Modified asphalt, and preparation method and use thereof

A modified asphalt and modifier technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of large index changes and poor storage stability of rubber asphalt, and achieve high softening point, excellent elastic recovery, and long storage time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

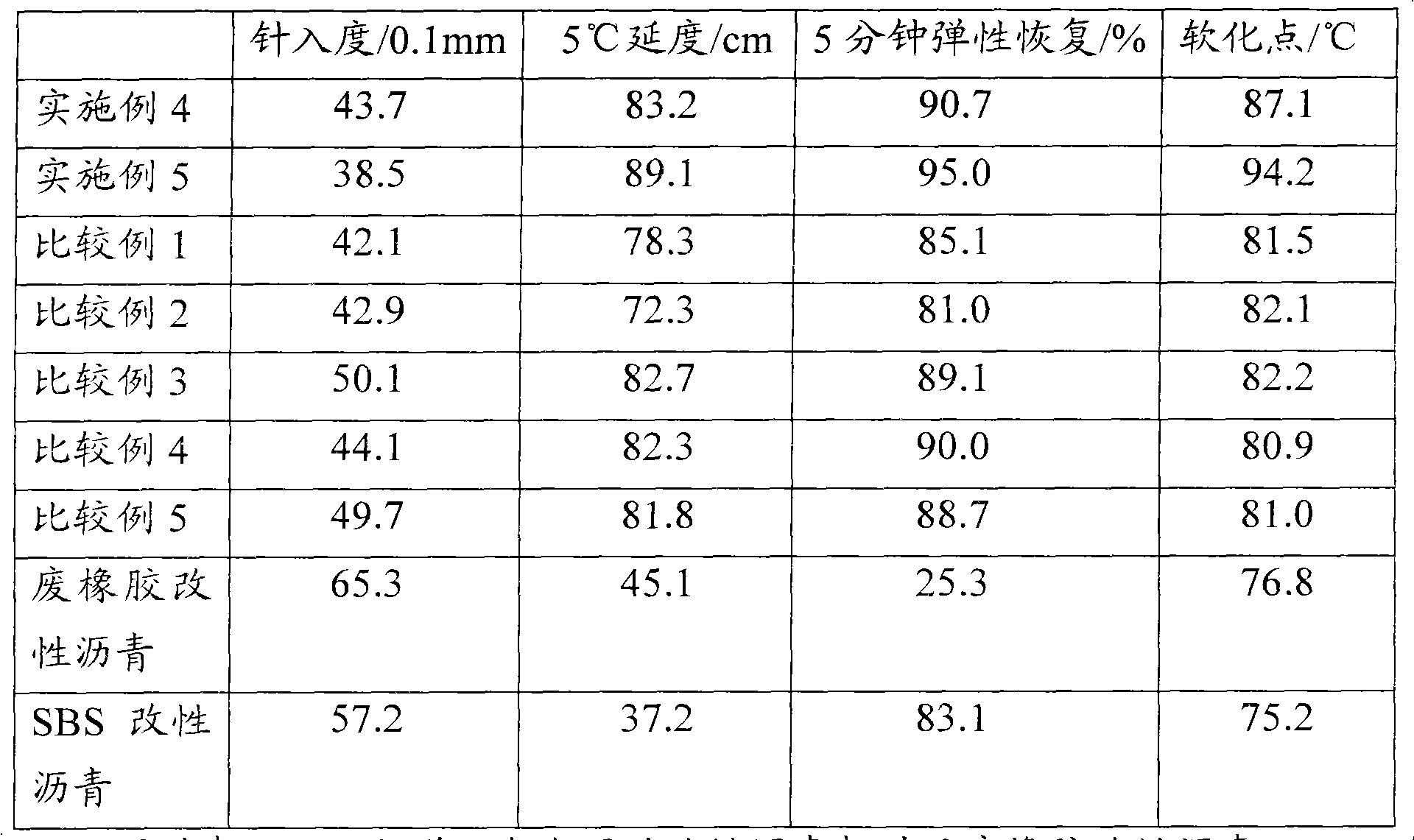

Examples

preparation example Construction

[0041] The preparation method of described modifying agent is further specifically as follows:

[0042] In the first step, the thermal polymerization initiator is mixed with a solvent accounting for 1 / 5-2 / 5 of the total volume of the solvent to prepare a thermal polymerization initiator solution;

[0043] In the second step, the styrene-butadiene-methyl methacrylate polymer and the polyol ester are stirred and mixed in a solvent accounting for 3 / 5-4 / 5 of the total volume of the solvent, and kept at 40°C-60°C, stirring for 1 hour-2 hours;

[0044] In the third step, the thermal polymerization initiator solution prepared in the first step is added dropwise to the mixed solution in the second step, and after the dropwise addition is completed, the stirring is continued for 4 hours to 8 hours, and finally the modifying agent is obtained.

[0045] With respect to 100 parts by weight of styrene-butadiene-methyl methacrylate polymer, the polyol ester is preferably 3 parts by weight ...

Embodiment 1

[0099] The preparation of embodiment 1 modifying agent

[0100] At room temperature, 10g of azobisisobutyronitrile and 10L of propylene glycol monomethyl ether are stirred and mixed to prepare a thermal polymerization initiator solution; subsequently, 1kg of styrene-butadiene-methylmethacrylate (Zibo Hai Chemical Industry Co., Ltd.) and 150g of pentaerythritol tetraacrylate (Nanjing Wangxu Chemical Co., Ltd.) were added to 40L of propylene glycol monomethyl ether, and stirred, and the temperature of the reactor was kept at about 50°C and stirred for 1 hour; The prepared thermal polymerization initiator was added dropwise to the reactor, during the process of dropping and during the stirring process after the dropwise addition, the temperature of the reactor was always kept at about 50°C, and after the dropwise addition was completed, it was stirred for 6 hours to obtain 1 kg of the present invention. required modifiers.

Embodiment 2

[0101] The preparation of embodiment 2 lignin

[0102] 1kg peanut shells are put into a stainless steel autoclave, then add 2L ethylene glycol solution (produced by Jinan Longjiang Chemical Co., Ltd.), 2L water and 50g p-toluenesulfonic acid catalyst (Zibo Like Chemical Co., Ltd.) successively, and heat up to Keep stirring at about 190°C for 2 hours, then cool down to 80°C, filter the reacted mixture, add 15L of cold water to the filtered solution, and stir for 2 hours, a precipitate occurs and precipitates, and the precipitate is filtered and frozen Dry to obtain 400g of lignin required by the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com