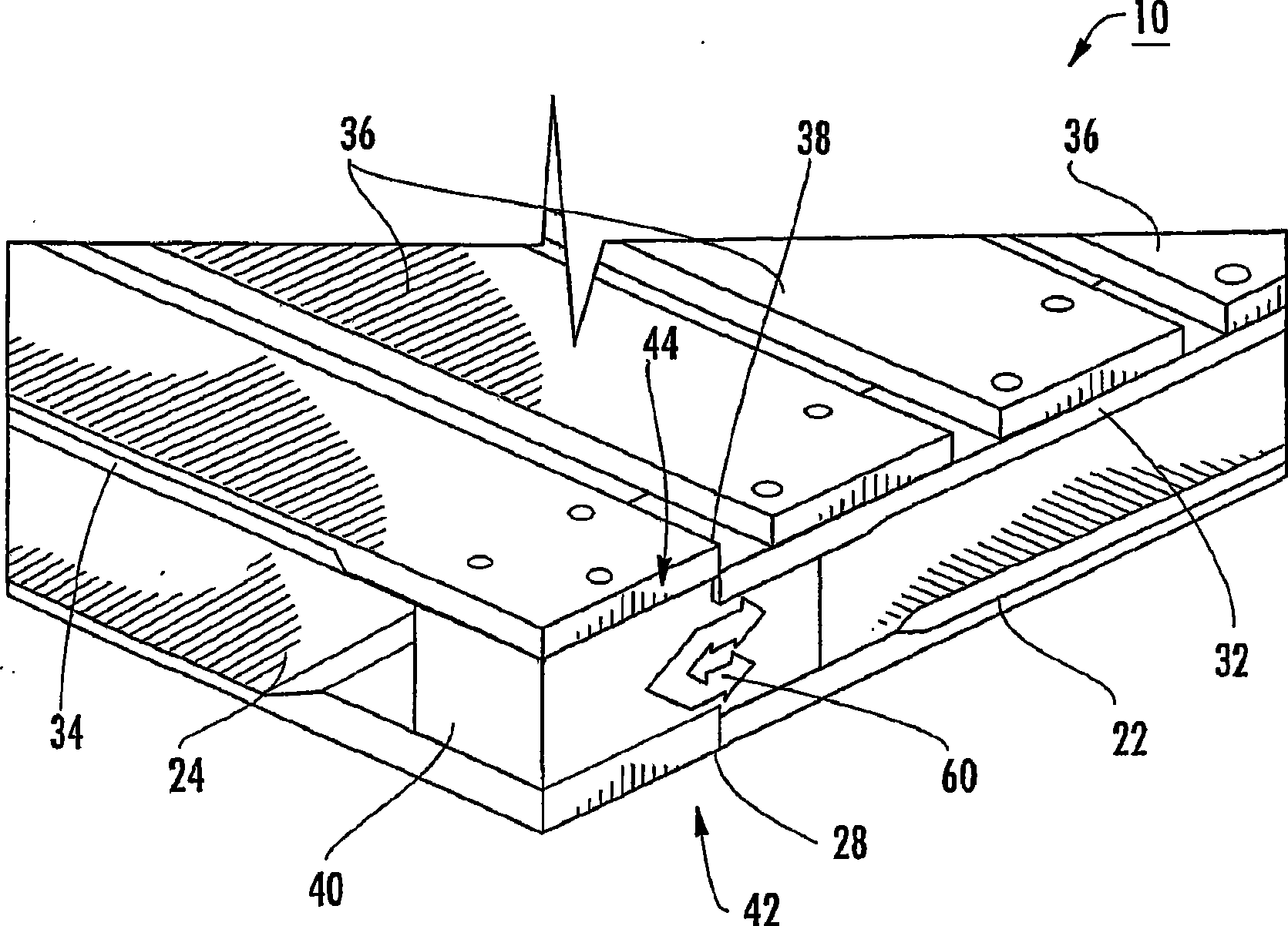

[0027] First, if Figure 1 to Figure 4 As shown, the pallet 10 according to the present invention comprises a bottom layer 20, a cargo layer 30 and a plurality of "stepped" support blocks 40, wherein the support blocks 40 are coupled between the bottom layer 20 and the cargo layer 30 to define a space 50 therebetween, This in turn accommo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com